The global metal cabinet market is experiencing steady expansion, driven by increasing demand across commercial, industrial, and residential sectors. According to Grand View Research, the global storage cabinets market size was valued at USD 13.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This growth is fueled by rising infrastructure development, expanding healthcare facilities, and the need for organized storage solutions in industrial environments. Additionally, Mordor Intelligence projects a continued uptick in demand, particularly in emerging economies, where urbanization and industrialization are accelerating the need for durable, fire-resistant, and secure storage systems. As sustainability and modular design gain traction, leading manufacturers are innovating with lightweight materials, improved corrosion resistance, and smart cabinet technologies. In this evolving landscape, selecting the right metal cabinet supplier is critical for performance, compliance, and long-term value. Here’s a data-driven look at the top 10 metal cabinet manufacturers shaping the industry in 2024.

Top 10 Metalcabinet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hammond Manufacturing

Domain Est. 1996

Website: hammfg.com

Key Highlights: Hammond Manufacturing is a leading manufacturer of industrial enclosures, electronic enclosures, racks & rack cabinets, transformers, outlet strips and ……

#2 Industrial & Commercial Metal Cabinets, Benchs, Carts & Trucks

Domain Est. 2002

Website: metalcabinetstore.com

Key Highlights: Discover a variety of industrial and commercial metal cabinets, workbenches and carts/trucks at Metal Cabinet Store. Top brands for storage solutions, work…

#3 Steel Cabinets USA

Domain Est. 2016

Website: steelcabinetsusa.com

Key Highlights: All cabinets are produced at our factory in Brownsville, Tennessee with quality American-made steel, powder coat paint, and heavy duty casters….

#4 JW Metal Cabinets

Domain Est. 2019

Website: jwmetalcabinets.com

Key Highlights: We specialize in designing and manufacturing world-class metal cabinets for kitchens, outdoor spaces, industrial settings, and laboratories….

#5 Durham Manufacturing

Domain Est. 1996

Website: durhammfg.com

Key Highlights: Durham MFG has the ability to ship your products from the US to anywhere in the world. Let us know how we can help you, help your customers worldwide….

#6 Custom Metal Enclosures

Domain Est. 1997

Website: bullmetal.com

Key Highlights: Certified ISO 9001:2015 – Specializing in custom manufacturing of metal enclosures, metal cases, metal cabinets, electrical enclosures, and metal toolboxes….

#7 Cabinets

Domain Est. 1997

Website: edsal.com

Key Highlights: Ready-to-Assemble Storage Cabinets, Heavy Duty Welded Steel Flammable Safety Cabinets, Heavy Duty Welded Steel Flammable Safety Cabinets….

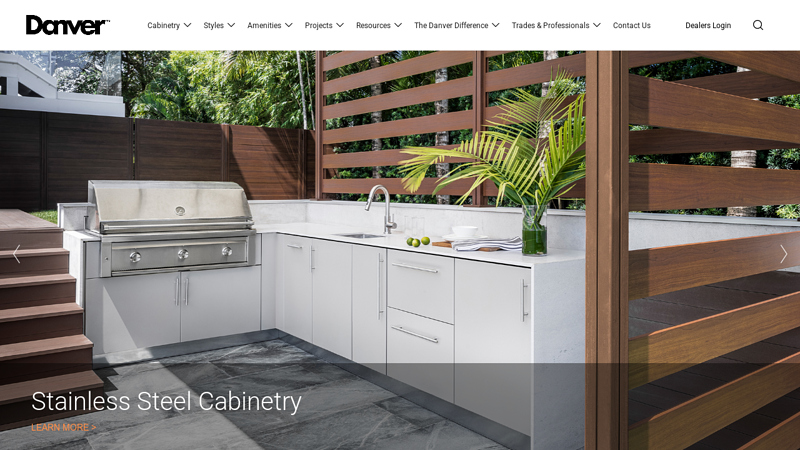

#8 Luxury Stainless Steel Outdoor Kitchens & Cabinets

Domain Est. 1998

Website: danver.com

Key Highlights: Danver is the leader in stainless steel outdoor kitchen cabinets. Make outdoor living a part of every home with the best luxury outdoor kitchens. Call Us!…

#9 Art Metal Products

Domain Est. 2000

Website: artmetalproducts.com

Key Highlights: LOCKERS, CABINETS, SHELVING … We have the perfect storage solution for your space. No matter your environment – school, office, gym, arena, indoor or outdoor, ……

#10 Metal Cabinet Suppliers

Domain Est. 2001

Website: sheet-metal-fabrication.com

Key Highlights: Discover top metal cabinet companies in the USA for quality products, fast delivery, and cutting-edge manufacturing, saving you time and money….

