Introduction: Navigating the Global Market for Milk Cooling Tanks

Milk quality deteriorates within hours of collection. Without rapid cooling to 4°C (39°F), bacterial counts multiply exponentially, acidity levels spike, and your product loses value—or becomes unsellable entirely. For dairy operations across the USA and Europe, selecting the right milk cooling tank isn’t just an equipment decision; it’s a critical investment in product integrity and regulatory compliance.

The Challenge Facing Today’s Dairy Buyers

The global milk cooling tank market presents buyers with a complex landscape:

- Diverse capacity requirements ranging from 50-liter systems for small-scale goat and sheep operations to industrial tanks exceeding 10,000 liters

- Varying regulatory standards including ISO 5708, EN 13732, and 3-A Sanitary Standards

- Energy efficiency demands as operational costs and sustainability pressures intensify

- Technology variations in cooling speed, agitation systems, and insulation materials

Making the wrong choice means compromised milk quality, wasted energy expenditure, or equipment that fails to meet your production scale.

What This Guide Covers

This B2B guide provides procurement professionals, farm managers, and dairy equipment distributors with:

| Section | Focus |

|———|——-|

| Technical Specifications | Cooling performance, materials, capacity options |

| Compliance Requirements | US and European regulatory standards |

| Supplier Evaluation | Key criteria for vendor assessment |

| Total Cost Analysis | Purchase price, energy consumption, maintenance |

| Market Trends | Emerging technologies and efficiency innovations |

Illustrative Image (Source: Google Search)

Whether you’re sourcing for a small-scale artisan creamery or a large commercial dairy, this guide delivers the insights needed to make informed purchasing decisions.

Article Navigation

- Top 10 Milk Cooling Tank Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for milk cooling tank

- Understanding milk cooling tank Types and Variations

- Key Industrial Applications of milk cooling tank

- 3 Common User Pain Points for ‘milk cooling tank’ & Their Solutions

- Strategic Material Selection Guide for milk cooling tank

- In-depth Look: Manufacturing Processes and Quality Assurance for milk cooling tank

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘milk cooling tank’

- Comprehensive Cost and Pricing Analysis for milk cooling tank Sourcing

- Alternatives Analysis: Comparing milk cooling tank With Other Solutions

- Essential Technical Properties and Trade Terminology for milk cooling tank

- Navigating Market Dynamics and Sourcing Trends in the milk cooling tank Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of milk cooling tank

- Strategic Sourcing Conclusion and Outlook for milk cooling tank

- Important Disclaimer & Terms of Use

Top 10 Milk Cooling Tank Manufacturers & Suppliers List

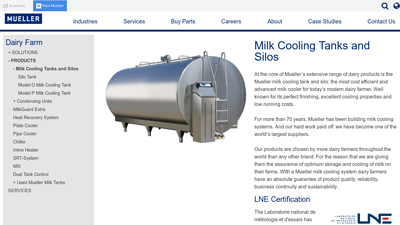

1. Milk Cooling Tanks – Dairy Farm – Paul Mueller Company

Domain: en.paulmueller.com

Registered: 1995 (30 years)

Introduction: For more than 70 years, Mueller has been building milk cooling systems. And our hard work paid off: we have become one of the world’s largest suppliers. Our ……

Illustrative Image (Source: Google Search)

2. MilkPlan Cooling Tanks – Caprine Supply

Domain: caprinesupply.com

Registered: 1996 (29 years)

Introduction: In stock 1-day deliveryMilkPlan is a well-established European brand with over 25 years of tradition and experience in manufacturing milk coolers, which guarantees reliable and ……

3. 4 Cooling Tank Manufacturers in 2025 – Metoree

Domain: us.metoree.com

Registered: 2020 (5 years)

Introduction: List of 4 Cooling Tank Manufacturers ; Risto GbR Manufacturer Mobile milk cooling tank ; WENZHOU JINBANG LIGHT IND MACHINERY CO.,LTD Manufacturer stainless steel ……

4. SERAP GROUP / MILK COOLER MANUFACTURER/ WINE TANK

Domain: groupeserap.com

Registered: 2003 (22 years)

Introduction: Created in 1963, SERAP is a family business, based in Mayenne, first European dairy region. Specialized in designing and manufacturing milk cooling tanks ……

5. Milk Tanks | Stainless Steel Milk Cooling Storage for the Dairy industry

Domain: gpi-tanks.com

Registered: 2017 (8 years)

Introduction: We regularly produce milk storage tanks with capacities of up to 500 m3, but larger storage tanks are also an option. In fact, we produce tanks up to 15,000 m3….

Illustrative Image (Source: Google Search)

6. Inox Steel Technical’s Milk Cooler – 15 Gallon – Homestead Supplier

Domain: homesteadsupplier.com

Registered: 2017 (8 years)

Introduction: In stock Free deliveryInox Steel Technical’s Milk Cooler – 15 Gallon is built to help farmers and dairy producers store milk safely and efficiently….

7. Cooling Tanks and Transport Tank – Homesteader’s Supply

Domain: homesteadersupply.com

Registered: 2008 (17 years)

Introduction: 5-day deliveryCall us for availability and Freight quotes on Cooling and Transport Tanks! Most are now in stock, but sometimes smaller tanks sell out ……

8. New Mueller Milk Cooling Tanks – Hamby Dairy Supply

Domain: hambydairysupply.com

Registered: 2003 (22 years)

Introduction: Free delivery over $250Oval Milk cooling tanks from 300 to 6000 gallons. The most efficient cooling systems of any tank available today. Spare parts in stock at Hamby Dairy Supply….

Understanding milk cooling tank Types and Variations

Understanding Milk Cooling Tank Types and Variations

Selecting the appropriate milk cooling tank is a critical infrastructure decision that directly impacts milk quality, operational efficiency, and regulatory compliance. This section examines the primary tank types available to dairy operations across the USA and Europe, helping procurement teams match equipment specifications to operational requirements.

