The global metal floor trusses market is experiencing steady growth, driven by increasing demand for lightweight, durable, and cost-effective structural solutions in residential and commercial construction. According to Grand View Research, the global structural steel market—of which metal floor trusses are a key component—was valued at USD 136.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. This growth is fueled by rising urbanization, infrastructure development, and the adoption of modular and prefabricated construction techniques. Additionally, Mordor Intelligence forecasts sustained momentum in the prefabricated steel structures market, with enhanced focus on sustainable building practices and faster project execution timelines. As demand for high-performance flooring systems grows, manufacturers of metal floor trusses are scaling innovation in design, load capacity, and ease of installation. In this evolving landscape, the following ten companies have emerged as leading manufacturers, recognized for their engineering excellence, product breadth, and market reach.

Top 10 Metal Floor Trusses Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Stark Truss is a leading manufacturer and supplier of roof and floor …

Domain Est. 1998

Website: starktruss.com

Key Highlights: Our construction product line includes Roof and Floor Trusses, Wall Panels, Laminated Veneer Lumber (LVL), I-Joists, Glulam posts, pre-built stairs, StarkLam ……

#2 US Steel Truss

Domain Est. 2006

Website: ussteeltruss.com

Key Highlights: US Steel truss is a direct source for steel truss and components for contactors and private labelers that want to put their own building packages together….

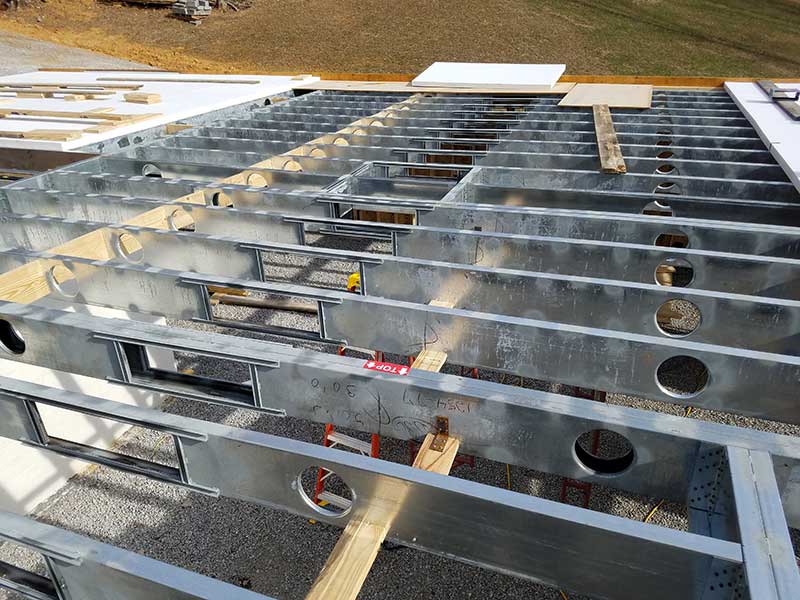

#3 Trimjoist

Domain Est. 1996

Website: trimjoist.com

Key Highlights: TrimJoist® floor joist products are used by discerning builders, contractors, and remodelers and are specified by leading architects, engineers, and designers….

#4 Roof & Floor Trusses

Domain Est. 1998

Website: bldr.com

Key Highlights: See all of our trusses for floor and roof framing from Builders FirstSource. We provide you with the tools you need to finish the job….

#5 Metwood

Domain Est. 1998

Website: metwood.com

Key Highlights: 6-day delivery 30-day returnsMetwood: Innovative cold-formed steel solutions for construction. Explore joist reinforcers, Ledger Brackets, ICF hangers, and more….

#6 Midwest Manufacturing

Domain Est. 2000

Website: midwestmanufacturing.com

Key Highlights: MM Truss. Residential, Pole Barn, or Floor Trusses; MM Truss can produce a truss for any application. Check out our easy ways to design and buy….