Expert Sourcing Insights for Metalcabinet

H2 2026 Market Trends for Metal Cabinet Industry

The metal cabinet market in H2 2026 is poised for continued evolution, shaped by technological advancements, shifting end-user demands, and macroeconomic factors. Key trends indicate growth in specific segments, heightened competition, and an increasing emphasis on sustainability and customization.

1. Rising Demand in Industrial & Commercial Sectors

H2 2026 sees sustained demand from manufacturing, logistics, and data centers. The expansion of automated warehouses and Industry 4.0 infrastructure drives need for robust, modular metal cabinets for machinery housing, control panels, and server racks. Growth in renewable energy projects (solar/wind) also fuels demand for outdoor-rated electrical enclosures.

2. Surge in Smart & Connected Cabinets

Integration of IoT sensors and smart monitoring systems into metal cabinets is accelerating. In data centers and telecom, cabinets with built-in temperature, humidity, and intrusion sensors are becoming standard. This trend supports predictive maintenance and remote management, appealing to enterprise clients prioritizing uptime and efficiency.

3. Sustainability as a Competitive Differentiator

Environmental regulations and corporate ESG goals are pushing manufacturers toward sustainable practices. Key developments include:

– Increased use of recycled steel and aluminum.

– Adoption of low-VOC powder coatings and eco-friendly finishes.

– Design for disassembly and end-of-life recyclability.

– Energy-efficient manufacturing processes (e.g., solar-powered plants).

Companies showcasing green credentials are gaining favor in public tenders and B2B procurement.

4. Customization and Modular Design

Off-the-shelf solutions are giving way to configurable and modular cabinet systems. Customers—particularly in healthcare, education, and high-tech industries—seek cabinets tailored to specific space, load, and aesthetic requirements. 3D modeling and digital configurators are enabling faster quoting and design iteration.

5. Supply Chain Resilience and Regionalization

Ongoing geopolitical tensions and logistics volatility have prompted a shift toward nearshoring and regional supply chains. North American and European manufacturers are investing in local production to reduce lead times and mitigate risks. This benefits regional metal cabinet suppliers able to offer shorter delivery cycles.

6. Labor and Automation Challenges

The industry faces persistent skilled labor shortages, especially in welding and finishing. In response, investment in robotic fabrication, automated powder coating lines, and AI-driven quality control is rising. Automation improves consistency and lowers long-term costs but requires significant capital investment.

7. Competitive Pricing Pressure

Despite rising input costs (steel, energy), price competition remains intense due to global overcapacity and economic uncertainty. Differentiation through value-added services—such as design support, installation, and lifecycle management—is becoming essential to maintain margins.

8. Growth in Hybrid and Lockable Storage Solutions

In commercial and institutional settings (schools, offices, gyms), demand for secure, multi-functional metal storage is increasing. Smart lock integration (RFID, keypad, app-based) and hybrid designs combining metal with wood or laminate fronts are gaining traction, blending durability with aesthetics.

Conclusion:

In H2 2026, success for metal cabinet manufacturers hinges on agility, innovation, and sustainability. Companies that embrace smart technology, modular design, and eco-conscious production—while strengthening regional supply chains—will be best positioned to capture market share in an increasingly competitive and specialized landscape.

Common Pitfalls When Sourcing Metal Cabinets (Quality and IP Rating)

Sourcing metal cabinets—especially for electrical enclosures, industrial equipment, or outdoor applications—requires careful attention to both build quality and Ingress Protection (IP) ratings. Overlooking these aspects can lead to product failure, safety hazards, or costly field replacements. Below are common pitfalls to avoid:

Inadequate IP Rating for the Environment

One of the most frequent mistakes is selecting a cabinet with an IP rating that doesn’t match the operating environment. For example, using an IP54-rated cabinet in a washdown area requiring IP66 or higher can result in water and dust ingress, leading to corrosion or electrical faults. Always match the IP rating to real-world conditions, considering exposure to moisture, dust, chemicals, and hose-directed water.

Poor Material Quality and Thickness

Low-cost suppliers may use thinner gauge steel or substandard materials to cut costs. This compromises structural integrity, reduces durability, and increases susceptibility to denting or warping. Insufficient corrosion protection (e.g., inadequate powder coating or lack of galvanization) can also lead to premature rusting, especially in humid or outdoor settings.

Inconsistent or Unverified IP Certification

Some suppliers claim high IP ratings without third-party testing or certification. Relying on self-declared ratings is risky. Always request test reports or certification from recognized bodies (e.g., IEC 60529 compliance) to verify that the cabinet’s IP rating is genuine and consistently maintained across production batches.

Poor Sealing and Gasket Design

Even cabinets with high IP ratings can fail if gaskets are poorly designed, incorrectly installed, or made from low-quality materials that degrade over time. Compression inconsistencies, gaps around doors, or non-uniform sealing pressure can compromise protection, especially after repeated door openings or temperature fluctuations.

