The global metal roofing market is experiencing robust growth, driven by rising demand for durable, energy-efficient, and low-maintenance building materials. According to Grand View Research, the global metal roofing market size was valued at USD 29.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing construction activities, particularly in residential and commercial sectors, as well as a growing preference for sustainable building solutions. As metal roofs become more prevalent, critical components such as chimney boots—essential for weatherproofing and longevity—have gained importance. These boots must meet high standards for durability and compatibility with metal roofing systems, prompting increased innovation among manufacturers. In this evolving landscape, a select group of companies has emerged as leaders in producing high-performance metal roof chimney boots, combining advanced materials, precision engineering, and extensive testing to deliver reliable solutions. The following list highlights the top 10 manufacturers shaping this niche yet vital segment of the roofing industry.

Top 10 Metal Roof Chimney Boot Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ATAS International, Inc.

Domain Est. 1996

Website: atas.com

Key Highlights: ATAS International, an American, family-owned company with global reach, is a leading, manufacturer of metal walls, metal roof systems, accessories & more….

#2 Roofing Products Manufacturer

Domain Est. 2010

Website: lifetimetool.com

Key Highlights: Roofing Products Manufacturer in Winchester, Virginia. Lifetime Tool® continues to design and manufacture quality components….

#3 Rooftop Accessories

Domain Est. 1996

Website: gaf.com

Key Highlights: Specialty roofing accessories designed to enhance the performance of your residential roofing system by helping to keep it dry, strong, ……

#4 Roof Flashings for Metal Roofs

Domain Est. 1996

Website: oatey.com

Key Highlights: Constructed from durable materials, they are built to endure the challenging conditions of metal roofing, including temperature fluctuations and harsh weather….

#5 Pipe Boots, Flashing & Roof Boots for Metal Roofs

Domain Est. 2002

#6 Trims, Flashing and Accessories

Domain Est. 2002

Website: ascbp.com

Key Highlights: ASC Building Products offers a comprehensive range of metal flashings, trims and accessories designed to provide a seamless finish for metal roofing and ……

#7 Pipe Flashing & Boots for Metal Roofs

Domain Est. 2010

Website: metalplusllc.com

Key Highlights: Protect your roof with our range of high-quality pipe boots and flashing systems. Engineered for long-lasting performance, these products ensure a watertight ……

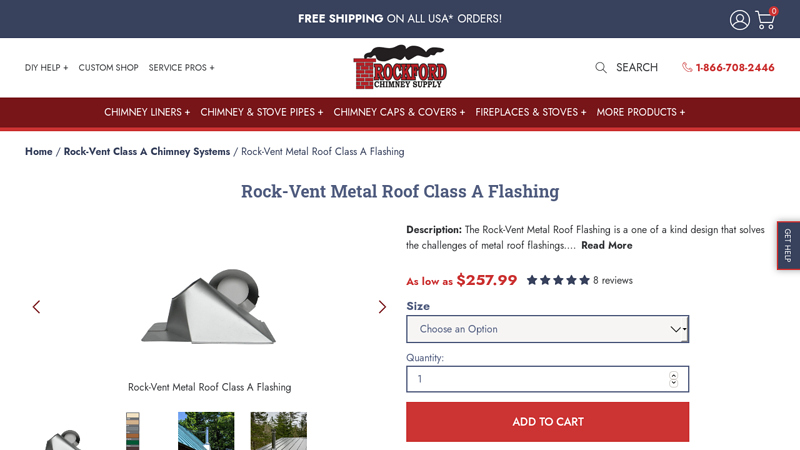

#8 Rock

Domain Est. 2010

#9 Curb/Chimney

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: This parts list is designed to help you calculate the quantity of accessories that you’ll need for your trim installation….