Overview of Milk Cooling Tank Types

| Type | Key Features | Ideal Applications | Pros | Cons |

|---|---|---|---|---|

| Direct Expansion (DX) Tanks | Built-in refrigeration evaporator in tank walls; self-contained cooling | Small to medium farms; operations without pre-cooling systems | Fast cooling; compact design; lower installation complexity | Higher energy consumption; limited scalability |

| Ice Bank Tanks | Ice reservoir built during off-peak hours; instant cooling capacity | High-volume operations; farms with variable milking schedules | Lower peak energy demand; rapid cooling for large volumes | Higher upfront cost; requires more floor space |

| Instant Cooling Tanks | Plate heat exchangers combined with storage; pre-chilled milk entry | Large-scale dairies; operations prioritizing milk quality | Fastest cooling times; optimal bacteria control | Requires chilled water system; higher infrastructure investment |

| Vertical (Verti) Tanks | Upright cylindrical design; small footprint; capacities 50–2,500 liters | Small-scale farms; goat/sheep dairies; limited space facilities | Space-efficient; suitable for specialty milk; meets ISO5708/EN13732/3A standards | Limited to smaller volumes; not ideal for high-throughput operations |

| Horizontal Bulk Tanks | Elongated design; large capacity; easy access for cleaning | Medium to large cow dairies; bulk collection points | High storage capacity; easier milk agitation; industry-standard design | Requires more floor space; higher installation requirements |

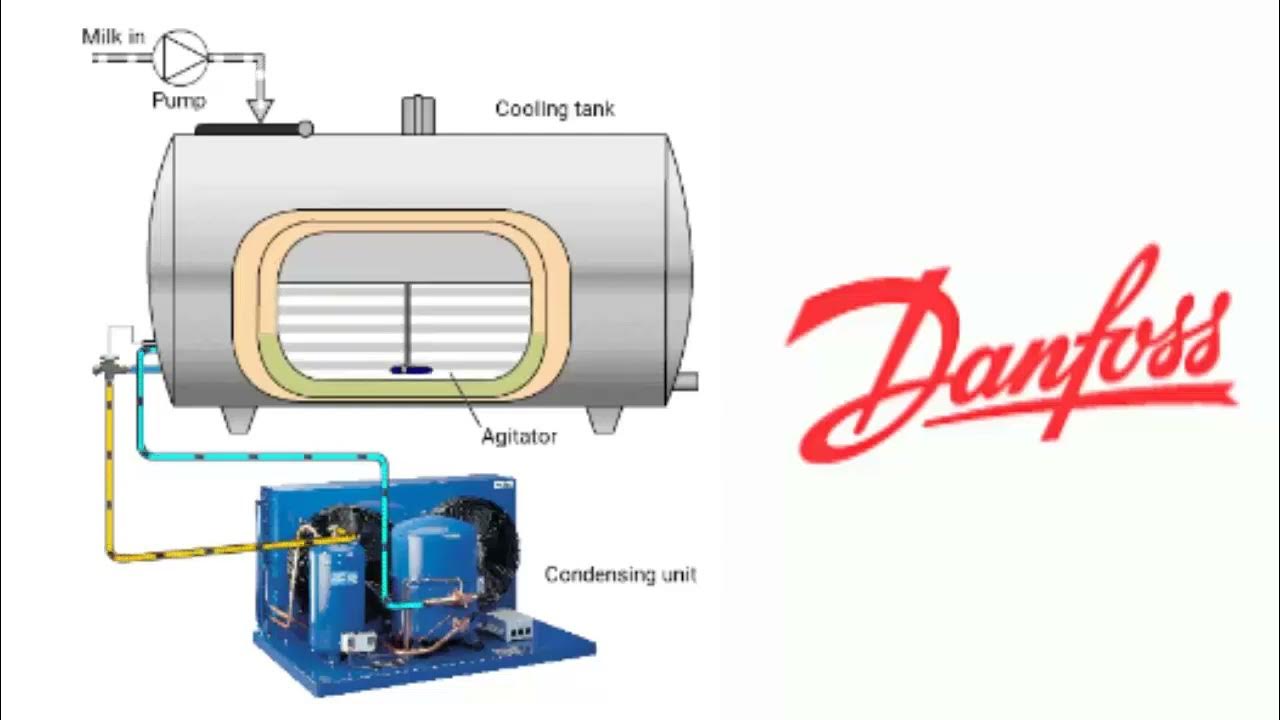

Direct Expansion (DX) Tanks

Direct expansion tanks remain the most widely deployed cooling solution for small to medium dairy operations. The refrigeration system’s evaporator is integrated directly into the tank’s inner wall, enabling milk to cool through direct contact with the chilled surface.

Technical Specifications:

– Cooling achieved via refrigerant circulating through channels in the tank wall

– Typical cooling time: 2–3 hours to reach 4°C (39°F) from 35°C (95°F)

– Available capacities: 200–10,000+ liters

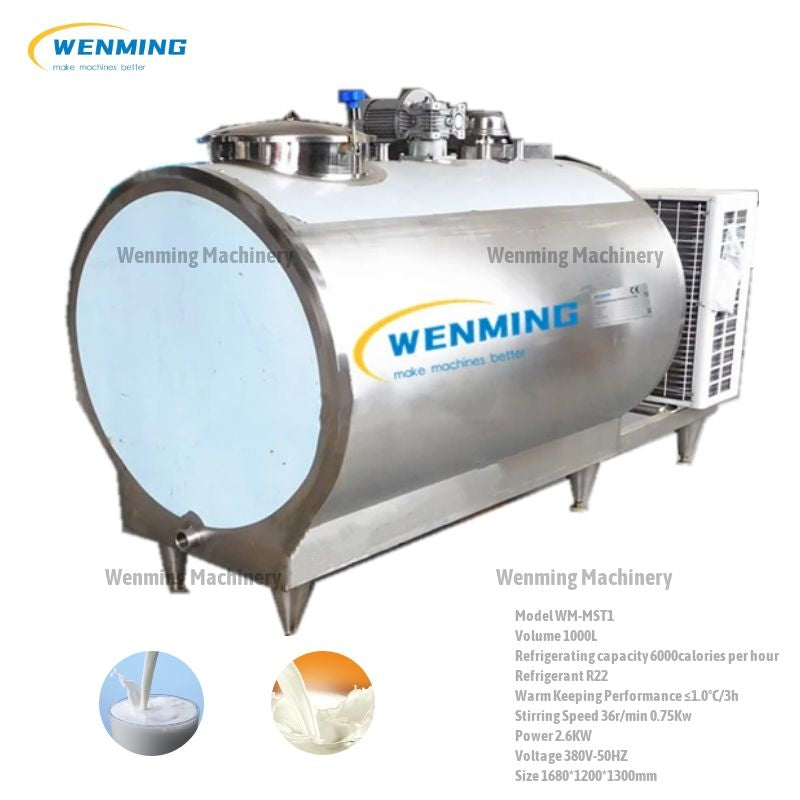

Illustrative Image (Source: Google Search)

Operational Considerations:

– Requires consistent electrical supply during cooling cycles

– Best suited for operations with predictable milking schedules

– Lower maintenance complexity compared to ice bank systems

Ice Bank Tanks

Ice bank systems build a reserve of ice during off-peak electrical hours, then utilize this stored cooling capacity during milking. This approach significantly reduces peak energy demand—a critical factor for operations in regions with time-of-use electricity pricing.

