The global market for high-performance coatings, including those meeting MIL-PRF-83483 specifications, is experiencing steady growth driven by increasing demand from defense, aerospace, and industrial sectors. According to Grand View Research, the global military coatings market was valued at USD 1.87 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This expansion is fueled by the need for durable, corrosion-resistant, and environmentally compliant coatings in extreme operational environments. MIL-PRF-83483, a U.S. military performance specification for chemical agent-resistant coating (CARC) systems, remains a critical standard for vehicles and equipment used in defense applications. As regulatory standards tighten and modernization efforts accelerate across global armed forces, the demand for certified manufacturers capable of delivering compliant, high-quality coatings has intensified. Based on production capacity, compliance history, and market presence, the following eight manufacturers have emerged as key players in the MIL-PRF-83483 coating supply landscape.

Top 8 Mil Prf 83483 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Armite Lubricants

Domain Est. 2000

Website: armitelabs.com

Key Highlights: MIL-PRF-83483 · Graphite Petrolatum SAE-AMS-2518 · Zinc Dust Petrolatum A-A … Armite Lubricants is a woman-owned, family operated designer, manufacturer ……

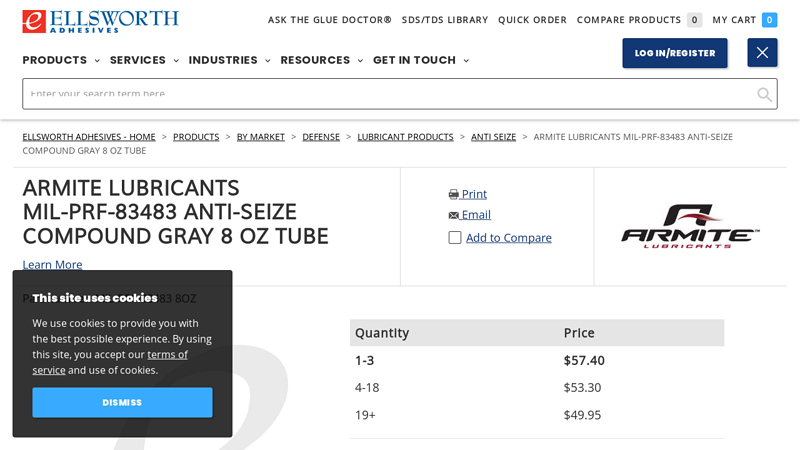

#2 Armite Lubricants MIL

Domain Est. 1997

Website: ellsworth.com

Key Highlights: In stock 6-day deliveryIt is typically used for aircraft spark plugs, threaded fasteners and fittings at temperatures below 427 °C. It provides excellent lubricity, water resistanc…

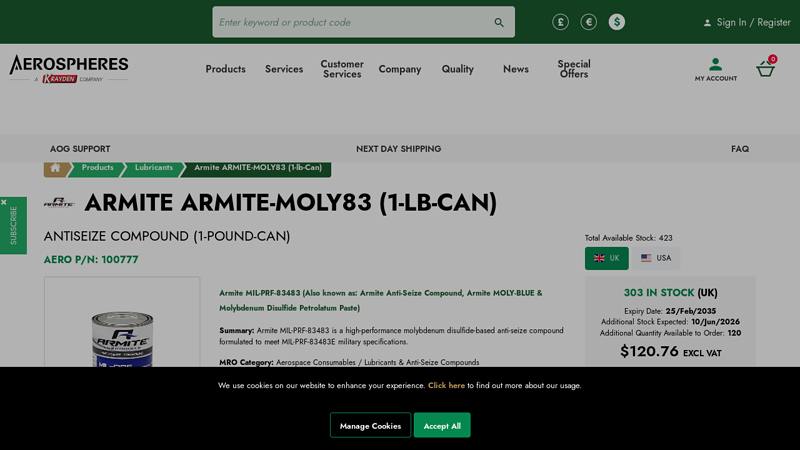

#3 Armite MIL

Domain Est. 1997

Website: aerospheres.com

Key Highlights: In stock Free deliveryDescription: Armite MIL-PRF-83483 is a high-performance molybdenum disulfide-based anti-seize compound specifically formulated for the aviation industry….

