The global market for metric all-thread rods—also known as fully threaded studs—is experiencing steady expansion, driven by growing demand across construction, automotive, and industrial manufacturing sectors. According to Grand View Research, the global threaded rod market was valued at USD 7.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increasing infrastructure development, rising urbanization, and the need for high-strength, standardized fastening solutions in modular and prefabricated construction. As precision and compliance with international standards like ISO and DIN become critical, manufacturers specializing in metric all-thread products are scaling production and enhancing quality control. In this evolving landscape, identifying leading suppliers with consistent output, material integrity, and global reach is essential for procurement professionals and project engineers. Based on market presence, production capacity, and technical compliance, we highlight the top six metric all-thread manufacturers shaping the industry.

Top 6 Metric All Thread Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Metric Threaded Rod

Domain Est. 1996

Website: nutty.com

Key Highlights: Free delivery over $100 30-day returnsPurchase Nutty’s metric threaded rods today — precision fastening in mechanical, construction, and custom fabrication projects with metric spe…

#2 Electronic Hardware Metric Product Lines by UNICORP Standoffs …

Domain Est. 1996

Website: unicorpinc.com

Key Highlights: UNICORP is a leader in manufacturing stock and custom electronic hardware, handles & precision fasteners used by leading companies in nearly every industry ……

#3 Threaded Rods, Studs & Pins

Domain Est. 1997

Website: metricmcc.com

Key Highlights: Metric & Multistandard is proud to offer the most comprehensive range of metric threaded rod, studs and pins in the US….

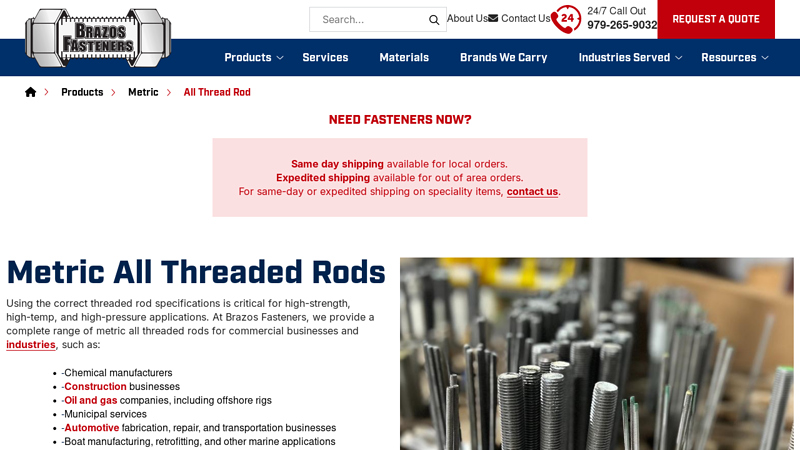

#4 Metric All Threaded Rods

Domain Est. 2006

Website: brazosfasteners.com

Key Highlights: A metric threaded rod supplier with a huge range of sizes. Choose from endless diameter, length, and thread pitch options for metric all threaded rods….

#5 Metric Threaded Products

Domain Est. 2010

Website: metric-threaded.com

Key Highlights: Metric Threaded Products — a Master Distributor in Metric Fasteners ; Hex Head Products. HCS ; Socket Head Products. Socket ; 12 Point Flange Bolt. 12Point ; Nut….

#6 Metric Threaded Products

Domain Est. 2010

Website: dev.metric-threaded.com

Key Highlights: Metric Threaded Products — a Master Distributor in Metric Fasteners ; Hex Head Products. HCS ; Socket Head Products. Socket ; 12 Point Flange Bolt. 12Point ; Nut….

Expert Sourcing Insights for Metric All Thread

H2: Projected Market Trends for Metric All Thread in 2026

The global market for Metric All Thread rod is expected to experience steady growth and notable shifts by 2026, driven by industrial expansion, infrastructure development, and evolving manufacturing standards. As a foundational fastener product used across construction, automotive, machinery, and renewable energy sectors, Metric All Thread rods will continue to benefit from rising demand in both mature and emerging economies. Below are key trends anticipated to shape the market landscape in 2026:

1. Rising Infrastructure Investment

Governments worldwide, particularly in Asia-Pacific, the Middle East, and parts of Africa, are prioritizing large-scale infrastructure projects—including transportation networks, urban development, and public utilities. These initiatives will significantly boost demand for durable fastening solutions like Metric All Thread rods, especially those compliant with international standards (e.g., ISO 898-1). The emphasis on seismic resilience and sustainable construction will further drive preference for high-tensile, corrosion-resistant variants.

2. Growth in Renewable Energy Sector

The renewable energy industry—especially solar photovoltaic (PV) mounting systems and wind turbine foundations—relies heavily on Metric All Thread rods for structural support and adjustability. As the global push toward clean energy accelerates under climate commitments, installations of solar farms and offshore wind projects are expected to surge, increasing demand for metric-threaded rods in customized lengths and grades (e.g., A4-80 stainless steel for coastal environments).

