The global metal stairs market is experiencing steady growth, driven by rising demand in commercial, industrial, and residential construction sectors. According to Grand View Research, the global steel structures market—of which metal stairs are a critical component—was valued at USD 105.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by increasing urbanization, infrastructure modernization, and the shift toward durable, low-maintenance building materials. Similarly, Mordor Intelligence projects continued expansion in the prefabricated metal building components market, supported by faster construction timelines and growing adoption in modular building designs. As demand for reliable, code-compliant, and customizable metal stair solutions rises, a select group of manufacturers have emerged as industry leaders, combining advanced engineering, scalable production, and global reach to dominate the space. Here are the top 9 metal stairs manufacturers shaping the future of architectural and structural access solutions.

Top 9 Metal Stairs Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lapeyre Stair

Domain Est. 1996

Website: lapeyrestair.com

Key Highlights: Compliant, prefabricated, and pre-engineered metal stairs designed to your exact specifications. The right systems for virtually any industrial application….

#2 Homepage

Domain Est. 2001

Website: woosterproducts.com

Key Highlights: Wooster Products has been providing consumers with anti-slip stars and walk way passages for over 100 years. Request a quote today!…

#3 Prefabricated Metal Stairs

Domain Est. 2004

Website: panelbuilt.com

Key Highlights: Panel Built manufactures prefabricated stairs for industrial, commercial, and exterior applications. Our steel staircases are fully customizable….

#4 Metal Stairs, Access & Work Platforms by ErectaStep

Domain Est. 2010

Website: erectastep.com

Key Highlights: Crafted from durable industrial-grade aluminum, our stair units, rolling steps, work platforms, and safety gates are proudly made in the USA, prefabricated, and ……

#5 L.J. Smith Stair Systems

Domain Est. 1997

Website: ljsmith.com

Key Highlights: LJ Smith is the largest stair parts manufacturing company in the country. Our continued growth over the past several decades is clearly a result of our ……

#6 American Stair

Domain Est. 1997

Website: americanstair.com

Key Highlights: Our products are fabricated by skilled craftsmen and we will put this experience and knowledge at your disposal to become your only steel stair supplier….

#7 Metal Staircase Co.

Domain Est. 2002

Website: metalstairs.com

Key Highlights: Beautifully designed custom-made staircases for the aspiring home-owner. A unique supply-only service offered at trade price….

#8 Paragon Stairs

Domain Est. 2005

Website: paragonstairs.com

Key Highlights: Metal Floating Stairs. Make a statement in your home with a one-of-kind Paragon floating staircase built in Pennsylvania with premium hand-forged steel….

#9 AndronX

Domain Est. 2012

Website: andronx.com

Key Highlights: We manufacture and install straight, curved, double curve, spiral, scissor, and other unique staircase systems. The Andronx team works with builders, homeowners ……

Expert Sourcing Insights for Metal Stairs

H2: 2026 Market Trends for Metal Stairs

The global metal stairs market is poised for significant evolution by 2026, shaped by technological advancements, shifting construction dynamics, and increasing emphasis on sustainability and safety. Driven by urbanization, industrial growth, and infrastructure modernization, metal stairs—valued for their durability, fire resistance, and design flexibility—are gaining traction across residential, commercial, and industrial sectors.

One of the defining trends in 2026 is the rising demand for prefabricated and modular metal stair systems. These systems offer faster installation, reduced labor costs, and improved quality control, making them highly attractive in large-scale construction projects. The adoption of Building Information Modeling (BIM) and digital fabrication techniques further enhances precision in design and manufacturing, supporting the growth of customized metal stair solutions.

Sustainability is another key driver. With green building certifications like LEED and BREEAM becoming more influential, architects and developers are prioritizing materials with low environmental impact. Metal stairs, especially those made from recycled steel or aluminum, align well with these goals due to their recyclability and long lifespan. Manufacturers are increasingly integrating eco-friendly coatings and low-carbon production methods to meet these demands.