Technical Specifications:

– Ice accumulation occurs over 8–12 hours during low-demand periods

– Instant cooling capacity available regardless of compressor cycling

– Ideal for farms with 2+ milkings per day

Operational Considerations:

– Higher capital expenditure offset by reduced operating costs

– Requires adequate space for ice bank reservoir

– Provides cooling redundancy during compressor maintenance

Illustrative Image (Source: Google Search)

Instant Cooling Systems

Instant cooling combines plate heat exchangers with bulk storage tanks, pre-cooling milk to near-storage temperature before it enters the tank. This method delivers the fastest bacteria count reduction and is preferred by premium milk buyers.

Technical Specifications:

– Milk enters tank at 6–10°C (43–50°F) rather than body temperature

– Requires chilled water supply (typically 1–2°C)

– Often integrated with heat recovery systems for water heating

Operational Considerations:

– Highest milk quality outcomes; meets stringent European and US Grade A standards

– Significant infrastructure requirements (chilled water loop, plate cooler maintenance)

– ROI improved when combined with energy recovery systems

Vertical (Verti) Tanks

Vertical tanks address the specific needs of small-scale and specialty dairy operations. Manufacturers such as MilkPlan produce units ranging from 50 to 2,500 liters, purpose-built for goat, sheep, and small cow dairies.

Illustrative Image (Source: Google Search)

Technical Specifications:

– Food-grade stainless steel construction meeting ISO5708, EN13732, and 3A sanitary standards

– Polyethylene insulation for energy efficiency

– Agitation systems operating at approximately 30 RPM to ensure fat homogenization without foaming

Operational Considerations:

– Minimal footprint ideal for converted or limited-space facilities

– Scalable—multiple units can serve growing operations

– Particularly suited for artisan cheese producers and direct-to-consumer dairies

Horizontal Bulk Tanks

Horizontal bulk tanks represent the industry standard for medium to large conventional dairies. Their elongated design facilitates efficient agitation and provides easy access for cleaning and inspection.

Technical Specifications:

– Capacities typically range from 2,000 to 30,000+ liters

– Horizontal agitator design ensures uniform cooling and fat distribution

– Compatible with automated CIP (Clean-in-Place) systems

Illustrative Image (Source: Google Search)

Operational Considerations:

– Requires dedicated floor space and structural support

– Standard configuration for milk collection by bulk tankers

– Readily available replacement parts and service support across USA and Europe

Selection Criteria Summary

When evaluating milk cooling tank options, procurement teams should assess:

- Daily milk volume and growth projections

- Available floor space and facility constraints

- Electrical infrastructure and energy cost structure

- Species-specific requirements (cow, goat, sheep)

- Regulatory standards applicable to target markets

- Integration requirements with existing or planned pre-cooling systems

Key Industrial Applications of milk cooling tank

Key Industrial Applications of Milk Cooling Tank

Milk cooling tanks serve as critical infrastructure across multiple sectors of the dairy industry, ensuring product quality, regulatory compliance, and operational efficiency. Below is a comprehensive breakdown of primary applications and their sector-specific benefits.

Industry Application Matrix

| Industry Sector | Tank Capacity Range | Primary Use Case | Key Requirements |

|---|---|---|---|

| Small-Scale Dairy Farms (Goat/Sheep) | 14–660 gallons (50–2,500 liters) | On-farm milk preservation | Compact footprint, multi-species compatibility |

| Small-Scale Cow Dairies | 100–660 gallons | Daily milk collection and storage | Rapid cooling, single-milking capacity |

| Artisan Cheese Production | 50–500 gallons | Raw milk storage pre-processing | Precise temperature control, gentle agitation |

| Specialty Milk Operations | 100–1,000 gallons | Organic, A2, or premium milk handling | Contamination prevention, traceability support |

| Mobile Collection Units | 50–300 gallons | Farm-to-processor transport | Durability, insulation efficiency |

| Research & Breeding Facilities | 14–200 gallons | Sample preservation, genetic programs | Small-batch precision, sanitary design |

Detailed Benefits by Application

Small-Scale Dairy Farms (Goat, Sheep, Small Cow Herds)

- Bacterial Control: Rapid cooling to 4°C (39°F) within regulatory timeframes prevents bacterial proliferation and maintains milk pH stability

- Energy Efficiency: Advanced polyethylene insulation minimizes energy consumption during extended storage cycles

- Homogenization: Paddle agitation systems operating at 30 RPM ensure uniform fat distribution without foam generation

- Compliance: Tanks meeting ISO 5708, EN 13732, and 3-A Sanitary Standards satisfy both European and U.S. regulatory requirements

Artisan and Specialty Dairy Processing

- Quality Preservation: Controlled agitation maintains milk integrity for cheese-making applications where fat globule structure impacts final product

- Batch Segregation: Smaller capacity units enable separation of milk by source, breed, or quality grade

- Traceability: Dedicated tanks support farm-to-table documentation requirements for premium and organic certifications

Collection and Distribution Networks

- Cold Chain Integrity: Food-grade stainless steel construction and superior insulation maintain temperature during transfer operations

- Scalability: Modular capacity options allow operations to match equipment to production volume without over-investment

Research and Genetic Programs

- Sample Integrity: Precise temperature management preserves milk composition for analysis

- Sanitary Design: Full compliance with food-grade standards prevents cross-contamination between test batches

Compliance Standards Overview

| Standard | Region | Application |

|---|---|---|

| ISO 5708 | International | Milk cooling tank performance |

| EN 13732 | European Union | Food contact materials, thermal performance |

| 3-A Sanitary Standards | United States | Hygienic design criteria |

Selecting tanks that meet all three standards ensures operational flexibility for businesses serving both U.S. and European markets or those pursuing export opportunities.

Illustrative Image (Source: Google Search)

3 Common User Pain Points for ‘milk cooling tank’ & Their Solutions

3 Common User Pain Points for Milk Cooling Tanks & Their Solutions

Pain Point 1: Bacterial Growth and Milk Quality Degradation

Scenario: A mid-sized dairy operation notices inconsistent milk quality results during processing plant inspections. Bulk tank somatic cell counts fluctuate, and occasional loads are rejected due to elevated bacterial counts.

Problem: Inadequate cooling speed allows bacteria to multiply rapidly in fresh milk. When milk isn’t cooled to the required 4°C (39°F) within the mandated timeframe, bacterial populations can double every 20 minutes, leading to increased acidity, quality downgrades, and financial penalties.