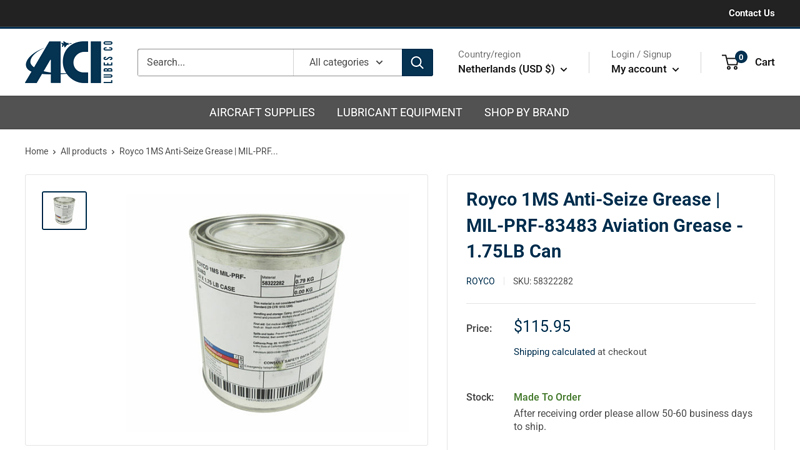

#4 Royco 1MS Anti-Seize Grease

Domain Est. 2003

Website: acilubes.com

Key Highlights: In stock $5 deliveryShop Royco 1MS, a high-quality anti-seize grease for threaded connections on aircraft. Meets MIL-PRF-83483 specs. Get your aviation grease from ACI Lubes….

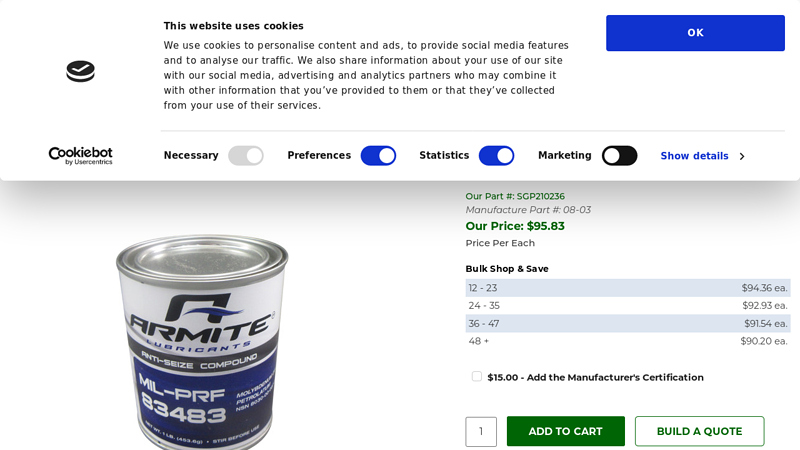

#5 Military Specification MIL

Domain Est. 2003

Website: skygeek.com

Key Highlights: In stock $33.53 deliveryMilitary Specification MIL-PRF-83483 Gray Molybdenum Disulfide Petrolatum Anti-Seize Compound – 1 lb Can. Our Part #: SGP210236. Manufacture Part #: 08-03….

#6 ROYCO® 1MS

Domain Est. 2004

Website: lanxess.com

Key Highlights: Royco® 1MS meets the requirements of MIL-PRF-83483D. Royco® 1MS is particularly suitable for use on aircraft engine spark plugs, threaded fasteners and fittings ……

#7 Armite MIL

Domain Est. 2019

Website: gracoroberts.com

Key Highlights: Armite MIL-PRF-83483 finds application in aerospace, aviation, and various advanced manufacturing sectors as a military-standard anti-seize compound….

#8 MIL

Domain Est. 1999

Website: silmid.com

Key Highlights: 14-day returnsMIL-PRF-83483 is a military specification for a thread compound designed to prevent seizing, galling and corrosion on threaded fasteners….

