The global metal laser welding market is experiencing robust expansion, driven by increasing demand for precision, automation, and energy-efficient joining technologies across industries such as automotive, aerospace, and electronics. According to a 2023 report by Mordor Intelligence, the laser welding market was valued at USD 5.87 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.6% through 2028. Similarly, Grand View Research estimates that the broader industrial laser market, which includes laser welding systems, will expand at a CAGR of over 7.2% from 2023 to 2030, fueled by advancements in high-power fiber lasers and rising adoption of electric vehicles requiring sophisticated manufacturing techniques. As industry leaders continue to innovate with improved beam quality, reduced cycle times, and enhanced integration capabilities, a select group of manufacturers has emerged at the forefront. Below are the top 10 metal laser welder manufacturers shaping the future of industrial manufacturing through technological leadership and global reach.

Top 10 Metal Laser Welder Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#2 Denaliweld

Website: denaliweld.com

Key Highlights: DenaliWeld INC, is a proud employee-owned fiber laser welding machine manufacturer based in Chicago, USA. Bolstered by the most experienced engineers and ……

#3 Laser Machines

Website: lclasers.com

Key Highlights: Distribution and manufacture of laser machinery. Sales of laser marking, laser cleaning, laser engraving and welding machines….

#4 Equipment & Systems

Website: amadaweldtech.com

Key Highlights: Manufacturer of equipment and systems for welding, cutting, marking, micromachining, sealing, and bonding. Resistance welding. Laser….

#5 Laser Technology & Laser Machines from ALPHA LASER

Website: alphalaser.eu

Key Highlights: High-quality laser technology & laser sytems from ALPHA LASER: powerful laser machines for metalworking: mobile, flexible, & precise ✓ technical support ✓….

#6 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#7 Laser Welding

Website: ipgphotonics.com

Key Highlights: Discover Your Laser Welding Solution IPG is a partner for every stage of production from research and development to full-scale manufacturing….

#8 Full Spectrum Laser

#9 Orotig: Laser Machinery

Website: orotig.com

Key Highlights: Orotig, with +30 years of experience, specializes in engineering and manufacturing laser solutions for welding engraving and casting metals….

#10 Laser Welding Machines

Website: coherent.com

Key Highlights: Get manual to fully automated laser welding machines that weld plastics and metals with speed and precision while improving throughput….

Expert Sourcing Insights for Metal Laser Welder

2026 Market Trends for Metal Laser Welder

The global metal laser welding market is poised for significant transformation by 2026, driven by technological advances, growing industrial automation, and increasing demand across high-precision manufacturing sectors. As industries shift toward smarter, faster, and more efficient production methods, metal laser welders are emerging as a cornerstone technology. This analysis explores key trends expected to shape the metal laser welder market in 2026.

Rising Adoption in Automotive and EV Manufacturing

The automotive industry, particularly the electric vehicle (EV) segment, is a major catalyst for the growth of metal laser welding technology. By 2026, automakers are expected to expand their use of laser welding for battery fabrication, powertrain components, and lightweight structural assemblies. The precision and speed of laser welding improve battery safety and performance—critical factors in EV production. Additionally, the ability of laser welders to join dissimilar metals supports the industry’s shift toward lighter, more fuel-efficient vehicle designs.

Advancements in Fiber and Hybrid Laser Technologies

Technological innovation remains a dominant trend, with fiber laser systems gaining market preference due to their higher efficiency, lower maintenance, and superior beam quality compared to traditional CO₂ lasers. By 2026, fiber lasers are expected to dominate over 70% of the industrial laser welding market. Moreover, hybrid laser-arc welding systems are gaining traction, combining the deep penetration of lasers with the gap-bridging capability of arc welding. These systems are increasingly adopted in heavy industries such as shipbuilding and construction equipment manufacturing.

