The global demand for high-performance sealing solutions continues to surge, driven by stringent reliability requirements in defense, aerospace, and industrial applications. Mil-Prf-680, a military-grade lubricating grease known for exceptional resistance to corrosion, water washout, and extreme temperatures, has become a critical component in mission-critical systems. According to Mordor Intelligence, the global specialty grease market—of which Mil-Prf-680 is a key segment—is projected to grow at a CAGR of 4.3% from 2023 to 2028, fueled by increasing defense spending and aerospace modernization programs worldwide. With stringent compliance and performance standards, only a select group of manufacturers consistently meet the rigorous specifications of Mil-Prf-680. Based on production capabilities, global footprint, compliance credentials, and market presence, the following eight manufacturers have emerged as leaders in producing Mil-Prf-680 certified greases, setting the benchmark for quality and reliability in demanding environments.

Top 8 Mil-Prf-680 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MIL

Domain Est. 1997

Website: ecolink.com

Key Highlights: Effective April 15, 2010, MIL PRF 680B has been replaced with MIL-PRF-680C. The difference? Finally MIL PRF 680 gets VOC compliant….

#2 Mil

Domain Est. 2014

Website: 145.aero

Key Highlights: In stock $32.29 deliveryMil-PRF-680 Type I: Aviation & industrial mineral spirits solvent. Cleans grease, oil, contaminants. Meets military specs. High-quality cleaner….

#3 [PDF] mil

Domain Est. 1997

Website: aerospheres.com

Key Highlights: All the products under specification MIL-PRF-680 are hydrocarbon based solvents used as degreasers and cleaners for painted and unpainted metal surface and….

#4 MIL

Domain Est. 2000

Website: metalfluids.com

Key Highlights: An approved MIL-PRF-680C Type II solvent cleaner formulated to effectively remove a wide range of soils such as greases, mineral oils, lubricants, coolants, ……

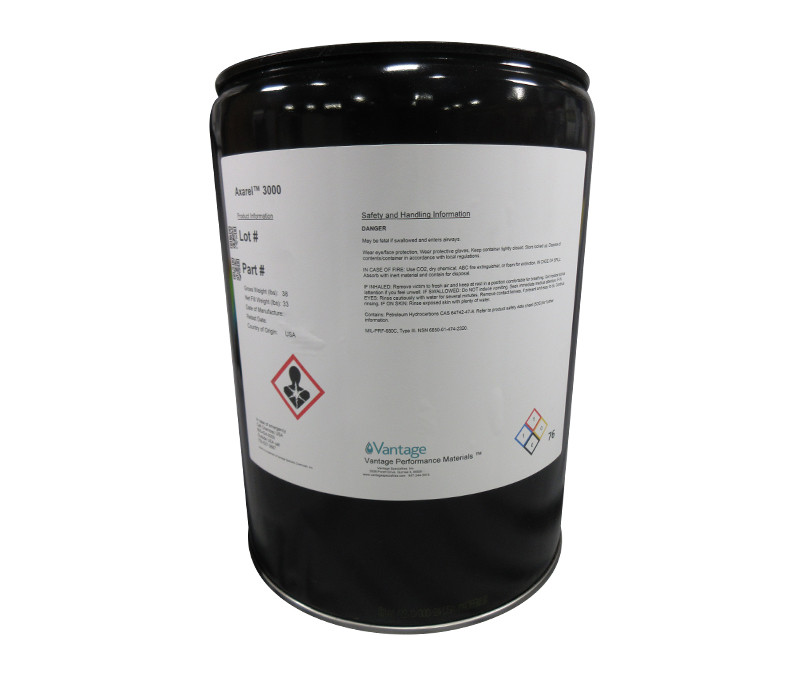

#5 AXARELTM 3000 Clear MIL

Domain Est. 2003

Website: skygeek.com

Key Highlights: AXAREL™ 3000 Solvent Cleaner is an approved MIL-PRF-680 Type III cleaner suitable for the replacement of isopropyl alcohol (IPA), acetone, methyl ethyl ……

#6 SOLVENT 680 TYPE II (environmentally friendly) (MIL

Domain Est. 2011

Website: eurochemgr.com

Key Highlights: All the products under specification MIL-PRF-680 are used as degreasers and cleaners for painted and unpainted metal surface and degreasing of machine parts….