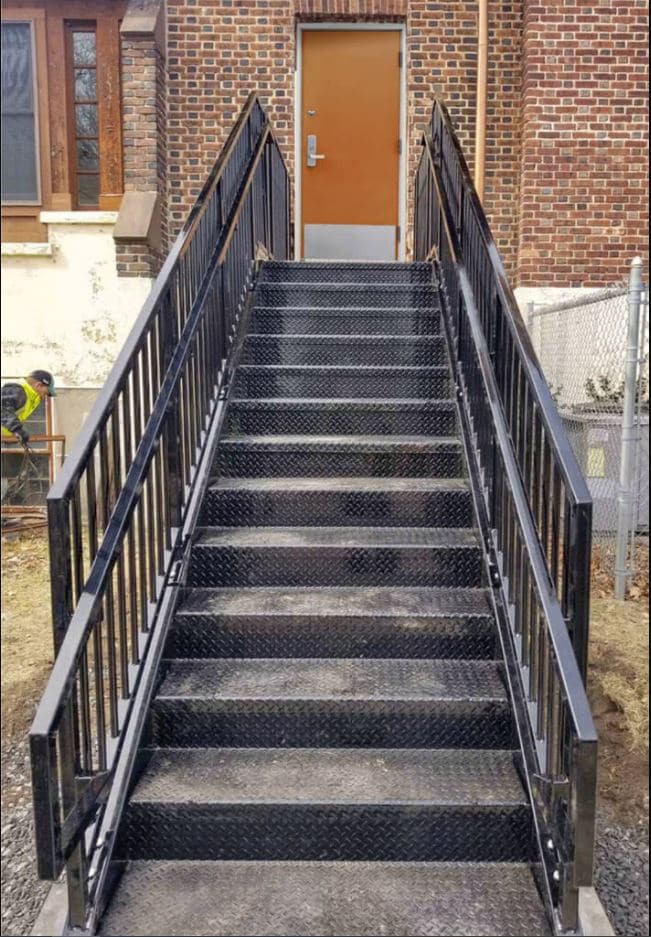

Additionally, safety and regulatory compliance are shaping design standards. In 2026, stricter building codes—particularly in seismic and high-occupancy zones—are boosting demand for structurally robust metal staircases with anti-slip treads, integrated handrails, and fire-resistant finishes. Innovations such as smart stairs equipped with LED lighting or sensors for usage monitoring are also emerging, particularly in smart buildings and public infrastructure.

Regionally, Asia-Pacific is expected to lead market growth, fueled by rapid urbanization in countries like India and Vietnam, alongside government investments in transportation and industrial hubs. North America and Europe will see steady growth, driven by retrofitting of aging infrastructure and the popularity of industrial-style architecture in commercial spaces.

In summary, the 2026 metal stairs market is characterized by innovation, sustainability, and regulatory alignment. As construction practices evolve and digital technologies become more embedded, metal stairs will continue to serve as a critical component in modern, resilient, and aesthetically versatile building design.

Common Pitfalls When Sourcing Metal Stairs (Quality & Intellectual Property)

Sourcing metal stairs involves navigating a range of potential issues that can impact safety, compliance, cost, and legal standing. Below are key pitfalls related to quality and intellectual property (IP) that procurement teams and project managers should be aware of.

Poor Material Quality and Workmanship

One of the most frequent challenges in sourcing metal stairs is receiving products made from substandard materials or with poor fabrication. Suppliers may use lower-grade steel or aluminum than specified, leading to reduced structural integrity, faster corrosion, and shorter lifespan. Inconsistent welding, rough edges, improper alignment, or inadequate surface finishes not only compromise safety but may also fail to meet building code requirements.

Lack of Compliance with Safety and Building Standards

Metal stairs must comply with regional and international safety standards (e.g., OSHA, IBC, EN 14122). A common pitfall is sourcing stairs that appear structurally sound but do not meet load-bearing, dimensional, or slip-resistance specifications. Non-compliant stairs can lead to failed inspections, project delays, costly retrofits, or legal liabilities in the event of accidents.

Inadequate or Missing Quality Certifications

Reputable suppliers should provide documentation such as mill test certificates, welder certifications, and third-party inspection reports. Sourcing from manufacturers who cannot produce verifiable quality certifications increases the risk of receiving defective or unsafe products. Always verify that the supplier adheres to recognized quality management systems like ISO 9001.

Ignoring Intellectual Property (IP) Rights

Metal stair designs—especially custom or proprietary modular systems—may be protected by patents, copyrights, or design rights. Sourcing identical or near-identical copies from unauthorized manufacturers can lead to IP infringement claims. This is particularly risky when sourcing from regions with lax IP enforcement, where counterfeit or cloned designs are common.

Using Reverse-Engineered or Counterfeit Designs

Some suppliers offer “cost-effective” alternatives that are clear copies of patented stair systems. While they may appear identical, these products often lack engineering validation and performance testing. Purchasing such products exposes the buyer to legal action from the original IP holder and potential liability for safety failures.

Unclear Ownership of Custom Designs

When working with suppliers to develop custom metal stair solutions, it’s essential to establish upfront who owns the design IP. Without a clear contract, the supplier may retain rights to reuse or sell the design to competitors. Ensure that design agreements specify full IP transfer to the buyer if intended.

Insufficient Due Diligence on Suppliers

Failing to vet suppliers thoroughly—especially overseas manufacturers—can result in quality issues and IP risks. Conduct factory audits, request reference projects, and verify the supplier’s history of compliance and innovation. A lack of due diligence often leads to unexpected defects, delivery delays, or legal complications.

