The global mezzanine flooring market is experiencing robust growth, driven by increasing demand for space optimization in commercial and industrial facilities. According to Grand View Research, the global industrial flooring market—which includes mezzanine systems—was valued at USD 9.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is fueled by rising construction activities, warehouse modernization, and the booming e-commerce sector, which requires efficient vertical space utilization. Mezzanine floors, known for their flexibility and cost-effectiveness in expanding usable square footage without structural overhauls, are becoming a strategic solution across logistics, manufacturing, and retail sectors. As demand intensifies, a select group of manufacturers are leading innovation in modular design, load capacity, and installation efficiency—setting the benchmark in quality and performance. Below, we examine the top 10 mezzanine floor manufacturers shaping the future of modern industrial and commercial infrastructure.

Top 10 Mezzanine Floor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Mezzanine Floor Solutions

Domain Est. 2000

Website: pro-dek.co.uk

Key Highlights: Prodek’s industrial mezzanine floors offer an affordable solution for manufacturers and industries looking to avoid the costs of relocating premises….

#2 ResinDek

Domain Est. 2002

Website: resindek.com

Key Highlights: Manufacturer of ResinDek composite engineered mezzanine floor system is the choice for distribution centers and material handling. Call 888.755.3048….

#3 Mezzanine Manufacturers

Domain Est. 2012

Website: mezzaninemanufacturers.org

Key Highlights: Quickly locate the USA’s top mezzanine manufacturers and suppliers who produce industrial grade, steel modular platforms that can help maximize storage ……

#4 Mezzanine Floor Systems Manufacturer

Website: palladiumdynamics.com

Key Highlights: Rating 4.8 (47) Mezzanine Floor Manufacturer. Maximize your vertical space with our durable, modular mezzanine solutions for industrial, commercial, and retail applications….

#5 Mohawk Industries, Inc.

Domain Est. 1996

Website: mohawkind.com

Key Highlights: Mohawk is the world’s largest flooring company and so much more. With … A broad range of chipboard, MDF, melamine-faced, HPL panels and mezzanine ……

#6 Mezzanine Floors Manufacturers & Suppliers

Domain Est. 2000

Website: doity.com

Key Highlights: Doity Engineering is one of the UK’s leading mezzanine floor suppliers. Our team designs, manufactures and constructs mezzanine floors across the UK….

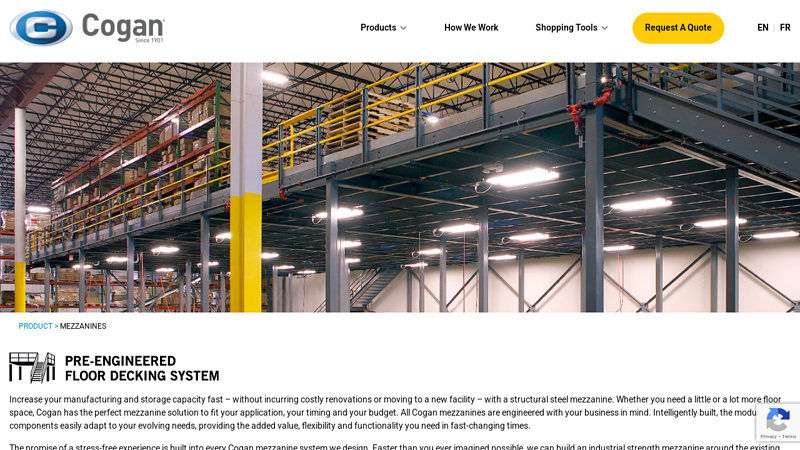

#7 Mezzanines and Work Platforms

Domain Est. 1995

Website: cogan.com

Key Highlights: Cogan has the perfect mezzanine solution to fit your application, your timing and your budget. All Cogan mezzanines are engineered with your business in mind….

