Introduction: Navigating the Global Market for Milk Cooling Equipment

Milk begins deteriorating the moment it leaves the animal. Within two hours of milking, bacterial counts can double if temperatures aren’t controlled—transforming a valuable commodity into an unsellable liability. For dairy operations across the USA and Europe, selecting the right cooling equipment isn’t just an operational decision; it’s a critical investment that directly impacts product quality, regulatory compliance, and profitability.

The global milk cooling equipment market presents buyers with an overwhelming array of options: bulk tanks ranging from 50 liters to industrial-scale systems, plate coolers, instant cooling technologies, and hybrid solutions. Each comes with different specifications, compliance certifications (ISO 5708, EN 13732, 3-A Sanitary Standards), and total cost of ownership considerations that vary significantly across regions.

The challenge is clear: How do you identify equipment that meets your specific operational scale, complies with both US and European standards, and delivers optimal energy efficiency without overinvesting?

What This Guide Covers

This comprehensive B2B guide will help you:

- Understand cooling technologies—from vertical tanks to plate coolers and their applications

- Navigate compliance requirements across US and EU markets

- Evaluate total cost of ownership, including energy consumption and maintenance

- Match equipment capacity to your operation size (small-scale goat/sheep operations through large dairy facilities)

- Identify reputable manufacturers and their specialty applications

- Make informed procurement decisions based on ROI, not just upfront cost

Let’s examine what separates adequate cooling from optimal performance.

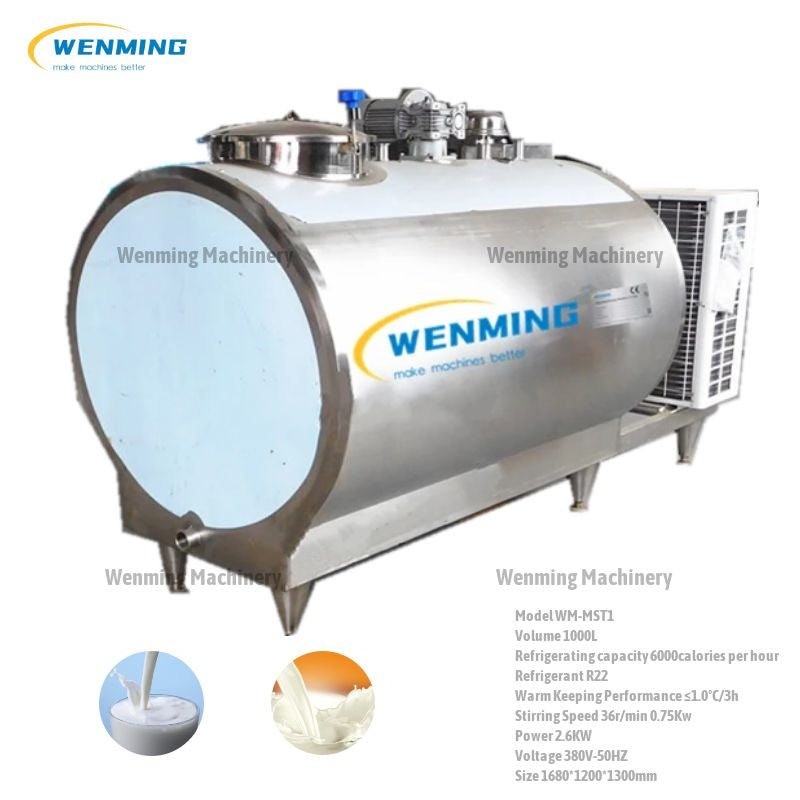

Illustrative Image (Source: Google Search)

Article Navigation

- Top 10 Milk Cooling Equipment Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for milk cooling equipment

- Understanding milk cooling equipment Types and Variations

- Key Industrial Applications of milk cooling equipment

- 3 Common User Pain Points for ‘milk cooling equipment’ & Their Solutions

- Strategic Material Selection Guide for milk cooling equipment

- In-depth Look: Manufacturing Processes and Quality Assurance for milk cooling equipment

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘milk cooling equipment’

- Comprehensive Cost and Pricing Analysis for milk cooling equipment Sourcing

- Alternatives Analysis: Comparing milk cooling equipment With Other Solutions

- Essential Technical Properties and Trade Terminology for milk cooling equipment

- Navigating Market Dynamics and Sourcing Trends in the milk cooling equipment Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of milk cooling equipment

- Strategic Sourcing Conclusion and Outlook for milk cooling equipment

- Important Disclaimer & Terms of Use

Top 10 Milk Cooling Equipment Manufacturers & Suppliers List

1. Dairy Farm | Paul Mueller Company

Domain: paulmueller.com

Registered: 1995 (30 years)

Introduction: Trusted by dairy farmers since 1940, our advanced milk cooling equipment and precision controls deliver reliable performance, efficiency, and quality….

2. Dairy Process Chiller Cooling Systems | Drake Chillers

Domain: drakechillers.com

Registered: 2001 (24 years)

Introduction: Our dairy chillers are equipped for on-demand chilling, jacketed milk tank cooling and energy conservation making them the best in the industry….

3. SERAP GROUP / MILK COOLER MANUFACTURER/ WINE TANK

Domain: groupeserap.com

Registered: 2003 (22 years)

Introduction: Experts in milk cooling solutions Closed milk coolers from 550 to 30,000 Liters capacities. SERAP has a long experience of 60 years in the farm milk cooling, ……

4. Dairy Equipment & Installation – Stratford – Buchanan & Hall

Domain: buchanan-hall.com

Registered: 2005 (20 years)

Introduction: 1-877-893-4628. Buchanan & Hall specializes in Mueller Dairy equipment & installation. Specializing in milk cooling and storage systems, A partner to Buchanan ……

Illustrative Image (Source: Google Search)

5. Inox Steel Technical’s Milk Cooler – 30 Gallon – Homestead Supplier

Domain: homesteadsupplier.com

Registered: 2017 (8 years)

Introduction: Free delivery 30-day returnsInox Steel Technical’s Milk Cooler – 30 Gallon is designed to maintain the best milk quality while saving energy. Designed with precision and backed by industry ……

6. Dairy Equipment Manufacturers | Neologic Engineers

7. DAIRY AND COOLING EQUIPMENT – Central AG Supply Services

Domain: centralagsupply.com

Registered: 2000 (25 years)

Introduction: Milk Cooling & Refrigeration, TANK_SMALL, GEA Koolway, GEA Expert Tank Control, GEA iCool Tank Control, Mueller Milk Cooling Tanks, HiPerForm III Tank Control….

Understanding milk cooling equipment Types and Variations

Understanding Milk Cooling Equipment Types and Variations

Selecting the right milk cooling equipment directly impacts milk quality, operational efficiency, and regulatory compliance. This section examines the primary equipment categories available to dairy operations across the USA and Europe, helping you identify the optimal solution for your specific requirements.