Solution:

– Invest in tanks with high-performance cooling systems that meet ISO 5708/EN 13732/3A standards

– Ensure proper agitation systems (approximately 30 RPM) for uniform temperature distribution without foaming

– Implement automated temperature monitoring with alert systems

– Schedule regular maintenance of refrigeration components

Pain Point 2: Energy Costs and Operational Efficiency

Scenario: A dairy farm manager reviews quarterly utility bills and discovers cooling operations account for a disproportionate share of energy expenses, cutting into already tight margins.

Illustrative Image (Source: Google Search)

Problem: Outdated or poorly insulated cooling tanks run compressors continuously, consuming excessive electricity. Inefficient heat exchange and inadequate insulation force systems to work harder, increasing operational costs by 15-30%.

Solution:

| Efficiency Measure | Expected Impact |

|——————-|—————–|

| State-of-the-art polyethylene insulation | Reduces heat ingress, lowers compressor runtime |

| Pre-cooling with plate coolers | Decreases tank cooling load by 40-50% |

| Variable-speed compressors | Matches cooling output to actual demand |

| Heat recovery systems (FreeHeaters) | Repurposes waste heat for water heating |

Pain Point 3: Capacity Mismatch and Scalability Challenges

Scenario: A growing goat or sheep dairy operation finds their current tank either too small for expanding production or oversized for current needs, resulting in inefficient cooling cycles.

Problem: Undersized tanks force multiple collection cycles, increasing labor and logistics costs. Oversized tanks cooling partial loads waste energy and may struggle to cool milk quickly enough, compromising quality.

Illustrative Image (Source: Google Search)

Solution:

– Assess current and projected 3-5 year production volumes before purchasing

– Consider modular tank configurations (available from 50L to 2,500L+) that align with herd size

– For small-scale operations (goats, sheep, small cow herds), select purpose-built tanks like the Verti tank series designed specifically for lower volumes

– Partner with suppliers offering flexible upgrade paths and trade-in programs

Strategic Material Selection Guide for milk cooling tank

Strategic Material Selection Guide for Milk Cooling Tanks

Selecting the appropriate materials for milk cooling tanks directly impacts operational efficiency, regulatory compliance, product safety, and total cost of ownership. This guide provides a systematic analysis of material options to inform procurement decisions.

Primary Construction Materials

Stainless Steel Grades

AISI 304 Stainless Steel

The industry standard for milk cooling tank construction. Contains 18% chromium and 8% nickel, providing excellent corrosion resistance against milk’s lactic acid content. Suitable for most dairy applications where cleaning chemicals are standard alkaline and acid detergents.

AISI 316/316L Stainless Steel

Premium grade containing 2-3% molybdenum for enhanced resistance to chloride-induced pitting and crevice corrosion. Recommended for:

– Facilities using aggressive sanitizing agents

– Coastal locations with salt air exposure

– Operations processing high-acid milk products

– Extended equipment lifecycle requirements (20+ years)

Illustrative Image (Source: Google Search)

Duplex Stainless Steel (2205)

Combines austenitic and ferritic properties. Offers superior strength-to-weight ratio and stress corrosion cracking resistance. Typically specified for large-capacity industrial installations exceeding 5,000 liters.

Surface Finish Specifications

Surface roughness directly affects cleanability and bacterial adhesion:

- Ra ≤ 0.8 μm (32 μin): Standard dairy grade, meets 3-A Sanitary Standards

- Ra ≤ 0.4 μm (16 μin): Enhanced cleanability for premium applications

- Electropolished finish: Maximum corrosion resistance, reduced biofilm formation

Insulation Materials

Polyurethane Foam (PUF)

– Thermal conductivity: 0.022-0.028 W/m·K

– Density: 38-45 kg/m³

– Industry standard for mid-range tanks

– CFC-free formulations now mandatory

Polyethylene Insulation

As noted in MilkPlan’s Verti tank series, state-of-the-art polyethylene insulation delivers maximum energy savings while maintaining structural integrity. This material offers:

– Moisture resistance superior to traditional foams

– Consistent thermal performance over equipment lifespan

– Environmental compliance advantages

Illustrative Image (Source: Google Search)

Vacuum Panel Insulation (VPI)

– Thermal conductivity: 0.004-0.008 W/m·K

– Highest efficiency option

– Premium cost, justified for energy-intensive operations

Agitator and Internal Component Materials

Shaft and Paddle Construction

Food-grade stainless steel (304 or 316) is mandatory for all milk-contact surfaces. Specialized shaft designs with paddles operating at approximately 30 RPM ensure:

– Complete fat homogenization

– Uniform temperature distribution

– Foam-free operation

Seals and Gaskets

– FDA-compliant EPDM rubber for standard applications

– Silicone for high-temperature CIP cycles

– PTFE for chemical resistance requirements

Regulatory Compliance Framework

All materials must meet applicable standards for US and European markets:

Illustrative Image (Source: Google Search)

| Standard | Jurisdiction | Key Requirements |

|---|---|---|

| 3-A Sanitary Standards | USA | Surface finish, material composition, cleanability |

| ISO 5708 | International | Cooling performance, construction specifications |

| EN 13732 | European Union | Bulk milk cooling tank requirements |

| FDA 21 CFR 177 | USA | Food-contact material safety |

| EC 1935/2004 | European Union | Food contact material regulations |

MilkPlan tanks exemplify compliance, meeting ISO 5708, EN 13732, and 3-A standards simultaneously—critical for operations serving both US and European markets.

Material Selection by Application Scale

Small-Scale Operations (50-2,500 liters)

Ideal for farms milking goats, sheep, or small cow herds. Standard 304 stainless steel with polyethylene insulation provides optimal cost-performance balance.

Medium-Scale Operations (2,500-10,000 liters)

304 or 316 stainless steel depending on water quality and cleaning protocols. PUF insulation standard; consider VPI for high energy costs.

Large-Scale Industrial (10,000+ liters)

316L or duplex stainless steel recommended. Enhanced insulation systems. Custom engineering for specific operational requirements.

