The global plumbing and piping systems market has experienced steady growth, driven by rising infrastructure development, urbanization, and increased investment in water management systems. According to Grand View Research, the global PVC pipes market size was valued at USD 57.8 billion in 2022 and is expected to expand at a CAGR of 5.8% from 2023 to 2030. This growth trajectory underscores the rising demand for reliable, corrosion-resistant connections between traditional metal piping and modern PVC systems—fueling the need for high-performance metal-to-PVC adapters. As industries in construction, irrigation, and municipal water services prioritize durability and leak-resistant joints, manufacturers specializing in adapter solutions are playing a critical role in ensuring system integrity. Based on performance, innovation, and market presence, the following nine companies have emerged as leading manufacturers of metal-to-PVC adapters, supporting seamless integration across diverse piping networks.

Top 9 Metal To Pvc Adapter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fittings

Domain Est. 1996

Website: nibco.com

Key Highlights: We offer metal and plastic fittings for industrial, commercial, mechanical, fire protection, and residential flow-control systems….

#2 Pipe couplings for industrial water supply

Domain Est. 1995

Website: romac.com

Key Highlights: Ductile iron pipe coupling with interchangeable gaskets and color-coded end rings. Nominal Sizes 2 – 24 inches. Working Pressure Up to 260 psi….

#3 Victaulic

Domain Est. 1995

Website: victaulic.com

Key Highlights: Victaulic is a global leading producer of mechanical pipe joining, flow control & fire protection solutions for the most complex piping applications….

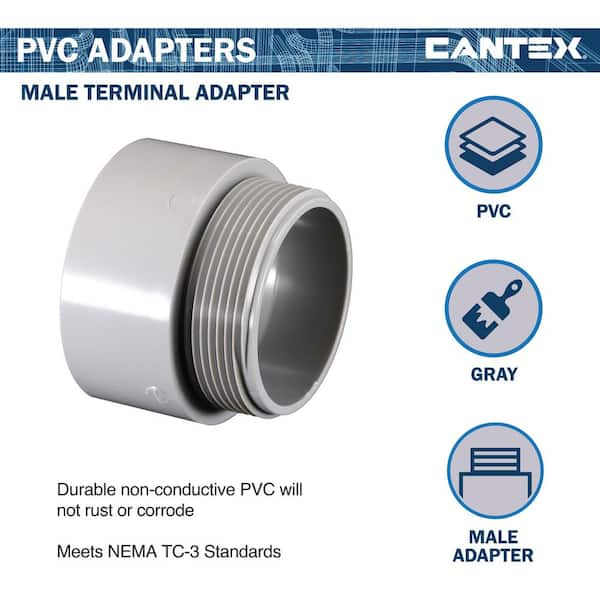

#4 Cantex PVC Conduit

Domain Est. 1996

Website: cantexinc.com

Key Highlights: LEADING MANUFACTURER OF PVC ELECTRICAL PRODUCTS CANTEX is the largest manufacturer of PVC electrical conduit, fittings, and boxes in the United States….

#5 Industrial Fittings, Tube Fittings and Pressure Fittings

Domain Est. 1996

Website: products.swagelok.com

Key Highlights: We offer a complete portfolio of fittings available in a variety of alloy materials for a wide range of industrial applications….

#6 Supply

Domain Est. 1997

Website: siouxchief.com

Key Highlights: Straight Adapter. Convenient transition fitting with PVC Sch. 40 IPS socket connection. Do NOT cut this fitting. Use Caution When Soldering – see installation ……

#7 PVC Schedule 40 Pressure Pipe & Fittings

Domain Est. 1997

Website: charlottepipe.com

Key Highlights: PVC schedule 40 is highly durable, with high-tensile and high-impact strength. It is easy to install and has better sound-deadening qualities than PVC schedule ……

#8

Domain Est. 1998

Website: consolidatedpipe.com

Key Highlights: A national leader in piping, fittings, valves, and all accessories for the energy, oil & gas, utility, construction, water and sewer industries….

#9 Allied Tube & Conduit

Domain Est. 2010

Website: atkore.com

Key Highlights: We are a manufacturing leader of steel, PVC, and aluminum conduit as well as mechanical, safety, and traffic solutions….