Equipment Types at a Glance

| Type | Key Features | Best Applications | Pros | Cons |

|---|---|---|---|---|

| Bulk Tank Coolers | Direct expansion refrigeration, integrated agitation, stainless steel construction | Small to large dairy farms, standard operations | Complete standalone solution, reliable cooling, meets ISO5708/EN13732/3A standards | Higher upfront cost, requires adequate electrical capacity |

| Vertical (Verti) Tanks | Compact vertical design, 50L–2,500L capacity, polyethylene insulation | Small-scale farms, goat/sheep dairies, limited floor space | Space-efficient, energy-saving insulation, ideal for specialty milk | Limited capacity range, not suited for large operations |

| Plate Coolers (Pre-Coolers) | Heat exchange plates, uses well/chilled water, inline installation | High-volume operations, pre-cooling before bulk tank | Reduces refrigeration load by 50%+, extends compressor life, recovers heat | Requires adequate water supply, additional equipment |

| Instant Cooling Systems | Rapid temperature reduction, continuous flow design | Large commercial dairies, processing facilities | Fastest cooling times, superior bacteria control | Highest capital investment, complex installation |

| Ice Bank Coolers | Ice storage reservoir, off-peak energy use, gradual heat absorption | Operations with variable milking schedules, high electricity costs | Lower peak energy demand, consistent cooling capacity | Larger footprint, ice build-up time required |

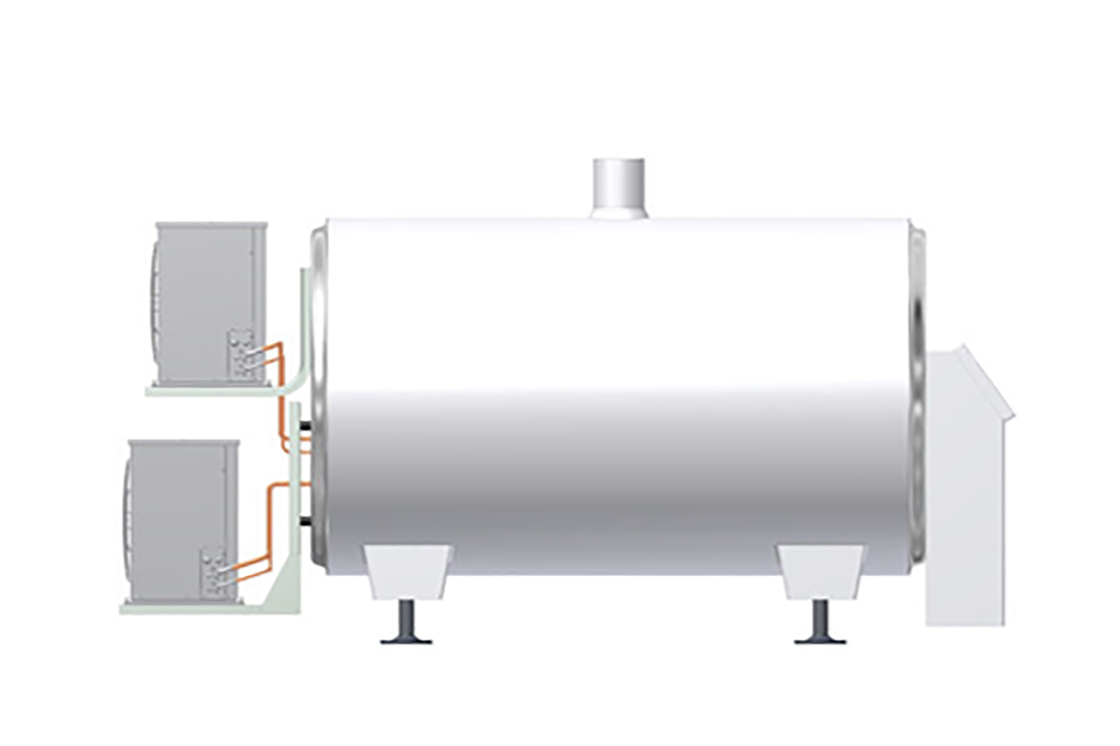

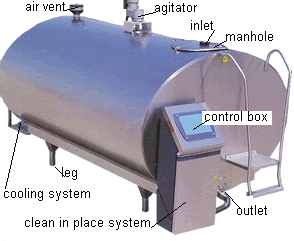

Bulk Tank Coolers

Bulk tank coolers remain the industry standard for on-farm milk storage and cooling. These units combine refrigeration, agitation, and insulated storage in a single vessel.

Technical specifications:

– Direct expansion refrigeration systems

– Food-grade stainless steel construction (304 or 316 grade)

– Integrated paddle agitators operating at approximately 30 RPM

– Compliance with ISO5708, EN13732, and 3A sanitary standards

Illustrative Image (Source: Google Search)

Operational considerations:

– Cooling capacity rated for 2-milking or 4-milking storage

– Must reduce milk temperature to 4°C (39°F) within regulatory timeframes

– Agitation prevents cream separation and ensures uniform cooling without foaming

Vertical (Verti) Tanks

Vertical tanks address the specific needs of small-scale and specialty dairy operations. Manufacturers like MilkPlan offer capacities from 14 gallons (50 liters) to 660 gallons (2,500 liters).

Ideal applications:

– Goat and sheep dairies

– Small cow operations

– Facilities with limited floor space

Design advantages:

– State-of-the-art polyethylene insulation maximizes energy efficiency

– Vertical orientation reduces footprint

– Gear reduction motors with paddle shafts ensure proper homogenization

– Same regulatory compliance as larger horizontal tanks

Illustrative Image (Source: Google Search)

