The global demand for durable outdoor combustion solutions has seen steady growth, driven by increasing residential, agricultural, and industrial waste management needs. According to Grand View Research, the global waste container market was valued at USD 7.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030, with metal burn barrels representing a significant segment due to their durability and regulatory compliance in controlled burning applications. This rising demand has spurred innovation and competition among manufacturers specializing in heavy-duty steel combustion units. As consumers prioritize safety, efficiency, and environmental compliance, eight key players have emerged as leaders in engineering high-performance metal burn barrels—combining reinforced construction, advanced ventilation systems, and rust-resistant finishes. Leveraging market insights and product benchmarking, this overview highlights the top manufacturers shaping the industry through quality, scalability, and customer-driven design.

Top 8 Metal Burn Barrel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 What We Do

Domain Est. 2010

Website: bumdrums.com

Key Highlights: BUMDRUMS, LLC is a Western Mass company that manufacturers burn barrels/fire pits out of steel 30 and 55 gallon drums for grilling and staying warm at outdoor ……

#2 Quality Drums & Barrels

Domain Est. 2015 | Founded: 1942

Website: jakackibarrels.com

Key Highlights: Jakacki Bag & Barrel, Inc. offers top-quality reconditioned fiber, steel, and plastic drums. Leading the industry since 1942. Request a quote today!…

#3 Barrel Company

Domain Est. 2012

Website: barrel-company.com

Key Highlights: We have a wide variety of products, not just barrels for storage but many other helpful products to get you what you need all in one place….

#4 Jay’s Barrel And Drum Supply

Domain Est. 2012

Website: jaysbarreldrumsupplyibctotecontainers.com

Key Highlights: Jay’s Barrel and Drum Supply is a supplier of metal,plastic,stainless steel containers and whiskey barrels. Contact us in Athens, AL for more details….

#5 X

Domain Est. 2014

Website: x-caliber.net

Key Highlights: Build a custom AR-15 barrel specifically for use with a Superlative Arms Piston Kit. This barrel will come with properly sized and spaced gas block journal ……

#6 Incinerators and Burn Barrels

Domain Est. 2015

Website: riversideindustriesllc.com

Key Highlights: Riverside designs and manufactures incinerators and burn barrels to meet the needs of the toughest industries….

#7 Burn Barrel

Website: 55gallondrumcompanies.com

Key Highlights: Burn barrels are cylindrical containers, typically made from repurposed steel drums or purpose-built metal cylinders, designed for the controlled incineration ……

#8 Burn Barrel Manufacturers and Suppliers

Domain Est. 2004

Website: iqsdirectory.com

Key Highlights: Burn barrel suppliers can be found here on IQS through a wide range of trusted companies. They offer fast shipping, competitive prices, and quality service….

Expert Sourcing Insights for Metal Burn Barrel

H2: Emerging Market Trends Shaping the Metal Burn Barrel Industry (2026 Outlook)

The metal burn barrel market in 2026 is expected to be shaped by a complex interplay of regulatory pressures, environmental awareness, technological shifts, and evolving consumer preferences. While demand persists for waste disposal and outdoor heating, significant trends point toward transformation, adaptation, and potential decline in traditional markets, alongside niche opportunities.

1. Regulatory Crackdown & Environmental Scrutiny (Dominant Trend):

* Stricter Regulations: Expect widespread implementation and enforcement of bans or severe restrictions on open burning, particularly in urban, suburban, and ecologically sensitive areas. This is driven by air quality concerns (PM2.5, VOCs, dioxins) linked to burn barrels and climate change policies.

* Shift to Alternatives: Regulations will accelerate the adoption of alternatives like municipal composting, curbside yard waste collection, professional waste disposal services, and electric or gas-powered outdoor heaters. The burn barrel will increasingly be seen as an outdated, non-compliant solution.

* Compliance-Driven Design (Niche): A small segment may see demand for barrels explicitly marketed as not for open burning, potentially repurposed for controlled composting (e.g., “rocket mass heater” designs) or non-combustion uses, but this is not the core traditional market.

2. Consumer Shift Towards Sustainability & Health Awareness:

* Environmental Consciousness: Growing public awareness of air pollution and climate impact will make consumers less tolerant of visible smoke and odors from neighbors’ burn barrels, increasing social pressure and reporting.

* Health Concerns: Heightened focus on respiratory health (especially post-pandemic) will make the health risks associated with burn barrel emissions a significant deterrent for many potential users.

* Preference for Cleaner Tech: Consumers seeking outdoor heat or waste management will increasingly opt for cleaner, more efficient, and often more convenient solutions like propane fire pits, electric patio heaters, or dedicated compost tumbler systems.