Expert Sourcing Insights for Metal To Pvc Adapter

2026 Market Trends for Metal to PVC Adapters

Increased Demand in Residential and Commercial Plumbing

The global construction sector is projected to grow steadily through 2026, with significant investments in residential and commercial infrastructure. This expansion is driving demand for reliable and cost-effective plumbing solutions. Metal to PVC adapters play a critical role in connecting modern PVC piping systems with existing metal (typically copper or galvanized steel) infrastructure. As renovation and retrofitting projects increase—especially in North America and Europe—these adapters are becoming essential for seamless transitions between old and new piping systems, supporting their sustained market growth.

Growing Preference for Hybrid Piping Systems

Hybrid plumbing systems that combine the durability of metal pipes with the corrosion resistance and lightweight nature of PVC are gaining traction. Metal to PVC adapters serve as key components in these hybrid installations. Technological improvements in adapter design, including enhanced seals and anti-leak features, are increasing consumer confidence. By 2026, building codes and industry standards in many regions are expected to further accommodate such hybrid setups, boosting demand for certified and code-compliant adapters.

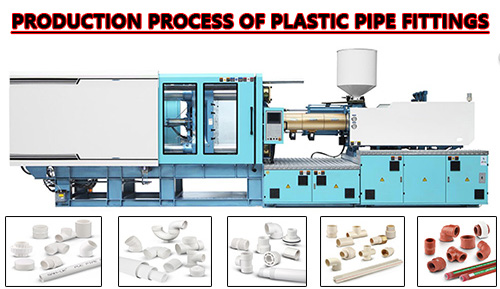

Advancements in Material and Design Innovation

Manufacturers are focusing on improving the durability and compatibility of metal to PVC adapters. Innovations include brass and stainless steel fittings with integrated rubber or EPDM seals to prevent galvanic corrosion and ensure watertight connections. Additionally, push-fit and compression-style adapters are gaining popularity due to ease of installation, reducing labor costs. By 2026, expect to see more smart adapters with built-in leak detection or alignment indicators, particularly in high-end commercial applications.

Regional Market Dynamics and Regulatory Influence

Regulatory standards around water safety, lead content, and plumbing efficiency are shaping the market. In the U.S., compliance with NSF/ANSI 61 and low-lead requirements is mandatory, influencing material choices and manufacturing processes. Emerging markets in Asia-Pacific and Latin America are witnessing increased adoption of modern plumbing systems, creating new opportunities for metal to PVC adapters. However, regional variations in building codes and material preferences may necessitate customized product offerings.

Supply Chain Optimization and Sustainability Focus

As environmental regulations tighten, manufacturers are prioritizing recyclable materials and sustainable production practices. Brass, a common material in adapters, is highly recyclable, which supports green building certifications like LEED. Additionally, supply chain resilience—impacted by geopolitical factors and raw material costs—will drive localization of production. By 2026, companies investing in regional manufacturing and digital inventory management will gain a competitive edge in delivering reliable, timely adapter supplies.

Competitive Landscape and Market Consolidation

The market for metal to PVC adapters is moderately fragmented but trending toward consolidation. Major plumbing component manufacturers are acquiring niche players to expand product portfolios and distribution networks. Increased competition is fueling innovation and pricing pressures, benefiting end-users. Online distribution channels are also expanding, providing easier access to specialized adapters for DIY consumers and contractors alike.

Common Pitfalls When Sourcing Metal to PVC Adapters (Quality and IP Ratings)

Sourcing Metal to PVC adapters—commonly used in plumbing, irrigation, and industrial systems—requires careful attention to both material quality and Ingress Protection (IP) ratings, especially in demanding environments. Overlooking key factors can lead to system failures, leaks, or safety hazards. Below are common pitfalls to avoid:

Poor Material Quality and Compatibility

One of the most frequent issues is selecting adapters made from substandard or incompatible materials. Using a low-grade metal (e.g., non-galvanized steel) in contact with PVC can lead to galvanic corrosion, especially in moist or outdoor environments. Additionally, poor-quality PVC may become brittle over time, increasing the risk of cracking under pressure or temperature fluctuations. Always verify that the metal component (typically brass, stainless steel, or galvanized steel) is compatible with the PVC grade and the fluid or gas being transported.