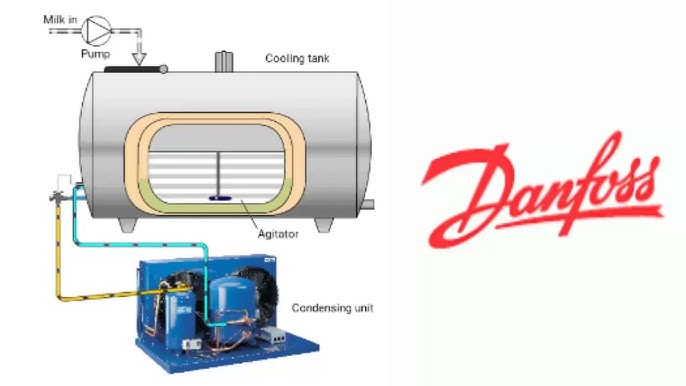

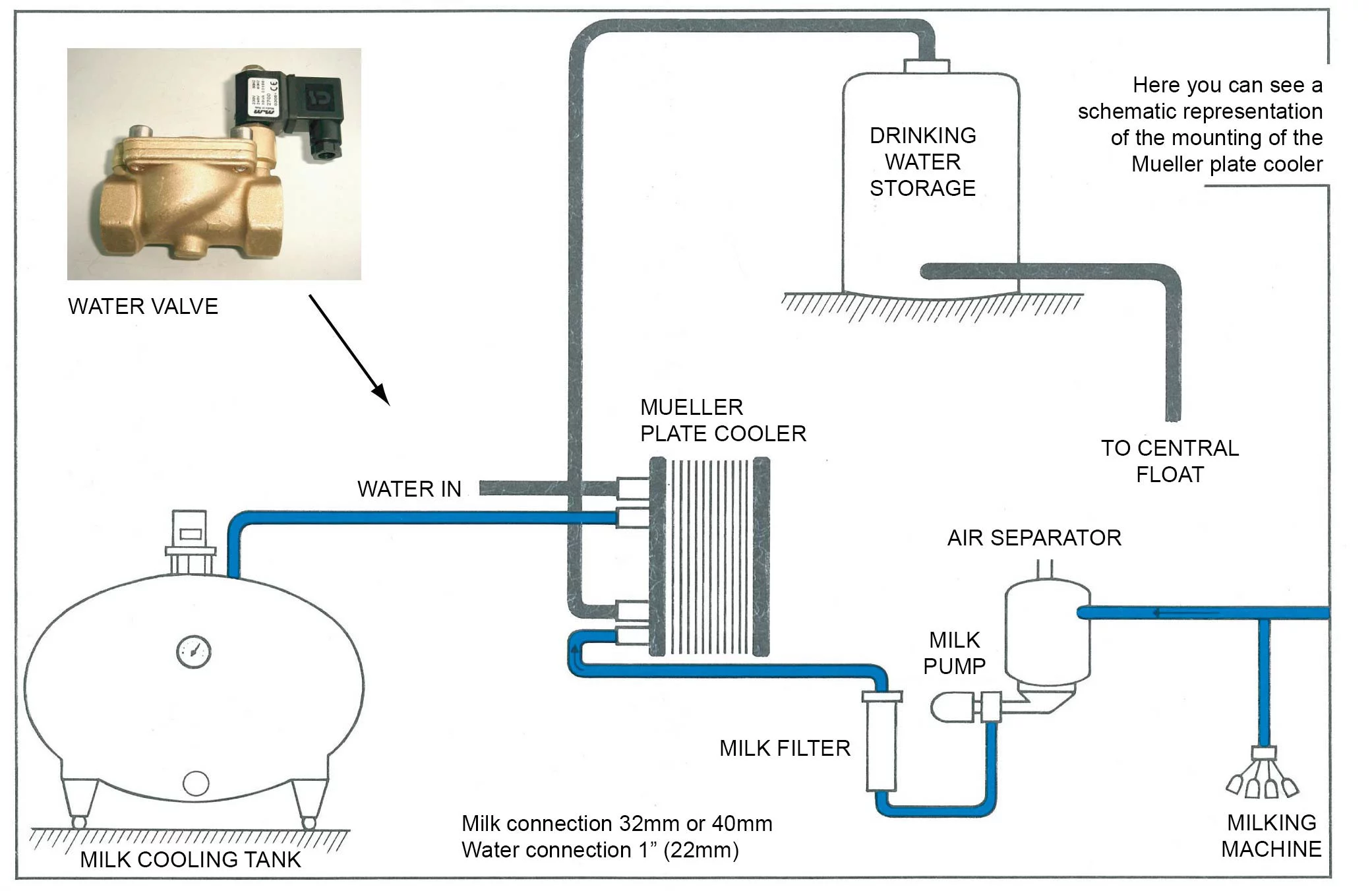

Plate Coolers (Pre-Coolers)

Plate coolers function as heat exchangers installed between the milking system and bulk tank. Cold water passes through alternating plates, absorbing heat from milk before it enters storage.

Performance metrics:

– Reduces milk temperature by 10–20°C before reaching bulk tank

– Decreases compressor runtime by 40–60%

– Water-to-milk ratio typically 2:1 or 3:1

Secondary benefits:

– Heated water output suitable for calf feeding, cleaning, or other farm uses (FreeHeaters)

– Extended refrigeration equipment lifespan

– Lower electricity costs during peak demand periods

Instant Cooling Systems

Instant cooling systems deliver the fastest temperature reduction, bringing milk from body temperature (38°C/100°F) to storage temperature (4°C/39°F) within seconds of leaving the animal.

Illustrative Image (Source: Google Search)

Where they excel:

– Large-scale commercial dairies

– Operations prioritizing maximum shelf life

– Facilities supplying premium or export markets

Technical requirements:

– Significant refrigeration capacity

– Continuous milk flow management

– Higher installation complexity and maintenance demands

Ice Bank Coolers

Ice bank systems build and store ice during off-peak electricity hours, then use this reserve to cool milk during milking periods.

Economic advantages:

– Shifts energy consumption to lower-rate periods

– Provides consistent cooling capacity regardless of ambient temperature

– Reduces peak electrical demand charges

Illustrative Image (Source: Google Search)

Operational trade-offs:

– Requires space for ice storage vessel

– Ice must be rebuilt between milking sessions

– Higher water usage than direct expansion systems

Selection Criteria

When evaluating milk cooling equipment, consider:

- Herd size and milk volume — Match tank capacity to milking frequency and collection schedules

- Species — Goat and sheep operations often benefit from smaller vertical tanks

- Energy costs — Plate coolers and ice banks offer savings in high-rate areas

- Space constraints — Vertical designs maximize limited floor space

- Regulatory requirements — Ensure equipment meets both US (3A) and European (EN13732) standards if operating across markets

Key Industrial Applications of milk cooling equipment

Key Industrial Applications of Milk Cooling Equipment

Milk cooling equipment serves critical functions across multiple agricultural and food processing sectors. The following table outlines primary industries, specific applications, and the operational benefits each sector gains from proper milk cooling infrastructure.

| Industry | Primary Applications | Key Benefits |

|---|---|---|

| Small-Scale Dairy Farms | On-farm milk storage for goat, sheep, and small cow operations (14–660 gallon capacity) | Rapid cooling prevents bacterial growth; maintains milk pH stability; polyethylene insulation maximizes energy efficiency |

| Commercial Dairy Operations | Bulk milk storage, pipeline integration, parlor systems | Continuous cooling during high-volume milking; seamless integration with automated milking systems |

| Artisan Cheese Production | Raw milk preservation prior to processing | Precise temperature control preserves milk proteins and fats essential for cheese quality; uniform fat homogenization |

| Goat & Sheep Dairy | Specialized cooling for smaller milk volumes with higher fat content | Equipment sized appropriately for lower daily yields; paddle agitation systems (30 RPM) ensure proper fat distribution without foaming |

| Organic & Specialty Dairy | Premium milk storage requiring strict quality standards | Food-grade stainless steel construction meets ISO 5708, EN 13732, and 3-A sanitary standards |

| Mobile Dairy Collection | Temporary storage at collection points serving multiple small producers | Compact vertical tank designs (Verti tank series) optimize floor space; reliable cooling maintains quality during transport delays |

Operational Advantages Across Applications

- Bacterial Control: Rapid temperature reduction inhibits pathogen proliferation, extending milk shelf life and meeting regulatory thresholds

- Quality Preservation: Controlled agitation homogenizes milk fat content without introducing air, preventing oxidation and foam formation

- Regulatory Compliance: Equipment meeting European (EN 13732) and US (3-A) standards simplifies certification for export and interstate commerce

- Energy Efficiency: Modern insulation technology reduces refrigeration cycling, lowering operational costs by 15–25% compared to older systems

3 Common User Pain Points for ‘milk cooling equipment’ & Their Solutions

3 Common User Pain Points for Milk Cooling Equipment & Their Solutions

Pain Point 1: Bacterial Growth and Milk Quality Degradation

Scenario: A mid-sized dairy operation in Wisconsin notices inconsistent milk quality test results. Despite following standard protocols, bacterial counts fluctuate, leading to rejected shipments and reduced payments from processors.

Illustrative Image (Source: Google Search)

Problem: Inadequate cooling speed allows bacteria to multiply rapidly in freshly harvested milk. When milk isn’t cooled to the required 4°C (39°F) within the critical window, bacterial proliferation accelerates, increasing acidity and compromising milk grade.

Solution: Invest in cooling tanks with optimized agitation systems. Modern equipment like the MilkPlan Verti tank series features:

– Specialized paddle shafts with gear reduction motors set to 30 RPM

– Uniform cooling without foaming

– Perfect fat homogenization throughout the entire milk volume

This ensures cooling occurs at the optimal rate, preventing both bacterial development and pH increases.

Pain Point 2: Energy Costs Eating Into Margins

Scenario: A European goat dairy cooperative faces rising operational costs. Energy bills for milk cooling represent a significant percentage of monthly expenses, threatening profitability during peak production seasons.

Illustrative Image (Source: Google Search)

Problem: Older cooling systems lack adequate insulation and efficient compressor technology, resulting in continuous energy draw and extended cooling cycles.

Solution: Upgrade to tanks with state-of-the-art polyethylene insulation that maximizes energy savings while maintaining rapid cooling performance. Modern systems deliver:

| Feature | Benefit |

|---|---|

| Advanced insulation | Reduced heat transfer, lower energy consumption |

| Efficient cooling cycles | Faster temperature reduction with less compressor runtime |

| Optimized motor systems | Lower electrical draw during agitation |

Pain Point 3: Equipment Sizing Mismatches for Small-Scale Operations

Scenario: A specialty sheep dairy in Vermont struggles to find cooling equipment appropriately sized for their 40-head operation. Available commercial options are either too large (wasting energy) or lack compliance certifications required by their buyers.

Problem: Most industrial cooling tanks target large-scale operations, leaving small and mid-sized farms with limited options that don’t match their production volumes or regulatory requirements.

