The global metal fencing market is experiencing steady growth, driven by increasing demand for durable and secure perimeter solutions across residential, commercial, and industrial sectors. According to Grand View Research, the global metal fencing market size was valued at USD 54.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by rising infrastructure development, urbanization, and a growing preference for low-maintenance, long-lasting fencing materials—particularly in regions like North America and Europe where white metal fences remain a popular aesthetic and functional choice. With heightened focus on security and property demarcation, the demand for high-quality metal white fence manufacturers has surged, leading to increased competition and innovation in materials such as aluminum and steel with powder-coated white finishes. In this evolving landscape, identifying manufacturers that combine durability, design, and scalability becomes critical. Here’s a data-driven look at the top 10 metal white fence manufacturers shaping the industry today.

Top 10 Metal White Fence Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Master Halco

Domain Est. 1996

Website: masterhalco.com

Key Highlights: Master Halco is your leading manufacturer and wholesale distributor of fencing & decking products across the US and Canada….

#2 Aluminum Fence

Domain Est. 1998

Website: ultrafence.com

Key Highlights: Our complete line of low-maintenance aluminum fencing products brings the traditional look of wrought-iron fence to Residential, Commercial and Industrial ……

#3 Ornamental Metal Fence

Domain Est. 1996

#4 Ametco Manufacturing

Domain Est. 1996

Website: ametco.com

Key Highlights: Ametco manufactures a wide range of steel fence and security gate systems as well as railings, sunshades, grilles, screens, louvers and perforated metal and ……

#5 Jerith

Domain Est. 1997

Website: jerith.com

Key Highlights: We manufacture aluminum fences for homes and businesses. Whether you need to meet pool codes, secure a property on the coast or keep your family and pets safe….

#6 Atlantic Fence Supply

Domain Est. 2001

Website: afsfence.com

Key Highlights: Broad range of fencing from wood to vinyl and chain link supplies. We also distribute fence accessories, railings, gates, kennels and hardware….

#7 Residential Grade Aluminum Fencing

Domain Est. 2001

Website: elitefence.com

Key Highlights: Our residential grade aluminum fencing is an excellent choice for security and protection while still being the perfect neighbor friendly aluminum fence….

#8 SPSFence.com

Domain Est. 2001

Website: spsfence.com

Key Highlights: HOME; PRODUCTS. Pipe and Tube · Chain Link Fabric · Ornamental · Square Tube · Hardware · Access Control · Alum Chain Link · Gates · Aluminum Gates ……

#9 Fence Depot

Domain Est. 2002

Website: fence-depot.com

Key Highlights: We sell aluminum fence, wrought iron fence, and more directly to homeowners and contractors who are looking for high quality fence, railing and gate products ……

#10

Domain Est. 2014

Website: ameristarperimeter.com

Key Highlights: We provide Fence & Security Solutions to protect what matters most. From the quality of materials, American made manufacturing, and the largest support team ……

Expert Sourcing Insights for Metal White Fence

H2: Projected 2026 Market Trends for Metal White Fences

The global market for metal white fences is poised for steady growth through 2026, driven by evolving consumer preferences, advancements in materials, and increased demand in both residential and commercial sectors. Several key trends are expected to shape the industry landscape in the coming years.

-

Rising Demand in Residential Construction

With the global housing market rebounding post-pandemic, especially in North America and parts of Asia-Pacific, homeowners are increasingly investing in durable and aesthetically pleasing fencing solutions. Metal white fences—particularly those made from aluminum or powder-coated steel—offer a blend of elegance, low maintenance, and longevity, making them a preferred choice for modern home exteriors. The crisp, clean appearance of white complements contemporary architectural styles, fueling adoption in suburban and urban developments. -

Growth in Smart and Decorative Fencing

By 2026, integration with smart home technologies is expected to influence fencing design. While not yet widespread, some manufacturers are exploring white metal fences with built-in lighting, surveillance compatibility, or automated gate systems. Additionally, decorative patterns and custom laser-cut designs in white finishes are gaining popularity, especially in high-end residential and hospitality projects. -

Sustainability and Eco-Friendly Materials

Environmental concerns are prompting manufacturers to adopt sustainable production practices. Recyclable aluminum white fences are gaining traction due to their corrosion resistance, lightweight nature, and minimal environmental footprint. Powder coating technology, which provides durable, fade-resistant white finishes without harmful VOCs, is becoming standard, aligning with green building certifications like LEED. -