Inadequate Thread Quality and Fit

Misaligned, stripped, or poorly machined threads are a common cause of leaks and installation difficulties. Adapters with inconsistent thread tolerances may not seal properly, even when tightened correctly. This is especially problematic in high-pressure systems where even minor thread defects can escalate into major failures. Always inspect samples for thread precision and ensure they meet relevant standards (e.g., NPT, BSP).

Misunderstanding IP Ratings

Ingress Protection (IP) ratings indicate the level of protection against solids and liquids, but they are often misinterpreted when sourcing adapters. A common mistake is assuming that a metal-to-PVC adapter inherently provides environmental protection. In reality, the IP rating applies to the entire assembled system, not just the adapter. If the adapter is used in an enclosure or junction box, the seal between the adapter and the conduit or housing must maintain the required IP rating. Using an adapter without proper sealing features (e.g., O-rings, gaskets, or compression seals) can compromise the system’s IP integrity.

Lack of Environmental Suitability

Adapters exposed to UV radiation, extreme temperatures, or corrosive chemicals require specific material formulations. Standard PVC can degrade under prolonged UV exposure, leading to cracking and loss of structural integrity. Similarly, temperature fluctuations can cause expansion and contraction at the metal-PVC interface, weakening the joint over time. Failing to select UV-stabilized PVC or temperature-rated components results in premature failure.

Overlooking Certification and Compliance

Many projects require adherence to industry standards (e.g., ASTM, ISO, NSF, or WRAS). Sourcing adapters without proper certifications can lead to compliance issues, especially in potable water or food-grade applications. Always confirm that the adapter meets the necessary regulatory requirements for its intended use.

Insufficient Pressure and Temperature Ratings

Another frequent pitfall is selecting an adapter that doesn’t match the system’s operating pressure and temperature. Metal-to-PVC adapters have specific pressure limitations, and exceeding these can result in joint failure or blowouts. Always cross-check the adapter’s rated pressure (e.g., PN10, PN16) and temperature range with your system specifications.

Poor Sealing Mechanism Design

Even with high-quality materials, a poorly designed sealing mechanism leads to leaks. Some adapters rely solely on thread tape or sealant, which may not be sufficient in dynamic or high-vibration environments. Look for adapters with integrated seals, compression fittings, or locking nuts that ensure a watertight and secure connection.

By addressing these common pitfalls—focusing on material compatibility, thread quality, accurate interpretation of IP ratings, environmental resilience, compliance, and proper sealing—buyers can ensure reliable, long-lasting performance of metal-to-PVC adapters in their applications.

Logistics & Compliance Guide for Metal to PVC Adapter

Product Overview

The Metal to PVC Adapter is a plumbing or industrial fitting designed to connect metal piping systems (such as steel or copper) to PVC (polyvinyl chloride) piping. These adapters ensure a secure, leak-proof transition between dissimilar materials and are commonly used in water supply, irrigation, and industrial fluid transfer systems.

Packaging Requirements

- Protective Packaging: Use double-walled corrugated cardboard boxes with internal dividers or foam inserts to prevent movement and damage during transit.

- Moisture Protection: Include moisture-resistant wrapping (e.g., polyethylene film) to protect metal components from corrosion, especially in humid environments.

- Labeling: Clearly label each package with product name, model number, quantity, weight, and handling symbols (e.g., “Fragile,” “This Side Up”).

- Barcoding: Apply standardized barcodes (e.g., UPC or GS1) for inventory and traceability.

Storage Conditions

- Environment: Store in a dry, temperature-controlled warehouse (10°C to 30°C recommended). Avoid direct sunlight and high humidity to prevent PVC degradation and metal corrosion.

- Shelving: Keep on raised pallets or shelves to avoid floor moisture.

- Segregation: Store away from chemicals, solvents, and oxidizing agents that may degrade PVC or corrode metal.

Transportation Guidelines

- Mode of Transport: Suitable for road, rail, sea, and air freight. Sea freight requires additional moisture protection (e.g., desiccants).

- Stacking: Limit stacking height to prevent crushing; follow manufacturer’s stacking specifications.