Illustrative Image (Source: Google Search)

Solution: Source equipment specifically designed for small-scale operations with full certification compliance. Look for:

– Capacity ranges from 14 gallons (50 liters) to 660 gallons (2,500 liters)

– Food-grade stainless steel construction

– Compliance with ISO 5708, EN 13732, and 3-A sanitary standards (meeting both European and US requirements)

This ensures regulatory compliance without over-investing in oversized equipment.

Strategic Material Selection Guide for milk cooling equipment

Strategic Material Selection Guide for Milk Cooling Equipment

Selecting the appropriate materials for milk cooling equipment directly impacts operational efficiency, regulatory compliance, product longevity, and total cost of ownership. This guide provides procurement teams and dairy operations managers with a systematic framework for evaluating material specifications.

Primary Construction Materials

Stainless Steel Grades

304 Stainless Steel (18/8)

The industry standard for milk contact surfaces, 304 stainless steel contains 18% chromium and 8% nickel. This composition delivers:

– Excellent corrosion resistance against milk acids and cleaning chemicals

– Non-reactive surface that preserves milk quality and taste

– Smooth finish capability (typically 0.8 μm Ra or better) preventing bacterial adhesion

– Compliance with FDA, 3-A Sanitary Standards, and EU food contact regulations

Illustrative Image (Source: Google Search)

316 Stainless Steel (18/10)

Premium applications specify 316 grade, which adds 2-3% molybdenum for enhanced performance:

– Superior resistance to chloride-based sanitizers and acidic CIP solutions

– Extended service life in high-humidity dairy environments

– Recommended for coastal installations or facilities using aggressive cleaning protocols

– Higher initial cost offset by reduced maintenance and replacement cycles

Duplex Stainless Steel

Emerging in large-scale installations, duplex grades combine austenitic and ferritic structures:

– Approximately twice the yield strength of 304/316 grades

– Enables thinner wall construction without compromising structural integrity

– Improved stress corrosion cracking resistance

– Premium pricing limits adoption to specialized applications

Insulation Materials

Effective thermal insulation directly influences energy consumption and cooling performance. Modern milk cooling tanks, including models meeting ISO 5708, EN 13732, and 3-A standards, utilize advanced insulation systems.

Polyurethane Foam (PUF)

The dominant choice for commercial milk cooling equipment:

– Thermal conductivity: 0.022-0.028 W/m·K

– Closed-cell structure resists moisture absorption

– CFC-free formulations meet environmental regulations

– Typical thickness: 50-75mm for standard applications

Illustrative Image (Source: Google Search)

Polyethylene Insulation

State-of-the-art polyethylene insulation, as specified in premium tank designs, offers:

– Enhanced energy savings compared to traditional materials

– Consistent thermal performance over extended service life

– Lightweight construction reducing structural load requirements

– Excellent moisture barrier properties

Vacuum Panel Insulation (VPI)

High-efficiency option for space-constrained installations:

– Thermal conductivity: 0.004-0.008 W/m·K

– Reduces insulation thickness by up to 80%

– Higher cost per square meter

– Requires careful handling during installation

Agitation System Components

Proper milk homogenization depends on agitator material selection. Food-grade stainless steel paddles and shafts operating at approximately 30 RPM ensure:

– Uniform fat distribution throughout the milk volume

– Consistent cooling across the entire tank capacity

– Minimal foaming that could compromise milk quality

– Easy cleaning and sanitization between cycles

Gear reduction motors should feature:

– Food-grade lubricants in sealed housings

– IP65 or higher ingress protection ratings

– Stainless steel or food-safe polymer shaft seals

Illustrative Image (Source: Google Search)

Gasket and Seal Materials

EPDM (Ethylene Propylene Diene Monomer)

– Temperature range: -40°C to +120°C

– Excellent resistance to dairy cleaning chemicals

– FDA and 3-A compliant formulations available

– Cost-effective for most applications

Silicone

– Superior temperature tolerance: -60°C to +200°C

– Ideal for high-temperature CIP cycles

– Lower chemical resistance than EPDM

– Higher cost justified in demanding thermal environments

PTFE (Polytetrafluoroethylene)

– Universal chemical resistance

– Temperature range: -200°C to +260°C

– Premium pricing for specialized applications

– Often used in valve seats and high-wear locations

Regulatory Compliance Framework

Material selection must satisfy multiple regulatory requirements across USA and European markets:

Illustrative Image (Source: Google Search)

United States

– 3-A Sanitary Standards (specific to dairy equipment)

– FDA 21 CFR 177 (food contact materials)

– USDA Dairy Grading requirements

European Union

– EN 13732 (bulk milk coolers)

– ISO 5708 (refrigerated bulk milk tanks)

– EC 1935/2004 (food contact materials)

– EC 2023/2006 (good manufacturing practice)

Equipment manufactured to meet combined ISO 5708, EN 13732, and 3-A standards, as specified by manufacturers like MilkPlan, ensures global market acceptance and simplified procurement for multinational operations.

Surface Finish Specifications

| Application | Finish Type | Ra Value (μm) | Typical Use |

|---|---|---|---|

| Milk contact surfaces | Electropolished | ≤0.5 | Premium installations |

| Milk contact surfaces | Mechanically polished | ≤0.8 | Standard dairy equipment |

| Non-contact interior | Mill finish | 1.0-2.0 | Structural components |

| Exterior surfaces | #4 brushed | 0.8-1.5 | Aesthetic/cleanability |

Capacity-Specific Material Considerations

Tank capacity influences optimal material specifications:

Illustrative Image (Source: Google Search)

Small-Scale Operations (50-2,500 liters / 14-660 gallons)

Designed for operations milking goats, sheep, or small cow herds:

– 304 stainless steel typically sufficient for milk contact

– Standard polyethylene or PUF insulation

– Single-piece construction reduces weld points and contamination risk

– Lighter gauge materials acceptable due to reduced structural demands

Medium-Scale Operations (2,500-10,000 liters)

– 304 or 316 stainless steel depending on cleaning protocols

– Enhanced insulation thickness for improved efficiency

– Reinforced structural elements at stress points

Large-Scale Operations (>10,000 liters)

– 316 stainless steel recommended for extended service life

– Duplex grades for structural components

– Premium insulation systems for energy optimization

– Multi-zone cooling may require varied material specifications

Material Selection Decision Matrix

| Factor | 304 SS | 316 SS | Duplex SS | Impact on Selection |

|---|---|---|---|---|

| Initial Cost | Low | Medium | High | Budget constraints |

| Corrosion Resistance | Good | Excellent | Superior | Cleaning chemical aggressiveness |

| Mechanical Strength | Standard | Standard | High | Tank size/pressure requirements |

| Weldability | Excellent | Excellent | Moderate | Field repair considerations |

| Availability | High | High | Limited | Lead time requirements |

| 3-A Compliance | Yes | Yes | Case-by-case | Regulatory requirements |

Insulation Material Comparison

| Property | PUF | Polyethylene | VPI |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 0.022-0.028 | 0.033-0.040 | 0.004-0.008 |

| Moisture Resistance | Good | Excellent | Excellent |

| Compression Strength | Moderate | Good | Low |

| Cost per m² | Low | Medium | High |

| Typical Thickness Required | 50-75mm | 60-80mm | 10-20mm |

| Service Life | 15-20 years | 20-25 years | 25+ years |

| Environmental Impact | Moderate | Low | Low |

Gasket and Seal Material Comparison

| Material | Temperature Range | Chemical Resistance | FDA/3-A Compliant | Relative Cost |

|---|---|---|---|---|

| EPDM | -40°C to +120°C | Good | Yes | Low |

| Silicone | -60°C to +200°C | Moderate | Yes | Medium |

| PTFE | -200°C to +260°C | Excellent | Yes | High |

| Viton | -20°C to +200°C | Excellent | Yes | High |

| Nitrile | -30°C to +100°C | Moderate | Limited | Low |

Total Cost of Ownership Considerations

Material selection extends beyond purchase price. Evaluate:

Illustrative Image (Source: Google Search)

- Maintenance frequency – Premium materials reduce cleaning cycle intensity and replacement intervals

- Energy consumption – Superior insulation reduces refrigeration costs by 15-30% over equipment lifetime

- Regulatory risk – Non-compliant materials create liability and market access issues

- Residual value – Quality stainless steel construction maintains resale value

- Spare parts availability – Standard materials ensure long-term serviceability

Procurement Recommendations

For Small-Scale Operations:

– Specify food-grade 304 stainless steel meeting ISO 5708/EN 13732/3-A standards

– Request polyethylene insulation for optimal energy performance

– Verify complete material certifications before purchase

– Confirm spare parts availability from supplier

For Medium to Large Operations:

– Conduct site-specific corrosion assessment before specifying 304 vs. 316 grade

– Calculate insulation ROI based on local energy costs and climate conditions

– Require mill test certificates for all stainless steel components

– Specify gasket materials compatible with planned CIP protocols

For All Operations:

– Request written confirmation of regulatory compliance for target markets

– Obtain material safety data sheets for all components

– Document material specifications for future maintenance and replacement

– Consider standardization across equipment fleet for spare parts efficiency

In-depth Look: Manufacturing Processes and Quality Assurance for milk cooling equipment

In-depth Look: Manufacturing Processes and Quality Assurance for Milk Cooling Equipment

Understanding how milk cooling equipment is manufactured provides valuable insight into product reliability, longevity, and compliance. This section examines the critical manufacturing stages and quality standards that distinguish professional-grade equipment from inferior alternatives.

Illustrative Image (Source: Google Search)

Manufacturing Process Overview

The production of milk cooling tanks follows a precise sequence of operations, each critical to final product performance.

Stage 1: Material Preparation

| Process Step | Description | Quality Considerations |

|---|---|---|

| Material Selection | Food-grade stainless steel procurement | Must meet 304 or 316 grade specifications |

| Sheet Cutting | Precision cutting to specifications | Dimensional accuracy within ±0.5mm tolerance |

| Surface Inspection | Visual and instrumental examination | Detection of surface defects, inclusions |

| Material Traceability | Batch documentation and certification | Full chain-of-custody records |

Raw materials undergo incoming inspection protocols verifying chemical composition, surface finish, and mechanical properties before entering production.

Stage 2: Forming and Fabrication

Primary Forming Operations:

– Rolling and Bending — Stainless steel sheets formed into cylindrical or conical shapes using hydraulic press brakes and plate rolling machines

– Deep Drawing — Tank bottoms and specialized components shaped through progressive die operations

– Welding — TIG (Tungsten Inert Gas) welding preferred for food-contact surfaces; ensures smooth, crevice-free joints

– Polishing — Interior surfaces polished to Ra ≤0.8 μm for sanitary compliance

Insulation Application:

Modern tanks utilize state-of-the-art polyethylene insulation applied between inner and outer shells. This layer is critical for:

– Thermal efficiency during cooling cycles

– Energy consumption reduction

– Condensation prevention on exterior surfaces

Illustrative Image (Source: Google Search)

Stage 3: Component Assembly

Assembly integrates multiple subsystems into a functional unit:

Mechanical Components:

– Agitation systems (shaft, paddles, gear reduction motor)

– Mounting brackets and support structures

– Inlet/outlet fittings and valves

Refrigeration Integration:

– Evaporator coil installation

– Compressor mounting

– Refrigerant charging and leak testing

Electrical Systems:

– Control panel installation

– Temperature sensors and probes

– Motor connections and safety interlocks

Illustrative Image (Source: Google Search)

The agitation system requires precise calibration—typically set to 30 RPM—to ensure proper homogenization of milk fats and uniform cooling without introducing foam or damaging milk proteins.

Stage 4: Quality Control and Testing

Pre-Shipment Testing Protocol:

| Test Category | Specific Tests | Acceptance Criteria |

|---|---|---|

| Structural Integrity | Pressure testing, weld inspection | No leaks at 1.5x operating pressure |

| Cooling Performance | Temperature pull-down test | Must meet ISO 5708 cooling curves |

| Agitation Verification | RPM measurement, coverage analysis | Uniform temperature distribution ±0.5°C |

| Electrical Safety | Continuity, insulation resistance | Compliance with regional electrical codes |

| Surface Quality | Visual inspection, Ra measurement | Food-contact surfaces ≤0.8 μm |

Quality Standards and Certifications

Professional milk cooling equipment must comply with multiple international standards to ensure food safety and operational reliability.

Primary Standards

ISO 5708 (Milk Cooling Equipment)

– Defines performance classifications (Classes I through IV)

– Specifies cooling time requirements based on milk volume

– Establishes energy efficiency benchmarks

Illustrative Image (Source: Google Search)

EN 13732 (European Standard)

– Covers bulk milk coolers for use on farms

– Addresses thermal performance, construction, and hygiene requirements

– Mandatory for equipment sold in EU markets

3-A Sanitary Standards

– U.S.-based standards for dairy equipment

– Focus on cleanability, material specifications, and surface finishes

– Required for equipment used in Grade A dairy operations

Compliance Verification

| Certification Body | Geographic Focus | Key Requirements |

|---|---|---|

| 3-A SSI | United States | Sanitary design, material compliance |

| CE Marking | European Union | Safety, health, environmental protection |

| NSF International | Global | Public health and safety certification |

Manufacturing Quality Indicators

When evaluating milk cooling equipment suppliers, assess these manufacturing quality indicators:

Documentation Requirements:

– Material certificates (mill test reports)

– Weld procedure specifications and welder qualifications

– Calibration records for testing equipment

– Final inspection reports

Facility Considerations:

– ISO 9001 quality management system certification

– Dedicated cleanroom or controlled environment for food-contact fabrication

– Traceability systems linking finished products to raw material batches

Post-Sale Support:

– Availability of genuine replacement parts

– Technical documentation and maintenance guides

– Warranty terms reflecting manufacturing confidence

Key Takeaways for Procurement

- Verify standards compliance — Request documentation confirming ISO 5708, EN 13732, and/or 3-A certification

- Inspect weld quality — Smooth, fully penetrated welds without crevices indicate proper fabrication

- Confirm material grades — Food-grade stainless steel (304 or 316) with supporting documentation

- Evaluate insulation specifications — Quality polyethylene insulation directly impacts operational costs

- Review testing protocols — Manufacturers should provide cooling performance test data for specific models

Practical Sourcing Guide: A Step-by-Step Checklist for ‘milk cooling equipment’

Practical Sourcing Guide: A Step-by-Step Checklist for Milk Cooling Equipment

Use this comprehensive checklist to systematically evaluate, select, and procure milk cooling equipment that meets your operational requirements and regulatory standards.

