The global metal corrugated fencing market is experiencing steady expansion, driven by increasing demand for durable, low-maintenance perimeter solutions across residential, commercial, and industrial sectors. According to Grand View Research, the global metal fencing market was valued at USD 52.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A key segment within this space—corrugated metal fencing—is gaining traction due to its strength, cost-efficiency, and adaptability to challenging environments, especially in infrastructure and agricultural applications. Supportive construction activities in emerging economies, coupled with rising urbanization and industrialization, are further fueling adoption. As the market becomes increasingly competitive, a select group of manufacturers have emerged as leaders, leveraging advanced production technologies, scalable operations, and geographic reach to capture significant market share. Based on market presence, product quality, innovation, and export capability, the following are the top 10 metal corrugated fencing manufacturers shaping the industry’s growth trajectory.

Top 10 Metal Corrugated Fencing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Berridge Manufacturing Co.

Domain Est. 1996

Website: berridge.com

Key Highlights: For over 50 years Berridge has worked to set the standard by designing, developing and manufacturing superior architectural metal products and technology….

#2

Domain Est. 2022

Website: davidiron.com

Key Highlights: David Iron Fence Manufacturer Inc. is a trusted manufacturer and distributor of wrought iron fences, gates, and railings across the United States. We combine ……

#3 Iron World Fencing

Domain Est. 2005

Website: ironworldfencing.com

Key Highlights: The fastest-growing manufacturer and distributor of decorative and ornamental iron fencing, aluminum fencing, chain link, slide, and swing gates nationwide….

#4 Corrugated Metal Fencing Panels

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: Buy corrugated metal fencing panels directly from the manufacturer and save. Over 100 colors to choose from. Delivery anywhere within the USA or Canada….

#5 Ametco Manufacturing

Domain Est. 1996

Website: ametco.com

Key Highlights: Ametco manufactures a wide range of steel fence and security gate systems as well as railings, sunshades, grilles, screens, louvers and perforated metal and ……

#6 Miller Fence

Domain Est. 2001

Website: millerfence.com

Key Highlights: Protect your garden in style with our customizable fencing, featuring vinyl, wood, or aluminum frames and your choice of infill — including wood, wire, ……

#7 Fencing & Roofing Materials

Domain Est. 2001

Website: madar.com

Key Highlights: Discover durable fencing and roofing materials for all projects. Steel fences and metal roofs offer strength, protection, and long-lasting reliability….

#8 Corrugated Metal Fence Panels for Privacy Fence

Domain Est. 2023

Website: barrierbossusa.com

Key Highlights: In stock Rating 5.0 (2) We are the first and only company to manufacture 7/8 corrugated metal fence panels specifically for sleek privacy fence applications….

#9 Corrugated Metal Fence

Domain Est. 2023

Website: coolcatfence.com

Key Highlights: A corrugated metal fence is built using ribbed or wavy metal panels, usually made from galvanized steel, mounted between posts and rails to form a sturdy, ……

#10 Metal Fence Panels for Security & Modern Style

Domain Est. 2023

Website: barrierboss.ca

Key Highlights: Explore BarrierBoss Metal Fencing Collection featuring durable, corrugated panels. Elevate your property’s security and curb appeal with premium metal ……

Expert Sourcing Insights for Metal Corrugated Fencing

H2: 2026 Market Trends for Metal Corrugated Fencing

The global metal corrugated fencing market is poised for significant evolution by 2026, driven by a confluence of economic, environmental, technological, and regulatory factors. Key trends shaping the landscape include:

1. Accelerated Demand in Infrastructure and Industrial Sectors:

Growth in public infrastructure projects (roads, railways, utilities) and expanding industrial zones (warehouses, logistics hubs, manufacturing plants) will remain the primary driver. Governments worldwide are increasing infrastructure spending, requiring durable, cost-effective, and quickly deployable fencing solutions. Corrugated metal fencing, valued for its strength and ease of installation, will see heightened demand, particularly in emerging economies.

2. Sustainability and Recyclability as Competitive Advantages:

With tightening environmental regulations and rising corporate ESG (Environmental, Social, Governance) commitments, the inherent recyclability of steel and aluminum corrugated fencing will become a major selling point. Producers emphasizing recycled content, low-carbon production methods (e.g., electric arc furnaces), and long product lifespans will gain market share. Demand for coatings with lower volatile organic compounds (VOCs) will also increase.