- Securement: Use strapping or shrink-wrapping to stabilize pallets during transit.

- Temperature Exposure: Avoid prolonged exposure to extreme temperatures (>60°C or < -10°C) to prevent PVC deformation or embrittlement.

Regulatory Compliance

- Material Safety: Ensure PVC components comply with FDA 21 CFR §177.2500 (if used in potable water systems) or equivalent standards (e.g., NSF/ANSI 61).

- RoHS Compliance: Confirm absence of restricted substances (lead, cadmium, mercury, etc.) per EU Directive 2011/65/EU.

- REACH: Comply with SVHC (Substances of Very High Concern) disclosure requirements under EC 1907/2006.

- Country-Specific Regulations:

- USA: Must meet ASTM F876/F877 standards for plastic tubing and fittings.

- Canada: Comply with CSA B137.5 for pressure ratings and material performance.

- EU: CE marking required under Construction Products Regulation (CPR) if used in permanent installations.

- Australia/NZ: Comply with AS/NZS 4129 and AS 2032 for material and pressure testing.

Customs and Documentation

- HS Code: Typically classified under 7307.29 (stainless steel pipe fittings) or 3917.33 (PVC fittings), depending on primary material. Final classification should be verified per country.

- Commercial Invoice: Include detailed description, quantity, value, country of origin, and HTS code.

- Packing List: Specify dimensions, gross/net weight, and number of packages.

- Certificates: Provide Certificates of Compliance (CoC), Material Test Reports (MTR), and RoHS/REACH declarations as required.

- Import Permits: Check destination country requirements—some may require third-party testing or approval from water authority bodies (e.g., WRAS in the UK, KIWA in the Netherlands).

Quality Assurance and Testing

- Pressure Testing: Conduct hydrostatic pressure tests per ASTM F1212 or ISO 15494 to verify integrity.

- Leak Testing: Perform leak tests at maximum rated pressure.

- Dimensional Inspection: Ensure adherence to ISO 20022 or ANSI/ASME B16.24 standards.

- Batch Traceability: Maintain records of batch/lot numbers, manufacturing dates, and test results for recall readiness.

Environmental and Disposal Considerations

- Recyclability: PVC and metal components should be separated and recycled according to local waste regulations.

- WEEE Directive: Not typically applicable unless integrated into electrical systems.

- SDS (Safety Data Sheet): Provide if requested, especially for industrial-scale users handling raw materials.

Supplier and Vendor Compliance

- Audit suppliers for ISO 9001 (quality management) and ISO 14001 (environmental management) certifications.

- Ensure adherence to anti-corruption policies (e.g., UK Bribery Act, US FCPA) and labor standards (e.g., ILO conventions).

Summary

Proper logistics and compliance management for Metal to PVC Adapters ensures product integrity, regulatory acceptance, and smooth customs clearance. Adherence to international standards, accurate documentation, and secure handling are critical for global distribution. Regular compliance reviews and supplier audits are recommended to maintain market access and customer trust.

Conclusion on Sourcing Metal to PVC Adapters

Sourcing metal to PVC adapters requires careful consideration of material compatibility, application requirements, industry standards, and supplier reliability. These adapters serve as a critical bridge between rigid metal piping systems (such as steel or copper) and PVC piping, commonly used in plumbing, irrigation, HVAC, and industrial applications. Ensuring a secure, leak-free connection is essential to system integrity and long-term performance.

Key factors in the sourcing process include selecting the appropriate metal type (e.g., brass, stainless steel, or galvanized steel) to prevent galvanic corrosion when joined with PVC, verifying pressure and temperature ratings match operational demands, and ensuring compliance with relevant standards such as ASTM, NSF, or local plumbing codes.

Working with reputable suppliers who provide certified materials, consistent product quality, and technical support can significantly reduce risks related to failure or maintenance. Additionally, evaluating total cost—not just unit price—by factoring in durability, ease of installation, and expected service life leads to more sustainable procurement decisions.

In conclusion, a strategic sourcing approach that balances technical specifications, material science, and supplier quality will ensure reliable performance of metal to PVC adapters, contributing to the overall efficiency and safety of fluid transport systems.