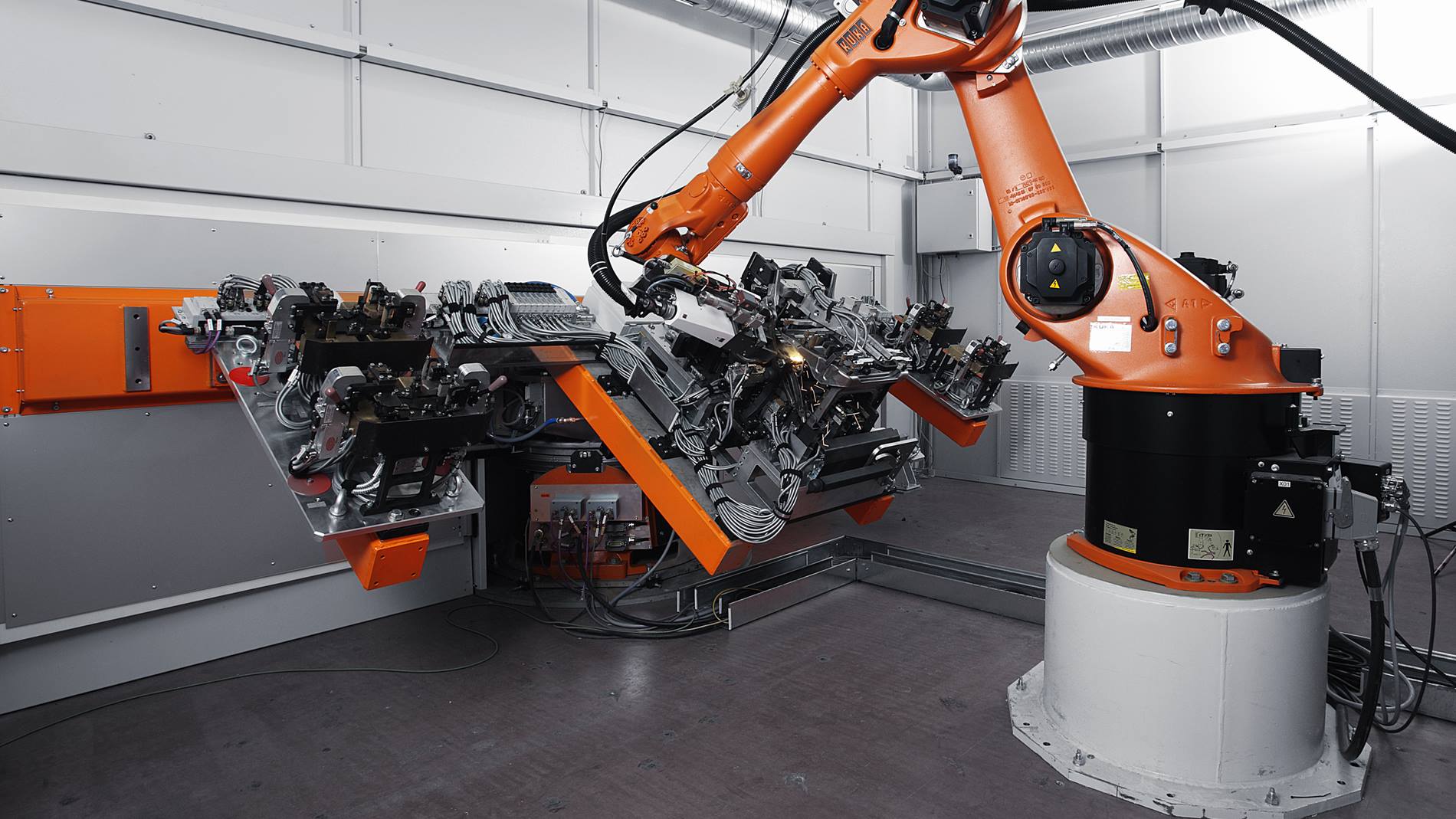

Integration with Industry 4.0 and Smart Manufacturing

Metal laser welding systems are becoming integral components of smart factories. In 2026, the integration of laser welders with IoT-enabled sensors, real-time monitoring, and AI-driven process optimization will be widespread. These features allow for predictive maintenance, quality assurance through inline inspection, and adaptive control of welding parameters. As digital twins and machine learning algorithms mature, manufacturers will leverage data from laser welding operations to enhance yield, reduce scrap, and improve traceability.

