The global micro switch and limit switch market is experiencing robust growth, driven by increasing automation across industrial, automotive, and consumer electronics sectors. According to Grand View Research (2023), the global limit switch market was valued at USD 1.58 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.4% from 2023 to 2030. This upward trajectory is fueled by rising demand for precision control mechanisms in manufacturing processes and the steady adoption of smart industrial systems. Meanwhile, Mordor Intelligence projects continued expansion in the micro switch market, underpinned by advancements in IoT-enabled devices and safety-critical applications in home appliances, medical equipment, and automotive systems. As demand for high-reliability switching solutions grows, a select group of manufacturers has emerged as leaders in innovation, quality, and global market reach—shaping the future of micro and limit switch technology.

Top 8 Micro Switch Limit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Micro Limit Switch Manufacturer

Domain Est. 2024

Website: microswitchmanufacturer.com

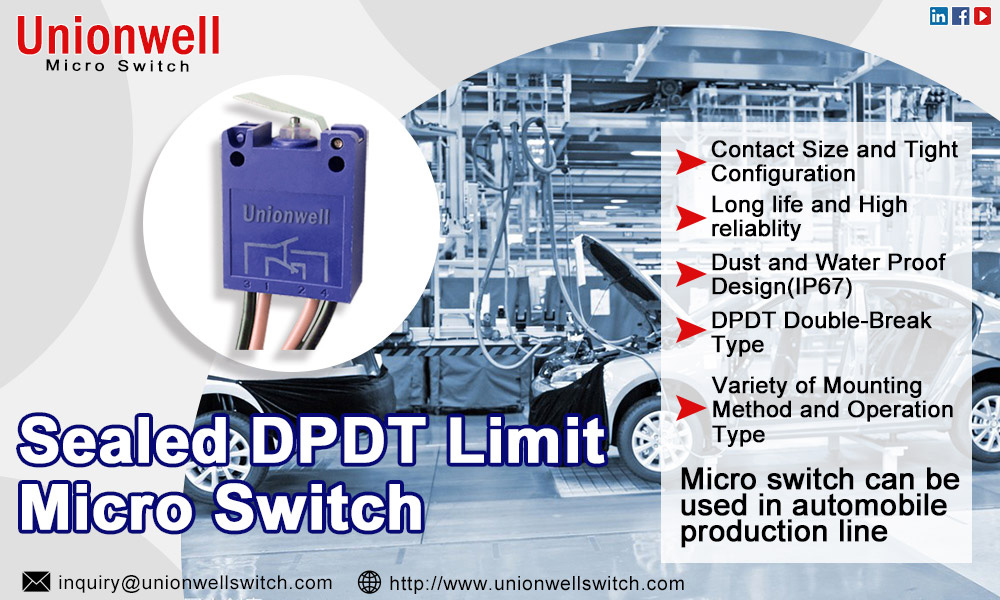

Key Highlights: Unionwell is a premier dustproof limit micro switch supplier, providing top-quality solutions for various industrial and consumer applications….

#2 High Quality Micro Switch Limit Switch Manufacturers and …

Domain Est. 2024

Website: renew-en.com

Key Highlights: Welcome to Zhejiang Renew Electronic Co., Ltd., a leading custom manufacturer company specialized in producing high-quality Micro Switch Limit Switches. Our ……

#3 MICROSENS

Domain Est. 1997

Website: microsens.com

Key Highlights: MICROSENS is setting new standards in terms of performance, reliability, and security for data networks in medical technology, hospitals, and medical practices….

#4 Limit Switches

Domain Est. 1997

Website: ia.omron.com

Key Highlights: Limit Switch are basic switches that have been encased to protect them from external forces, water, oil, and dirt. Many models are available….

#5 Limit Switches

Domain Est. 2018

Website: switch-manufacturers.com

Key Highlights: Auspicious specialize in micro switches, limit switches, switches in wide range type, push button in different types, etc. We focus on reliability and ……

#6 Limit Switches – Automation

Domain Est. 1988

Website: automation.honeywell.com

Key Highlights: Honeywell MICRO SWITCH limit switches, available in a range of actuators, electrical specifications, terminations, circuitries, and sealing ratings….

#7 Sensors and Switches

Domain Est. 1997

Website: rockwellautomation.com

Key Highlights: We offer proximity and photoelectric sensors, limit switches and safety switches, and RFID and operator safety devices….

#8 Limit Switches

Domain Est. 2006

Website: aa-industrial.azbil.com

Key Highlights: We offer an extensive lineup of limit switches that can be installed and used in many different environments….

