The global self-tapping screws market, driven by rising demand in automotive, construction, and electronics industries, is projected to grow at a CAGR of 5.3% from 2023 to 2028, according to Mordor Intelligence. A key segment within this space—metal-to-metal self-tapping screws—has seen increased adoption due to their ability to create durable, high-strength joints in hard materials without pre-threading. With expanding industrial automation and infrastructure development, particularly in North America and Asia-Pacific, manufacturers are investing in advanced coatings, thread designs, and materials like stainless steel and carbon steel to enhance corrosion resistance and performance. As demand surges, a select group of global producers has emerged as leaders, combining innovation, scalability, and strict quality control to dominate supply chains worldwide. Based on production capacity, geographic reach, R&D investment, and market reputation, here are the top 10 metal-to-metal self-tapping screws manufacturers shaping the industry’s future.

Top 10 Metal To Metal Self Tapping Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wholesale Self

Domain Est. 1997

Website: intercorpusa.com

Key Highlights: Trusted self-drilling tek screw manufacturer, including self drilling metal screws, concrete screws for thick steel etc. View our extensive range of screws….

#2 Pro-Twist

Domain Est. 2003

Website: pro-twist.com

Key Highlights: Pro-Twist is an industry-leading manufacturer of professional-grade fasteners that are used for a wide variety of applications. Get started with us today!…

#3 BDN Fasteners: Asia’s Leading Self

Domain Est. 2015

Website: bdnfasteners.com

Key Highlights: OUR PRODUCT. BDN Fasteners offer a full range of self-drilling and self-tapping screws that drill, tap threads, and fasten in one swift process….

#4 Self Tapping Screws

Domain Est. 1991

Website: us.sfs.com

Key Highlights: Self Tapping Screws. Filters. Product Type. Self-tapping screw (11). Diameter. #12 (1). #14 (3). 1/4″ (4). #17 (3). Head Style. Dome head (1). Hex head (7)….

#5 Metal Screws

Domain Est. 1995

Website: strongtie.com

Key Highlights: Our metal screws are designed to provide strength and superior performance in steel and other metal applications….

#6 Specialty Fastening Solutions for the Commercial Construction …

Domain Est. 1996

Website: itwbuildex.com

Key Highlights: We manufacture self-drilling and tapping screws, anchors, toggles, and other fastening systems under the Teks, Sammys, Dec-King, EZ Ancor, and Rock-On-brands….

#7 Self Tapping Fasteners & Screws

Domain Est. 1997

Website: ejot.com

Key Highlights: The EJOT self-tapping screws form the thread in a pre-drilled hole. They feature a coarse or fine pitch thread. ▻ Learn more….

#8 Metal-to-Metal Fasteners

Domain Est. 1997

Website: atlasfasteners.com

Key Highlights: Atlas has a wide selection of Metal-to-Metal Fasteners for all your building needs. View all of our Metal-to-Metal Fasteners here….

#9 Self Tapping Screws

Domain Est. 2003

#10 Teks Screws

Domain Est. 2018

Website: teksscrews.com

Key Highlights: Drill, Tap, Fasten in One Motion. Teks® Metal Fasteners are the original self-drilling screws developed to drill, tap, and fasten metal in one motion….

Expert Sourcing Insights for Metal To Metal Self Tapping Screws

H2: Projected Market Trends for Metal-to-Metal Self-Tapping Screws in 2026

The global market for metal-to-metal self-tapping screws is poised for steady growth by 2026, driven by advancements in manufacturing technologies, rising demand across key industrial sectors, and a shift toward lightweight and durable construction materials. Below is an analysis of the major trends expected to shape the market landscape in 2026:

-

Increased Demand from Automotive and Aerospace Industries

The automotive and aerospace sectors are projected to remain dominant end-users of metal-to-metal self-tapping screws. As manufacturers continue adopting lightweight metal alloys to improve fuel efficiency and reduce emissions, the need for reliable fastening solutions that can securely join dissimilar or thin-gauge metals will rise. Self-tapping screws offer time and cost advantages in high-volume assembly lines, making them increasingly popular in electric vehicle (EV) production, where battery enclosures and chassis assemblies require robust, corrosion-resistant fasteners. -