Growth in Aerospace and Defense Applications

The aerospace and defense sectors are expected to increase their investment in high-precision laser welding for components such as turbine blades, fuselage structures, and engine parts. The demand for improved strength-to-weight ratios and performance under extreme conditions makes laser welding ideal. By 2026, stricter regulatory standards and the need for repeatable, defect-free welds will drive adoption of automated laser welding cells in certified production environments.

Regional Market Dynamics

Asia-Pacific is projected to lead global demand for metal laser welders in 2026, fueled by rapid industrialization in China, India, and South Korea. China’s focus on advanced manufacturing under its “Made in China 2025” initiative is accelerating domestic production and adoption of laser systems. Meanwhile, North America and Europe are investing heavily in reshoring manufacturing, where laser welding supports high-precision, low-volume production runs, especially in medical devices and aerospace.

Sustainability and Energy Efficiency

Environmental considerations are influencing equipment choices. Laser welding consumes less energy than conventional methods and produces minimal waste, aligning with corporate sustainability goals. By 2026, manufacturers will increasingly evaluate laser systems based on total cost of ownership and environmental impact, with a preference for energy-efficient, recyclable, and low-emission technologies.

Conclusion

In 2026, the metal laser welder market will be characterized by technological sophistication, deeper integration with digital ecosystems, and expanding applications across high-growth industries. Companies that innovate in automation, connectivity, and energy efficiency will gain a competitive edge. As global manufacturing evolves, metal laser welding is set to become not just a tool, but a strategic enabler of next-generation production.

Common Pitfalls When Sourcing a Metal Laser Welder: Quality and Intellectual Property Risks

Sourcing a metal laser welder—especially from international or less-established suppliers—can present significant challenges related to both the quality of the equipment and intellectual property (IP) protection. Overlooking these pitfalls can lead to production downtime, safety hazards, legal disputes, and financial loss.

Quality-Related Pitfalls

Inconsistent Build Quality and Component Sourcing

Many lower-cost laser welders, particularly from emerging manufacturers, use substandard materials and inconsistently sourced components (e.g., lasers, optics, cooling systems). This can result in frequent breakdowns, poor weld consistency, and reduced machine lifespan. Always verify certifications (such as CE, ISO 9001), request third-party inspection reports, and conduct factory audits if possible.

Overstated Performance Specifications

Suppliers may exaggerate key performance metrics like laser power output, beam quality (M² factor), welding speed, or penetration depth. These inflated claims can mislead buyers into purchasing underperforming equipment. To mitigate this, demand live demonstrations with your actual materials and request detailed technical documentation backed by test data.

Inadequate After-Sales Support and Spare Parts Availability

Even high-quality machines require maintenance and repairs. Sourcing from suppliers without local service networks or unclear spare parts policies can lead to extended downtimes. Confirm the availability of technical support, training, and spare parts logistics before purchase—ideally with service level agreements (SLAs) in place.

Lack of Safety and Compliance Features

Some budget laser welders may lack essential safety interlocks, proper enclosure, or compliance with international safety standards (e.g., IEC 60825 for laser safety). Using non-compliant equipment risks operator injury and regulatory fines. Ensure the machine meets all relevant regional safety and environmental regulations.

Intellectual Property (IP) Pitfalls

Risk of Infringing on Patented Technologies

Low-cost laser welders may incorporate components or designs that infringe on patents held by major manufacturers (e.g., IPG Photonics, Trumpf, or Coherent). Purchasing such equipment could expose your company to third-party IP litigation, especially in markets with strong IP enforcement like the EU or U.S. Conduct due diligence on the technology used and request IP indemnification clauses in contracts.

Reverse-Engineered or Clone Systems

Some suppliers offer “compatible” or “economy” versions of well-known laser systems that are reverse-engineered copies. These clones often lack reliability and may violate design or utility model patents. Be wary of unusually low prices or vague technical origins—these are red flags for potential IP issues.