#7 MIL-PRF-680TYPE3

Domain Est. 2014

Website: ww2.txtav.com

Key Highlights: MIL-PRF-680TYPE3 | DEGREASING SOLVENT (1 GALLON) : Quality parts for Beechcraft, Cessna and Hawker aircraft with same day shipping and worldwide ……

#8 MIL

Domain Est. 1999

Expert Sourcing Insights for Mil-Prf-680

H2: Projected 2026 Market Trends for MIL-PRF-680

As of 2026, the market for MIL-PRF-680, a military specification for high-performance lubricating grease used in extreme environments, is expected to reflect a combination of sustained demand, technological adaptation, and supply chain evolution. Originally designed for use in aviation, ordnance, and ground support equipment, MIL-PRF-680 grease is valued for its exceptional resistance to water washout, wide service temperature range, and ability to protect against corrosion and wear under high loads.

Key market trends influencing the MIL-PRF-680 landscape in 2026 include:

-

Increased Defense Spending and Modernization Programs

Global geopolitical tensions have driven increased defense budgets across NATO countries, the United States, and select Asia-Pacific nations. This uptick in military spending supports the maintenance and modernization of aging aircraft and ground vehicle fleets—many of which still rely on MIL-PRF-680-compliant lubricants. As legacy platforms remain in service, demand for certified, specification-grade greases like MIL-PRF-680 continues to grow. -

Supply Chain Resilience and Domestic Sourcing

In response to supply chain disruptions experienced during the early 2020s, defense contractors and government agencies are prioritizing domestic production and strategic stockpiling of critical materials. In 2026, there is a noticeable shift toward sourcing MIL-PRF-680 grease from certified U.S.-based or allied manufacturers to reduce dependency on foreign suppliers and ensure compliance with Defense Federal Acquisition Regulation Supplement (DFARS) requirements. -

Environmental and Regulatory Pressures

While MIL-PRF-680 itself is not being phased out, environmental regulations are pushing for greener alternatives in non-critical applications. However, due to its unmatched performance in extreme conditions, MIL-PRF-680 remains irreplaceable in high-stress military systems. Manufacturers are responding by improving the biodegradability and reducing the toxicity of base components without compromising performance, aligning with broader DoD sustainability initiatives. -

Technological Enhancements and Performance Monitoring

Advances in condition-based maintenance and predictive analytics are influencing how MIL-PRF-680 is applied and monitored. In 2026, smart lubrication systems and sensor-integrated grease fittings allow for real-time monitoring of grease performance and degradation, enabling more precise re-lubrication cycles. This trend improves equipment uptime and reduces waste, extending the operational life of components using MIL-PRF-680. -

Market Consolidation and Certification Barriers

The market remains relatively consolidated due to the stringent qualification requirements for MIL-PRF-680 compliance. Only a limited number of manufacturers maintain active Qualified Products Lists (QPL) certification. This creates a stable but competitive environment where established players dominate, and new entrants face high barriers to entry. -

Emerging Use in Commercial and Aerospace Sectors

While primarily a military specification, select commercial aerospace and offshore industries are adopting MIL-PRF-680 in niche, high-reliability applications. The 2026 market sees a slight expansion into these adjacent sectors, particularly in rotorcraft maintenance and marine propulsion systems where performance under extreme conditions is critical.

In summary, the 2026 market for MIL-PRF-680 is characterized by steady demand driven by defense needs, enhanced supply chain security, and incremental technological improvements. While alternative greases are emerging for less demanding applications, MIL-PRF-680 retains its critical role in mission-critical systems, ensuring its continued relevance in the global defense and aerospace sectors.