3. Advancements in Material Technology

By 2026, manufacturers are anticipated to expand offerings of high-performance alloys and coated products to meet stringent environmental and load-bearing requirements. Innovations such as duplex stainless steels, ceramic-based anti-corrosion coatings, and smart threads integrated with IoT sensors for structural health monitoring may begin to enter niche markets, especially in aerospace and critical infrastructure.

4. Regional Market Shifts and Supply Chain Localization

Geopolitical dynamics and supply chain resilience concerns will prompt a shift toward regional production hubs. Countries like India, Vietnam, and Mexico are likely to emerge as key manufacturing centers, reducing dependency on traditional exporters such as China. This localization trend will support faster delivery times and compliance with regional regulations, including carbon footprint disclosures and recycled material usage.

5. Standardization and Regulatory Compliance

Harmonization of metric fastener standards across international markets will continue, driven by organizations like ISO and CEN. By 2026, stricter traceability, certification (e.g., CE, UKCA, INMETRO), and testing protocols are expected to become mandatory, especially for use in safety-critical applications. This will raise the barrier to entry for low-cost, non-compliant producers and favor established suppliers with robust quality management systems.

6. Sustainability and Circular Economy Pressures

Environmental regulations and corporate ESG (Environmental, Social, and Governance) goals will push manufacturers to adopt greener production methods. Increased use of recycled steel, energy-efficient manufacturing processes, and lifecycle assessment reporting will become competitive differentiators. Buyers in construction and industrial sectors will increasingly prioritize suppliers with verified sustainable practices.

7. Digitalization and E-Commerce Expansion

The B2B procurement landscape for fasteners will continue shifting online, with platforms offering real-time inventory, CAD integration, and automated reordering. By 2026, digital marketplaces and AI-driven inventory management tools will enhance supply chain transparency and responsiveness, particularly for customized or just-in-time delivery needs.

Conclusion

By 2026, the Metric All Thread market will be shaped by a confluence of infrastructural demand, technological innovation, and sustainability imperatives. Companies that invest in product diversification, compliance, and digital engagement will be best positioned to capitalize on emerging opportunities across global markets.

Common Pitfalls Sourcing Metric All Thread Rods (Quality, IP)

Sourcing Metric All Thread Rods—especially with specific quality grades and International Procurement (IP) considerations—can present several challenges. Being aware of these pitfalls helps ensure you receive reliable, compliant, and fit-for-purpose fasteners. Below are key issues to watch for:

Poor Material and Quality Control

One of the most frequent problems is receiving rods that do not meet the specified material or mechanical properties. Suppliers, particularly low-cost overseas vendors, may claim compliance with standards like ISO 898-1 (e.g., Grade 8.8 or 10.9) but deliver substandard products. This can result in inconsistent tensile strength, poor ductility, or inadequate heat treatment.

Mitigation: Require certified mill test reports (MTRs), conduct third-party testing, and work with reputable suppliers who adhere to ISO 9001 or equivalent quality systems.

Inaccurate or Inconsistent Thread Quality

All thread rods require uniform thread geometry along their entire length. Poor threading—such as rolled threads with splits, inconsistent pitch, or undersized threads—can compromise nut engagement and structural integrity.

Mitigation: Specify thread tolerance class (e.g., 6g per ISO 965), inspect samples, and perform go/no-go gauge testing.

Misrepresentation of International Standards Compliance

Some suppliers incorrectly label products as compliant with ISO, DIN, or ASTM standards without proper certification. This is especially common when sourcing from regions with less stringent regulatory oversight.

Mitigation: Verify compliance through documentation, audit suppliers, and use independent inspection services when sourcing internationally.

Lack of Traceability and Certification

In regulated industries (e.g., construction, oil & gas, infrastructure), full traceability is essential. Rods without proper heat lot traceability, material certifications, or test reports can lead to project delays or rejection during quality audits.

Mitigation: Require full documentation packages including MTRs, COC (Certificate of Conformity), and heat numbers marked on packaging or rods.

Coating and Corrosion Protection Deficiencies

If rods require corrosion resistance (e.g., galvanized, zinc-plated, or duplex coated), inconsistent or substandard coatings are a common issue. Thin or uneven coatings fail prematurely in harsh environments.

Mitigation: Specify coating type and thickness (e.g., ISO 1461 for hot-dip galvanizing), and verify through salt spray testing or coating thickness gauges.

Dimensional Inaccuracies

Length tolerances, straightness, and diameter consistency are critical. Off-spec rods can interfere with assembly, anchoring, or fit within pre-drilled holes.

Mitigation: Define acceptable tolerances per ISO 9624 or project specifications, and inspect incoming goods against these standards.

Supply Chain and Lead Time Risks

International procurement introduces logistics risks—delays, customs issues, or communication gaps—that can disrupt project timelines.

Mitigation: Build lead time buffers, choose suppliers with proven logistics capabilities, and maintain clear communication throughout the sourcing process.

Counterfeit or Gray Market Goods

In global markets, counterfeit fasteners or diverted stock may enter the supply chain, undermining quality and safety.