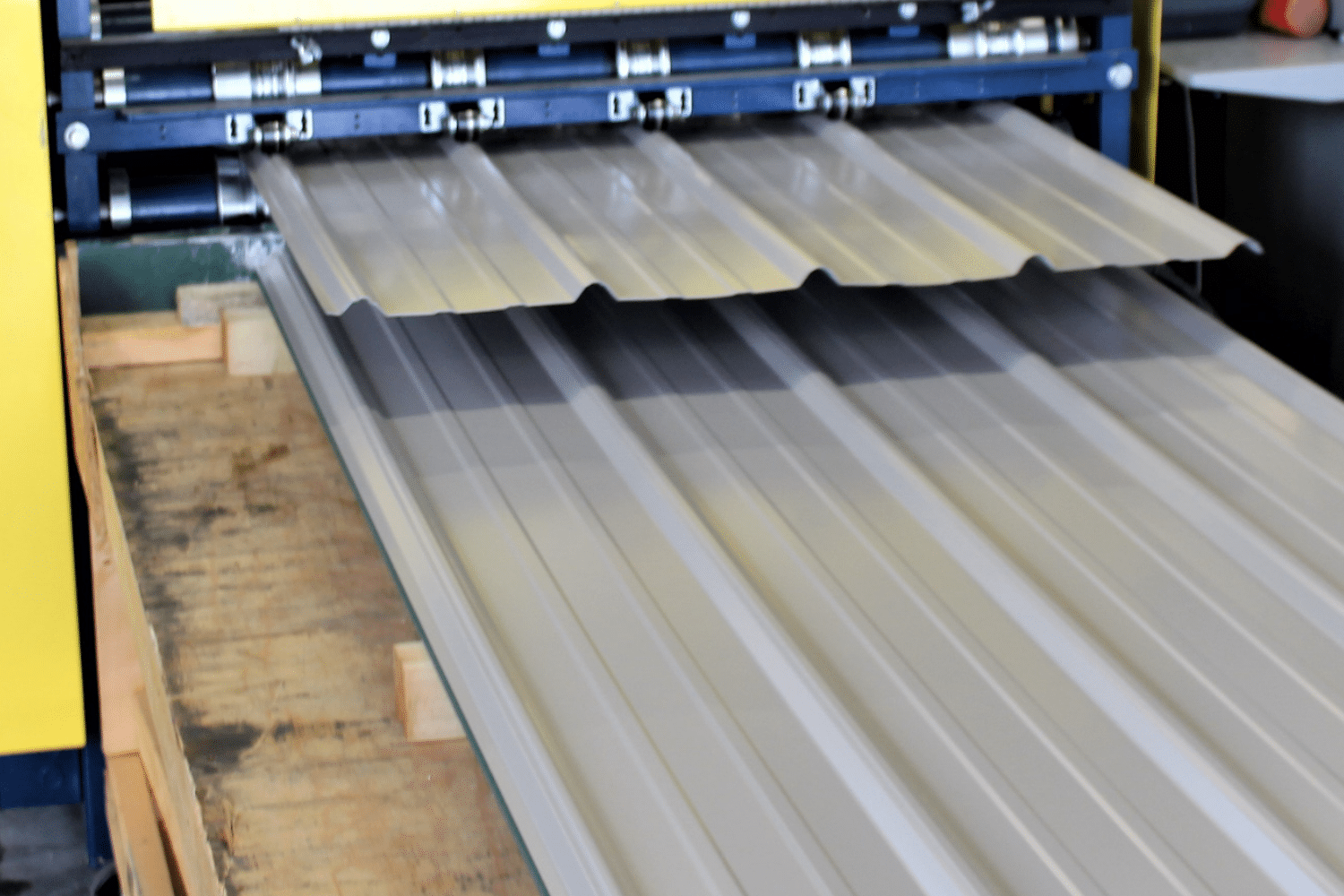

3. Technological Advancements in Coatings and Materials:

Innovations will focus on enhancing durability and reducing maintenance. Expect wider adoption of advanced corrosion-resistant coatings like:

* Zinc-Aluminum-Magnesium (ZAM) alloys: Offering superior protection, especially in harsh environments (coastal, industrial).

* Durable Organic Coatings (e.g., PVDF, SMP): Providing long-lasting color retention and weather resistance, appealing for aesthetic applications.

* Self-healing coatings: Emerging technologies that repair minor scratches to prevent rust propagation.

4. Regional Market Diversification and Urbanization:

While North America and Europe maintain steady demand due to replacement cycles and security needs, the fastest growth is anticipated in:

* Asia-Pacific: Driven by rapid urbanization, industrial expansion (especially in India, Southeast Asia), and government smart city initiatives.

* Middle East & Africa: Fueled by large-scale construction projects (e.g., NEOM, giga-projects) and oil & gas infrastructure security requirements.