Growth in Construction and Infrastructure Development

Ongoing urbanization, especially in emerging economies in Asia-Pacific and Africa, is driving demand for prefabricated metal structures, HVAC systems, and metal roofing—applications where self-tapping screws are widely used. Governments investing in green buildings and sustainable infrastructure are also favoring materials and components that reduce installation time and labor costs, further boosting the adoption of self-tapping fasteners. -

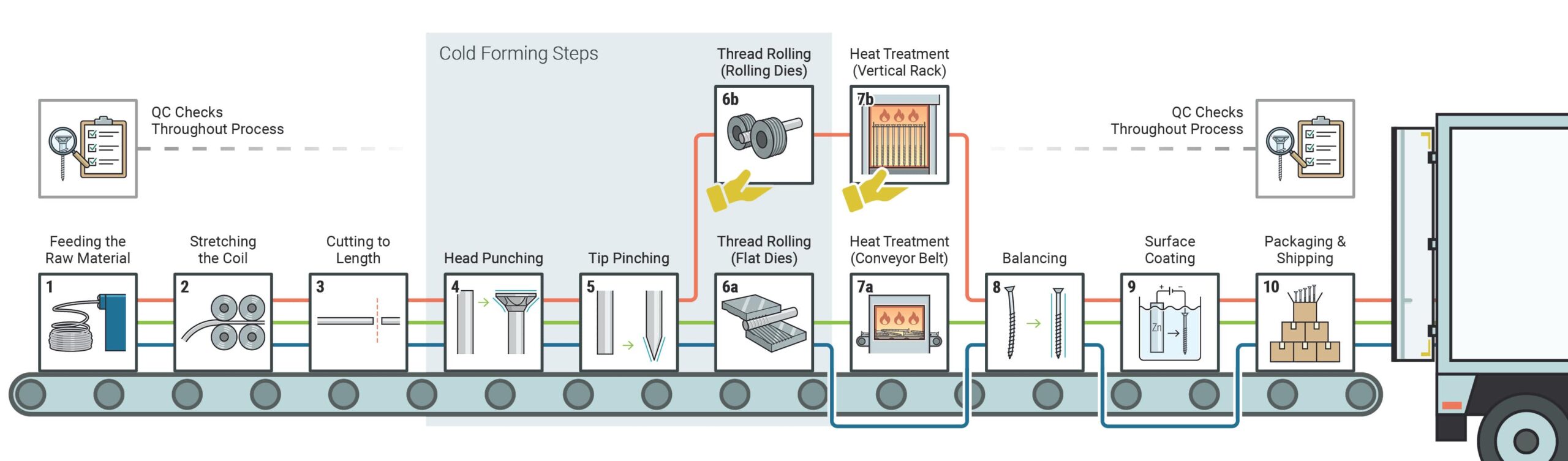

Technological Advancements and Material Innovation

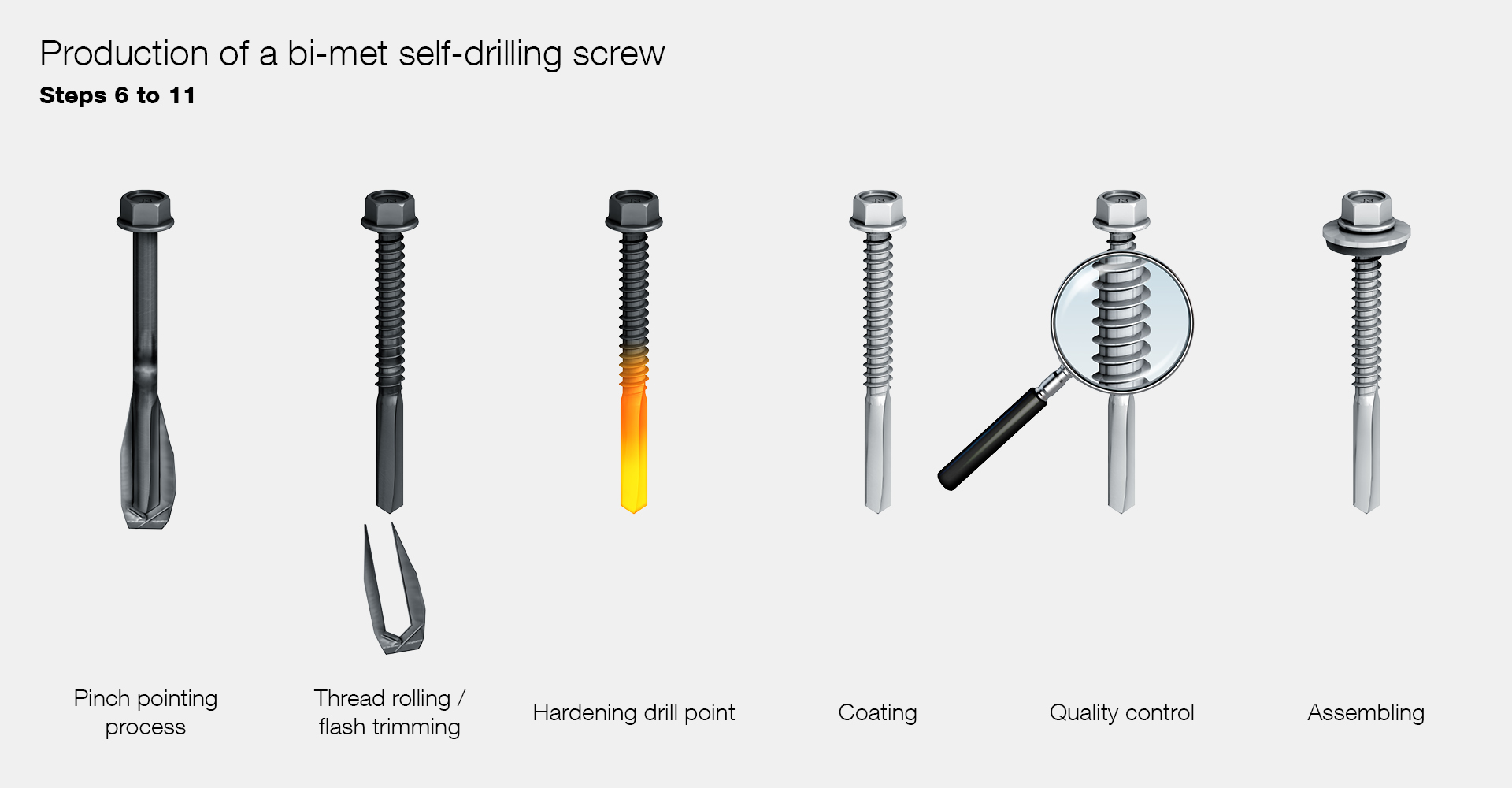

By 2026, manufacturers are expected to introduce next-generation self-tapping screws with enhanced thread-forming geometries, improved coatings (such as zinc-nickel and ceramic-based finishes), and superior corrosion resistance. Innovations like drill-point tips that eliminate pre-drilling and reduce installation time will gain traction, especially in automation-driven assembly environments. Additionally, the integration of smart manufacturing (Industry 4.0) will enable tighter quality control and customized screw production to meet specific industrial requirements. -

Sustainability and Recycling Initiatives

Environmental regulations and corporate sustainability goals are influencing material sourcing and product lifecycle management. Metal-to-metal self-tapping screws made from recycled steel or with eco-friendly surface treatments are expected to see increased demand. Manufacturers are likely to emphasize recyclability and reduced carbon footprints in production processes to align with global ESG (Environmental, Social, and Governance) standards. -

Regional Market Dynamics

The Asia-Pacific region, led by China, India, and Southeast Asian nations, is forecasted to dominate the market due to rapid industrialization and expanding manufacturing bases. North America and Europe will maintain strong demand, particularly in high-tech and renewable energy sectors like wind turbine assembly and solar panel mounting systems. Localized production and supply chain resilience will become strategic priorities post-pandemic, reducing dependency on single-source suppliers. -

Competitive Landscape and Consolidation

The market is expected to witness increased consolidation, with major fastener manufacturers acquiring niche players to expand product portfolios and geographic reach. Differentiation through product performance, technical support, and just-in-time delivery will be key competitive advantages. Digital platforms for B2B procurement and inventory management will also play a growing role in connecting suppliers with end-users.

In summary, the metal-to-metal self-tapping screw market in 2026 will be shaped by technological innovation, sector-specific demand growth, sustainability imperatives, and regional economic trends. Companies that invest in R&D, sustainable practices, and agile supply chains are likely to capture significant market share in this evolving landscape.