Mitigation: Source directly from authorized distributors or manufacturers, avoid suspiciously low prices, and verify supplier credentials.

By proactively addressing these pitfalls, procurement teams can ensure reliable performance, regulatory compliance, and long-term cost savings when sourcing Metric All Thread Rods.

Logistics & Compliance Guide for Metric All Thread

Product Overview

Metric All Thread refers to fully threaded fasteners with a continuous thread along the entire length of the rod, manufactured to metric standards (e.g., M6, M8, M10). These rods are commonly made from materials such as carbon steel, stainless steel (A2/A4), or alloy steel and conform to international standards like ISO 901, ISO 4014, or DIN 975. Their primary applications include construction, machinery, automotive, and infrastructure.

Packaging & Labeling Requirements

- Packaging: Metric All Thread rods must be packaged to prevent corrosion, bending, or thread damage. Common methods include shrink-wrapping, bundling with protective end caps, and boxing in moisture-resistant materials.

- Labeling: Each package must include:

- Product designation (e.g., M10 x 1000 mm)

- Material grade (e.g., 8.8, A2-70)

- Manufacturer or supplier name

- Batch/lot number

- Quantity and total weight

- Compliance marks (e.g., CE, UKCA if applicable)

- Country of origin

International Shipping & Handling

- Transportation: Use palletized loads secured with strapping or stretch wrap. Overhang should be minimized to avoid damage. Avoid exposure to moisture during transit.

- Customs Documentation: Ensure shipping documents include:

- Commercial invoice with HS Code (e.g., 7318.15 for threaded rods)

- Packing list

- Certificate of Origin

- Material Test Report (MTR), if required

- Incoterms: Clearly specify terms (e.g., FOB, CIF) to determine responsibility for logistics and risk transfer.

Regulatory Compliance

- CE Marking (EU): Required for construction and structural applications. Must comply with EN 14399 or EN 15048, depending on use. Technical documentation and Declaration of Performance (DoP) must be available.

- UKCA Marking (UK): Required post-Brexit for products placed on the UK market; similar requirements to CE.

- RoHS/REACH (EU): Ensure materials do not contain restricted substances, especially for coated or plated rods.

- ITAR/EAR (USA): Generally not applicable unless used in defense applications. Verify if export-controlled.

Quality & Certification Standards

- ISO 898-1: Mechanical properties of fasteners made of carbon steel and alloy steel.

- ISO 3506: Corrosion-resistant stainless steel fasteners.

- DIN 975: German standard for metric all-thread rods.

- Material Test Reports (MTRs): Must be provided per batch, certifying chemical composition and mechanical properties.

- Third-Party Testing: Recommended for high-integrity applications (e.g., structural, seismic).

Storage & Inventory Management

- Store in a dry, indoor environment to prevent rust and corrosion.

- Keep rods off the ground using pallets or racks.

- Segregate by size, grade, and material to avoid mix-ups.

- Implement FIFO (First In, First Out) inventory practices.

- Inspect periodically for thread damage or corrosion.

Environmental & Safety Considerations

- Use appropriate PPE (gloves, eye protection) during handling due to sharp threads and edges.

- Recycle packaging materials where possible.

- Dispose of any oil or protective coatings in accordance with local environmental regulations.

- Ensure compliance with OSHA (USA) or equivalent local workplace safety standards.

Returns & Non-Conformance Handling

- Define a clear process for handling damaged or non-compliant shipments.

- Require documented evidence (photos, inspection reports) for return authorization.

- Quarantine non-conforming products and initiate root cause analysis with suppliers.

- Maintain records for traceability and audit purposes.

Key Documentation Checklist

- Certificate of Compliance (CoC)

- Material Test Report (MTR)

- Declaration of Performance (DoP) – for CE/UKCA

- Safety Data Sheet (SDS) – if coated or treated

- Packing list and commercial invoice

- Bill of Lading / Air Waybill

Adhering to this guide ensures efficient logistics, regulatory compliance, and product integrity throughout the supply chain for Metric All Thread rods.

Conclusion for Sourcing Metric All Thread:

In summary, the “Sourcing Metrics All Thread” analysis highlights the critical importance of a comprehensive and data-driven approach to talent acquisition. By tracking key sourcing metrics—such as time-to-fill, source quality, candidate conversion rates, cost-per-hire, and diversity sourcing effectiveness—organizations can gain valuable insights into the efficiency and impact of their recruitment channels and strategies.

The discussion underscores that no single metric provides a complete picture; instead, a holistic view across the sourcing funnel enables talent teams to identify high-performing channels, optimize resource allocation, and improve overall hiring outcomes. Furthermore, leveraging these metrics fosters continuous improvement, supports strategic decision-making, and aligns sourcing efforts with broader organizational goals.

Ultimately, consistent measurement, cross-functional collaboration, and the use of analytics are essential to building a robust and agile sourcing function. Organizations that prioritize and refine their sourcing metrics are better positioned to attract top talent, reduce hiring cycles, and maintain a competitive edge in the talent market.