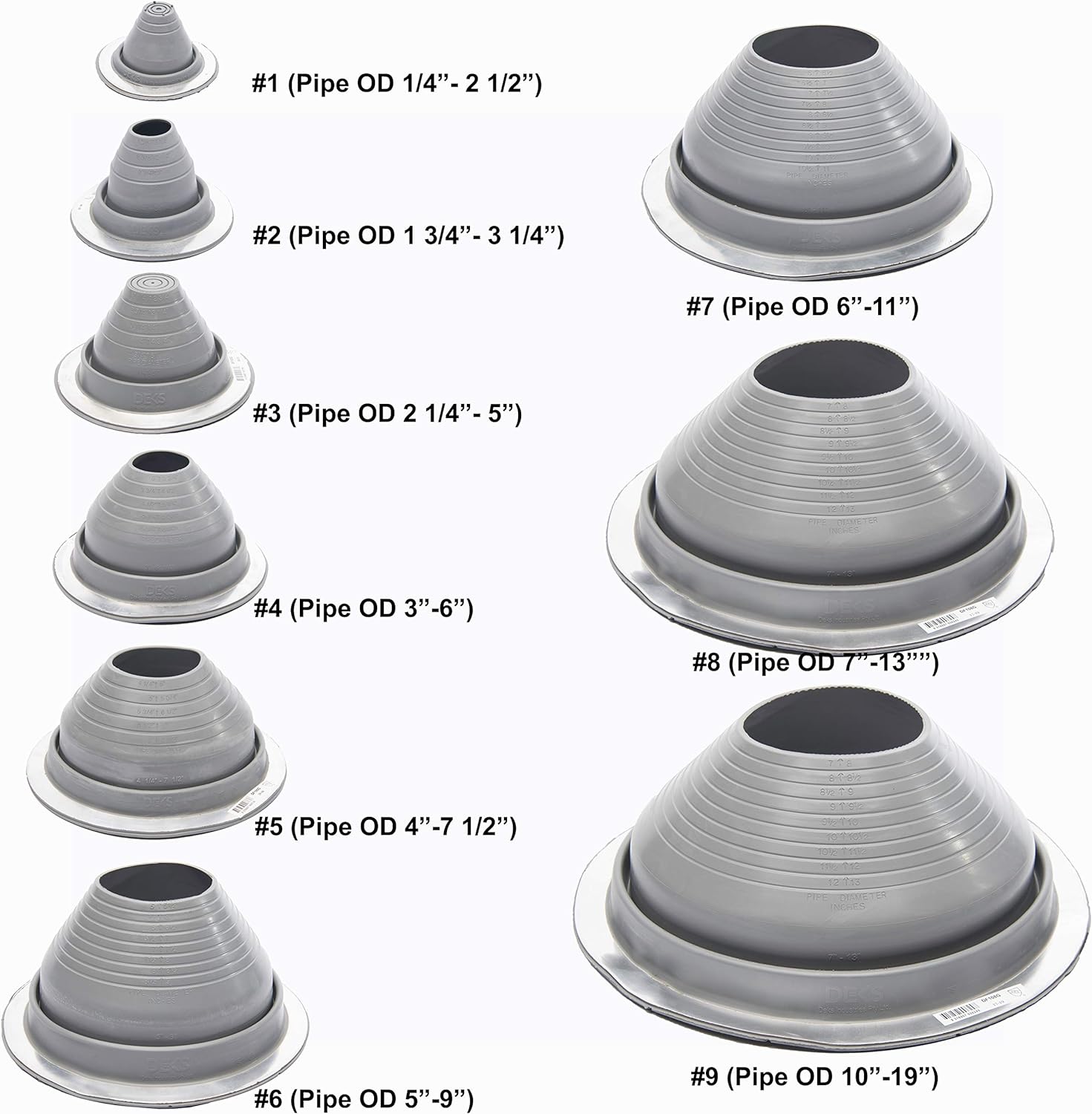

#10 Dektite Metal Roof Flashings

Domain Est. 2020

Website: deksus.com

Key Highlights: The original Dektite designed to seal both hot and cold flues and pipes on metal roofs. A strong watertight seal and a strong flexible base featuring a ……

Expert Sourcing Insights for Metal Roof Chimney Boot

H2: 2026 Market Trends for Metal Roof Chimney Boots

The global market for metal roof chimney boots is poised for significant transformation by 2026, driven by evolving construction practices, increasing demand for energy-efficient and durable roofing solutions, and growing emphasis on fire safety and weather resistance. This analysis explores key trends shaping the metal roof chimney boot sector in the coming years.

1. Rising Demand in Residential Construction and Retrofitting

The residential construction sector is expected to remain a primary driver of demand for metal roof chimney boots. With a surge in new homebuilding—particularly in North America and Europe—and increased homeowner focus on long-term durability, chimney boots made from stainless steel, aluminum, and galvanized steel will see higher adoption. Additionally, aging housing stock in developed markets will fuel retrofit and repair activities, further boosting replacement demand.

2. Preference for High-Performance, Corrosion-Resistant Materials

By 2026, there will be a notable shift toward premium materials such as 304 and 316 stainless steel, which offer superior resistance to rust and extreme weather conditions. Homeowners and contractors are prioritizing longevity, especially in coastal and high-humidity regions where corrosion is a major concern. This trend will push manufacturers to innovate with advanced coatings and alloys to extend product life.

3. Integration with Sustainable and Energy-Efficient Building Standards

As green building certifications like LEED and ENERGY STAR gain traction, chimney boots that contribute to overall roof integrity and energy efficiency will be favored. Products designed to minimize thermal bridging and air leakage around chimney penetrations will become increasingly important. Manufacturers may respond by developing insulated or thermally broken chimney boot models.