Phase 1: Requirements Assessment

Capacity Planning

- [ ] Calculate current daily milk production volume (gallons/liters)

- [ ] Project growth requirements for 3-5 years

- [ ] Determine peak production periods and seasonal variations

- [ ] Assess milk type: cow, goat, sheep, or mixed operation

Operational Specifications

- [ ] Define cooling time requirements (target: 4°C/39°F within 2-3 hours)

- [ ] Identify space constraints and installation location

- [ ] Evaluate existing electrical infrastructure (voltage, phase requirements)

- [ ] Assess water supply availability for plate coolers

| Tank Size Range | Typical Application |

|---|---|

| 14-100 gallons (50-400L) | Small-scale goat/sheep operations |

| 100-300 gallons (400-1,200L) | Medium dairy farms |

| 300-660 gallons (1,200-2,500L) | Larger operations, cow dairies |

| 660+ gallons (2,500L+) | Commercial-scale operations |

Phase 2: Supplier Qualification

Vendor Research

- [ ] Identify minimum 3-5 qualified suppliers

- [ ] Verify manufacturer credentials and industry reputation

- [ ] Request references from similar-scale operations

- [ ] Confirm geographic coverage for service and support

Compliance Verification

- [ ] Confirm equipment meets ISO 5708 standards

- [ ] Verify EN 13732 compliance (European market)

- [ ] Check 3-A Sanitary Standards certification (USA)

- [ ] Request documentation for food-grade stainless steel materials

- [ ] Obtain certificates of conformity

Supplier Capability Assessment

| Criteria | Questions to Ask |

|---|---|

| Manufacturing | Where are units manufactured? What quality controls exist? |

| Lead Times | Standard delivery timeframes? Expedited options? |

| Customization | Can specifications be modified? What’s the process? |

| Inventory | Stock availability? Regional distribution centers? |

Phase 3: Technical Evaluation

Equipment Specifications

- [ ] Review insulation type and efficiency ratings (polyethylene preferred)

- [ ] Confirm agitator specifications (optimal: ~30 RPM for homogenization without foaming)

- [ ] Evaluate refrigeration system efficiency (energy consumption data)

- [ ] Check control panel features and automation capabilities

- [ ] Assess cleaning system compatibility (CIP-ready)

Performance Standards

- [ ] Request cooling performance curves

- [ ] Verify temperature uniformity across tank volume

- [ ] Confirm bacteria count control effectiveness

- [ ] Review energy efficiency ratings and operational costs

Construction Quality

- [ ] Confirm food-grade 304/316 stainless steel construction

- [ ] Inspect weld quality standards

- [ ] Review surface finish specifications (sanitary requirements)

- [ ] Evaluate leg/support structure durability

Phase 4: Commercial Evaluation

Pricing Analysis

- [ ] Obtain itemized quotes from qualified suppliers

- [ ] Request volume discount schedules

- [ ] Clarify freight/shipping costs (call suppliers directly for accurate quotes)

- [ ] Identify any installation costs not included in base price

- [ ] Calculate total cost of ownership (purchase + installation + operating costs)

Payment and Terms

- [ ] Review payment terms and schedules

- [ ] Negotiate milestone-based payments for large orders

- [ ] Confirm currency and exchange rate handling (international purchases)

- [ ] Evaluate financing options if available

Warranty and Support

| Coverage Area | Minimum Acceptable Terms |

|---|---|

| Compressor | 2-5 years |

| Tank/Vessel | 5-10 years |

| Electrical Components | 1-2 years |

| Labor Coverage | 1 year minimum |

- [ ] Obtain warranty terms in writing

- [ ] Clarify warranty claim procedures

- [ ] Confirm spare parts availability and pricing

- [ ] Identify authorized service providers in your region

Phase 5: Pre-Purchase Verification

Site Preparation

- [ ] Confirm floor load capacity for filled tank weight

- [ ] Verify doorway/access dimensions for equipment delivery

- [ ] Plan electrical service upgrades if required

- [ ] Arrange plumbing connections for water supply/drainage

Documentation Requirements

- [ ] Request operation and maintenance manuals

- [ ] Obtain installation specifications

- [ ] Secure spare parts lists with part numbers

- [ ] Get wiring diagrams and technical drawings

Final Supplier Confirmation

- [ ] Verify stock availability before ordering

- [ ] Confirm exact delivery timeline

- [ ] Establish point of contact for order tracking

- [ ] Review cancellation and return policies

Phase 6: Order Execution

Purchase Order Checklist

- [ ] Include complete equipment specifications

- [ ] Specify delivery address and requirements

- [ ] Document agreed pricing and payment terms

- [ ] Include warranty terms and conditions

- [ ] Attach compliance certification requirements

- [ ] Note installation support expectations

Delivery Coordination

- [ ] Schedule delivery during appropriate weather conditions

- [ ] Arrange unloading equipment (forklift, crane if needed)

- [ ] Plan for inspection upon arrival

- [ ] Document any shipping damage immediately

Phase 7: Post-Purchase Actions

Installation Verification

- [ ] Confirm professional installation by qualified technicians

- [ ] Witness startup and commissioning

- [ ] Verify all safety systems function correctly

- [ ] Test cooling performance against specifications

Documentation and Training

- [ ] File all warranty registration documents

- [ ] Archive maintenance schedules and procedures

- [ ] Complete operator training

- [ ] Establish spare parts inventory for common wear items

Ongoing Relationship

- [ ] Schedule preventive maintenance agreements

- [ ] Register for manufacturer updates and recalls

- [ ] Maintain supplier contact information for support

- [ ] Document equipment performance for future reference

Quick Reference: Key Compliance Standards

| Standard | Region | Scope |

|---|---|---|

| ISO 5708 | International | Milk cooling equipment performance |

| EN 13732 | European Union | Bulk milk coolers |

| 3-A Sanitary Standards | USA | Sanitary design and fabrication |

| FDA 21 CFR | USA | Food contact materials |

| PMO (Pasteurized Milk Ordinance) | USA | Grade A dairy requirements |

Red Flags to Avoid

- Suppliers unwilling to provide compliance documentation

- Significantly below-market pricing without clear justification

- No local service/support network

- Vague or verbal-only warranty terms

- Inability to provide customer references

- Extended lead times without explanation

Comprehensive Cost and Pricing Analysis for milk cooling equipment Sourcing

Comprehensive Cost and Pricing Analysis for Milk Cooling Equipment Sourcing

Understanding the total cost of ownership for milk cooling equipment requires analyzing multiple cost components beyond the initial purchase price. This section provides B2B buyers in the USA and Europe with actionable pricing intelligence and cost optimization strategies.

Cost Breakdown by Component

Materials Costs

| Component | Cost Driver | Typical % of Total Equipment Cost |

|---|---|---|

| Food-grade stainless steel tank body | Steel grade, thickness, tank capacity | 35-45% |

| Polyethylene insulation | Density, thickness, thermal efficiency rating | 8-12% |

| Refrigeration compressor unit | Cooling capacity, energy efficiency rating | 20-28% |

| Agitation system (shaft, paddles, gear motor) | Motor quality, RPM specifications (typically 30 RPM) | 10-15% |

| Control systems & sensors | Automation level, monitoring capabilities | 5-10% |

Compliance Premium: Equipment meeting ISO 5708, EN 13732, and 3-A Sanitary Standards commands 10-20% higher pricing but ensures market access across USA and Europe.

Capacity-Based Pricing Tiers

| Capacity Range | Typical Price Range (USD) | Target Operation |

|---|---|---|

| 14-50 gallons (50-200L) | $3,500-$8,000 | Small-scale goat/sheep operations |

| 50-150 gallons (200-600L) | $8,000-$15,000 | Small dairy farms, mixed herds |

| 150-400 gallons (600-1,500L) | $15,000-$30,000 | Mid-size dairy operations |

| 400-660 gallons (1,500-2,500L) | $30,000-$55,000 | Commercial dairy farms |

Note: Prices vary by manufacturer, features, and market conditions. Contact suppliers directly for current quotes.

Labor Costs

| Labor Category | USA Estimate | Europe Estimate | Notes |

|---|---|---|---|

| Professional installation | $800-$2,500 | €700-€2,200 | Varies by system complexity |

| Electrical/plumbing connections | $500-$1,500 | €450-€1,300 | Local code compliance required |

| Initial calibration & training | $300-$800 | €250-€700 | Often included by supplier |

| Annual maintenance service | $400-$1,200/year | €350-€1,000/year | Preventive maintenance contracts |

Logistics Costs

| Factor | Impact on Cost |

|---|---|

| Shipping weight (stainless steel units) | $0.50-$2.00 per pound for freight |

| Oversized freight surcharges | 15-30% premium for tanks >200 gallons |

| International import duties | USA: 0-5%; EU: varies by origin country |

| Crating and handling | $200-$800 depending on size |

| Last-mile delivery (liftgate, inside delivery) | $150-$500 additional |

Critical: Always request shipping quotes before ordering. As noted by suppliers, freight costs for cooling tanks require individual quotation due to size and weight variables.