Overlooking Door and Hinge Durability

Frequent access can strain hinges and latches. Low-quality hinges may sag or fail, breaking the door seal and reducing effective IP protection. Ensure hinges are robust, tamper-resistant (if needed), and designed to maintain alignment and compression on the gasket over the cabinet’s lifetime.

Ignoring Internal Component Clearance and Ventilation

Overpacking components or failing to account for heat buildup can lead to overheating, even in a well-sealed cabinet. While ventilation may seem at odds with high IP ratings, improperly designed vents (e.g., non-IP-rated) can become entry points for contaminants. Use filtered vents or pressurization systems rated for the target IP level.

Lack of Traceability and Supplier Vetting

Sourcing from unqualified or unknown suppliers increases the risk of receiving counterfeit or non-compliant products. Conduct thorough supplier audits, request material certifications, and perform incoming quality inspections to ensure consistency and compliance.

Assuming All “Metal” Cabinets Are Equal

Not all metals offer the same performance. Mild steel, stainless steel, and aluminum each have different strengths, corrosion resistance, and suitability for specific environments. Choosing the wrong material—such as mild steel in a coastal area—can lead to rapid degradation despite a high initial IP rating.

By addressing these pitfalls during the sourcing process, you can ensure that metal cabinets meet both quality and environmental protection requirements, reducing long-term maintenance and failure risks.

Logistics & Compliance Guide for Metal Cabinet Shipments

This guide outlines key logistics and compliance considerations when shipping metal cabinets to ensure safe, timely, and regulation-compliant delivery.

Packaging & Handling Requirements

Metal cabinets must be securely packaged to prevent damage during transit. Use wooden crates or heavy-duty corrugated cardboard with internal bracing to protect edges and surfaces. Apply protective corner guards and plastic wrapping to prevent scratches and corrosion. Clearly label packages with “Fragile,” “This Side Up,” and weight indicators. Ensure all cabinets are dry and free from moisture before packaging to avoid mold or rust.

Transportation Modes & Carrier Selection

Choose transportation methods based on shipment size, destination, and urgency. For domestic shipments, LTL (Less Than Truckload) or full truckload freight are common. International shipments may require ocean container or air freight. Work with carriers experienced in handling industrial metal goods. Confirm that carriers provide liftgate service if dock facilities are unavailable at delivery points.

Domestic Regulatory Compliance (U.S.)

Ensure compliance with U.S. Department of Transportation (DOT) regulations for freight classification, weight limits, and hazardous materials (if applicable). Most metal cabinets fall under NMFC code 308050 (Metal Cabinets and Shelving). Use proper Bill of Lading documentation and adhere to FMCSA safety standards for load securement. Verify state-specific requirements for overweight or oversized loads.

International Shipping & Customs Clearance

For cross-border shipments, prepare accurate commercial invoices, packing lists, and certificates of origin. Classify products using correct HS (Harmonized System) codes—typically 7322.90 for metal storage cabinets. Comply with import regulations in the destination country, including safety and environmental standards. Account for tariffs, duties, and potential anti-dumping measures on steel products.

Safety & Environmental Standards

Metal cabinets must meet relevant safety certifications, such as OSHA standards for workplace storage or UL listings for electrical enclosures. Confirm compliance with environmental regulations like REACH (EU) or TSCA (U.S.) regarding restricted substances in coatings or materials. Provide Safety Data Sheets (SDS) if hazardous finishes are used.

Documentation & Recordkeeping

Maintain detailed records of all shipping documents, compliance certifications, and inspection reports. Include proof of insurance, customs filings, and carrier agreements. Retain records for a minimum of five years to support audits or dispute resolution.

Returns & Reverse Logistics

Establish a clear process for handling damaged or incorrect shipments. Require photographic documentation upon delivery and a formal return authorization (RA) process. Use the original packaging for returns when possible to minimize additional damage. Track reverse shipments and update inventory systems promptly.

By adhering to this logistics and compliance guide, Metalcabinet can ensure reliable delivery, regulatory adherence, and customer satisfaction across all markets.

In conclusion, sourcing metal cabinets requires a strategic approach that balances cost, quality, durability, and supplier reliability. It is essential to evaluate potential suppliers based on their manufacturing capabilities, adherence to industry standards, lead times, and after-sales support. Conducting thorough due diligence—such as requesting samples, verifying certifications, and performing site visits—can significantly reduce risks associated with quality inconsistencies or supply chain disruptions. Additionally, considering factors like customization options, logistics, and total cost of ownership ensures that the selected metal cabinets meet both operational requirements and long-term objectives. By establishing strong partnerships with reputable suppliers and maintaining clear communication, businesses can secure reliable, high-performance metal cabinet solutions that support efficiency, safety, and scalability across their operations.