Expansion in Commercial and Urban Applications

Beyond homes, metal white fences are being used in urban parks, schools, healthcare facilities, and retail complexes. Municipalities are increasingly specifying white metal fencing for public infrastructure projects due to its clean appearance and vandal resistance. This trend is particularly strong in Europe and parts of North America, where urban beautification initiatives are on the rise. -

Influence of E-Commerce and Direct-to-Consumer Models

Online platforms are transforming how metal fences are marketed and sold. By 2026, more consumers are expected to purchase pre-fabricated white metal fence panels through e-commerce channels, supported by augmented reality (AR) tools that allow visualization in their own spaces. This shift is reducing distribution costs and enabling faster installation, appealing to DIY homeowners. -

Competitive Pricing and Regional Manufacturing Shifts

While raw material costs (especially steel and aluminum) remain volatile, manufacturers are optimizing supply chains and investing in regional production hubs to reduce costs. Countries like Vietnam, India, and Mexico are emerging as key production centers, offering cost-effective alternatives without compromising on quality—benefiting global export markets.

In conclusion, the 2026 market for metal white fences will be defined by aesthetic appeal, technological integration, and sustainability. As urbanization continues and design-conscious consumers seek long-term, stylish solutions, metal white fencing is expected to maintain strong growth across residential, commercial, and public sectors worldwide.

Common Pitfalls When Sourcing Metal White Fence (Quality, IP)

Sourcing metal white fences—especially those requiring high quality and specific Ingress Protection (IP) ratings—can present several challenges. Buyers often encounter issues related to material quality, finish durability, compliance, and misinterpretation of IP ratings. Below are the most common pitfalls to watch out for:

Poor Material Quality and Thickness

One of the most frequent issues is receiving fences made from substandard metal. Low-grade steel or aluminum with inadequate thickness can compromise structural integrity and lifespan. Always verify the gauge or thickness specifications and request material certifications. Thin or weak metals may bend easily, rust prematurely, or fail under environmental stress.

Inconsistent or Low-Durability Powder Coating

A white finish may look pristine initially, but poor-quality powder coating can fade, chalk, or chip within months—especially in direct sunlight or harsh weather. Ensure the fence uses UV-resistant, high-quality powder coating with proper pre-treatment (e.g., zinc phosphating). Ask for accelerated weathering test reports (QUV or salt spray tests) to verify durability.

Misunderstanding IP Ratings

Ingress Protection (IP) ratings are often misunderstood when sourcing metal fencing. IP ratings apply primarily to electrical enclosures and do not typically govern structural fencing. However, if the fence includes integrated lighting, access control systems, or electrical components, ensure the IP rating (e.g., IP65) applies to those parts—not the entire fence. Assuming the whole fence has a certain IP protection can lead to incorrect expectations.

Lack of Corrosion Resistance

Even with a white coating, metal fences can corrode if the base material isn’t corrosion-resistant or if the coating is poorly applied. Galvanized steel underneath the powder coating is essential in humid or coastal environments. Verify whether the product uses galvanization (e.g., hot-dip galvanized) before coating.

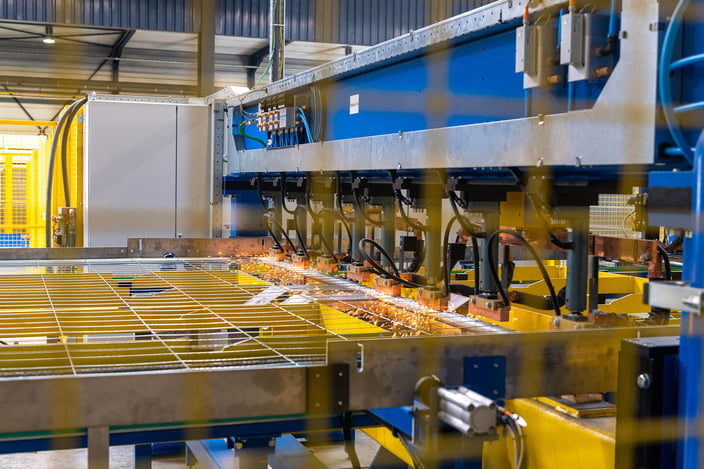

Inadequate Welding and Construction

Poor welding techniques result in weak joints and reduced longevity. Inspect sample welds for consistency, penetration, and finishing. Robotic or automated welding generally provides better quality than manual processes. Unfinished or rough welds can become corrosion points over time.

Non-Compliance with Local Standards and Regulations

Fences must often meet local building codes, safety standards, and height restrictions. Sourcing from overseas suppliers without verifying compliance can lead to installation delays or fines. Confirm that the product meets relevant regional standards (e.g., ASTM, EN, AS/NZS).