5. Integration with Smart Security Systems:

While the fencing itself is passive, there will be a growing trend toward compatibility with smart security ecosystems. Corrugated panels may be designed to integrate seamlessly with:

* Perimeter intrusion detection systems (PIDS): Sensors mounted on or within the fence structure.

* Surveillance cameras and lighting: Pre-drilled mounts or integrated channels for wiring.

* Access control systems: Coordinated entry points using compatible gates.

6. Price Volatility and Supply Chain Resilience:

The market will remain sensitive to fluctuations in raw material prices (steel, aluminum, zinc) and energy costs. Geopolitical tensions and trade policies (e.g., tariffs) could impact supply chains. Producers investing in regional manufacturing, diversified sourcing, and efficient logistics will be better positioned to mitigate these risks and offer stable pricing.

7. Increased Focus on Aesthetics and Customization:

Beyond pure functionality, demand for visually appealing fencing will grow, especially in commercial, residential, and public space applications. This includes:

* Wider color palettes and textured finishes.

* Custom panel profiles and heights.

* Design elements that blend security with architectural appeal.

In conclusion, the 2026 metal corrugated fencing market will be characterized by robust demand fueled by infrastructure development, a strong emphasis on sustainability and durability, regional growth shifts toward Asia and the Middle East, and increasing integration with smart technologies. Success will depend on innovation in materials and coatings, supply chain agility, and the ability to meet evolving aesthetic and environmental standards.

Common Pitfalls When Sourcing Metal Corrugated Fencing: Quality and Intellectual Property Concerns

Sourcing metal corrugated fencing can be a cost-effective solution for construction, agriculture, and security applications. However, buyers often encounter challenges related to product quality and intellectual property (IP) rights. Being aware of these pitfalls can help ensure a reliable supply chain and protect legal and financial interests.

Inconsistent Product Quality

One of the most prevalent issues in sourcing metal corrugated fencing is inconsistent quality. Variations can occur in material thickness, coating durability, and structural integrity.

- Substandard Gauge Thickness: Suppliers may provide fencing sheets that are thinner than specified, compromising strength and longevity.

- Poor Galvanization: Inadequate zinc coating leads to premature rusting and corrosion, especially in humid or coastal environments.

- Inconsistent Corrugation Profile: Differences in wave pattern dimensions can affect interlocking capabilities and aesthetic uniformity.

To mitigate this, always request material test reports (MTRs), conduct third-party inspections, and perform site audits of manufacturing facilities.

Lack of Compliance with International Standards

Many suppliers, particularly in emerging markets, fail to adhere to recognized standards such as ASTM, ISO, or EN specifications.

- Fencing that doesn’t meet load or wind resistance standards may not perform as expected in harsh conditions.

- Non-compliant products can lead to project delays, rework, or legal liabilities.

Ensure suppliers certify compliance and verify through independent testing when necessary.

Intellectual Property (IP) Infringement Risks

Metal corrugated fencing designs—especially proprietary profiles, coatings, or connection systems—may be protected by patents or design rights.

- Copying Patented Profiles: Some manufacturers replicate patented corrugation patterns or interlocking mechanisms without authorization, exposing buyers to legal action.

- Trademark Violations: Unauthorized use of branded product names or logos can result in customs seizures or lawsuits, particularly in regulated markets like the EU or U.S.

Always conduct due diligence on design origins and request IP indemnification clauses in supplier contracts.

Supply Chain Transparency Issues

Opaque supply chains make it difficult to trace raw material sources or verify manufacturing practices.

- Risk of sourcing materials from conflict zones or unethical labor environments.

- Lack of traceability complicates quality control and IP verification.

Engage suppliers who provide full documentation and consider partnering with audited or certified vendors.

Conclusion

To avoid common pitfalls in sourcing metal corrugated fencing, prioritize quality assurance, regulatory compliance, and IP due diligence. Establish clear specifications, conduct thorough vetting of suppliers, and include protective terms in procurement agreements to safeguard your project and business.

Logistics & Compliance Guide for Metal Corrugated Fencing

Product Overview

Metal corrugated fencing, commonly made from galvanized steel or aluminum, is widely used for agricultural, industrial, and residential perimeter security. Its durability, ease of installation, and cost-efficiency make it a preferred choice. This guide outlines key logistics and compliance considerations for the international and domestic shipment of metal corrugated fencing.

Classification & Harmonized System (HS) Code

Accurate product classification is essential for customs clearance and tariff assessment.