Conclusion

To mitigate these pitfalls, prioritize suppliers with proven track records, transparent manufacturing processes, and respect for intellectual property. Always require detailed specifications, quality documentation, and legal assurances regarding design rights. Proactive oversight during sourcing ensures safer, compliant, and legally sound metal stair installations.

Logistics & Compliance Guide for Metal Stairs

Overview

Metal stairs are essential structural components used in commercial, industrial, and residential construction. Due to their weight, size, and material composition, their transportation, handling, and compliance with regulations require careful planning. This guide outlines key logistics considerations and compliance requirements to ensure safe and efficient delivery and installation of metal stairs.

Packaging and Handling

Proper packaging and handling are critical to prevent damage and ensure worker safety:

- Protective Coating: Apply protective films or wraps to prevent scratches, corrosion, or paint damage during transit.

- Crating or Palletizing: Secure individual stair components (treads, stringers, handrails) on wooden pallets or in crates to prevent shifting.

- Strapping and Bracing: Use steel or heavy-duty poly straps with edge protectors. Reinforce long or heavy sections with corner boards and internal bracing.

- Lifting Points: Clearly mark lifting points and use slings or forklifts as appropriate. Never lift by handrails unless designed for such use.

Transportation Requirements

Transporting metal stairs involves compliance with road, rail, and maritime regulations:

- Load Dimensions: Ensure stair bundles comply with local and international dimensional limits (e.g., width ≤ 2.55m, height ≤ 4m in most EU countries).

- Weight Distribution: Distribute weight evenly across the trailer. Overweight loads may require special permits.

- Securement: Follow EUMOS, CTU (Cargo Transport Unit), or FMCSA (U.S.) guidelines for securing cargo. Use dunnage, chocks, and tiedowns to prevent movement.

- Oversize/Overweight Permits: If dimensions or weight exceed legal limits, obtain necessary permits from transportation authorities.

International Shipping Compliance

For cross-border shipments, adhere to international standards:

- ISPM 15: Wooden packaging (pallets, crates) must be heat-treated and marked if shipping internationally.

- Customs Documentation: Provide commercial invoices, packing lists, certificates of origin, and material declarations.

- HS Code Classification: Metal stairs typically fall under HS Code 7308.40 (structures and parts of structures, of iron or steel).

- RoHS/REACH: Comply with EU chemical regulations if applicable (especially for coatings or finishes).

Safety and Installation Standards

Ensure product compliance with structural and safety codes:

- OSHA (U.S.): Stair design must meet OSHA 1910.24 and 1910.25 standards for rise, run, handrails, and load capacity.

- IBC (International Building Code): Follow IBC Chapter 10 for means of egress, including stair width, headroom, and slip resistance.

- EN 14122 (Europe): Safety of machinery – fixed ladders, stairways, and walkways.

- Load Testing: Verify compliance with required live and dead load specifications (e.g., 100 psf in commercial buildings).

Environmental and Material Compliance

Address environmental regulations related to materials and finishes:

- Steel Certification: Provide mill test certificates (e.g., EN 10204 3.1) to verify steel grade and quality.

- Coating Compliance: Powder coatings or paints should meet VOC regulations (e.g., EPA or EU Directive 2004/42/EC).

- Recycling and Disposal: Inform clients about recyclability of steel components and proper disposal of packaging.

Documentation and Record-Keeping

Maintain thorough records for traceability and compliance audits:

- Inspection Reports: Document pre-shipment quality checks (weld integrity, dimensions, finish).

- Certificates of Conformance (CoC): Issue CoCs affirming compliance with relevant standards.

- Shipping Manifests: Include detailed item descriptions, weights, and handling instructions.

- Retention Period: Retain compliance and shipping documents for a minimum of 5–7 years, depending on jurisdiction.

Conclusion

Effective logistics and compliance for metal stairs require coordination across manufacturing, packaging, transport, and regulatory domains. Adhering to safety standards, securing proper documentation, and following international shipping protocols will minimize risks, ensure timely delivery, and support long-term product reliability.

Conclusion for Sourcing Metal Stairs

Sourcing metal stairs requires a careful balance between structural integrity, safety, durability, cost-efficiency, and compliance with building codes and regulations. After evaluating various suppliers, materials (such as steel, aluminum, or stainless steel), fabrication methods, and installation requirements, it is clear that partnering with a reputable manufacturer or fabricator is essential to ensure quality and long-term performance.

Key considerations such as load capacity, environmental exposure (indoor vs. outdoor, corrosion resistance), fire safety, and design flexibility must guide the selection process. Additionally, prefabricated solutions can offer faster installation and cost savings, while custom designs provide greater adaptability to unique architectural or space constraints.

Ultimately, a well-informed sourcing decision—based on thorough vetting of suppliers, material specifications, lead times, and total lifecycle costs—will ensure that the metal stairs not only meet current project requirements but also provide safe, reliable access for years to come.