#8 Mezzanine floor

Domain Est. 2000

Website: profielnorm.com

Key Highlights: We manufacture mezzanine floors with a floor load of up to 4,000 kg/m2. In which RAL colour would you like to have the mezzanine floor delivered? In this way, ……

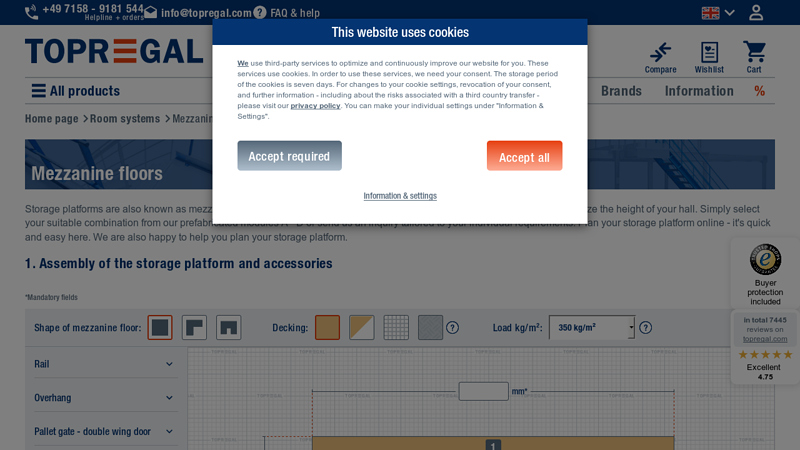

#9 Mezzanine floors

Domain Est. 2008

Website: topregal.com

Key Highlights: Storage platforms are also known as mezzanine floors, false ceilings or just mezzanines offer you an additional level to fully utilize the height of your hall….

#10 Mezzanine

Domain Est. 2023

Website: profielnorm-usa.com

Key Highlights: We design, manufacture, and install custom cold-formed mezzanines across the USA. Maximize your warehouse space with a strong, scalable steel mezzanine….

Expert Sourcing Insights for Mezzanine Floor

2026 Market Trends for Mezzanine Floors

The global mezzanine floor market is poised for substantial evolution by 2026, driven by shifting industrial demands, urbanization, and advancements in modular construction technologies. As businesses continue to prioritize space optimization and operational efficiency, mezzanine floors are increasingly being adopted across logistics, manufacturing, retail, and e-commerce sectors. This analysis explores key market trends expected to shape the mezzanine floor industry in 2026.

Rising Demand for Space Optimization in Warehousing and E-Commerce

One of the most influential drivers of the mezzanine floor market in 2026 is the exponential growth of e-commerce and last-mile delivery networks. With urban land costs rising and available warehouse space becoming scarce, companies are turning to vertical expansion as a cost-effective solution. Mezzanine floors allow businesses to double or even triple usable space within existing facilities without requiring relocation or new construction. By 2026, the integration of mezzanines in automated fulfillment centers and distribution hubs is expected to become standard practice, particularly in densely populated metropolitan areas.

Growth in Modular and Pre-Engineered Mezzanine Systems

The trend toward modular construction is significantly impacting the mezzanine floor market. Pre-engineered, bolt-together mezzanine systems offer rapid installation, minimal disruption to operations, and high reconfigurability—making them ideal for dynamic environments. By 2026, manufacturers are expected to focus on lightweight, high-strength materials such as structural steel and aluminum composites, further enhancing the appeal of modular designs. Customization capabilities, including integration with conveyors, racking, and office spaces, will be key differentiators among leading suppliers.

Sustainability and Green Building Standards

Sustainability is becoming a critical consideration in industrial and commercial construction. Mezzanine floors contribute to green building goals by extending the life cycle of existing structures and reducing the need for new builds, thereby lowering carbon footprints. In 2026, increased adoption of recycled materials and energy-efficient lighting and safety systems integrated into mezzanine designs will align with LEED, BREEAM, and other green certifications. Regulatory incentives and corporate sustainability targets are likely to accelerate this trend.

Technological Integration and Smart Mezzanines

The convergence of industrial automation and smart technologies is leading to the emergence of “smart mezzanines.” By 2026, advanced mezzanine systems are expected to incorporate IoT sensors for load monitoring, safety alerts, and environmental controls. Integration with warehouse management systems (WMS) and robotic process automation (RPA) will enable real-time tracking of inventory and workflow efficiency. These smart features will enhance safety, reduce maintenance costs, and improve operational decision-making, making intelligent mezzanine solutions highly desirable in high-tech facilities.