Common Pitfalls Sourcing Metal To Metal Self Tapping Screws (Quality, IP)

1. Inconsistent Material Quality

One of the most frequent issues when sourcing metal-to-metal self tapping screws is variability in base material quality. Suppliers may use substandard alloys or low-grade steel that compromises strength, durability, and corrosion resistance. This can result in screws that strip easily, fail under load, or corrode prematurely—especially in harsh environments. Always verify the material specifications (e.g., carbon steel grade, stainless steel type) and request material certification.

2. Poor Thread Precision and Dimensional Tolerances

Inaccurate thread cutting or inconsistent pitch and diameter can lead to improper fit, galling, or thread stripping during installation. Low-cost manufacturers may lack precision tooling or quality control, leading to batch-to-batch variations. Ensure screws meet recognized standards such as ISO 1479 or DIN 7500, and request sample testing before bulk orders.

3. Inadequate or Misrepresented Surface Finish and Coating

Corrosion protection is critical in metal-to-metal applications. A common pitfall is receiving screws with insufficient or poorly applied coatings (e.g., zinc plating, Dacromet, or Geomet). Some suppliers may claim IP (Ingress Protection) or corrosion resistance without proper testing. Beware of exaggerated claims—verify coating thickness and salt spray test results (e.g., 480+ hours per ASTM B117).

4. Lack of IP Certification and Misuse of Terminology

The term “IP” (Ingress Protection) refers to protection against solids and liquids for enclosures, not fasteners themselves. A frequent sourcing mistake is assuming screws have an IP rating. While screws can contribute to an assembly’s overall IP rating, they do not have one individually. Ensure suppliers understand this distinction and focus instead on environmental resistance and sealing compatibility.

5. Counterfeit or Non-Compliant Products

In global supply chains, counterfeit fasteners or those falsely claiming compliance with standards (e.g., ISO, ASTM, RoHS) are a real risk. These screws may look identical but fail under stress or corrode quickly. Partner with reputable suppliers, conduct third-party audits, and perform batch testing to mitigate this risk.

6. Inadequate Quality Control and Documentation

Many low-cost suppliers lack robust quality management systems. Missing or falsified inspection reports, lack of traceability, and no batch testing can lead to undetected defects. Require mill certificates, inspection reports, and evidence of quality processes (e.g., ISO 9001 certification) before finalizing suppliers.

7. Overlooking Driving Feature Quality

The drive type (e.g., Torx, Phillips, Hex) must withstand installation torque without cam-out or damage. Poorly formed drives—especially in mass-produced screws—lead to tool slippage and installation failures. Inspect drive depth, symmetry, and coating integrity in the recess, which is prone to chipping if not properly finished.

8. Insufficient Testing for Real-World Performance

Suppliers may provide screws that pass basic dimensional checks but fail under real application conditions such as vibration, thermal cycling, or repeated disassembly. Request application-specific testing (e.g., pull-out strength, torque-to-yield) to ensure long-term reliability.

By addressing these pitfalls early—through due diligence, clear specifications, and rigorous supplier vetting—purchasers can ensure reliable, high-performance metal-to-metal self tapping screws that meet both quality and environmental requirements.

Logistics & Compliance Guide for Metal-to-Metal Self Tapping Screws

Product Overview and Classification

Metal-to-metal self tapping screws are engineered fasteners designed to create their own internal threads when driven into pre-drilled or punched holes in metal substrates. They are typically manufactured from hardened steel, stainless steel (e.g., A2/AISI 304 or A4/AISI 316), or other alloyed materials and may include coatings such as zinc plating, black oxide, or Dacromet for corrosion resistance. These screws fall under HS Code 7318.15 (Screws, bolts, and nuts, of iron or steel) for international trade purposes, which impacts import/export compliance, tariffs, and customs clearance.

Packaging and Labeling Requirements

Proper packaging is essential to prevent damage during transit and ensure product integrity. Screws should be packed in moisture-resistant, durable materials such as sealed plastic bags inside corrugated cardboard boxes or reusable plastic totes. Bulk shipments may require palletizing with stretch-wrapping and corner boards for stability. Each package must include clear labeling with the following information: product description (e.g., “M4 x 20mm Metal-to-Metal Self Tapping Screw”), material grade (e.g., “Stainless Steel A2”), finish/coating, quantity, batch/lot number, manufacturer details, and compliance markings (e.g., ISO, ASME, DIN standards). Labels must be legible, weather-resistant, and comply with destination country regulations.