Illustrative Image (Source: Google Search)

Material Comparison Table

| Material/Component | Cost Index | Corrosion Resistance | Lifespan | Best Application |

|---|---|---|---|---|

| Tank Body | ||||

| AISI 304 SS | 1.0x | Good | 15-20 years | Standard dairy operations |

| AISI 316L SS | 1.3-1.5x | Excellent | 20-25 years | Aggressive environments, coastal |

| Duplex 2205 SS | 1.8-2.2x | Superior | 25+ years | Large industrial, high stress |

| Insulation | ||||

| Polyurethane Foam | 1.0x | N/A | 15-20 years | Standard applications |

| Polyethylene | 1.1-1.2x | N/A | 20+ years | Energy-focused operations |

| Vacuum Panel | 2.5-3.0x | N/A | 20+ years | Maximum efficiency required |

| Surface Finish | ||||

| Ra 0.8 μm | 1.0x | Standard | — | Meets minimum standards |

| Ra 0.4 μm | 1.15x | Enhanced | — | Premium cleanability |

| Electropolished | 1.3x | Maximum | — | Critical hygiene applications |

| Seals/Gaskets | ||||

| EPDM | 1.0x | Good | 3-5 years | Standard CIP chemicals |

| Silicone | 1.4x | Good | 4-6 years | High-temperature cycles |

| PTFE | 2.0x | Excellent | 5-8 years | Aggressive chemicals |

Total Cost of Ownership Considerations

Material selection should account for:

- Initial acquisition cost — Premium materials increase upfront investment 20-50%

- Energy efficiency — Superior insulation reduces cooling costs 15-30% annually

- Maintenance frequency — Higher-grade materials reduce repair intervals

- Replacement parts availability — Ensure supplier maintains spare parts inventory

- Resale value — 316L stainless tanks retain higher secondary market value

- Regulatory future-proofing — Anticipate tightening standards in both US and EU markets

Procurement Recommendations

- Request material certifications (mill certificates) for all stainless steel components

- Verify surface finish measurements with documented Ra values

- Confirm insulation R-values and CFC-free compliance

- Validate multi-standard compliance (3-A, ISO, EN) for export flexibility

- Obtain spare parts pricing and availability commitments before purchase

In-depth Look: Manufacturing Processes and Quality Assurance for milk cooling tank

In-Depth Look: Manufacturing Processes and Quality Assurance for Milk Cooling Tanks

Understanding how milk cooling tanks are manufactured—and the quality standards they must meet—is essential for B2B buyers evaluating equipment investments. This section breaks down the core manufacturing stages and the certifications that ensure compliance with international food safety requirements.

Manufacturing Process Overview

Milk cooling tank production follows a rigorous sequence designed to ensure structural integrity, thermal efficiency, and hygienic performance. The process typically involves four key stages:

1. Material Preparation

| Step | Description |

|---|---|

| Material Selection | Food-grade stainless steel (typically 304 or 316 grades) is sourced to meet corrosion resistance and sanitary requirements |

| Sheet Cutting | Steel sheets are precision-cut using laser or plasma cutting technology to exact specifications |

| Surface Treatment | Raw materials undergo cleaning and degreasing to prepare for forming |

2. Forming and Fabrication

- Rolling and Shaping: Steel sheets are rolled into cylindrical or vertical tank bodies using hydraulic forming equipment

- Welding: Seams are joined using TIG (Tungsten Inert Gas) welding to create smooth, sanitary welds without crevices that could harbor bacteria

- Polishing: Interior surfaces are polished to achieve the required surface finish (typically Ra ≤ 0.8 μm) for easy cleaning and bacterial resistance

3. Assembly and Integration

| Component | Assembly Process |

|---|---|

| Evaporator Coils | Refrigeration coils are fitted to the tank exterior or base for direct expansion cooling |

| Insulation Layer | Polyurethane foam or polyethylene insulation is applied between inner and outer shells for thermal efficiency |

| Agitation System | Paddle-style agitators with gear reduction motors (typically 30 RPM) are installed to ensure uniform cooling and fat homogenization without foaming |

| Control Systems | Temperature sensors, digital controllers, and automatic start/stop mechanisms are integrated |

4. Quality Control and Testing

Before leaving the production facility, each tank undergoes comprehensive testing:

Illustrative Image (Source: Google Search)

- Pressure Testing: Verifies weld integrity and leak-free construction

- Cooling Performance Tests: Confirms the tank meets required cool-down times per capacity rating

- Electrical Safety Checks: Ensures all components meet regional electrical standards

- Surface Inspection: Visual and instrumental verification of interior finish quality

Quality Standards and Certifications

Reputable manufacturers certify their milk cooling tanks to internationally recognized standards. Buyers in the USA and Europe should verify compliance with the following:

| Standard | Region | Scope |

|---|---|---|

| 3-A Sanitary Standards | USA | Establishes criteria for design, materials, and fabrication of dairy equipment to ensure cleanability |

| ISO 5708 | International | Specifies performance requirements for milk cooling tanks, including cooling times and temperature maintenance |

| EN 13732 | Europe | European standard for bulk milk coolers covering construction, performance, and testing methods |

| CE Marking | Europe | Indicates conformity with EU health, safety, and environmental protection standards |

Buyer Note: Tanks meeting ISO 5708, EN 13732, and 3-A standards—as seen with manufacturers like MilkPlan—demonstrate compliance across both US and European markets, simplifying procurement for operations with international supply chains.

Key Takeaways for B2B Buyers

- Material traceability: Request documentation confirming food-grade stainless steel sourcing

- Weld quality: Specify TIG-welded construction with sanitary finish requirements

- Certification verification: Confirm ISO 5708/EN 13732/3-A compliance before purchase

- Performance guarantees: Ensure cooling time specifications match your operational milk volumes and milking schedules

Practical Sourcing Guide: A Step-by-Step Checklist for ‘milk cooling tank’

Practical Sourcing Guide: A Step-by-Step Checklist for Milk Cooling Tanks

Use this comprehensive checklist to streamline your milk cooling tank procurement process and ensure you select equipment that meets your operational requirements and regulatory standards.

Phase 1: Requirements Assessment

Capacity Planning

– [ ] Calculate current daily milk production volume (gallons/liters)

– [ ] Project growth requirements for the next 3-5 years

– [ ] Determine tank capacity needed (available range: 14-660 gallons / 50-2,500 liters for small-scale; larger for commercial operations)

– [ ] Identify species-specific needs (cow, goat, sheep, or mixed operation)

Illustrative Image (Source: Google Search)

Technical Specifications

– [ ] Define required cooling speed (time to reach 4°C/39°F)

– [ ] Specify agitation requirements (standard: 30 RPM paddle systems)

– [ ] Determine insulation type preference (polyurethane vs. polyethylene)

– [ ] Assess electrical requirements and available power supply

– [ ] Evaluate space constraints and installation location

Phase 2: Compliance Verification

| Standard | Region | Requirement |

|---|---|---|

| ISO 5708 | International | Milk cooling equipment performance |

| EN 13732 | Europe | Bulk milk coolers on farms |

| 3-A Sanitary Standards | USA | Food-grade equipment certification |

| FDA PMO | USA | Grade “A” milk production |

Compliance Checklist

– [ ] Confirm food-grade stainless steel construction

– [ ] Verify manufacturer certifications match your market (USA/Europe)

– [ ] Request documentation for all applicable standards

– [ ] Confirm tank meets local dairy inspection requirements

Phase 3: Supplier Evaluation

Supplier Qualification Criteria

– [ ] Verify manufacturer reputation and industry experience

– [ ] Request customer references from similar-scale operations

– [ ] Confirm spare parts availability and lead times

– [ ] Evaluate technical support and service network coverage

– [ ] Assess warranty terms and conditions

Key Questions for Suppliers

– [ ] What is the current stock availability?