#7 Global Truss America

Domain Est. 2003

Website: globaltruss.com

Key Highlights: Available in 2-way, 3-way, 4-way and various angles ranging from 45 to 135 degrees, F33 Junctions provide endless design possibilities and strength….

#8 RedBuilt™ Open

Domain Est. 2009

Website: redbuilt.com

Key Highlights: Open web trusses that support floor areas and roof spaces up to and over 100 feet. Crafted by hand to your precise specifications, these strong and light ……

#9 Carolina Structural Systems

Domain Est. 2016

Website: carolinastructuralsystems.com

Key Highlights: Much like our roof trusses, floor trusses are custom designed and fabricated to your plans. Open Web Floor Trusses provide a wide 3.5” nailing surface, long ……

#10 CF Steel LLC

Domain Est. 2017

Website: flattruss.com

Key Highlights: CF-Steel is your #1 source for Cold Formed Steel Trusses. We provide the highest quality, most efficient, non combustible Light Gauge Steel Trusses that are ……

Expert Sourcing Insights for Metal Floor Trusses

2026 Market Trends for Metal Floor Trusses

The metal floor truss market is poised for significant evolution by 2026, driven by construction innovation, sustainability demands, and economic shifts. Key trends shaping the industry include:

Accelerated Adoption in Multifamily and Commercial Construction

Metal floor trusses are increasingly favored in mid-rise multifamily, hospitality, and light commercial projects due to their long spans, design flexibility, and compatibility with prefabrication. By 2026, continued urban densification and demand for faster build times will accelerate adoption, particularly in urban centers where modular and off-site construction methods are gaining traction.

Integration with Sustainable and Green Building Practices

With growing emphasis on environmental regulations and green certifications (e.g., LEED, BREEAM), metal floor trusses are benefiting from their recyclability, reduced material waste, and compatibility with energy-efficient building envelopes. Manufacturers are enhancing product sustainability through low-carbon steel sourcing and improved lifecycle assessments, aligning with net-zero construction goals expected to dominate by 2026.

Advancements in Digital Design and BIM Integration

Building Information Modeling (BIM) and digital engineering tools are becoming standard in structural planning. By 2026, seamless integration of metal truss designs into BIM workflows will streamline coordination between architects, engineers, and contractors, reducing errors and accelerating project timelines. Generative design and AI-assisted optimization will further refine truss configurations for material efficiency and performance.

Competitive Pressure from Engineered Wood Alternatives

Despite metal’s advantages, engineered wood products like LVL and mass timber floor systems continue to compete aggressively, especially in residential and low-rise applications. By 2026, cost fluctuations in steel and wood, coupled with regional preferences, will shape market share. Metal truss providers will need to emphasize durability, fire resistance, and non-combustible benefits to maintain competitiveness.

Regional Market Diversification and Supply Chain Resilience

Geopolitical and logistical factors are pushing manufacturers to regionalize production and logistics networks. By 2026, North America and Europe will remain strong markets due to stringent building codes and renovation activity, while Asia-Pacific will see rapid growth driven by urbanization. Companies investing in localized fabrication hubs will gain an edge in delivery speed and supply chain reliability.

Labor Efficiency and Skilled Workforce Challenges

As labor shortages persist across the construction sector, the ease of installation and lightweight nature of metal floor trusses will become a key selling point. By 2026, truss systems designed for simplified field assembly—with pre-punched holes, alignment features, and clear digital instructions—will be in higher demand to reduce dependency on highly skilled labor.

In summary, the 2026 market for metal floor trusses will be defined by technological integration, sustainability mandates, and adaptability to evolving construction methodologies—positioning metal trusses as a strategic solution in modern, efficient building practices.

