The global demand for dairy processing equipment has surged in recent years, driven by increasing milk consumption, stricter hygiene regulations, and a shift toward efficient, scalable packaging solutions. According to Grand View Research, the global dairy processing equipment market was valued at USD 16.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. A key component in this ecosystem is the milk bag strainer—a critical tool for ensuring product purity and consistency during filling operations. With the milk bag packaging segment gaining traction in regions like North America, Eastern Europe, and parts of Asia-Pacific due to its cost-effectiveness and reduced environmental impact, the need for reliable straining equipment has intensified. As manufacturers focus on improving operational efficiency and meeting food safety standards, sourcing high-performance milk bag strainers has become a strategic priority. Based on production capacity, geographic reach, customer reviews, and innovation in filtration technology, the following six manufacturers have emerged as leaders in the milk bag strainer space.

Top 6 Milk Bag Strainer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Manufacturer for Nut Milk Bag Fine Mesh Nylon Filter Strainer Bag

Domain Est. 2020

Website: filtersheets.com

Key Highlights: 1. These brew bags are made of durable polyester and can be washed and reused multiple times. 2. Durable polyester and rugged stitching ensures no….

#2 Draining/Straining Bags for Cheese, Yogurt or Nut Milk

Domain Est. 2004

Website: thecheesemaker.com

Key Highlights: These reusable bags are perfect for making cheese at home. Use these Draining/Straining Bags to replace traditional cheese cloth in the cheesemaking process….

#3 Nylon Nut Milk Bag

Domain Est. 2019

Website: satopradhan.com

Key Highlights: Rating 5.0 (47) · Free delivery over $2,000…

#4 This Strainer Is A One Man Circus!

Domain Est. 2019

Website: positivelyprobiotic.com

Key Highlights: Turn any colander into an ultra-fine strainer. Simply line your colander with this bowl-shaped, reusable strainer pouch and spoon in freshly made yogurt….

#5 milk bag strainer

Domain Est. 2019

Website: becharoflodgefishing.com

Key Highlights: HOT ! milk bag strainer. ※becharoflodgefishing.com Limited model YouTubers have introduced us to the usability of our products! Introducing video here….

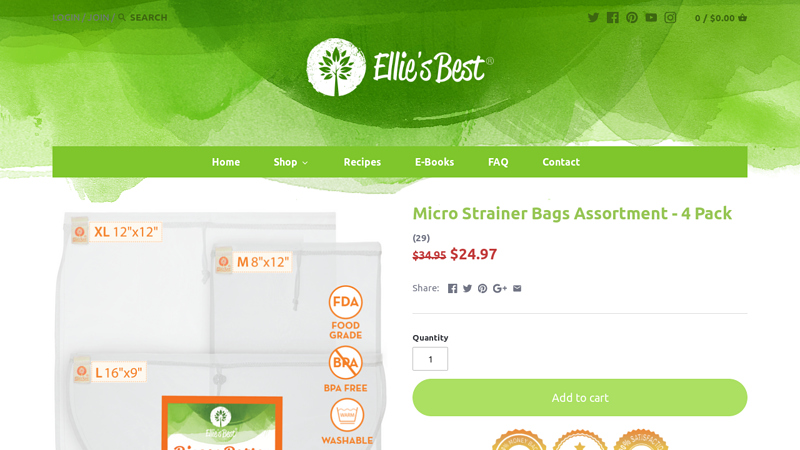

#6 Micro Strainer Bags Assortment

Domain Est. 2014

Expert Sourcing Insights for Milk Bag Strainer

2026 Market Trends for Milk Bag Strainer

The global market for milk bag strainers is expected to undergo notable transformation by 2026, driven by evolving consumer preferences, advancements in dairy processing technology, and increased hygiene awareness. As packaged milk consumption rises—particularly in developing economies—the demand for efficient, cost-effective straining solutions such as milk bag strainers continues to grow. These strainers, commonly used to filter residue and impurities from milk dispensed from bag-based packaging, are gaining traction due to their convenience, affordability, and compatibility with existing distribution systems.