Expert Sourcing Insights for Micro Switch Limit

H2: 2026 Market Trends for Micro Switch Limit

The micro switch limit market is expected to witness steady growth and notable technological evolution by 2026, driven by increasing automation across industrial, consumer electronics, automotive, and smart home sectors. Micro switch limits—compact electromechanical devices designed to detect the presence or position of objects—are becoming increasingly integral in systems requiring precision and reliability. The following are key market trends projected for 2026:

-

Growing Demand in Industrial Automation

As industries continue to adopt Industry 4.0 principles, the need for reliable position sensing and safety interlocks is rising. Micro switch limits are widely used in conveyor systems, assembly lines, and machine guarding, contributing to enhanced operational safety and efficiency. The integration of micro switches into smart manufacturing environments is expected to drive significant demand through 2026. -

Expansion in Consumer Electronics and Home Automation

The proliferation of smart appliances, such as washing machines, refrigerators, and HVAC systems, is increasing the use of micro switch limits for door detection, safety cutoffs, and mode switching. With the global push toward energy efficiency and intelligent household systems, the residential automation market will remain a key growth driver for micro switches. -

Automotive Sector Integration

In the automotive industry, micro switch limits are used in seat positioning, door locks, gear shifters, and trunk latches. As vehicle electrification and advanced driver assistance systems (ADAS) become standard, the demand for compact, durable, and reliable switching components is expected to rise. By 2026, increased production of electric and autonomous vehicles will further boost micro switch adoption. -

Miniaturization and High-Reliability Designs

Manufacturers are focusing on developing smaller, more robust micro switches capable of withstanding extreme temperatures, vibrations, and high-cycle operations. Trends indicate a shift toward sub-miniature switches with higher electrical ratings and longer life cycles, meeting the needs of compact and high-performance applications. -

Rise of Smart and IoT-Enabled Switching

While traditional mechanical micro switches remain dominant, there is growing interest in hybrid solutions that integrate digital feedback or IoT connectivity. By 2026, some market segments may see early adoption of “smart” micro switches with embedded diagnostics or wireless communication, enabling predictive maintenance and remote monitoring. -

Regional Market Shifts

Asia-Pacific, particularly China, India, and Southeast Asia, will continue to lead in both production and consumption due to rapid industrialization and electronics manufacturing growth. North America and Europe will see steady demand driven by automation upgrades and stringent safety regulations. -

Sustainability and Material Innovation

Environmental regulations are pushing manufacturers to adopt RoHS-compliant materials and improve recyclability. Expect to see increased use of lead-free components and eco-friendly packaging by 2026, aligning with global sustainability goals.

In conclusion, the micro switch limit market in 2026 will be shaped by technological advancements, expanding application areas, and regional industrial growth. While traditional mechanical switches will remain dominant, innovation in design, durability, and connectivity will define competitive advantage in this mature yet evolving market.

Common Pitfalls When Sourcing Micro Switch Limit Switches (Quality, IP Rating)

Sourcing micro switch limit switches can be deceptively complex, especially when balancing cost, performance, and environmental requirements. Overlooking critical factors can lead to premature failures, safety hazards, and increased maintenance costs. Below are key pitfalls related to quality and IP (Ingress Protection) ratings to avoid:

Inadequate Quality Assessment

One of the most common mistakes is prioritizing low cost over quality, leading to the selection of micro switches with subpar materials, inconsistent performance, or poor manufacturing tolerances. Low-quality switches may suffer from contact bounce, unreliable actuation, or shortened mechanical life. Buyers often fail to verify certifications (such as UL, CE, or RoHS), neglect lifecycle testing data (e.g., millions of operations), or skip sample testing under real-world conditions. This results in higher long-term costs due to frequent replacements and downtime.

Misunderstanding IP Ratings

A frequent oversight is assuming that a general “industrial-grade” label ensures adequate environmental protection. The IP rating system (e.g., IP65, IP67) precisely defines protection against dust and moisture, but many purchasers misinterpret or overlook these specifications. For example, selecting an IP40-rated switch for outdoor or washdown environments leaves the device vulnerable to dust and water ingress, leading to internal corrosion and failure. Conversely, over-specifying with unnecessarily high IP ratings (like IP69K) can drive up costs without added benefit.

Neglecting Application-Specific Requirements

Not all environments are the same, yet buyers often source generic micro switches without considering factors like temperature extremes, vibration, chemical exposure, or electrical load. For instance, using a standard switch in a high-vibration setting without reinforced terminals or ruggedized housing can result in loose connections and intermittent operation. Similarly, ignoring electrical ratings (voltage/current) can cause arcing and contact welding.

Overlooking Long-Term Supplier Reliability

Choosing suppliers based solely on price or availability without evaluating their track record, technical support, or consistency in quality control poses a significant risk. Poor supply chain transparency can lead to counterfeit components or batch inconsistencies, especially with offshore manufacturers. A reliable supplier should provide detailed datasheets, test reports, and responsive technical assistance.

Failing to Validate Sealing and Actuator Integrity

Even with a high IP rating, poor sealing around the actuator or terminals can compromise protection. Some switches may meet IP standards in static conditions but fail under repeated actuation, which can pump moisture or debris into the housing. Ensure the design includes effective seals and that the actuator mechanism does not degrade the ingress protection over time.

By carefully evaluating quality indicators, accurately interpreting IP ratings, and matching specifications to the actual application environment, these pitfalls can be avoided—ensuring reliable, long-lasting performance of micro switch limit switches.