Import and Export Compliance

Exporters and importers must adhere to relevant international trade regulations. Key considerations include:

– Harmonized System (HS) Code: Use HS 7318.15 for accurate tariff classification.

– Export Controls: Verify if the screws fall under dual-use or strategic goods regulations (e.g., EAR in the U.S.). Most standard fasteners are EAR99, meaning they are not subject to stringent export licensing.

– Import Duties and Taxes: Check destination country tariff schedules; some regions offer reduced or zero duties under free trade agreements (e.g., USMCA, EU agreements).

– Documentation: Prepare a commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. A Material Test Report (MTR) may be required for industrial applications.

Regulatory and Safety Standards

Metal-to-metal self tapping screws must comply with applicable industry standards to ensure performance and safety. Key standards include:

– ISO 1479: Mechanical properties of penetration screws (tapping screws).

– DIN 7500: Thread forming screws for blind holes.

– ASME B18.6.3: Standard for wood and metal screws in the U.S.

– RoHS & REACH (EU): Ensure coatings and materials are free from restricted substances (e.g., lead, cadmium, certain phthalates).

– Conflict Minerals (U.S. Dodd-Frank Act): If applicable, report the use of tin, tantalum, tungsten, or gold (3TG) in manufacturing processes.

Transportation and Handling

Screws must be transported under conditions that prevent moisture exposure, physical damage, and contamination. Use enclosed, dry cargo containers or trucks. For air freight, follow IATA guidelines for secure packaging to avoid shifting. Handle with care during loading/unloading to prevent deformation, especially for coated or precision-threaded screws. Implement FIFO (First In, First Out) inventory practices to reduce risk of degradation over time.

Environmental and Sustainability Compliance

Manufacturers and distributors should adhere to environmental regulations related to coating processes (e.g., wastewater treatment for plating operations) and waste disposal. Promote recyclability—steel and stainless steel screws are 100% recyclable. Where possible, use eco-friendly coatings and minimize packaging waste. Some markets may require Environmental Product Declarations (EPDs) or compliance with local green building standards (e.g., LEED).

Quality Assurance and Traceability

Maintain a robust quality management system (e.g., ISO 9001) to ensure consistency and reliability. Implement batch traceability to track materials, production dates, and testing results. Conduct regular quality checks including tensile strength, thread accuracy, head integrity, and coating thickness. Provide customers with inspection certificates or test reports upon request.

Returns and Non-Conformance Handling

Establish a clear process for handling defective or non-compliant shipments. Document root causes of non-conformance (e.g., incorrect size, damaged threads) and report to relevant authorities if safety issues arise. Coordinate returns or replacements in compliance with local consumer protection and warranty laws. Retain records for audit purposes.

Summary

Compliance in the logistics and distribution of metal-to-metal self tapping screws requires attention to classification, packaging, international regulations, and quality standards. By following this guide, stakeholders can ensure smooth customs clearance, regulatory adherence, and customer satisfaction across global supply chains.

Conclusion: Sourcing Metal-to-Metal Self-Tapping Screws

Sourcing metal-to-metal self-tapping screws requires a strategic approach that balances quality, cost, lead times, and supplier reliability. These specialized fasteners are critical in industries such as automotive, construction, aerospace, and manufacturing, where high strength, durability, and secure thread-forming capabilities in metal substrates are essential.

Key considerations in the sourcing process include material selection—typically steel, stainless steel, or alloy—to ensure corrosion resistance and mechanical strength; compliance with international standards (such as ISO, DIN, or ASTM); and the importance of proper thread design and surface treatments for optimal performance. Additionally, partnering with reputable suppliers who offer consistent quality, technical support, and scalability helps mitigate supply chain risks.

Ultimately, successful sourcing involves thorough supplier evaluation, continuous quality assurance, and staying updated on material and manufacturing advancements. By prioritizing these factors, organizations can secure reliable, high-performance self-tapping screws that enhance product integrity and operational efficiency while minimizing long-term maintenance and failure risks.