The global market for tractor replacement parts, including components for classic models like the Massey Ferguson 135, is experiencing steady growth driven by increasing demand for agricultural mechanization and cost-effective maintenance of legacy machinery. According to Grand View Research, the global agricultural machinery market was valued at USD 163.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.1% from 2023 to 2030. A significant portion of this growth is attributed to aftermarket parts, as farmers and operators seek reliable, high-quality replacements to extend the lifespan of workhorse models like the MF 135. Mordor Intelligence also highlights rising demand in emerging economies, where maintenance of older but durable equipment remains a cost-efficient solution. Against this backdrop, identifying the top manufacturers specializing in MF 135 parts is critical for sourcing durable, precision-engineered components that ensure operational continuity and maximize equipment ROI.

Top 7 Mf 135 Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Massey Ferguson 135’s

Domain Est. 2022

Website: alltractorparts.ca

Key Highlights: The parts listed on this website are not manufactured by the Original Equipment Manufacturer (OEM). Original Manufacturer’s names, part numbers, pictures ……

#2 AGCO Parts Books

Domain Est. 1996

Website: masseyferguson.com

Key Highlights: Our AGCO Parts Books, available on web and mobile, provides you with access to an electronic catalog where you can easily find replacement part information ……

#3 AGCO Parts

Domain Est. 1996

Website: agcocorp.com

Key Highlights: With AGCO Parts, you get worldwide support for all AGCO machinery brands, including Massey Ferguson, Fendt, Valtra and more….

#4 MF

Domain Est. 1997

Website: yesterdaystractors.com

Key Highlights: We sell tractor parts! We have the parts you need to repair your tractor – the right parts. Our low prices and years of research make us your best choice….

#5 Massey Ferguson 135 Tractor Parts

Domain Est. 2006

Website: tractorpartsasap.com

Key Highlights: Free delivery over $250 · 30-day returns…

#6 Massey Ferguson

Domain Est. 2021

Website: masseytractorparts.com

Key Highlights: Massey Ferguson Parts Lookup That Allows You To Find Genuine Parts For Your Massey Ferguson 135. Simply Select Your Model From The Selection Tool And Browse ……

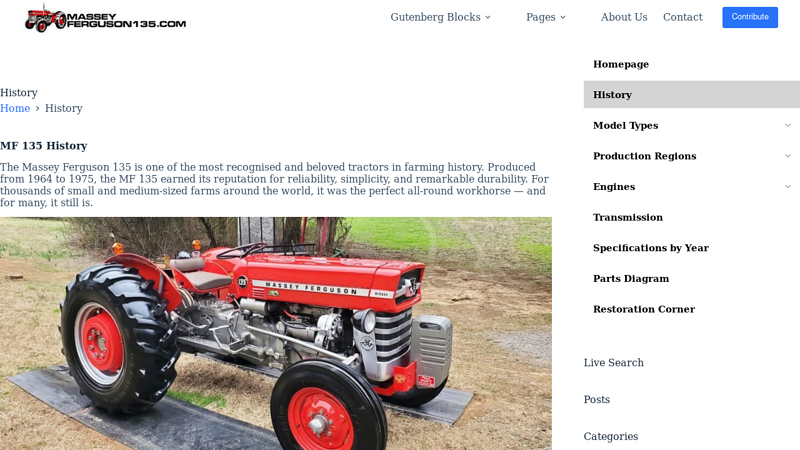

#7 MF 135 History

Website: masseyferguson135.com

Key Highlights: The MF 135 was designed as the successor to the successful MF 35. It was part of the new Massey Ferguson 100 Series, which modernised the company’s lineup for ……

Expert Sourcing Insights for Mf 135 Parts

H2: Projected 2026 Market Trends for MF 135 Parts

As the agricultural sector continues to evolve, demand for vintage and classic tractor parts—particularly for iconic models like the Massey Ferguson 135 (MF 135)—is expected to undergo notable shifts by 2026. Despite being originally produced from the 1960s to the 1970s, the MF 135 remains a staple in small farms, restoration projects, and developing agricultural economies. The market for MF 135 parts in 2026 will be shaped by several interrelated trends:

1. Sustained Demand from Restoration and Enthusiast Communities

The global classic tractor restoration movement is gaining momentum, especially in North America, Europe, and parts of Asia-Pacific. By 2026, an aging population of skilled mechanics and a younger generation of retro machinery enthusiasts are expected to sustain strong demand for authentic and high-quality MF 135 components. Online communities, social media groups, and vintage machinery expos will continue to drive visibility and demand, supporting a niche but profitable aftermarket.

2. Increasing Scarcity of OEM and NOS Parts

Original Equipment Manufacturer (OEM) parts for the MF 135 are increasingly rare. As of 2026, the availability of New Old Stock (NOS) components is expected to dwindle further, pushing prices upward. This scarcity will benefit third-party manufacturers who produce accurate reproductions using modern materials and techniques, provided they maintain compatibility and reliability.

3. Growth of Reproduction and Aftermarket Manufacturing

The aftermarket for MF 135 parts is poised for growth, led by specialized manufacturers in countries like India, Turkey, and Eastern Europe. These suppliers are investing in precision tooling and quality control to meet global standards. In 2026, expect an expansion of certified reproduction parts—especially for high-wear components such as clutches, brake systems, and engine gaskets—offering cost-effective alternatives to vintage originals.

4. Digital Marketplaces and E-Commerce Dominance

By 2026, e-commerce platforms such as eBay, Etsy, TractorParts.com, and specialized agri-equipment portals will dominate MF 135 parts distribution. Enhanced search algorithms, global shipping networks, and customer review systems will increase market transparency and accessibility. This digital shift enables even remote users in rural areas to source rare parts efficiently, reducing downtime for operational vintage tractors.

5. Sustainability and Circular Economy Trends

Growing emphasis on sustainability in agriculture is reinforcing the value of repairing and maintaining older machinery instead of replacing it. The MF 135, known for its durability and simplicity, aligns well with circular economy principles. In 2026, this trend will bolster the parts market as farmers and cooperatives prioritize cost-effective, eco-friendly solutions over new, resource-intensive equipment.

6. Regional Market Divergence

While demand in North America and Western Europe will focus on restoration and collectibility, markets in Africa, South Asia, and Latin America will continue to use MF 135s as functional farm equipment. This dual demand stream ensures a diversified global market. In developing regions, affordability and durability will drive demand for robust aftermarket parts, supporting local economies and repair ecosystems.

Conclusion

The 2026 market for MF 135 parts will remain resilient due to a combination of nostalgic appeal, functional utility, and sustainable agricultural practices. While original parts become scarcer, innovation in reproduction manufacturing and digital distribution will ensure continued support for this enduring tractor model. Stakeholders—suppliers, collectors, and farmers—should anticipate rising prices for rare OEM components and increased competition among aftermarket producers focused on quality and authenticity.

Common Pitfalls When Sourcing Massey Ferguson 135 Parts (Quality and Intellectual Property)

Logistics & Compliance Guide for Massey Ferguson 135 Parts

This guide outlines the essential logistics and compliance considerations when sourcing, transporting, and handling parts for the Massey Ferguson 135 tractor. Proper adherence ensures operational efficiency, legal compliance, and preservation of part integrity.