One of the key drivers shaping the 2026 market landscape is the expanding use of milk bags in regions like Canada, parts of Europe, and Latin America. Unlike traditional plastic jugs or cartons, milk bags require secondary containers and often necessitate the use of strainers to ensure a smooth transfer and filtration process. This has led to a steady demand for reusable and easy-to-clean strainers made from food-grade plastics and stainless steel.

Additionally, rising health and sanitation standards are pushing manufacturers to innovate. By 2026, expect to see more ergonomic designs, antimicrobial surface treatments, and multi-functional strainers that integrate measuring capabilities or drip-free pouring features. Sustainability is also influencing product development, with companies exploring biodegradable or recyclable materials to meet eco-conscious consumer demands.

The e-commerce boom is further accelerating market accessibility. Online retail platforms are making milk bag strainers more available to niche and rural markets, contributing to broader adoption. Furthermore, educational campaigns by dairy producers on the benefits of using strainers to enhance milk quality are helping to drive consumer awareness.

In summary, the 2026 market for milk bag strainers will be shaped by regional packaging preferences, technological innovation, hygiene standards, and sustainability trends. As the dairy industry adapts to modern consumer needs, the milk bag strainer is poised to remain a small but essential component in household milk handling.

Common Pitfalls When Sourcing Milk Bag Strainers (Quality and Intellectual Property)

Sourcing milk bag strainers—used to filter milk during milking operations—can present several challenges, particularly concerning product quality and intellectual property (IP) risks. Being aware of these pitfalls is essential for ensuring reliable performance, regulatory compliance, and legal safety.

Poor Material Quality and Food-Grade Compliance

One of the most frequent issues is receiving strainers made from substandard or non-food-grade materials. Inferior plastics or metals may leach harmful substances into the milk, compromising food safety and violating health regulations. Buyers must verify that materials comply with standards such as FDA, NSF, or EU 10/2011 for food contact surfaces.

Inadequate Filtration Efficiency

Low-quality strainers often have inconsistent mesh sizes or poorly constructed filtration layers, leading to ineffective removal of debris, somatic cells, or contaminants. This can result in reduced milk quality and potential rejection by dairy processors. Always test or request performance data on filtration micron rating and flow rate.

Weak Structural Integrity

Cheaply manufactured strainers may crack or warp under pressure or temperature changes, especially during cleaning or sterilization. This reduces product lifespan and increases replacement costs. Ensure the strainer is designed to withstand repeated use and standard farm sanitation procedures (e.g., hot water washing, chemical disinfection).

Lack of Standardization and Compatibility

Some suppliers provide strainers that do not conform to standard milking equipment fittings, leading to leaks or improper attachment. This can disrupt milking operations and cause hygiene issues. Confirm compatibility with common milking machine brands and standard hose diameters before procurement.

Counterfeit or IP-Infringing Designs

Many milk bag strainer designs are patented or protected under intellectual property laws. Sourcing from unauthorized manufacturers—especially in regions with weak IP enforcement—risks importing counterfeit products that infringe on existing patents. This can result in legal action, shipment seizures, or reputational damage.

Inadequate Supplier Verification and Traceability

Working with unverified suppliers increases the risk of receiving inconsistent or non-compliant products. Lack of transparency in the supply chain may also prevent traceability in case of product recalls or quality issues. Always conduct due diligence, including factory audits, sample testing, and certification reviews.

Missing or Falsified Certifications

Some suppliers may claim certifications (e.g., ISO, HACCP, food safety compliance) that are outdated or forged. Relying on these without third-party verification can expose buyers to regulatory non-compliance. Request original documentation and consider using independent inspection services.

Avoiding these pitfalls requires thorough supplier vetting, clear specifications, and ongoing quality control—ensuring that milk bag strainers meet both performance standards and legal requirements.

Logistics & Compliance Guide for Milk Bag Strainer

This guide outlines the essential logistics and compliance considerations for the safe and legal handling, transportation, and use of Milk Bag Strainers in dairy operations.

Product Overview

A Milk Bag Strainer is a disposable or reusable filter used during milk transfer from bulk storage bags or containers to processing equipment. Its primary function is to remove debris, clots, or foreign particles from raw milk before further processing, ensuring product quality and equipment protection.