4. Growth in DIY and Pre-Fabricated Solutions

The DIY home improvement market is expanding, supported by online tutorials and e-commerce platforms. In response, manufacturers are likely to offer universal-fit, adjustable, or modular metal chimney boots that simplify installation for non-professionals. Pre-fabricated kits with flashing, sealants, and installation guides will gain popularity, particularly in the U.S. and Canada.

5. Regional Market Dynamics

North America is expected to dominate the market due to strict building codes, widespread use of metal roofing, and high chimney usage in colder climates. Europe will follow, driven by renovation projects and regulations on fire safety. Meanwhile, Asia-Pacific will emerge as a high-growth region, especially in countries like Japan and South Korea, where metal roofs are common and seismic resilience is a priority.

6. Technological Advancements and Smart Roofing Integration

While still in early stages, there is potential for smart roofing systems to influence chimney boot design. By 2026, we may see chimney boots integrated with moisture sensors or thermal monitoring components to detect leaks or overheating—particularly in homes with high-efficiency heating systems like wood-burning stoves or gas chimneys.

7. Supply Chain and Raw Material Volatility

Fluctuations in steel and aluminum prices, influenced by geopolitical tensions and trade policies, could impact production costs. Manufacturers may respond by investing in local sourcing, recycling programs, or alternative materials to maintain margins and ensure supply stability.

8. Regulatory and Safety Compliance

Stricter fire safety codes and building regulations, especially in wildfire-prone areas (e.g., California), will mandate the use of non-combustible chimney flashing and boots. This will accelerate the shift from rubber or plastic alternatives to metal-based solutions, reinforcing market growth.

In conclusion, the 2026 market for metal roof chimney boots will be characterized by innovation in materials, design, and functionality, supported by regulatory tailwinds and consumer demand for durability and safety. Companies that focus on quality, adaptability, and sustainability are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Metal Roof Chimney Boots (Quality, IP)

Sourcing a metal roof chimney boot—also known as a chimney flashing—is critical for ensuring long-term roof integrity and weather resistance. However, several common pitfalls can compromise performance, especially concerning quality and Ingress Protection (IP) standards. Being aware of these issues helps avoid leaks, premature failure, and costly repairs.

Poor Material Quality

One of the most frequent issues is selecting chimney boots made from substandard materials. Low-grade metals such as thin-gauge steel or inferior aluminum corrode quickly when exposed to weather, pollutants, or dissimilar metals on the roof. This leads to rust, warping, and eventual failure. Always verify the material specifications—such as galvanized steel, stainless steel (grade 304 or 316), or heavy-duty aluminum—and ensure they match the environmental conditions of the installation site.

Inadequate Weather Sealing and IP Rating

Many chimney boots are marketed without clear Ingress Protection (IP) ratings, leaving ambiguity about their ability to resist water and dust intrusion. A proper chimney boot should offer effective sealing against driven rain and moisture ingress. Without sufficient IP performance—especially in high-wind or rainy climates—water can penetrate around the chimney, leading to rot, mold, and structural damage. Look for boots designed with integrated rubber seals or neoprene gaskets that maintain a watertight barrier under thermal expansion and contraction.

Incorrect Fit and Sizing

A common sourcing mistake is selecting a one-size-fits-all boot without considering the exact chimney dimensions or roof pitch. An ill-fitting boot cannot create a proper seal, allowing water to seep beneath the flashing. Always confirm compatibility with specific chimney cross-sections (square, rectangular, round) and roof angles. Custom or adjustable boots may be necessary for non-standard installations.

Lack of UV and Thermal Resistance

Low-quality boots often use rubber or sealants that degrade under prolonged UV exposure or extreme temperature fluctuations. This leads to cracking, shrinkage, and loss of elasticity—compromising the seal over time. Ensure the product uses UV-stabilized EPDM or similar durable materials that can withstand the local climate’s thermal cycles.

Ignoring Regional Compliance and Standards

Some suppliers offer chimney boots that don’t meet regional building codes or certification standards (e.g., ASTM, CE, or local fire safety regulations). Using non-compliant products can void warranties and fail inspections. Always verify that the boot meets relevant safety and durability standards, particularly for fire resistance and wind uplift performance.

Overlooking Installation Complexity

Even high-quality boots can fail if they’re not designed for proper installation. Boots that lack clear instructions, require specialized tools, or are incompatible with common roofing materials increase the risk of improper fitting. Choose products with user-friendly designs and compatibility with standard roofing underlayment and fastening methods.