Total Cost of Ownership Considerations

| Cost Category | Year 1 | Years 2-5 (Annual) |

|---|---|---|

| Equipment purchase | 100% of capital cost | — |

| Installation & setup | 8-15% of equipment cost | — |

| Energy consumption | $600-$2,400 | $600-$2,400 |

| Maintenance & repairs | Warranty coverage | 2-4% of equipment cost |

| Replacement parts (inflations, gaskets, seals) | $100-$300 | $200-$500 |

| Cleaning supplies | $300-$600 | $300-$600 |

Cost-Saving Strategies

Procurement Optimization

- Request multi-unit quotes — Discounts of 5-15% available for purchasing multiple tanks or bundling with pipeline systems

- Negotiate spare parts packages — Include common replacement parts (gaskets, seals, agitator components) in initial purchase at reduced rates

- Compare regional suppliers — European manufacturers (e.g., MilkPlan) may offer competitive pricing for EU buyers; factor in import costs for cross-Atlantic purchases

- Evaluate refurbished equipment — Quality used tanks from reputable suppliers can reduce costs 30-50%

Specification Optimization

- Right-size capacity — Avoid over-specifying; calculate actual peak milk volume plus 20% buffer

- Prioritize energy efficiency — State-of-the-art insulation reduces long-term operating costs; ROI typically 2-4 years

- Standardize components — Select equipment compatible with existing vacuum systems, cleaning equipment, and spare parts inventory

Logistics Cost Reduction

- Consolidate shipments — Combine cooling tank orders with other equipment (bucket milkers, pipeline components, cleaning supplies)

- Plan seasonal purchasing — Off-peak ordering (late winter/early spring) may yield better availability and pricing

- Request FOB vs. delivered pricing — Compare costs; arranging own freight may reduce expenses for large operations

Long-Term Savings

| Strategy | Potential Savings |

|---|---|

| Preventive maintenance contracts | 20-40% reduction in emergency repair costs |

| Operator training programs | Extends equipment life 15-25% |

| Energy-efficient models | 15-30% lower annual operating costs |

| Bulk cleaning chemical purchases | 10-20% savings on consumables |

Key Procurement Recommendations

- Verify compliance certifications upfront to avoid market access issues

- Obtain itemized quotes separating equipment, freight, installation, and training

- Establish spare parts sourcing before purchase—confirm availability and lead times

- Document warranty terms including coverage for compressor, agitation motor, and control systems

- Factor in 10-15% contingency for installation variables and site-specific requirements

Alternatives Analysis: Comparing milk cooling equipment With Other Solutions

Alternatives Analysis: Comparing Milk Cooling Equipment With Other Solutions

When evaluating milk cooling strategies, dairy operations must weigh multiple factors including cooling efficiency, regulatory compliance, operational costs, and scalability. Below is a comprehensive comparison of primary milk cooling approaches available to small and mid-scale dairy farms.

Comparison Table: Milk Cooling Solutions

| Factor | Bulk Cooling Tanks | Plate/Heat Exchanger Coolers | Ice Bank Systems |

|---|---|---|---|

| Initial Investment | $3,000–$25,000+ (capacity dependent) | $1,500–$8,000 | $8,000–$30,000+ |

| Cooling Speed | 2–4 hours to reach 4°C/39°F | Immediate (inline cooling) | 1–2 hours |

| Energy Efficiency | Moderate–High (with modern insulation) | High (uses existing water supply) | Lower (requires ice generation) |

| Space Requirements | Moderate (vertical options available) | Minimal | Large (tank + ice builder) |

| Scalability | Available from 50L to 2,500L+ | Scales with milking system flow | Fixed capacity; costly to expand |

| Regulatory Compliance | ISO5708/EN13732/3A certified options | Requires paired storage tank | Meets standards when properly maintained |

| Maintenance Complexity | Low–Moderate | Low | High (compressor + ice system) |

| Best Suited For | Small-to-mid farms; goat/sheep/cow operations | High-volume operations with pre-cooling needs | Large operations with consistent volume |

Analysis

Bulk Cooling Tanks

Modern bulk cooling tanks, such as the MilkPlan Verti series, represent the most versatile solution for small-scale dairy operations milking goats, sheep, or limited cow herds. Key advantages include:

- Integrated agitation systems (30 RPM paddle mixing) ensure fat homogenization and uniform cooling without foaming

- Food-grade stainless steel construction meeting both European (EN13732) and US (3A) sanitary standards

- Polyethylene insulation maximizes energy efficiency during storage

- Capacity flexibility from 14 gallons (50L) to 660 gallons (2,500L) accommodates growth

The primary limitation is cooling time—bulk tanks require 2–4 hours to bring milk to safe storage temperatures, which may necessitate operational scheduling adjustments.

Plate/Heat Exchanger Coolers

Plate coolers provide immediate inline cooling using chilled water or glycol, reducing milk temperature before it enters storage. This approach:

- Decreases bulk tank workload and energy consumption by 40–60%

- Requires a separate compliant storage vessel

- Performs optimally in operations with consistent water supply and temperature

- Adds system complexity and additional points of potential failure

Plate coolers are typically cost-effective as a supplementary solution rather than a standalone system.

Ice Bank Systems

Ice bank coolers build ice reserves during off-peak hours and use stored cooling capacity during milking. While effective for rapid cooling:

- Higher capital and maintenance costs limit ROI for smaller operations

- Compressor and ice-building equipment require dedicated space and regular servicing

- Best justified at volumes exceeding 1,000 gallons daily

Recommendation Framework

| Operation Profile | Recommended Solution |

|---|---|

| Small farms (<100 animals, goat/sheep/small cow herds) | Bulk cooling tank (50–660 gallon capacity) |

| Mid-scale operations with pre-cooling infrastructure | Plate cooler + bulk tank combination |

| Large-volume dairy (1,000+ gallons/day) | Ice bank or plate cooler system |

For most small-to-mid scale North American and European dairy operations, bulk cooling tanks offer the optimal balance of regulatory compliance, operational simplicity, and total cost of ownership. Operations anticipating significant volume growth should evaluate hybrid configurations incorporating plate pre-coolers to extend bulk tank efficiency.

Essential Technical Properties and Trade Terminology for milk cooling equipment

Essential Technical Properties and Trade Terminology for Milk Cooling Equipment

Critical Technical Specifications

When evaluating milk cooling equipment for procurement, focus on these measurable properties:

| Property | Description | Industry Standard |

|---|---|---|

| Cooling Capacity | Volume range in gallons/liters | 14 gal (50L) to 660 gal (2,500L) for small-scale; 1,000+ gal for commercial |

| Cooling Rate | Time to reach target temperature | Must cool milk to 4°C (39°F) within 2-3 hours |

| Agitation Speed | Paddle rotation rate | Typically 30 RPM for optimal homogenization without foaming |

| Material Grade | Construction standards | Food-grade stainless steel (304 or 316) |

| Insulation Type | Thermal barrier material | Polyethylene or polyurethane foam |

Compliance Standards

Equipment must meet regional certifications:

- ISO 5708 – International milk cooling tank performance standards

- EN 13732 – European bulk milk cooler requirements

- 3-A Sanitary Standards – USA dairy equipment hygiene certification

- FDA 21 CFR – US food contact material compliance

Key Trade Terminology

Procurement Terms:

– MOQ (Minimum Order Quantity) – Lowest unit count per purchase order

– OEM (Original Equipment Manufacturer) – Custom branding/specification options

– FOB (Free on Board) – Shipping cost responsibility transfer point

– Lead Time – Production-to-delivery timeframe

Equipment-Specific Terms:

– Direct Expansion (DX) – Refrigerant-based cooling system

– Ice Bank – Pre-chilled water reservoir cooling method

– CIP (Clean-in-Place) – Automated internal sanitization system

– Bulk Tank – Primary milk storage vessel

– Plate Cooler/Pre-Cooler – Heat exchanger for initial temperature reduction

Specification Checklist for RFQs

- Tank capacity (gallons/liters)

- Cooling performance (hours to 4°C)

- Power requirements (voltage, phase, Hz)

- Agitator specifications

- Insulation R-value

- Warranty terms

- Spare parts availability

- Installation requirements

Navigating Market Dynamics and Sourcing Trends in the milk cooling equipment Sector

Navigating Market Dynamics and Sourcing Trends in the Milk Cooling Equipment Sector

Market Overview and Growth Trajectory

The global milk cooling equipment market continues to expand, driven by stringent food safety regulations, rising dairy consumption, and the modernization of farming operations across both established and emerging markets. For B2B buyers in the USA and Europe, understanding current market dynamics is essential for strategic procurement decisions.