Common Pitfalls Sourcing Mil-Prf-680 (Quality, IP)

Sourcing compliant Mil-Prf-680 lubricating compounds requires careful attention to detail to ensure performance, reliability, and legal compliance. Overlooking key aspects can lead to significant quality and intellectual property (IP) issues.

1. Accepting Non-Certified or Unverified Suppliers

Relying on suppliers who cannot provide valid certification or traceable documentation is a major risk. Many vendors may claim compliance without possessing current Qualified Products List (QPL) status or valid test reports. Always verify the supplier’s listing on the official DoD QPL database to confirm active approval for Mil-Prf-680.

2. Using Non-Approved Substitutes or “Mil-Spec Grade” Products

A common pitfall is purchasing lubricants labeled as “Mil-Spec grade” or “comparable to Mil-Prf-680” that are not officially certified. These substitutes may not meet the rigorous performance, corrosion resistance, or temperature stability requirements. Such products lack formal qualification and can compromise equipment integrity in critical applications.

3. Inadequate Batch Traceability and Documentation

Failure to obtain full traceability—including lot numbers, Certificates of Conformance (CoC), and test data—can result in quality disputes or audit failures. Proper documentation ensures that the product meets the specification at the time of manufacture and supports defense contract compliance requirements.

4. Intellectual Property Infringement via Unauthorized Formulations

Some suppliers reverse-engineer or copy proprietary formulations without authorization, potentially infringing on patented processes or trade secrets. This not only poses legal risks but may also result in inconsistent performance. Always source from authorized, licensed manufacturers to avoid IP violations.

5. Overlooking Shelf Life and Storage Conditions

Mil-Prf-680 compounds have defined shelf lives and storage requirements (e.g., temperature, humidity control). Sourcing from suppliers with poor inventory management can result in expired or degraded product, reducing effectiveness and potentially leading to equipment failure.

6. Ignoring Revision Control and Specification Updates

Mil-Prf-680 has undergone revisions (e.g., from MIL-G-680F to MIL-PRF-680G). Using outdated specifications or failing to confirm the correct revision can result in non-compliance. Ensure the supplier provides product meeting the latest applicable revision specified in your procurement documents.

7. Lack of Testing and Quality Assurance Oversight

Assuming compliance without independent verification is risky. Reputable programs include third-party testing or in-house quality checks. Skipping this step may result in accepting substandard products that fail under operational stress.

Avoiding these pitfalls requires due diligence, supplier vetting, and strict adherence to defense acquisition standards to ensure both quality integrity and IP compliance when sourcing Mil-Prf-680 lubricants.

Logistics & Compliance Guide for MIL-PRF-680

Overview of MIL-PRF-680

MIL-PRF-680 is a U.S. military performance specification for high-temperature, corrosion-inhibiting lubricating grease. It is designed for use in military and aerospace applications where extreme environmental conditions, high loads, and wide temperature ranges are encountered. The grease provides lubrication, prevents corrosion, and maintains stability under harsh operational conditions.

This guide outlines the logistics and compliance requirements for handling, storing, procuring, and using MIL-PRF-6880-compliant greases.

Procurement and Sourcing

Approved Sources List (ASL)

Only greases produced by manufacturers listed on the Qualified Products List (QPL) for MIL-PRF-680 are authorized for military use. Procurement must ensure that the product:

- Is sourced from an approved manufacturer.

- Bears the correct QPL designation (e.g., QPL-680).

- Includes certification documentation with each shipment.

Documentation Requirements

Each shipment must include:

- Certificate of Conformance (CoC) referencing MIL-PRF-680.

- Lot number traceability.

- Date of manufacture and shelf life expiration.

- Test results for key performance parameters (e.g., dropping point, corrosion resistance, oxidation stability).

Storage and Handling

Environmental Conditions

Store MIL-PRF-680 grease in a clean, dry, temperature-controlled environment. Recommended storage conditions:

- Temperature: 15°C to 30°C (59°F to 86°F).

- Avoid direct sunlight and moisture.

- Keep containers sealed to prevent contamination.