Inaccurate Product Specifications from Suppliers

Some suppliers may exaggerate material thickness, coating quality, or IP ratings to win contracts. Always request third-party test reports, material certifications, and physical samples before placing bulk orders. Conducting independent lab tests may be necessary for critical applications.

Overlooking Long-Term Maintenance Requirements

Even high-quality white metal fences require maintenance. Buyers may assume the finish is maintenance-free, but environmental exposure demands periodic cleaning and inspection. Clarify maintenance expectations with the supplier and consider lifecycle costs, not just initial price.

By being aware of these common pitfalls, buyers can make more informed decisions and ensure they source durable, compliant, and high-quality white metal fencing solutions.

Logistics & Compliance Guide for Metal White Fence

Product Overview

The Metal White Fence is a pre-finished, powder-coated metal fencing solution designed for residential, commercial, and industrial applications. It typically consists of galvanized steel or aluminum components supplied in panel, post, rail, and hardware kits. The white finish ensures aesthetic consistency and corrosion resistance. Proper logistics planning and compliance adherence are essential for efficient delivery, installation, and regulatory approval.

Packaging and Handling Requirements

Metal White Fence components are generally shipped in flat-packed or bundled configurations on wooden pallets or in shrink-wrapped bundles. Panels and posts should be stored horizontally on a flat, dry surface to prevent warping. Protective film or coating on the white finish must remain intact until installation to avoid scratches or chemical exposure. Handling should be performed with clean gloves and lifting straps to prevent surface damage.

Transportation and Shipping Guidelines

Shipments should be secured to prevent shifting during transit. Over-the-road carriers must use tarps or enclosed trailers to protect against moisture, road debris, and UV exposure, which may degrade packaging or coating. Load heights and weights must comply with local transportation regulations. International shipments require adherence to ISPM-15 standards for wooden pallets and proper export documentation.

Storage and Site Management

Upon delivery, materials should be stored under cover or on elevated platforms with breathable coverings to prevent moisture accumulation. Avoid direct contact with soil or concrete to minimize corrosion risk. Maintain adequate ventilation around stored bundles to prevent condensation. Inventory should be rotated using a first-in, first-out (FIFO) approach to ensure timely installation of older stock.

Regulatory Compliance

Metal White Fence installations must comply with local building codes, zoning regulations, and safety standards. In the U.S., relevant standards may include ASTM A123 for zinc (galvanized) coatings and ASTM D4236 for powder coating materials. If installed near property lines, adherence to local height, setback, and visibility requirements is mandatory. International projects must comply with regional standards such as EN 1090 (Europe) for structural metal components.

Environmental and Safety Considerations

The powder coating used in Metal White Fences is typically free of volatile organic compounds (VOCs), complying with EPA and EU REACH regulations. Waste materials such as off-cuts and packaging should be recycled where possible. Installation crews must follow OSHA (or equivalent) safety guidelines, including proper use of PPE, fall protection for elevated work, and safe handling of power tools.

Documentation and Traceability

Suppliers must provide material test reports (MTRs), certificates of compliance (CoC), and installation manuals with each shipment. Batch numbers and manufacturing dates should be traceable to support warranty claims and quality audits. Import/export documentation, including commercial invoices, packing lists, and certificates of origin, must be maintained for customs clearance.

Installation and Final Inspection Compliance

Installation must follow manufacturer specifications to maintain product integrity and warranty coverage. Final inspections should verify alignment, structural stability, and finish quality. Local authorities may require third-party inspections for commercial or public projects. As-built documentation should be submitted where necessary for code compliance and permitting closure.

Conclusion for Sourcing Metal White Fences

Sourcing metal white fences requires a strategic approach that balances quality, cost, durability, and aesthetic appeal. After evaluating various suppliers, materials (such as aluminum and powder-coated steel), and manufacturing processes, it is evident that selecting the right vendor is crucial for long-term satisfaction and performance. Aluminum fences offer lightweight strength and excellent corrosion resistance, making them ideal for residential and commercial use, while steel options provide enhanced durability at a slightly higher maintenance cost.

Key considerations include verifying the supplier’s compliance with industry standards, assessing the quality of powder coating for color retention and weather resistance, and confirming the availability of customization options. Additionally, evaluating lead times, shipping logistics, and after-sales support ensures a smooth procurement process.

Ultimately, partnering with reputable manufacturers or distributors who provide warranties, consistent finishes, and responsive customer service will ensure a reliable supply of high-quality white metal fencing. By prioritizing these factors, businesses and property owners can achieve both functional security and visual appeal, enhancing the value and curb appeal of their premises.