Logistics & Compliance Guide for Micro Switch Limit

This guide outlines the essential logistics and compliance considerations for the handling, transport, storage, and regulatory adherence of Micro Switch Limit devices. Proper management ensures product integrity, safety, and legal conformity throughout the supply chain.

Product Overview and Specifications

Micro Switch Limit devices are precision electromechanical components designed to detect the presence, position, or movement of machinery parts. They are widely used in industrial automation, safety systems, consumer electronics, and HVAC applications. Key specifications include actuation force, electrical ratings (voltage/current), operating temperature range, ingress protection (IP) rating, and mechanical life expectancy. Understanding these specifications is critical for correct handling and application.

Packaging and Labeling Requirements

Micro Switch Limit units must be packaged in anti-static, moisture-resistant materials to prevent electrostatic discharge (ESD) damage and corrosion. Individual units should be sealed in static-shielded bags, with desiccant packs included in larger containers if shipping to humid environments. Outer packaging must be sturdy and clearly labeled with:

– Part number and product description

– Quantity per package

– Electrostatic-sensitive device (ESD) warning symbol

– Manufacturer and batch/lot number

– Country of origin

– Handling instructions (e.g., “Fragile,” “Do Not Stack”)

Storage Conditions

Store Micro Switch Limit devices in a controlled environment with the following parameters:

– Temperature: 10°C to 30°C (50°F to 86°F)

– Relative Humidity: 30% to 60% (non-condensing)

– Location: Clean, dry, and free from dust, corrosive gases, and direct sunlight

Ensure stock rotation follows First-In, First-Out (FIFO) principles to prevent aging of components. Devices with moisture-sensitive levels (MSL) must be stored in dry cabinets or sealed containers with humidity indicators.

Transportation Guidelines

Transport Micro Switch Limit devices using climate-controlled vehicles whenever possible. Packages should be secured to prevent movement and shock during transit. Avoid exposure to extreme temperatures, humidity, or vibration. For international shipments:

– Use freight forwarders compliant with IATA (air) or IMDG (sea) regulations

– Ensure proper documentation including commercial invoices, packing lists, and certificates of origin

– Declare as electronic components; no hazardous materials classification is typically required unless specified

Regulatory Compliance

Micro Switch Limit devices must comply with regional and international standards, including:

– RoHS (Restriction of Hazardous Substances): Compliant with EU Directive 2011/65/EU for lead, mercury, cadmium, and other restricted materials

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Ensure no SVHCs (Substances of Very High Concern) above threshold limits

– CE Marking: Required for sale in the European Economic Area, indicating conformity with health, safety, and environmental protection standards

– UL/CSA Certification: Required for North American markets; verify product listings with Underwriters Laboratories or Canadian Standards Association

– IEC Standards: Compliance with IEC 60947-5-1 for low-voltage switchgear and control gear

Export Controls and Documentation

Verify if Micro Switch Limit devices are subject to export control regulations such as:

– EAR (Export Administration Regulations) – U.S. Department of Commerce

– ITAR (International Traffic in Arms Regulations) – if used in defense applications

Most micro switches fall under ECCN 3A999 (non-controlled), but confirm based on technical specifications. Required export documents include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Compliance (upon request)

– Export License (if applicable)

Quality Assurance and Traceability

Maintain full traceability through batch/lot numbers and serial tracking where applicable. Implement quality checks upon receipt and before dispatch. Retain records of:

– Incoming inspection reports

– Storage environment logs

– Shipping documentation

– Compliance certifications (RoHS, REACH, UL, etc.)

This ensures accountability and supports audits or recalls if necessary.

End-of-Life and Environmental Responsibility

Dispose of non-functional Micro Switch Limit devices in accordance with WEEE (Waste Electrical and Electronic Equipment) Directive requirements in applicable regions. Partner with certified e-waste recyclers to ensure environmentally sound recycling and recovery of materials. Avoid landfill disposal.

Summary and Best Practices

To ensure seamless logistics and full compliance:

– Use ESD-safe packaging and labeling

– Store in controlled, clean environments

– Transport under stable climate conditions

– Maintain up-to-date compliance certifications

– Keep detailed records for traceability

– Train personnel on handling and regulatory requirements

Adhering to this guide supports product reliability, regulatory compliance, and sustainable operations across the supply chain.

Conclusion on Sourcing Micro Switch Limits:

Sourcing micro switches requires a thorough understanding of technical specifications, application requirements, and supply chain considerations. Key factors such as electrical ratings, mechanical lifespan, actuator type, environmental resistance (e.g., IP rating), and certification standards (e.g., UL, CE) must be carefully evaluated to ensure reliable performance in the intended application. Additionally, sourcing from reputable manufacturers or suppliers ensures consistency, quality, and compliance with industry standards. Cost-efficiency should not compromise durability or safety, especially in critical applications such as industrial machinery, medical devices, or consumer electronics. Therefore, a balanced approach—prioritizing quality, technical compatibility, and supplier reliability—is essential when sourcing micro switch limits. Proper selection and sourcing ultimately contribute to enhanced product longevity, operational safety, and reduced maintenance costs.