Expert Sourcing Insights for Mil Prf 83483

H2: Projected 2026 Market Trends for MIL-PRF-83483 Coatings

As defense modernization, infrastructure resilience, and advanced material performance remain strategic priorities globally, the market for MIL-PRF-83483 coatings—high-performance inorganic zinc-rich primers used for corrosion protection—is expected to experience steady growth and technological evolution by 2026. This analysis outlines the key market trends shaping the demand, supply, and innovation landscape for MIL-PRF-83483 compliant coatings in the coming years.

-

Increasing Defense and Aerospace Spending

Global geopolitical tensions and national security initiatives are driving higher defense budgets in the U.S., Europe, and the Indo-Pacific region. MIL-PRF-83483 coatings are critical for protecting military platforms—including naval vessels, aircraft hangars, armored vehicles, and missile systems—against harsh environmental conditions. The U.S. Department of Defense’s continued investment in corrosion control programs is expected to sustain strong demand for certified coatings, with projected procurement increases supporting market expansion through 2026. -

Emphasis on Long-Term Durability and Lifecycle Cost Reduction

Government and industrial end-users are prioritizing materials that reduce lifecycle maintenance costs. MIL-PRF-83483 coatings offer exceptional cathodic protection and adhesion on steel substrates, significantly extending asset service life. As infrastructure projects (e.g., bridges, offshore platforms, and military bases) increasingly adopt performance-based specifications, the use of MIL-PRF-83483 compliant systems is expected to grow beyond traditional military applications into civil engineering and energy sectors. -

Environmental and Regulatory Pressures Driving Formulation Innovation

While MIL-PRF-83483 allows both solvent-based and water-based formulations, tightening VOC (volatile organic compound) regulations are pushing manufacturers toward low-VOC and water-based alternatives. By 2026, the market is likely to see a shift toward environmentally compliant, water-based zinc-rich primers that still meet the rigorous performance standards of the specification. Innovations in binder chemistry (e.g., silicate hybrids and modified ethyl silicates) are expected to enhance application safety and reduce environmental impact without compromising corrosion resistance. -

Supply Chain Resilience and Domestic Sourcing

Recent supply chain disruptions and strategic concerns over critical material dependencies are prompting defense agencies to prioritize domestic production. In the U.S., initiatives under the Defense Production Act and Buy American provisions are encouraging local manufacturing of MIL-PRF-83483 coatings. This trend is likely to foster partnerships between government labs, coating manufacturers, and raw material suppliers, leading to more resilient and secure supply chains by 2026. -

Integration with Multi-Coat and Smart Coating Systems

MIL-PRF-83483 primers are increasingly being used as part of advanced multi-coat systems incorporating epoxy intermediates and polyurethane topcoats. Additionally, research into “smart” coatings—those with corrosion-sensing or self-healing properties—may begin to interface with MIL-PRF-83483 base layers. While full commercialization of such technologies may extend beyond 2026, pilot programs and R&D investments are expected to grow, positioning zinc-rich primers as foundational elements in next-generation protective systems. -

Expansion in Non-Traditional Applications

Beyond military and marine environments, the oil & gas, renewable energy (especially offshore wind), and transportation sectors are adopting MIL-PRF-83483 coatings for critical steel structures exposed to corrosive conditions. The offshore wind boom in Europe and the U.S. presents a significant growth vector, where durability against saltwater and high humidity is paramount. This cross-sector adoption is expected to diversify the customer base and drive certification of new compliant products.

Conclusion

By 2026, the MIL-PRF-83483 market will be shaped by rising defense needs, sustainability mandates, and technological innovation. While the core specification remains focused on corrosion protection performance, the competitive landscape will increasingly reward manufacturers capable of delivering environmentally compliant, domestically sourced, and system-integrated coating solutions. Companies investing in R&D, regulatory compliance, and strategic partnerships are well-positioned to capture growth in this resilient and mission-critical segment.

Common Pitfalls When Sourcing MIL-PRF-83483 (Quality and Intellectual Property Considerations)

Sourcing materials or components that comply with MIL-PRF-83483, the military performance specification for high-reliability electrical connectors, presents unique challenges—particularly concerning quality assurance and intellectual property (IP) rights. Failing to navigate these issues properly can lead to supply chain disruptions, noncompliance, legal exposure, or compromised system performance. Below are the most common pitfalls organizations encounter.