Key Market Drivers:

– Increasingly rigorous compliance standards (FDA, EU Regulation 853/2004)

– Growing demand for raw milk quality preservation

– Expansion of small-scale and specialty dairy operations (goat, sheep, organic)

– Energy cost pressures pushing demand for high-efficiency systems

Current Sourcing Landscape

| Segment | Capacity Range | Primary Applications | Key Sourcing Regions |

|---|---|---|---|

| Small-scale tanks | 14–660 gallons (50–2,500 liters) | Goat, sheep, small cow operations | Europe (Greece, Germany), USA |

| Mid-scale systems | 660–2,600 gallons | Regional dairy farms | Europe, North America |

| Industrial systems | 2,600+ gallons | Large-scale commercial operations | Global OEMs |

European manufacturers, such as MilkPlan, have established strong footholds in the small-scale segment, offering equipment that meets dual-certification requirements (ISO 5708/EN 13732/3-A standards). This cross-compliance capability simplifies procurement for operations serving both US and EU markets.

Sustainability and Efficiency Trends

Energy efficiency has become a non-negotiable specification. Modern procurement priorities include:

- Advanced insulation technologies: Polyethylene insulation systems reduce energy consumption during cooling cycles

- Optimized agitation systems: Gear reduction motors operating at 30 RPM minimize energy draw while ensuring proper homogenization without foaming

- Heat recovery integration: Plate coolers and “FreeHeater” systems capture waste heat for water pre-heating, reducing overall facility energy costs

Regulatory Compliance Considerations

B2B buyers must verify equipment meets applicable standards:

| Market | Required Standards |

|---|---|

| USA | 3-A Sanitary Standards, FDA PMO requirements |

| Europe | EN 13732, ISO 5708 |

| Dual-market operations | Equipment certified to both frameworks |

Food-grade stainless steel construction remains the baseline requirement across all regulated markets.

Strategic Sourcing Recommendations

- Verify dual-certification for equipment intended for cross-border dairy operations

- Evaluate total cost of ownership, including energy consumption and maintenance parts availability

- Confirm spare parts supply chains—domestic availability reduces downtime risk

- Request cooling performance data demonstrating bacterial growth prevention and pH stability maintenance

- Assess scalability if expansion plans exist within a 5–10 year horizon

The sector continues consolidating around manufacturers offering comprehensive solutions—from cooling tanks to plate coolers and ancillary equipment—simplifying vendor management for procurement teams.

Frequently Asked Questions (FAQs) for B2B Buyers of milk cooling equipment

Frequently Asked Questions (FAQs) for B2B Buyers of Milk Cooling Equipment

1. What capacity range should I consider for my operation?

Milk cooling tanks are available from small-scale units (14 gallons/50 liters) to large commercial systems (660+ gallons/2,500+ liters). Select capacity based on:

- Daily milk production volume

- Number and type of animals (cows, goats, sheep)

- Collection frequency

- Future expansion plans

Recommendation: Choose a tank with 15-20% additional capacity beyond current daily production to accommodate growth.

2. What regulatory standards must milk cooling equipment meet?

For USA and European markets, equipment should comply with:

| Region | Standards |

|---|---|

| International | ISO 5708 |

| European Union | EN 13732 |

| USA | 3-A Sanitary Standards |

Ensure all equipment uses food-grade stainless steel materials that meet these certifications for regulatory compliance and buyer acceptance.

3. How quickly should milk cooling equipment reduce milk temperature?

Industry standards require cooling milk to 4°C (39°F) within:

- 2 hours for bulk tank cooling

- 3°C (37°F) maximum before the next milking is added

Rapid cooling prevents bacterial growth and maintains milk quality by stabilizing pH levels.

4. What features impact energy efficiency?

Key energy-saving features include:

- Polyethylene insulation – State-of-the-art insulation minimizes heat transfer

- Pre-cooling systems – Plate coolers reduce compressor workload

- Variable speed compressors – Adjust to actual cooling demand

- Heat recovery units (FreeHeaters) – Capture waste heat for water heating

5. Why is agitation important in milk cooling tanks?

Proper agitation ensures:

- Uniform cooling throughout the entire milk volume

- Homogenization of milk fats

- Prevention of cream separation

- No foam formation

Quality systems use gear reduction motors operating at approximately 30 RPM with specially designed paddle shafts.

6. What are the differences between cooling solutions for different livestock?

| Factor | Dairy Cows | Goats/Sheep |

|---|---|---|

| Tank Size | Larger capacity (500+ gallons typical) | Smaller capacity (50-300 gallons typical) |

| Milk Composition | Higher volume, standard fat | Higher fat content, requires gentler agitation |

| Collection Frequency | 2x daily standard | Variable based on operation |

7. What should I budget for installation and ongoing maintenance?

Initial costs include:

– Equipment purchase

– Shipping (request quotes based on location)

– Installation and electrical/plumbing connections

– Compliance verification

Ongoing costs:

– Replacement parts (gaskets, seals, agitator components)

– Compressor maintenance

– Cleaning supplies and sanitization equipment

– Energy consumption

Request spare parts availability and pricing before purchase to assess total cost of ownership.

8. What support services should I expect from suppliers?

Reputable B2B suppliers should offer:

- Pre-sale: System planning, capacity calculations, compliance guidance

- Installation: Professional setup and commissioning

- Post-sale: Spare parts availability, repair services, technical support

- Documentation: Equipment manuals, maintenance schedules, warranty terms

Always verify stock availability and lead times before placing orders, particularly for specialized or high-capacity equipment.

Strategic Sourcing Conclusion and Outlook for milk cooling equipment

Strategic Sourcing Conclusion: Milk Cooling Equipment

Effective milk cooling equipment procurement directly impacts product quality, regulatory compliance, and operational profitability. The strategic sourcing decisions outlined in this guide position dairy operations to achieve optimal cold chain performance while managing total cost of ownership.

Key Takeaways for Procurement Success

| Priority | Strategic Action |

|---|---|

| Compliance | Source equipment meeting ISO 5708, EN 13732, and 3-A sanitary standards |

| Scalability | Match tank capacity (50L–2,500L+) to current and projected herd size |

| Efficiency | Prioritize advanced insulation and energy-efficient cooling systems |

| Quality | Specify food-grade stainless steel construction and proper agitation (30 RPM) |

Market Outlook

The milk cooling equipment sector continues advancing toward:

– Enhanced energy efficiency through improved insulation technologies

– Automation integration for real-time temperature monitoring

– Modular solutions accommodating diversified dairy operations (cow, goat, sheep)

Final Recommendations

- Establish relationships with suppliers offering comprehensive parts availability

- Verify equipment certifications for both European and US market compliance

- Factor installation, maintenance, and energy costs into procurement decisions

- Request performance guarantees for bacterial growth prevention and cooling times

Strategic equipment selection today ensures regulatory compliance, product integrity, and competitive positioning for years ahead.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.