– [ ] What are shipping costs and delivery timelines?

– [ ] Is installation support provided?

– [ ] What training is included with purchase?

– [ ] What is the expected equipment lifespan?

Illustrative Image (Source: Google Search)

Phase 4: Cost Analysis

Total Cost of Ownership Calculation

– [ ] Equipment purchase price

– [ ] Shipping and freight costs

– [ ] Installation expenses

– [ ] Electrical/plumbing modifications

– [ ] Annual energy consumption costs

– [ ] Maintenance and spare parts budget

– [ ] Extended warranty options

ROI Considerations

– [ ] Energy efficiency ratings (polyethylene insulation offers maximum savings)

– [ ] Milk quality premiums from proper cooling

– [ ] Reduced spoilage and bacterial growth

– [ ] Labor savings from automated systems

Phase 5: Pre-Purchase Verification

- [ ] Request detailed product specifications sheet

- [ ] Obtain written quotation with all costs itemized

- [ ] Confirm lead time and delivery schedule

- [ ] Review payment terms and financing options

- [ ] Verify return/exchange policy

- [ ] Contact supplier directly to confirm stock availability

Phase 6: Post-Purchase Actions

- [ ] Schedule professional installation

- [ ] Arrange staff training on operation and cleaning

- [ ] Register warranty with manufacturer

- [ ] Establish maintenance schedule

- [ ] Document spare parts ordering process

- [ ] Schedule initial inspection with local dairy authority

Quick Reference: Key Performance Features

| Feature | Purpose | What to Verify |

|---|---|---|

| Stainless steel construction | Food safety, durability | Grade and certification |

| Paddle agitation system | Fat homogenization, uniform cooling | RPM rating (optimal: 30 RPM) |

| Insulation quality | Energy efficiency, cooling retention | Material type and thickness |

| Cooling speed | Bacteria prevention, milk quality | Time to reach target temperature |

| Control system | Operation monitoring | Digital vs. analog, data logging |

Pro Tip: Always contact suppliers directly (phone preferred) to verify current stock levels and obtain accurate shipping quotes before finalizing purchase decisions.

Comprehensive Cost and Pricing Analysis for milk cooling tank Sourcing

Comprehensive Cost and Pricing Analysis for Milk Cooling Tank Sourcing

Understanding the full cost structure of milk cooling tank procurement is essential for making informed B2B purchasing decisions. This analysis breaks down the key cost components and provides actionable strategies to optimize your investment.

Illustrative Image (Source: Google Search)

Cost Breakdown by Component

Materials Cost (40-55% of Total Price)

| Material Component | Cost Impact | Quality Considerations |

|---|---|---|

| Food-grade stainless steel (304/316) | 35-45% | Must meet ISO5708, EN13732, and 3A standards |

| Polyethylene insulation | 5-8% | Directly affects energy efficiency |

| Refrigeration components | 15-20% | Compressor quality determines longevity |

| Agitation system (shaft, paddles, gear motor) | 8-12% | 30 RPM standard for optimal homogenization |

| Control systems/electronics | 5-10% | Digital vs. analog affects price |

Capacity-Based Pricing Reference

| Tank Capacity | Approximate Price Range (USD) | Primary Application |

|---|---|---|

| 14-50 gallons (50-200L) | $3,500-$8,000 | Small-scale goat/sheep operations |

| 50-150 gallons (200-600L) | $8,000-$15,000 | Small dairy farms |

| 150-400 gallons (600-1,500L) | $15,000-$28,000 | Mid-size operations |

| 400-660 gallons (1,500-2,500L) | $28,000-$45,000 | Larger small-scale farms |

Note: Prices vary based on manufacturer, specifications, and market conditions. Contact suppliers directly for current quotes.

Labor Costs

- Manufacturing labor: 15-20% of unit cost

- Installation: $500-$2,500 depending on complexity and location

- Electrical/plumbing hookup: $300-$1,200 (separate from tank installation)

- Commissioning and calibration: Often included; verify with supplier

Logistics and Delivery

| Factor | Cost Range | Variables |

|---|---|---|

| Domestic shipping (USA) | $500-$2,500 | Distance, tank size, freight class |

| International shipping (Europe to USA) | $1,500-$5,000 | Port proximity, customs, container type |

| Lift-gate delivery | $75-$200 additional | Required for sites without loading dock |

| Inside delivery/positioning | $200-$800 | Accessibility, equipment needed |

Important: Always request shipping quotes before finalizing orders. Tank dimensions and weight significantly impact freight costs.

Total Cost of Ownership Considerations

Beyond purchase price, factor these ongoing costs:

- Energy consumption: High-efficiency insulation reduces operating costs 15-25%

- Maintenance: Annual service contracts typically run 2-4% of purchase price

- Spare parts availability: Domestic suppliers offer faster, cheaper parts access

- Compliance inspections: Budget $200-$500 annually for regulatory certifications

Cost-Saving Strategies

Procurement Tactics

- Request stock availability first — In-stock units avoid custom manufacturing lead times and potential price increases

- Bundle purchases — Combine cooling tanks with plate coolers, FreeHeaters, or pipeline systems for volume discounts

- Compare regional suppliers — European manufacturers (e.g., MilkPlan) may offer competitive pricing despite shipping costs

- Evaluate refurbished options — Quality used tanks at 40-60% of new prices for budget-conscious operations

Specification Optimization

- Right-size your capacity — Oversizing increases capital and energy costs; calculate based on peak production + 20% buffer

- Standardize across operations — Multiple locations benefit from parts interchangeability

- Prioritize insulation quality — Higher upfront cost yields significant long-term energy savings

Logistics Savings

- Consolidate shipments — Coordinate delivery with other equipment purchases

- Consider regional distribution — Some manufacturers maintain US warehouse stock

- Plan seasonal timing — Order during slower periods (typically late winter) for better pricing and availability

Negotiation Leverage Points

- Multi-unit purchases

- Long-term supplier relationships

- Flexible delivery timelines

- Payment terms (net-30/60 vs. prepayment discounts)

- Warranty extensions in lieu of price reductions

Due Diligence Checklist Before Purchase

- [ ] Verify compliance certifications (ISO5708, EN13732, 3A) for your market

- [ ] Confirm total delivered cost including all logistics fees

- [ ] Obtain spare parts pricing and availability commitments

- [ ] Review warranty terms and service network coverage

- [ ] Calculate 5-year total cost of ownership, not just purchase price

Alternatives Analysis: Comparing milk cooling tank With Other Solutions

Alternatives Analysis: Comparing Milk Cooling Tanks With Other Solutions

Selecting the right milk cooling solution directly impacts milk quality, operational efficiency, and regulatory compliance. This analysis examines milk cooling tanks against two primary alternatives to help you make an informed procurement decision.