Regional Market Expansion

While North America and Europe remain dominant markets due to mature logistics infrastructures, the Asia-Pacific region is projected to witness the fastest growth in mezzanine floor adoption by 2026. Countries like China, India, and Vietnam are experiencing rapid industrialization and urban development, fueling demand for efficient storage and production layouts. Government initiatives supporting smart cities and industrial parks are expected to further stimulate investments in industrial mezzanine systems across emerging economies.

Customization and Multi-Functional Applications

Beyond storage and warehousing, mezzanine floors are increasingly being used for multi-functional purposes such as office spaces, training areas, and equipment platforms. By 2026, demand for aesthetically pleasing, architecturally integrated mezzanines in retail and mixed-use developments is expected to rise. Design flexibility, acoustic insulation, and compliance with building codes will be crucial for these applications, prompting manufacturers to offer tailored solutions that blend functionality with design.

Conclusion

By 2026, the mezzanine floor market will be shaped by a confluence of space constraints, technological innovation, and sustainability imperatives. As industries adapt to evolving logistical and operational challenges, mezzanine floors will transition from simple intermediate platforms to intelligent, integrated components of modern facilities. Companies that embrace customization, modular design, and digital integration will be best positioned to capitalize on the growing demand across global markets.

Common Pitfalls When Sourcing a Mezzanine Floor (Quality and Intellectual Property)

Sourcing a mezzanine floor involves more than just selecting a design and placing an order. Overlooking key quality and intellectual property (IP) aspects can lead to safety risks, legal complications, and costly delays. Below are common pitfalls to avoid:

Overlooking Structural Integrity and Certification

One of the most critical mistakes is failing to verify that the mezzanine floor design meets local building codes and structural safety standards. Some suppliers may offer attractive pricing but cut corners on materials or engineering. Always ensure the floor comes with certified load calculations, stamped engineering drawings, and compliance with standards such as BS EN 1090 (in Europe) or OSHA/IBC (in the US).

Ignoring Material Quality and Finish

Not all steel is created equal. Low-grade materials may corrode faster or fail under stress. Buyers should specify the required steel grade, coating (e.g., galvanized or powder-coated), and weld quality. Substandard finishes can lead to premature deterioration, especially in humid or industrial environments.

Accepting Generic or Non-Compliant Designs

Some suppliers use generic design templates that haven’t been adapted to the specific site conditions—such as floor loading, column spacing, or seismic requirements. Using a non-site-specific design risks instability and non-compliance. Always demand a site survey and a customized design report.

Failing to Verify Design Ownership and IP Rights

A major intellectual property pitfall arises when the design of the mezzanine floor is not clearly owned or licensed. If a supplier uses a patented or proprietary design without authorization, the end user could face legal exposure. Ensure the supplier either owns the design or has the right to use and transfer it. Request documentation confirming IP clearance, especially for modular or branded systems.

Assuming Design Responsibility Without Clarity

In many projects, it’s unclear who holds design responsibility—the supplier, installer, or client. If the supplier provides the design but isn’t a licensed engineer, this can invalidate insurance and compliance. Confirm that a qualified structural engineer has signed off on the design and that responsibility is contractually assigned.

Skipping As-Built Documentation

After installation, lacking accurate “as-built” drawings can complicate future modifications, audits, or property transfers. These documents should reflect real-world adjustments made during installation. Their absence may also breach regulatory or lease requirements.

Relying on Unverified Third-Party Manufacturers

When sourcing through brokers or online platforms, the actual manufacturer may be unknown or unvetted. This increases the risk of subpar fabrication and makes tracing IP or quality issues difficult. Conduct due diligence on both the supplier and the fabricator, including audits or site visits if possible.

By addressing these quality and IP-related pitfalls early, buyers can ensure a safe, compliant, and legally sound mezzanine floor installation.

Logistics & Compliance Guide for Mezzanine Floors

Understanding Mezzanine Floors: Definition and Purpose

A mezzanine floor is an intermediate level structure installed between the floor and ceiling of a building, typically in warehouses, distribution centers, and manufacturing facilities. It is designed to maximize vertical space utilization without requiring structural expansion. Mezzanines are commonly used for storage, office space, light assembly, or pick modules in logistics environments.