Common Pitfalls When Sourcing Metal Floor Trusses (Quality, IP)

Sourcing metal floor trusses involves navigating several potential pitfalls, particularly concerning product quality and intellectual property (IP) protection. Overlooking these aspects can lead to structural failures, project delays, legal disputes, and increased costs. Below are key issues to watch for:

Poor Material Quality and Manufacturing Defects

One of the most critical risks is receiving trusses made from substandard materials or with poor fabrication. Low-grade steel or improper galvanization can lead to premature corrosion, reduced load capacity, and compromised structural integrity. Inadequate welding, inconsistent hole punching, or incorrect component alignment during manufacturing can also weaken trusses, risking on-site failures during installation or under load.

Lack of Certification and Compliance

Procuring trusses without proper engineering certifications or compliance with local building codes (e.g., IBC, AISC, or regional standards) is a major pitfall. Trusses must be designed and stamped by a licensed engineer and adhere to load, fire, and seismic requirements. Suppliers without verifiable documentation may offer non-compliant products, leading to failed inspections, costly rework, or liability in the event of structural issues.

Inadequate Quality Control Processes

Suppliers with weak or non-existent quality control systems may deliver inconsistent products. Without rigorous in-process and final inspections, defects may go undetected until installation. This can delay projects and increase labor costs. Always verify that the manufacturer implements standardized QC protocols, such as ISO 9001 certification or third-party audits.

Intellectual Property Infringement Risks

Metal floor truss designs, connection details, and proprietary engineering methods are often protected by patents, copyrights, or trade secrets. Sourcing from unauthorized manufacturers or knock-off suppliers can expose your project or company to IP infringement claims. Using counterfeit or copied truss designs may also compromise performance and safety, as these copies are rarely tested to the same standards.

Insufficient Design Documentation and Traceability

Reputable suppliers provide detailed design drawings, load tables, and traceable documentation for each truss batch. A pitfall arises when suppliers fail to deliver these, making it difficult to verify performance specifications or troubleshoot issues. Lack of traceability also complicates accountability in case of defects or failures.

Hidden Costs from Rework and Delays

Compromising on quality or IP compliance often results in hidden expenses. On-site rejection of trusses due to dimensional inaccuracies or non-compliance can halt construction, incurring labor and scheduling penalties. Legal fees from IP disputes or liability from structural failures can far exceed initial material savings.

Choosing Unverified or Offshore Suppliers

While offshore or low-cost suppliers may offer attractive pricing, they often come with higher risks in quality consistency and IP transparency. Communication barriers, longer lead times, and limited recourse in case of disputes amplify these risks. Without proper vetting—including site audits and reference checks—sourcing from such suppliers is a significant pitfall.

To mitigate these risks, conduct thorough due diligence on suppliers, prioritize certified manufacturers with strong IP practices, and ensure all trusses come with complete, verifiable engineering and quality documentation.

Logistics & Compliance Guide for Metal Floor Trusses

Overview

Metal floor trusses are engineered structural components used in residential, commercial, and industrial construction to provide strong, lightweight support for floors. Due to their size, weight, and material composition, proper logistics and compliance procedures are essential to ensure safety, regulatory adherence, and project efficiency.

Transportation and Handling

Loading and Securing

- Trailer Selection: Use flatbed, step-deck, or specialized lowboy trailers depending on truss length and job site access.

- Load Distribution: Distribute trusses evenly across the trailer to maintain balance and prevent overloading axles.

- Securing Methods: Use rated straps, chains, and edge protectors to secure trusses. Minimum of four tie-down points per load; more may be required for longer spans.

- Load Height & Width: Ensure the load complies with state and federal oversize load regulations. Use warning flags and signage as required.

Handling Equipment

- Forklifts and Cranes: Use equipment with sufficient lifting capacity. Attach lifting hardware only at designated points to prevent deformation.

- Spreader Bars: Use spreader bars when lifting multiple trusses to prevent bending or buckling during hoisting.

- Ground Protection: Place timbers or pads under trusses during on-site storage to prevent moisture absorption and warping.

Storage Requirements

On-Site Storage

- Location: Store on level, well-drained ground away from high-traffic areas.

- Elevation: Keep trusses elevated at least 6 inches off the ground using wood blocking to prevent corrosion and water damage.