Illustrative Image (Source: Google Search)

Comparison Overview

| Factor | Bulk Milk Cooling Tanks | Instant Cooling Systems (Plate Coolers) | Ice Bank Cooling Systems |

|---|---|---|---|

| Initial Investment | Moderate ($3,000–$50,000+) | Lower ($1,500–$8,000) | Higher ($15,000–$80,000+) |

| Operating Costs | Moderate | Lower (uses well water) | Higher (ice production) |

| Cooling Speed | 2–4 hours to 4°C/39°F | Immediate (inline) | 30–60 minutes |

| Capacity Range | 50L–50,000L+ | Limited by flow rate | 500L–20,000L+ |

| Space Requirements | Moderate | Minimal | Significant |

| Maintenance Complexity | Low | Low–Moderate | High |

| Best For | Small-to-large dairy operations | Pre-cooling supplement | High-volume, rapid cooling needs |

Detailed Analysis

Bulk Milk Cooling Tanks

Milk cooling tanks remain the industry standard for on-farm milk storage. Modern units—such as those meeting ISO5708/EN13732/3A standards—feature polyethylene insulation for energy efficiency and integrated agitation systems (typically 30 RPM) that ensure fat homogenization without foaming. Available capacities from 14 gallons to 660+ gallons accommodate operations from small goat/sheep dairies to larger cattle farms.

Advantages:

– All-in-one cooling and storage solution

– Proven regulatory compliance (EU and US standards)

– Reliable bacteria control through consistent temperature maintenance

– Lower maintenance requirements

Limitations:

– Slower initial cooling compared to instant systems

– Fixed capacity constraints

Instant Cooling Systems (Plate Coolers)

Plate coolers provide immediate temperature reduction by passing milk through stainless steel plates counter-current to cold water. These systems typically reduce milk temperature by 10–15°C before it enters bulk storage.

Advantages:

– Reduces cooling tank workload by 50–60%

– Lower energy consumption when paired with well water

– Extends compressor lifespan on bulk tanks

Limitations:

– Requires separate bulk storage

– Dependent on adequate cold water supply

– Additional cleaning protocols required

Ice Bank Cooling Systems

Ice bank systems pre-build ice reserves during off-peak hours, then use this stored cooling capacity for rapid milk chilling. These systems excel in operations requiring fast cooling of large milk volumes.

Advantages:

– Fastest cooling times

– Can leverage off-peak electricity rates

– Handles surge volumes effectively

Limitations:

– Highest capital and maintenance costs

– Significant floor space requirements

– Complex refrigeration systems require specialized service

Recommendation Matrix

| Operation Type | Recommended Solution |

|---|---|

| Small-scale dairy (goat/sheep, <500L/day) | Bulk cooling tank |

| Mid-size dairy (500–2,000L/day) | Bulk tank + plate cooler |

| Large-scale dairy (>2,000L/day) | Ice bank or bulk tank + plate cooler combination |

| Operations with abundant cold well water | Plate cooler + smaller bulk tank |

Key Takeaway

For most small-to-medium dairy operations, bulk milk cooling tanks offer the optimal balance of compliance, reliability, and total cost of ownership. Operations seeking enhanced efficiency should consider integrating plate coolers as a pre-cooling stage, reducing energy costs while maintaining milk quality standards required by US and EU regulators.

Essential Technical Properties and Trade Terminology for milk cooling tank

Essential Technical Properties and Trade Terminology for Milk Cooling Tanks

Key Technical Specifications

| Property | Description | Typical Values |

|---|---|---|

| Capacity | Total milk volume the tank can hold | 50L (14 gal) to 30,000L+ (7,925 gal) |

| Cooling Rate | Time to reduce milk temperature from 35°C to 4°C | 2-hour or 4-hour cycles (per ISO 5708) |

| Agitation Speed | RPM of mixing paddles for homogenization | 25-35 RPM (30 RPM standard) |

| Insulation Type | Material preventing heat transfer | Polyurethane foam or polyethylene |

| Construction Material | Interior tank surface | Food-grade stainless steel (304 or 316) |

| Refrigerant Type | Cooling agent used in compressor system | R404A, R449A, R290 (varies by region) |

Regulatory Standards and Certifications

- ISO 5708: International standard for milk cooling tank performance

- EN 13732: European standard for bulk milk coolers

- 3-A Sanitary Standards: U.S. dairy equipment hygiene certification

- FDA 21 CFR: U.S. food contact material compliance

- CE Marking: European conformity for equipment safety

B2B Trade Terminology

| Term | Definition |

|---|---|

| MOQ | Minimum Order Quantity—lowest unit count per purchase order |

| OEM | Original Equipment Manufacturer—custom branding/specifications available |

| FOB | Free On Board—shipping cost responsibility transfer point |

| CIF | Cost, Insurance, Freight—delivered price including shipping |

| Lead Time | Production-to-delivery timeframe (typically 4-12 weeks) |

| DX System | Direct Expansion—evaporator coils in direct contact with tank |

| IB System | Ice Bank—ice water reservoir for rapid cooling |

Performance Classifications

Cooling Performance Classes (ISO 5708):

– BII: Cools milk to 4°C within 2 hours (2 milkings/day)

– BIV: Cools milk to 4°C within 4 hours (single milking)

Tank Categories by Application:

– Open-top tanks: Small-scale operations, manual cleaning

– Closed/sealed tanks: Commercial dairies, CIP-compatible

– Vertical tanks: Space-efficient, smaller capacities

– Horizontal tanks: Higher capacities, easier access

Navigating Market Dynamics and Sourcing Trends in the milk cooling tank Sector

Navigating Market Dynamics and Sourcing Trends in the Milk Cooling Tank Sector

Market Evolution and Current Landscape

The milk cooling tank sector has undergone significant transformation over the past two decades, driven by tightening food safety regulations, energy efficiency demands, and the diversification of dairy operations. What began as simple bulk storage has evolved into sophisticated temperature management systems that directly impact milk quality, shelf life, and processor acceptance.