Regulatory Compliance Overview

Before installing a mezzanine floor, compliance with local building codes, fire safety regulations, and occupational health and safety standards is mandatory. Key regulatory frameworks include the International Building Code (IBC), Occupational Safety and Health Administration (OSHA) standards in the U.S., and the UK Building Regulations (e.g., Part A – Structure, Part B – Fire Safety). Always consult with local authorities to ensure adherence to jurisdiction-specific requirements.

Structural Requirements and Load Capacity

Mezzanine floors must be engineered to support anticipated loads, including static (racking, shelving) and dynamic (personnel, material handling equipment) forces. Load capacity should be clearly marked on the structure and calculated by a licensed structural engineer. Typical load ranges vary from 500 to 1,500 lbs per square foot, depending on application.

Fire Safety and Egress Compliance

Fire safety is critical in mezzanine installations. Compliance includes:

– Installation of fire-rated materials where required.

– Integration with existing fire suppression systems (e.g., sprinklers).

– Provision of at least two means of egress if the mezzanine is occupied by personnel.

– Clear signage and unobstructed access to emergency exits.

Access and Fall Protection

OSHA and similar safety bodies require guardrails, handrails, and toeboards on all open sides of mezzanines above 48 inches (1.2 meters). Stairways and ladders must meet code specifications for width, rise, run, and handrail placement. Personnel access points should be designed to accommodate safe movement of workers and materials.

Material Handling and Logistics Integration

Mezzanine floors should be seamlessly integrated into existing logistics workflows. Consider:

– Clearances for forklifts, pallet jacks, or conveyors.

– Placement of lifts or vertical conveyors for material transfer.

– Workflow optimization to reduce travel time and bottlenecks.

– Coordination with warehouse management systems (WMS) for inventory tracking.

Electrical and Utility Considerations

If the mezzanine includes office space or equipment, proper electrical wiring, lighting, HVAC, and data cabling must be installed in compliance with the National Electrical Code (NEC) or equivalent. All utilities should be routed safely and secured to avoid trip hazards or damage.

Permitting and Documentation

Most jurisdictions require building permits for mezzanine installations. Submit engineered drawings, load calculations, and fire safety plans to local authorities. Maintain documentation for inspections, certifications, and future audits. As-built drawings should be archived for facility management.

Maintenance and Inspections

Regular inspections are essential to ensure ongoing compliance and safety. Develop a maintenance schedule to check:

– Structural integrity (bolts, connections, decking).

– Guardrails and safety barriers.

– Fire protection systems.

– Flooring for wear, damage, or corrosion.

Document all inspections and address issues promptly.

Decommissioning and Relocation

If a mezzanine is to be removed or relocated, follow a structured decommissioning plan. Ensure safe dismantling procedures are followed, waste materials are disposed of properly, and the site is restored to its original condition if required. Relocated mezzanines must be re-certified for structural and safety compliance at the new site.

Conclusion

A well-planned mezzanine floor enhances warehouse efficiency and space utilization, but only when logistical and compliance requirements are strictly followed. Engage qualified engineers, adhere to safety standards, and maintain thorough documentation to ensure a safe, legal, and effective installation.

Conclusion for Sourcing a Mezzanine Floor

Sourcing a mezzanine floor is a strategic investment that can significantly enhance the functionality, efficiency, and capacity of your workspace without the need for relocation or costly building expansions. After evaluating various suppliers, design options, load requirements, and installation considerations, it is clear that selecting the right mezzanine floor involves balancing quality, cost, safety, and long-term adaptability.

Key factors such as structural integrity, compliance with local building regulations, ease of installation, and future scalability must be prioritized. Additionally, partnering with reputable suppliers who offer tailored solutions, professional installation services, and comprehensive after-sales support ensures a smooth implementation process and long-term satisfaction.

Ultimately, a well-sourced mezzanine floor not only optimizes vertical space but also supports operational growth, improves workflow, and delivers a strong return on investment. By carefully considering your specific operational needs and working with trusted industry professionals, you can successfully integrate a mezzanine floor that meets current demands and adapts to future business challenges.