Quality Assurance Pitfalls

1. Assuming Commercial-Grade Components Are Equivalent

A frequent mistake is assuming that commercial off-the-shelf (COTS) connectors perform similarly to MIL-PRF-83483-compliant parts. While they may look identical, military-grade connectors undergo stringent environmental, mechanical, and electrical testing—such as salt fog, vibration, and thermal cycling—that COTS versions do not. Using non-compliant parts risks mission failure in harsh environments.

2. Relying on Unverified Supplier Claims

Some suppliers claim their products meet MIL-PRF-83483 without providing full certification or traceable test data. Procurement teams may accept these claims without third-party validation or independent testing, leading to counterfeit or substandard parts entering the supply chain.

3. Inadequate Lot Traceability and Documentation

Military standards require complete traceability of materials, manufacturing processes, and quality testing. A common pitfall is procuring parts without proper certificates of conformance (CoC), test reports, or lot history records. This lack of documentation can fail audits and disqualify components from use in defense programs.

4. Overlooking Qualified Products List (QPL) Requirements

MIL-PRF-83483 includes a Qualified Products List (QPL) managed by DLA (Defense Logistics Agency). Sourcing from non-QPL manufacturers, even if they claim compliance, introduces risk. Many programs mandate QPL-listed suppliers to ensure pre-validated performance and reliability.

Intellectual Property Pitfalls

5. Unauthorized Use of Proprietary Design Data

The physical dimensions, tooling, and design details of MIL-PRF-83483 connectors are often protected by technical data rights or custom tooling IP held by original manufacturers. Sourcing from unauthorized second sources without proper licensing may infringe on IP rights, leading to legal disputes or injunctions.

6. Reverse Engineering Without Proper Rights

Some suppliers attempt to reverse engineer connectors to replicate MIL-PRF-83483 compliance. If technical data packages (TDPs) or form-fit-function data are protected under DFARS 252.227-7013/7014, reverse engineering without government authorization or IP rights clearance can result in violations of federal acquisition regulations and intellectual property law.

7. Misunderstanding Data Rights and Licensing

When sourcing through subcontractors or aftermarket suppliers, organizations may not verify whether the supplier has legitimate rights to produce or distribute the design. Unclear data rights can lead to disputes over ownership, production rights, and future supportability, especially in long-term defense programs.

8. Supply Chain Transparency Gaps

Lack of visibility into sub-tier suppliers increases the risk of IP infringement and counterfeit parts. If lower-tier manufacturers use unlicensed tooling or designs, the prime contractor may inherit liability—even if unknowingly.

Mitigation Strategies

- Always verify compliance through DLA’s QPL database and request full test documentation.

- Require traceable CoCs and audit supplier manufacturing processes.

- Conduct independent reliability testing when sourcing from new or unproven suppliers.

- Ensure technical data rights are properly licensed under DFARS and FAR clauses.

- Use trusted, authorized distributors and avoid grey-market sources.

- Include IP indemnification clauses in procurement contracts.

By addressing these quality and IP-related pitfalls proactively, organizations can ensure compliance, maintain mission reliability, and protect themselves from legal and operational risk when sourcing MIL-PRF-83483 connectors.

Logistics & Compliance Guide for MIL-PRF-83483

Overview of MIL-PRF-83483

MIL-PRF-83483 is a U.S. military performance specification that defines the requirements for synthetic high-temperature lubricating grease used in aerospace and defense applications. This grease is designed to perform under extreme environmental conditions, including high and low temperatures, moisture, and mechanical stress. Compliance with this specification ensures reliability and performance in critical military systems.

Intended Applications

MIL-PRF-83483 grease is typically used in:

– Aircraft wheel bearings

– Landing gear components

– Actuators and control systems

– Weapon systems requiring high thermal stability

– Other high-load, high-temperature environments

The grease must maintain lubricity across a wide temperature range (typically from -54°C to +204°C or higher, depending on the type), resist oxidation, and provide corrosion protection.

Types and Classes

MIL-PRF-83483 defines several types and classes based on performance requirements:

– Type I: General-purpose high-temperature grease

– Type II: Enhanced water resistance

– Type III: High-speed bearing applications

– Class A: Standard performance

– Class B: Extended high-temperature performance

Proper identification and selection of the correct type and class are essential for compliance and optimal equipment performance.