- Covering: Protect trusses with breathable tarpaulins to shield from rain and snow while allowing airflow to reduce condensation.

- Stacking: Limit stack height to prevent bottom trusses from being crushed. Do not stack more than 3–4 layers unless designed for such loads.

Regulatory Compliance

Building Codes and Standards

- IBC and IRC Compliance: Metal floor trusses must meet International Building Code (IBC) and International Residential Code (IRC) standards for structural performance.

- ASTM Standards: Verify trusses comply with ASTM A653 (steel coating), ASTM A370 (mechanical testing), and other relevant material standards.

- Engineered Design: Each truss must be stamped by a licensed professional engineer (PE) indicating compliance with load, span, and deflection requirements.

Safety Regulations

- OSHA Guidelines: Follow OSHA 29 CFR 1926 for construction safety, including fall protection, rigging, and material handling.

- Lifting Safety: Ensure all personnel are trained in safe lifting practices and use proper personal protective equipment (PPE).

- Site Safety: Establish clear exclusion zones during unloading and installation to protect workers.

Documentation and Traceability

Required Documentation

- Shop Drawings: Provide approved shop drawings showing dimensions, member sizes, connection details, and labeling.

- Material Test Reports (MTRs): Supply MTRs certifying steel chemistry and mechanical properties.

- Inspection Records: Maintain quality control and third-party inspection reports as required by jurisdiction or project specifications.

- Certificates of Compliance: Include compliance certificates for fire resistance (if applicable), coatings, and environmental standards.

Labeling and Marking

- Truss Tags: Each truss must have a permanent, weather-resistant label indicating:

- Project name or number

- Truss designation (e.g., T-101)

- Orientation (top chord up)

- Installation location

- Date of manufacture

- Batch Tracking: Maintain batch numbers and production dates for traceability in case of recalls or field issues.

Environmental and Sustainability Compliance

Coatings and Finishes

- Galvanization: Confirm trusses are hot-dip galvanized per ASTM A123 to prevent corrosion.

- Alternative Coatings: If using painted or powder-coated finishes, ensure VOC compliance with local environmental regulations (e.g., EPA or CARB).

Recycling and Waste

- Scrap Metal Handling: Recycle off-cuts and damaged trusses through certified metal recyclers.

- Packaging Materials: Reuse or recycle wood dunnage, strapping, and protective films.

Installation Best Practices

Pre-Installation Checks

- Verify Deliveries: Inspect trusses upon arrival for damage, correct labeling, and compliance with shop drawings.

- Site Readiness: Confirm bearing surfaces are level, aligned, and properly prepared to receive trusses.

Erection Procedures

- Follow Manufacturer Guidelines: Install trusses per engineered instructions, including temporary bracing requirements.

- Bracing: Install permanent and temporary lateral bracing as specified to prevent buckling during and after installation.

- Connection Hardware: Use only specified fasteners (e.g., bolts, clips) and install to required torque values.

Conclusion

Adhering to this logistics and compliance guide ensures that metal floor trusses are transported, stored, and installed safely and in accordance with all applicable codes and standards. Proper documentation, handling, and coordination between suppliers, logistics providers, and construction teams are critical to project success and structural integrity.

In conclusion, sourcing metal floor trusses requires careful consideration of several key factors to ensure structural integrity, cost-effectiveness, and project efficiency. It is essential to partner with reputable suppliers or manufacturers who adhere to industry standards and provide high-quality, code-compliant materials. Evaluating the design specifications, load requirements, and compatibility with other building systems will help in selecting the most suitable truss system. Additionally, considering lead times, logistics, and technical support from suppliers can significantly impact project timelines and overall success. By conducting thorough research, obtaining competitive quotes, and maintaining clear communication with fabricators and engineers, builders and contractors can ensure a reliable supply of metal floor trusses that meet both performance expectations and budget constraints. Ultimately, a strategic sourcing approach contributes to safer, more durable, and cost-efficient construction outcomes.