Regulatory Compliance

Food Contact Material Standards

The strainer must comply with food safety regulations governing materials in contact with consumable products. In the United States, this includes FDA 21 CFR compliance for food-grade polymers (e.g., polypropylene, nylon). In the EU, compliance with Regulation (EC) No 1935/2004 and specific framework Regulation (EU) No 10/2011 for plastic materials is required. Documentation of compliance should be available from the supplier.

Sanitation and Hygiene Requirements

Reusable strainers must be cleaned and sanitized according to HACCP protocols and relevant local food safety regulations (e.g., FDA Pasteurized Milk Ordinance (PMO) in the U.S.). Single-use strainers must be pre-sterilized and stored in sealed, contamination-free packaging.

Labeling and Traceability

All strainers must be clearly labeled with:

– Product name and purpose

– Material composition

– Expiration or shelf life (if applicable)

– Lot number for traceability

– Compliance markings (e.g., FDA, EU food-safe symbols)

– Manufacturer or supplier information

Storage Conditions

Store strainers in a dry, cool, and clean environment away from direct sunlight and extreme temperatures. Avoid exposure to dust, moisture, or chemical fumes. Original packaging should remain sealed until use to prevent contamination. Temperature range should typically be maintained between 10°C and 30°C (50°F – 86°F), unless otherwise specified by the manufacturer.

Transportation Guidelines

Packaging

Strainers should be transported in sturdy, sealed containers or cartons that prevent physical damage, moisture ingress, and contamination. Palletized shipments must be secured to prevent shifting during transit.

Handling

Use clean handling equipment (e.g., sanitized forklifts, gloves) to avoid contamination. Do not stack non-palletized loads excessively to prevent crushing.

Temperature Control

While most strainers are not temperature-sensitive, avoid prolonged exposure to extreme heat or freezing conditions during transport, which may affect material integrity.

Documentation

Ensure shipping manifests include:

– Product description and quantity

– Lot numbers

– Compliance certifications (upon request)

– Proper shipping name and UN number (if classified as hazardous, though typically not applicable)

Usage and Disposal

Installation

Ensure compatibility with existing milk transfer systems. Install according to manufacturer instructions, ensuring a secure fit to prevent bypass or leakage.

Monitoring

Inspect strainers regularly during operation for clogging or damage. Replace disposable strainers after a single use or as per facility SOPs. Reusable models should be inspected for wear and replaced when integrity is compromised.

Disposal

Dispose of used disposable strainers according to local waste management regulations. If contaminated with raw milk, treat as organic waste and dispose of in accordance with biohazard or dairy waste protocols. Reusable strainers must be cleaned, sanitized, and stored properly between uses.

Supplier and Quality Assurance

Procure strainers only from certified suppliers with verifiable quality management systems (e.g., ISO 9001, ISO 22000). Request and maintain documentation including:

– Certificates of Conformance (CoC)

– Material Safety Data Sheets (MSDS/SDS), if applicable

– Third-party testing reports for extractables and leachables (especially for single-use items)

Training and Recordkeeping

Train all personnel involved in handling, installing, or disposing of milk bag strainers on proper procedures, hygiene practices, and compliance requirements. Maintain records of:

– Supplier documentation

– Incoming inspection logs

– Usage logs (especially for reusable units)

– Sanitation schedules

– Staff training completion

Adherence to this guide ensures the safe, compliant, and efficient use of Milk Bag Strainers within dairy logistics and processing environments.

Conclusion:

Sourcing a milk bag strainer is a practical and cost-effective solution for dairy processors, small-scale farmers, and home-based producers aiming to improve the quality and hygiene of their milk handling process. After evaluating various suppliers, material options, and design features, it is evident that selecting the right strainer involves balancing durability, ease of cleaning, mesh fineness, and compliance with food safety standards. Stainless steel strainers with fine mesh (typically 100–200 microns) offer the best combination of performance and longevity. Additionally, sourcing from reputable suppliers ensures product reliability and adherence to regulatory requirements.

In conclusion, investing in a high-quality milk bag strainer not only enhances milk purity by removing debris and contaminants but also supports efficient, sanitary processing. For sustainable and scalable operations, sourcing decisions should prioritize quality, supplier reputation, and long-term usability, ultimately contributing to improved product safety and consumer confidence.