Key Market Segments:

| Segment | Capacity Range | Primary Applications |

|---|---|---|

| Small-scale | 14–660 gallons (50–2,500 liters) | Goat, sheep, small cow operations |

| Mid-scale | 660–2,000 gallons | Regional dairy farms |

| Commercial | 2,000–10,000+ gallons | Large-scale dairy operations |

Sourcing Trends Shaping Procurement Decisions

Regulatory Compliance as a Baseline

Buyers increasingly prioritize equipment meeting dual-market certifications. Tanks conforming to ISO 5708, EN 13732 (European), and 3A sanitary standards (USA) offer procurement flexibility and resale value. This convergence reflects the globalization of dairy equipment supply chains and the need for standardized quality benchmarks.

Material and Construction Priorities

- Food-grade stainless steel remains the industry standard for contact surfaces

- Advanced polyethylene insulation has become the preferred thermal barrier, offering superior energy efficiency over traditional foam alternatives

- Integrated agitation systems (typically 30 RPM paddle configurations) are now expected rather than optional, ensuring fat homogenization without foam generation

Sustainability and Energy Considerations

Energy consumption represents a significant operational cost in milk cooling. Current market trends emphasize:

- Heat recovery integration — Repurposing extracted heat for water warming or facility heating

- Variable-speed compressor technology — Matching cooling output to actual load requirements

- Enhanced insulation R-values — Reducing thermal loss during storage periods

Procurement teams should evaluate total cost of ownership (TCO) rather than acquisition price alone. Tanks with superior insulation and efficient refrigeration systems typically deliver 15–25% lower operating costs over their service life.

Regional Sourcing Dynamics

European suppliers (including manufacturers like MilkPlan) have established strong positions in the small-to-mid-scale segment, particularly for specialty dairy operations (goat, sheep, artisan). Their equipment often leads in energy efficiency certifications and compact footprint design.

North American distributors increasingly stock European-manufactured equipment alongside domestic options, providing buyers with broader specification choices and competitive pricing through established import channels.

Strategic Sourcing Recommendations

- Verify certification documentation before purchase—counterfeit compliance claims exist in secondary markets

- Assess spare parts availability and regional service networks; equipment without accessible support creates operational risk

- Request energy consumption specifications under standardized test conditions for accurate comparison

- Consider scalability if production expansion is anticipated within the equipment’s 15–20 year typical service life

Frequently Asked Questions (FAQs) for B2B Buyers of milk cooling tank

Frequently Asked Questions (FAQs) for B2B Buyers of Milk Cooling Tanks

1. What capacity range should I consider for my operation?

Milk cooling tanks are available in capacities ranging from 14 gallons (50 liters) for small-scale operations to 660+ gallons (2,500+ liters) for larger facilities. Selection depends on:

| Operation Type | Recommended Capacity |

|---|---|

| Small goat/sheep farms | 50-200 liters |

| Mid-size dairy operations | 200-1,000 liters |

| Commercial dairy farms | 1,000-2,500+ liters |

Calculate your daily milk volume and factor in potential growth when selecting capacity.

2. What compliance standards should milk cooling tanks meet?

For USA and European markets, ensure tanks comply with:

- ISO 5708 – International milk cooling tank standards

- EN 13732 – European performance requirements

- 3-A Sanitary Standards – Required for US dairy operations

Tanks must be constructed from food-grade stainless steel to meet regulatory requirements.

3. How quickly should a tank cool milk to safe temperatures?

Quality tanks should cool milk to 4°C (39°F) within 2-3 hours of milking to prevent bacterial growth and maintain milk acidity (pH) levels. Rapid cooling is critical for preserving milk quality and meeting dairy processor specifications.

4. What agitation specifications matter for milk quality?

Look for tanks with:

- 30 RPM paddle rotation – Industry standard for optimal mixing

- Gear reduction motors – Ensures consistent, controlled agitation

- Homogenization capability – Uniform fat distribution without foaming

Proper agitation ensures consistent cooling throughout the entire milk volume.

5. What insulation type offers the best energy efficiency?

State-of-the-art polyethylene insulation provides optimal thermal efficiency, reducing energy consumption and operational costs. Quality insulation maintains cooling performance while minimizing compressor run time.

6. What are typical lead times and shipping considerations?

Lead times vary by manufacturer and capacity. Key considerations:

- Contact suppliers directly to verify stock availability

- Request shipping quotes—tanks are heavy and require specialized freight

- Factor in installation timeline and any site preparation requirements

7. What spare parts availability should I verify before purchase?

Confirm supplier access to:

- Compressor components

- Agitator motors and paddles

- Gaskets and seals

- Control panels and sensors

- Refrigerant service capability

Reliable parts availability minimizes downtime and protects your investment.

8. Are these tanks suitable for different milk types?

Yes, quality cooling tanks accommodate milk from various livestock:

- Cow milk – Standard dairy operations

- Goat milk – Smaller-scale specialty operations

- Sheep milk – Artisan cheese producers

Ensure tank specifications align with your specific milk volume, fat content, and processing requirements.

Strategic Sourcing Conclusion and Outlook for milk cooling tank

Strategic Sourcing Conclusion: Milk Cooling Tank Investment

Selecting the right milk cooling tank directly impacts operational efficiency, regulatory compliance, and long-term profitability. Key sourcing priorities should include:

Critical Selection Factors

| Factor | Business Impact |

|---|---|

| Capacity alignment | Prevents under/over-investment |

| Cooling efficiency | Reduces bacterial growth, preserves milk quality |

| Energy consumption | Controls ongoing operational costs |

| Compliance certifications | Ensures market access (ISO5708, EN13732, 3A) |

| Insulation quality | Maximizes energy savings |

Market Outlook

The milk cooling tank sector continues evolving toward:

- Enhanced energy efficiency through advanced polyethylene insulation and optimized refrigeration systems

- Scalable solutions spanning 50-liter small-scale operations to industrial capacities

- Stricter quality standards requiring food-grade stainless steel construction meeting both European and US specifications

- Precision agitation systems (30 RPM paddle designs) ensuring homogenization without foaming

Final Recommendations

- Verify certifications before purchase to guarantee compliance across target markets

- Calculate total cost of ownership, including energy consumption and spare parts availability

- Partner with suppliers offering installation support and accessible replacement components

- Match tank capacity to current production with consideration for growth projections

Investing in quality milk cooling infrastructure protects product integrity and positions operations for sustained competitive advantage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.