Shelf Life and Rotation

- Shelf life: Typically 3 to 5 years from the date of manufacture (verify with manufacturer).

- Use a First-In, First-Out (FIFO) inventory system.

- Monitor expiration dates and remove outdated stock from service.

Container Integrity

- Use only original, unopened containers unless transferred to clean, dedicated dispensing equipment.

- Label all secondary containers with product name, specification, lot number, and expiration date.

Application and Use Compliance

Equipment Compatibility

Ensure compatibility with the intended application. MIL-PRF-680 grease is commonly used in:

- Aircraft control systems.

- Landing gear assemblies.

- Weapon systems.

- Ground support equipment.

Verify OEM specifications before application.

Application Procedures

- Apply grease using clean, dedicated tools to avoid cross-contamination.

- Follow recommended torque and lubrication intervals.

- Do not mix MIL-PRF-680 grease with other greases unless compatibility is confirmed.

Testing and Quality Assurance

Incoming Inspection

Conduct visual and documentation checks upon receipt. Sample testing may include:

- Visual inspection for discoloration or separation.

- Verification of packaging and labeling.

- Spot testing for key properties if shelf life is near expiration.

Periodic Re-Testing

For long-term storage, conduct re-testing before use if the grease is within 6 months of expiration or has been stored beyond recommended conditions.

Disposal and Environmental Compliance

Waste Management

Used or expired MIL-PRF-680 grease is considered hazardous waste in many jurisdictions due to potential heavy metal content (e.g., lead or zinc additives). Disposal must comply with:

- EPA regulations (40 CFR).

- DoD waste management policies.

- Local environmental laws.

Recycling and Disposal Methods

- Use authorized hazardous waste disposal contractors.

- Maintain records of disposal, including manifests and certificates of destruction.

- Avoid dumping, burning, or landfilling without proper authorization.

Audit and Compliance Verification

Internal Audits

Conduct regular audits of:

- Inventory records.

- Storage conditions.

- Usage logs.

- Disposal documentation.

Audits ensure adherence to MIL-PRF-680 handling protocols and regulatory requirements.

Regulatory and Contractual Compliance

Ensure compliance with:

- DFARS (Defense Federal Acquisition Regulation Supplement).

- ITAR (International Traffic in Arms Regulations) if applicable.

- Contract-specific requirements for traceability and reporting.

Training and Personnel Requirements

Personnel Training

All personnel handling MIL-PRF-680 grease must be trained in:

- Proper handling and application.

- Safety data sheet (SDS) review.

- Environmental and disposal procedures.

- Documentation and traceability protocols.

Certification Records

Maintain training records for audit readiness and compliance verification.

Conclusion

Adherence to MIL-PRF-680 logistics and compliance guidelines ensures operational reliability, regulatory compliance, and mission readiness. Proper procurement, storage, handling, and disposal are critical to maintaining the integrity and performance of this specialized lubricant in military and aerospace applications.

Conclusion for Sourcing MIL-PRF-680 Lubricating Compound

Sourcing MIL-PRF-680 lubricating compound requires careful attention to compliance, quality assurance, and supplier reliability. As a military specification grease designed for extreme conditions—including resistance to water, corrosion, and wide temperature ranges—it is critical to procure material that meets or exceeds the exact requirements outlined in the specification. Verified manufacturers and suppliers certified to produce MIL-PRF-680 compliant products must be prioritized to ensure performance, durability, and regulatory adherence.

Key considerations include validating product certifications, reviewing technical data sheets, confirming lot traceability, and ensuring proper packaging and storage as per military standards. Additionally, engaging suppliers with a proven track record in defense or aerospace supply chains enhances confidence in product authenticity and performance reliability.

In conclusion, successful sourcing of MIL-PRF-680 hinges on strict adherence to the specification, due diligence in supplier selection, and continuous quality verification. By following these best practices, organizations can ensure operational readiness, equipment longevity, and compliance with federal procurement requirements.

![[PDF] mil](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-mil-790.jpg)