Cost vs. Longevity Trade-Offs

Sourcing based solely on upfront cost often leads to lower-quality boots with shorter lifespans. While budget options may seem economical initially, they typically require earlier replacement and increase long-term maintenance costs. Invest in a durable, well-engineered boot that offers better value over time through reduced risk of leaks and roof damage.

By addressing these pitfalls during the sourcing process—focusing on verified material quality, proper IP performance, correct sizing, and compliance—buyers can ensure a reliable, long-lasting seal between the chimney and the roof system.

Logistics & Compliance Guide for Metal Roof Chimney Boot

Product Overview

A Metal Roof Chimney Boot is a prefabricated flashing component designed to create a weathertight seal around the intersection of a metal roof and a chimney. It is typically made from corrosion-resistant materials such as galvanized steel, aluminum, or copper to ensure durability and long-term performance in various climates. Proper logistics and compliance are essential to ensure safe delivery, correct installation, and adherence to building codes.

Shipping & Handling

Metal roof chimney boots are generally shipped flat or in compact, stackable configurations to optimize freight space. They are packaged in protective wrapping or cardboard to prevent surface scratching or deformation during transit. Handle with care to avoid bending or warping the flashing flange or base. Use appropriate lifting equipment when moving large quantities. Store in a dry, covered area off the ground to prevent moisture exposure and material degradation prior to installation.

Transportation Requirements

Ship via standard freight carriers capable of handling lightweight but bulky construction materials. Ensure secure loading and bracing to prevent shifting during transport. Use weather-resistant tarps if shipping via open trailers. Avoid extreme temperature exposure during long-haul transport, especially for boots with factory-applied sealants or coatings that may be temperature-sensitive.

Import & Export Compliance (if applicable)

For international shipments, verify compliance with destination country regulations. Metal chimney boots may fall under HS Code 7308.90 (Other construction structures, of iron or steel). Ensure all export documentation, including commercial invoices, packing lists, and certificates of origin, are accurately completed. Check for any anti-dumping duties or trade restrictions on steel or aluminum products in the target market.

Regulatory & Building Code Compliance

Metal roof chimney boots must comply with local and national building codes, including the International Building Code (IBC) and International Residential Code (IRC). Key requirements include:

– Proper integration with the roofing underlayment and chimney structure

– Use of compatible materials to prevent galvanic corrosion

– Adequate overlap and sealing to prevent water infiltration

– Compliance with fire resistance standards when installed near combustible materials

Verify that the chimney boot meets ASTM standards for metal flashings (e.g., ASTM A653 for galvanized steel) and is listed or evaluated by recognized testing agencies such as ICC-ES (International Code Council – Evaluation Service).

Environmental & Safety Compliance

Manufacturers must comply with environmental regulations regarding metal processing, coating application, and waste disposal (e.g., EPA guidelines in the U.S.). Workers involved in handling or installing chimney boots should follow OSHA safety standards, including the use of gloves and eye protection to prevent injury from sharp edges. Products containing lead-based coatings (now rare) must comply with lead-safe work practices under EPA’s Renovation, Repair, and Painting (RRP) rule.

Installation & Warranty Compliance

Proper installation is critical for performance and warranty validity. Follow manufacturer instructions precisely, including:

– Correct alignment with roof pitch and chimney dimensions

– Use of approved sealants and fasteners

– Integration with step flashing and counter-flashing systems

Failure to follow installation guidelines may void the product warranty and result in compliance issues during building inspections.

Documentation & Traceability

Maintain records of product specifications, material certifications, test reports, and batch numbers for traceability. Distributors and contractors should provide end-users with installation manuals, warranty information, and compliance statements to support code inspections and insurance requirements.

Disposal & Recycling

At end-of-life, metal chimney boots are recyclable. Follow local regulations for disposal of construction debris. Separate metals by type (e.g., aluminum, steel) for proper recycling. Do not dispose of in regular landfill waste when recycling options are available.

Conclusion:

Sourcing a metal roof chimney boot requires careful consideration of factors such as material compatibility, durability, proper fit, and local weather conditions. Metal boots—typically made from stainless steel, aluminum, or copper—offer superior longevity and resistance to extreme temperatures and corrosion compared to rubber or composite alternatives. Ensuring the boot matches the chimney size, roof pitch, and surrounding roofing material is crucial to prevent leaks and maintain the roof’s integrity. Additionally, selecting a product that meets local building codes and UL certifications contributes to long-term performance and safety. By sourcing a high-quality metal chimney boot from reputable suppliers and ensuring professional installation, homeowners and contractors can significantly extend the life of the roofing system and avoid costly water damage repairs. Therefore, investing time in proper selection and procurement of the right metal chimney boot is a critical step in maintaining a durable and weather-tight roof.