– Typical HS Code: 7308.90 – “Fences, gates, balustrades and similar structures and parts thereof, of iron or steel”

– Regional Variations:

– US: 7308.90.99 (Other assembled fence sections)

– EU: 7308.90.90 (Other structures and parts of iron or steel)

– Australia: 7308.90.00

Note: Confirm classification based on material composition, finish, and assembly status (pre-assembled vs. panels).

Packaging & Unit Load Configuration

Proper packaging ensures product integrity during transit.

– Standard Packaging:

– Panels bundled with rust-inhibiting film or wrap

– Secured with steel or polymer strapping

– Wooden or metal skids for palletization

– Pallet Dimensions:

– Standard EUR/EPAL pallet: 1200mm × 800mm

– Standard US pallet: 48″ × 40″

– Load Stability: Use corner boards and stretch-wrapping to prevent shifting during transport.

Transportation Modes & Considerations

Choose transportation based on cost, distance, and delivery timeline.

– Maritime Shipping (FCL/LCL):

– Ideal for large-volume international shipments

– Secure cargo against saltwater exposure using VCI (Vapor Corrosion Inhibitor) wraps

– Ensure proper container ventilation to reduce condensation

– Overland (Truck/Rail):

– Use flatbed or enclosed trailers

– Cover loads with waterproof tarps to prevent rain damage

– Confirm road clearance height and weight limits

– Air Freight: Rare due to high cost and weight; typically reserved for urgent, small-batch deliveries.

Import & Export Documentation

Complete and accurate documentation prevents delays at borders.

– Essential Documents:

– Commercial Invoice

– Packing List

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin

– Import/Export License (if required by destination country)

– Additional Requirements:

– Phytosanitary certificate (if wooden skids/packaging are used – ISPM 15 compliance required)

– Customs bond (for US imports)

Regulatory & Safety Compliance

Adherence to international and local standards is mandatory.

– Material Standards:

– ASTM A653/A653M (Standard for galvanized steel sheet)

– ISO 1461:2020 (Hot-dip galvanized coatings on fabricated iron and steel articles)

– Environmental & Chemical Regulations:

– REACH (EU): Ensure no restricted substances (e.g., lead, chromium VI) exceed permissible limits

– RoHS (if applicable): Though typically for electronics, check for coated finishes

– Safety in Use:

– Comply with local building codes (e.g., height restrictions, setback requirements)

– Provide installation and safety guidelines to end users

Country-Specific Compliance Requirements

Regulations vary by destination; verify before shipping.

– United States:

– Imported fencing may be subject to anti-dumping or countervailing duties (e.g., from certain countries)

– CBP (Customs and Border Protection) may require prior notice for steel products

– European Union:

– CE marking not typically required for basic fencing, but structural installations may need conformity with EN 1090 for execution of steel structures

– Green Public Procurement (GPP) considerations for public projects

– Australia/New Zealand:

– Must meet AS/NZS 4687:2021 (Metal fencing systems)

– Quarantine inspection for wooden packaging (ISPM 15)

Storage & Handling Recommendations

Proper on-site handling maintains product quality.

– Storage Conditions:

– Store indoors or under cover to prevent moisture accumulation

– Elevate pallets off the ground to avoid water pooling

– Avoid direct contact with soil or concrete to reduce corrosion risk

– Handling:

– Use forklifts or cranes with appropriate lifting slings

– Avoid dragging panels to prevent coating damage

Sustainability & End-of-Life Considerations

Environmental responsibility enhances compliance and brand image.

– Recyclability:

– Steel and aluminum components are 100% recyclable

– Provide recycling guidelines to customers

– Carbon Footprint:

– Optimize logistics routes to reduce emissions

– Use recyclable or reusable packaging materials

Conclusion

Shipping metal corrugated fencing efficiently and compliantly requires attention to classification, packaging, documentation, and regional regulations. Proactive planning and adherence to international standards ensure smooth logistics operations and minimize customs delays. Always consult with freight forwarders and legal experts to stay updated on evolving trade requirements.

In conclusion, sourcing metal corrugated fencing requires careful consideration of material quality, supplier reliability, cost-effectiveness, and long-term durability. Choosing the right type of metal—such as galvanized steel or aluminum—ensures resistance to corrosion and enhances longevity, particularly in challenging environmental conditions. It is essential to evaluate suppliers based on reputation, compliance with industry standards, and ability to meet project timelines. Additionally, factoring in installation requirements, maintenance needs, and total lifecycle costs will contribute to a more sustainable and economical fencing solution. By conducting thorough research and due diligence, businesses and individuals can secure high-performance metal corrugated fencing that offers security, aesthetic appeal, and value for money over time.