Ambiguous Software Licensing and Proprietary Controls

Laser welding systems rely on proprietary control software. Some suppliers may use unlicensed or pirated software, exposing buyers to legal and cybersecurity risks. Ensure software is legally licensed, and verify whether you retain access to machine parameters and firmware updates.

Limited Protection for Custom Integrations

If you modify or integrate the laser welder into your production line, unclear IP ownership terms in the supplier contract could prevent you from protecting or scaling your innovations. Define IP rights for custom tooling, software interfaces, and process improvements upfront in your procurement agreement.

By proactively addressing these quality and IP-related pitfalls, businesses can make informed sourcing decisions that protect their operations, reputation, and long-term innovation goals.

Logistics & Compliance Guide for Metal Laser Welder

Import/Export Regulations

Ensure compliance with international trade laws when shipping metal laser welders across borders. Verify applicable Harmonized System (HS) codes—typically under 8515.21 or similar categories for laser welding machines. Obtain necessary export licenses, especially if the equipment contains controlled technologies or originates from regulated jurisdictions. Comply with destination country import requirements, including customs documentation, valuation, and potential import duties or tariffs.

Safety Standards & Certifications

Metal laser welders must meet stringent safety certifications prior to operation and transport. Confirm compliance with IEC 60825 (laser safety), IEC 61010 (safety requirements for electrical equipment), and regional standards such as CE (Europe), UKCA (UK), or UL/CSA (North America). Include all certification documentation with shipments and ensure equipment bears required safety labels and warning signs.

Packaging & Handling Requirements

Use robust, custom-designed packaging to secure the laser welder during transit. Include shock-absorbent materials, moisture barriers, and rigid outer casings to protect sensitive optical and electronic components. Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture” indicators. Secure mirrors, lenses, and fiber cables according to manufacturer guidelines to prevent misalignment or damage.

Transportation Mode & Requirements

Choose transportation methods based on equipment size, weight, and delivery urgency. For international shipments, air freight may be preferred for speed, while sea freight offers cost efficiency for heavy units. Ensure compliance with IATA (air) or IMDG (sea) regulations if batteries or hazardous materials (e.g., laser coolants) are included. Use certified carriers experienced in handling precision industrial machinery.

Regulatory Compliance (Environmental & Waste)

Adhere to environmental regulations concerning the disposal of laser components, cooling fluids, and packaging materials. Follow local and international guidelines such as RoHS (restriction of hazardous substances) and WEEE (waste electrical and electronic equipment). Maintain documentation for proper end-of-life handling and recycling of the laser welder and its parts.

Installation & Site Compliance

Prior to installation, verify that the end-user facility meets electrical, ventilation, and safety requirements. Ensure grounding, power supply compatibility, and laser-safe enclosures are in place. Conduct a site audit to confirm compliance with OSHA (U.S.) or equivalent occupational safety regulations. Provide operators with training documentation and safety protocols as part of the delivery process.

Documentation & Traceability

Maintain a complete logistics and compliance dossier, including commercial invoices, packing lists, certificates of origin, conformity certificates, and user manuals. Keep serialized records of each unit for traceability, warranty, and service purposes. Digital copies should be securely archived for audit and regulatory review.

Conclusion for Sourcing a Metal Laser Welder

After a thorough evaluation of technical requirements, production needs, budget constraints, and long-term operational goals, sourcing a metal laser welder represents a strategic investment in enhancing manufacturing precision, efficiency, and product quality. Fiber laser welding systems have emerged as the preferred choice due to their high energy efficiency, low maintenance, excellent beam quality, and compatibility with automation.

Key factors influencing the final decision include welding precision, material compatibility (especially for stainless steel, aluminum, and other alloys), required weld strength, throughput demands, and integration with existing production lines. Additionally, supplier reliability, after-sales support, training availability, and warranty terms play a crucial role in ensuring sustained performance and minimizing downtime.

By selecting a laser welder that aligns with both current production volumes and future scalability needs, the organization can achieve improved weld consistency, reduced post-processing, and lower operational costs over time. Ultimately, acquiring the right metal laser welding solution strengthens competitiveness, supports innovation, and positions the company for growth in high-precision manufacturing sectors.