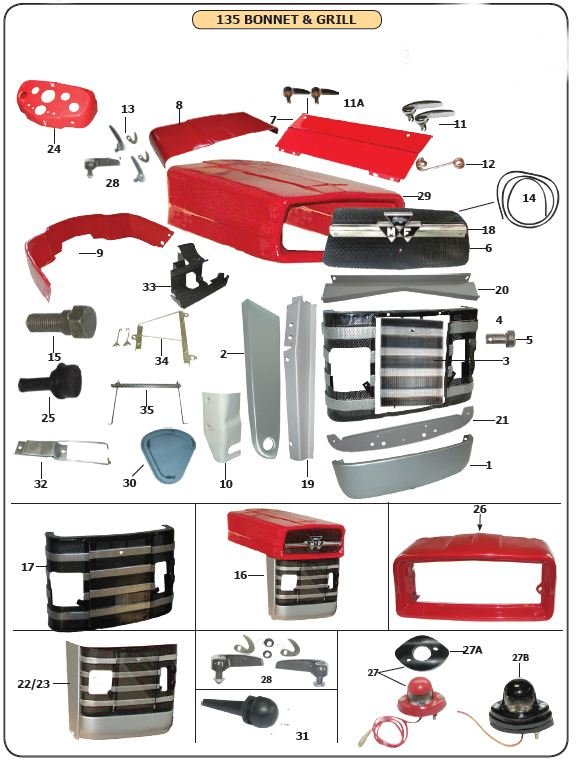

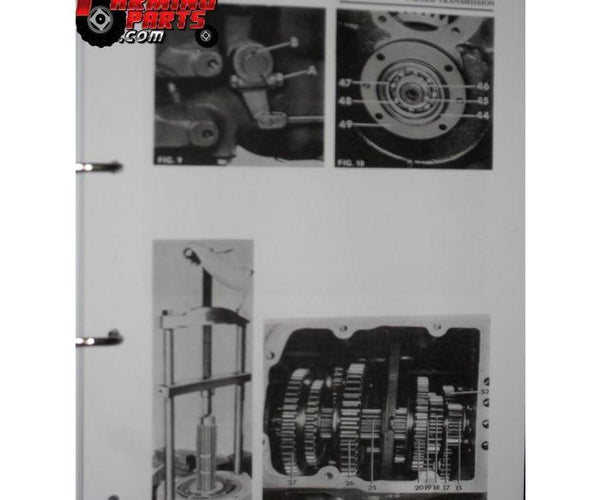

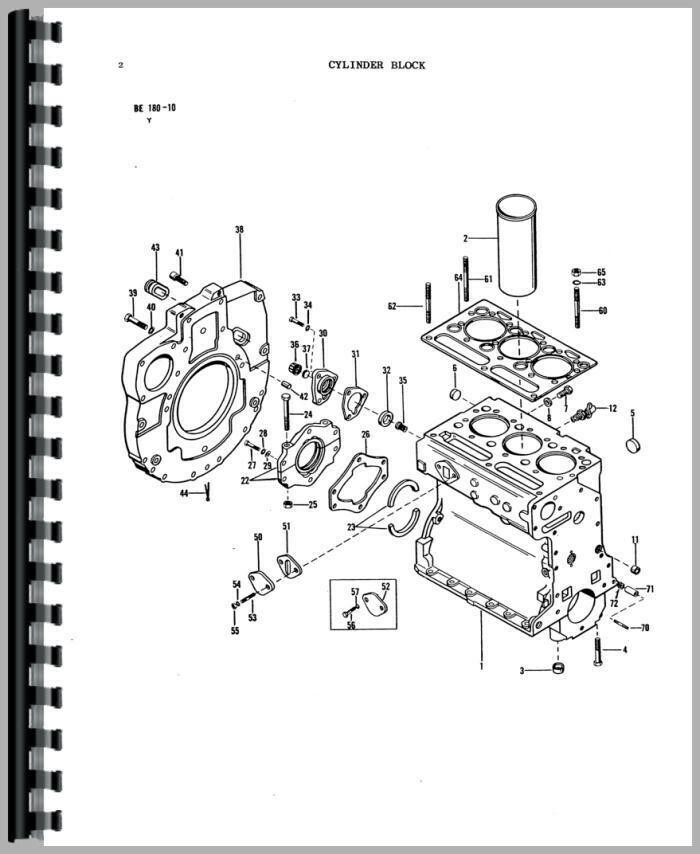

Part Identification and Authenticity

Accurate identification of Massey Ferguson 135 parts is critical to ensure compatibility and performance. Use official Massey Ferguson part numbers, serial numbers, and reference the MF 135 parts manual to verify specifications. When sourcing parts, prioritize OEM (Original Equipment Manufacturer) or certified aftermarket suppliers to maintain authenticity and reliability. Counterfeit or incorrectly specified parts can lead to equipment failure and safety hazards.