Key Performance Requirements

To meet MIL-PRF-83483, lubricating grease must pass rigorous testing, including:

– Dropping Point Test: Must exceed 288°C (550°F)

– Oxidation Stability: Measured by ASTM D942 or equivalent; low pressure drop after extended testing

– Water Washout Resistance: ASTM D1264 – limited grease loss after water exposure

– Corrosion Protection: ASTM D1743 – no rust on test bearings

– Shear Stability: ASTM D217 or equivalent – minimal consistency change after mechanical working

– Low-Temperature Torque: ASTM D1478 – acceptable starting and running torque at -40°C

Logistics Considerations

Storage and Handling

- Store in original, sealed containers in a dry, climate-controlled environment

- Avoid exposure to moisture, direct sunlight, and temperature extremes

- Use first-in, first-out (FIFO) inventory rotation

- Prevent contamination by using clean tools and dispensing equipment

Shelf Life

- Typical shelf life is 5 years from date of manufacture when stored properly

- Monitor lot numbers and expiration dates

- Retest or replace expired material per DoD guidelines

Transportation

- Complies with Department of Defense transportation regulations (e.g., MIL-STD-3037)

- Label containers with MIL-PRF-83483 type/class, NSN (NATO Stock Number), lot number, and expiration date

- Ensure compatibility with hazardous materials (HazMat) regulations if applicable

Compliance and Certification

Qualified Products List (QPL)

- Only greases listed on the Defense Logistics Agency’s (DLA) QPL for MIL-PRF-83483 are authorized for military use

- Manufacturers must submit test data and undergo periodic requalification

- Verify current QPL status at DLA Acquisition website or ASSIST-Quick Search

Documentation Requirements

- Certificate of Conformance (CoC) from supplier

- Test reports demonstrating compliance with all required performance criteria

- Batch/lot traceability documentation

- Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS)

Inspection and Testing

- Incoming inspections should verify:

- Correct type and class per purchase order

- Valid certification and lot traceability

- Container integrity and labeling

- Periodic testing recommended for long-term storage or critical applications

Substitution and Interchangeability

- Substitution with non-MIL-PRF-83483 greases is not permitted without engineering approval

- Use only authorized equivalents listed in military technical orders or engineering bulletins

- Mixing with other greases is prohibited unless compatibility is proven and approved

Disposal and Environmental Compliance

- Follow EPA, OSHA, and local regulations for disposal

- Used grease may be classified as hazardous waste depending on contaminants

- Recycle or dispose through authorized hazardous waste handlers

- Maintain records of disposal per environmental compliance standards

Conclusion

Adherence to MIL-PRF-83483 ensures reliable performance of critical defense systems under extreme conditions. Effective logistics management, strict compliance with storage and handling procedures, and use of only qualified products are essential for mission readiness and safety. Always consult the latest version of the specification and coordinate with DLA or appropriate military support commands for updates and technical guidance.

Conclusion for Sourcing MIL-PRF-83483

Sourcing lubricants compliant with MIL-PRF-83483 requires careful attention to technical specifications, qualified products list (QPL) certification, and supplier reliability. This military specification outlines stringent performance requirements for extreme pressure (EP) lubricating greases used in aerospace, naval, and ground vehicle applications, particularly under high load, wide temperature ranges, and harsh environmental conditions. Therefore, successful sourcing depends on selecting greases that are officially qualified under the specification and listed in the Defense Logistics Agency’s (DLA) Qualified Products List (QPL-83483).

Key considerations include verifying current qualification status, ensuring proper testing and documentation (such as MIL-STD-810 or AMS test compliance), and working with reputable suppliers or manufacturers authorized by DLA. Additionally, attention must be paid to shelf life, packaging, and traceability to meet military or defense contractor requirements.

In conclusion, sourcing MIL-PRF-83483-compliant grease is not just about product availability—it demands due diligence in certification, quality assurance, and supply chain integrity. Only through adherence to these standards can users ensure reliability, safety, and compliance in critical defense and aerospace operations.