Regulatory Compliance

All parts must comply with relevant national and international regulations. In the European Union, ensure parts meet CE marking requirements. In the United States, verify compliance with EPA and DOT standards where applicable (e.g., for fuel system or lighting components). Documentation such as Certificates of Conformance (CoC) should accompany shipments to demonstrate regulatory adherence.

Import and Export Documentation

When shipping MF 135 parts across borders, prepare complete customs documentation, including commercial invoices, packing lists, and bills of lading. Accurately classify parts using the Harmonized System (HS) code—typically 8708.99 for agricultural machinery parts. Include country of origin and part descriptions to avoid delays. Be aware of import duties, tariffs, and trade restrictions in the destination country.

Packaging and Handling

Use robust, anti-corrosive packaging to protect parts during transit, especially for fragile or metal components prone to rust. Clearly label packages with part numbers, handling instructions (e.g., “Fragile,” “This Side Up”), and destination details. For vintage parts, include protective wrapping and desiccants to prevent moisture damage. Proper handling reduces the risk of damage and ensures parts arrive in working condition.

Storage Conditions

Store MF 135 parts in a dry, temperature-controlled environment to prevent degradation. Metal parts should be kept off the floor and away from moisture to avoid rust. Rubber and plastic components must be shielded from UV light and extreme temperatures to prevent cracking or warping. Organize inventory with clear labeling for easy retrieval and stock rotation.

Transportation and Carrier Selection

Choose reliable freight carriers experienced in handling agricultural parts. For international shipments, consider air freight for urgent needs or sea freight for bulk orders. Ensure parts are insured against loss or damage during transit. Track shipments in real time and maintain communication with carriers to manage delivery schedules effectively.

Environmental and Safety Compliance

Dispose of packaging materials and any obsolete or damaged parts in accordance with local environmental regulations. Follow safety protocols when handling heavy or sharp components, using proper lifting equipment and personal protective equipment (PPE). Maintain Material Safety Data Sheets (MSDS) for parts involving lubricants or hazardous substances.

Recordkeeping and Traceability

Maintain detailed records of all transactions, including purchase orders, shipping documents, compliance certificates, and supplier information. Traceability is essential for warranty claims, recalls, and audit purposes. Implement an inventory management system to track part usage, shelf life, and stock levels.

Supplier Verification and Due Diligence

Verify the legitimacy and reliability of suppliers through audits, certifications (e.g., ISO 9001), and customer reviews. Ensure suppliers comply with ethical sourcing practices and international trade laws. Regularly review supplier performance to maintain supply chain integrity.

By following this logistics and compliance guide, businesses and individuals can ensure the safe, legal, and efficient handling of Massey Ferguson 135 parts throughout the supply chain.

In conclusion, sourcing parts for the Massey Ferguson 135 tractor requires a combination of research, patience, and access to reliable resources. Given the model’s age and enduring popularity, a wide network of suppliers, both online and offline, specializes in MF 135 components. Reputable agricultural equipment dealers, online marketplaces, salvage yards, and tractor enthusiast forums are valuable sources for finding both new and used parts. It is crucial to verify part compatibility, assess the condition of used components, and prioritize quality to ensure longevity and optimal performance. Additionally, maintaining documentation and consulting service manuals can streamline the sourcing process. With careful planning and the right suppliers, keeping a Massey Ferguson 135 in working order remains a feasible and rewarding endeavor for classic tractor enthusiasts and working farmers alike.