3. Economic & Material Cost Pressures:

* Steel Price Volatility: Fluctuations in global steel prices (driven by energy costs, tariffs, supply chains) will impact manufacturing costs and retail prices for metal burn barrels, potentially squeezing margins.

* Competition from Alternatives: While the core market shrinks, competition from established, often higher-margin alternatives (gas fire pits, professional disposal services) will intensify, making it harder for traditional burn barrel manufacturers to compete on value or perception.

4. Niche Persistence & Adaptation:

* Rural & Remote Areas: Demand will likely persist strongest in rural, agricultural, or remote regions where disposal options are limited, regulations are less enforced, and land is abundant. This will remain the core market segment.

* Specialized Uses: Limited demand may exist for barrels used in very specific, non-open-burning applications (e.g., contained industrial waste pre-treatment where permitted, specific metalworking processes, or as components in DIY off-grid systems like wood gasifiers – though these are not typical consumer burn barrels).

* “Survivalist” & Off-Grid Markets: A small but dedicated market exists among preppers and off-grid communities valuing self-reliance and low-tech solutions, though even here, cleaner alternatives are gaining ground.

5. Technological Stagnation & Limited Innovation:

* Low Innovation: The fundamental design of the metal burn barrel is simple and mature. Significant technological innovation is unlikely. Any minor improvements (e.g., slightly better airflow, dual-wall designs for safety) will be incremental and unlikely to overcome core environmental drawbacks.

* Focus on Safety (Compliance): Any innovation will likely focus on mitigating risks (e.g., lids, spark arrestors) rather than enhancing the core burning function, driven by liability and regulatory compliance needs.

Conclusion for 2026:

The dominant H2 trend for the metal burn barrel market in 2026 is significant contraction and marginalization due to overwhelming regulatory and environmental pressures. Growth is highly improbable. The market will shrink further as bans spread and consumer preferences shift decisively towards cleaner, more sustainable alternatives for waste management and outdoor heating. Survival will depend almost entirely on serving the persistent niche in rural areas and adapting marketing to focus on non-combustion repurposing or compliance with increasingly strict safety features. Manufacturers face a challenging future requiring adaptation or exit from the traditional open-burning barrel segment.

Common Pitfalls Sourcing Metal Burn Barrels (Quality, IP)

Sourcing metal burn barrels, especially for industrial or controlled burning applications, requires careful attention to both quality standards and intellectual property (IP) considerations. Overlooking these aspects can lead to safety hazards, regulatory non-compliance, and legal exposure. Below are key pitfalls to avoid:

Poor Material Quality and Construction

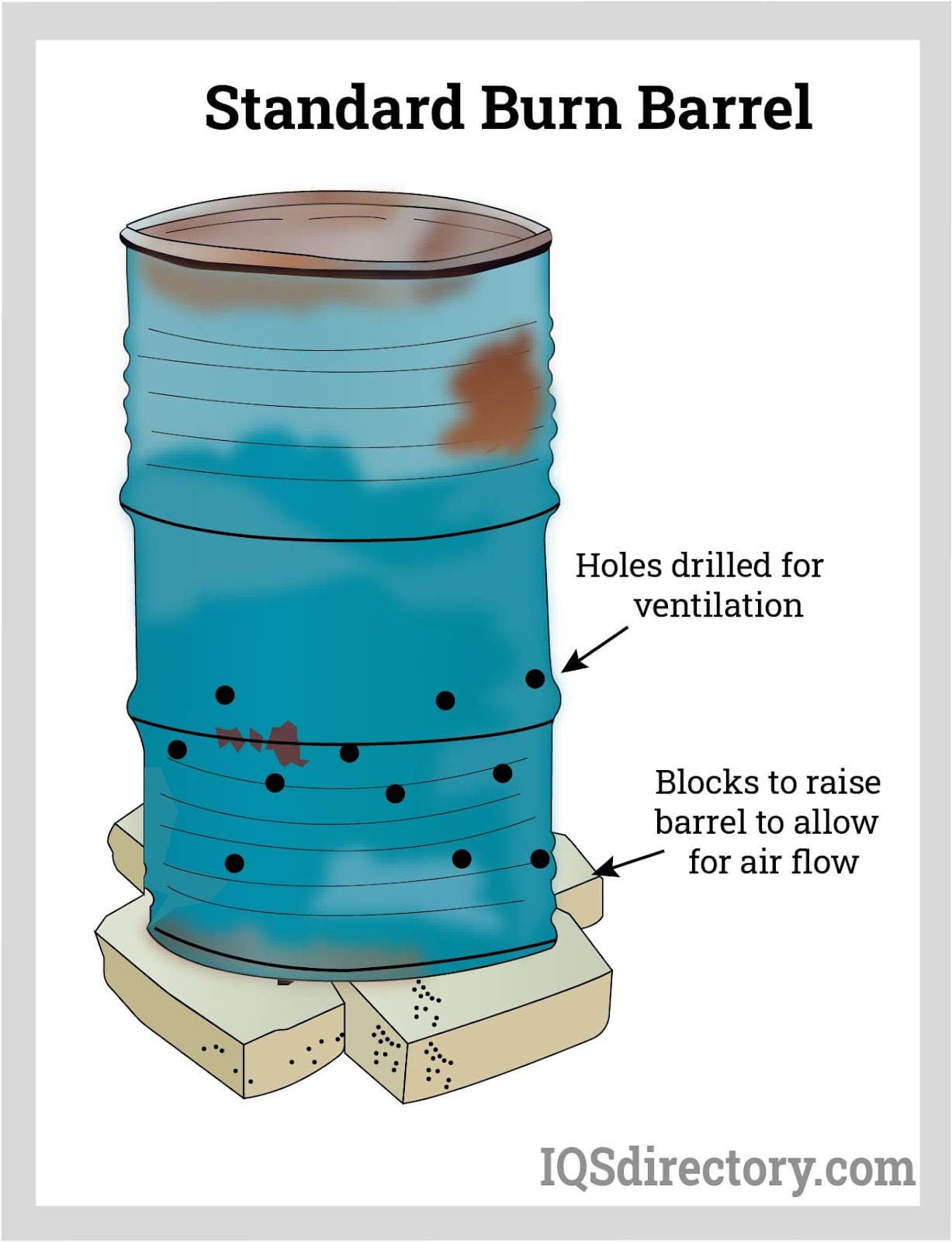

One of the most frequent issues when sourcing burn barrels is receiving products made from substandard materials or with inadequate craftsmanship. Low-quality steel may be too thin, prone to warping, or susceptible to rapid corrosion under high heat, significantly shortening the barrel’s lifespan and creating safety risks. Poor welding can lead to structural failure during use, increasing the risk of fire spread or injury. Always verify material specifications (e.g., steel gauge, heat resistance) and inspect for consistent, clean welds before procurement.

Lack of Compliance with Safety and Environmental Standards

Many suppliers, particularly overseas or uncertified manufacturers, produce burn barrels that do not meet regional safety or emissions regulations (e.g., EPA guidelines in the U.S.). Barrels without proper ventilation design, fire containment features, or spark arrestors may be illegal to use in certain jurisdictions. Sourcing non-compliant barrels can expose buyers to fines or liability in case of accidents. Ensure the supplier provides documentation confirming adherence to relevant standards.

Infringement on Protected Designs or Patents

Burn barrel designs—especially those with unique airflow systems, locking lids, or proprietary mounting features—may be protected by patents or design rights. Sourcing from manufacturers that replicate patented designs without authorization exposes the buyer to IP infringement claims, particularly if the barrels are imported or resold. Conduct due diligence to confirm that the design does not violate existing patents, and request indemnification clauses in supplier contracts where possible.

Misrepresentation of Origin and Branding

Some suppliers falsely advertise burn barrels as being made in specific countries (e.g., “Made in USA”) or falsely associate them with reputable brands. This misrepresentation affects both quality expectations and legal compliance. Verify the actual manufacturing origin and check for authentic branding or certifications. Third-party audits or site visits can help validate supplier claims.

Inadequate Documentation and Traceability

Lack of proper quality control documentation—such as material test reports, weld certifications, or compliance certificates—makes it difficult to verify the barrel’s integrity or defend against liability claims. Additionally, poor traceability hinders product recalls or warranty claims. Insist on complete documentation packages and batch traceability from your supplier.

By proactively addressing these pitfalls, buyers can ensure they source durable, compliant, and legally sound metal burn barrels while mitigating operational and legal risks.

Logistics & Compliance Guide for Metal Burn Barrel

Shipping and Handling Procedures

When transporting a metal burn barrel, ensure the unit is clean, dry, and free of residual ash or combustible materials. Secure the barrel in an upright position during transit using straps or bracing to prevent rolling or tipping. Use palletized shipping for bulk orders to maintain stability and protect against damage. Clearly label packages as “Heavy Equipment” and “Do Not Stack” when appropriate. Coordinate delivery times with the receiving party to avoid extended outdoor storage, which may lead to rust or water accumulation.

Storage Recommendations

Store metal burn barrels in a dry, well-ventilated area away from flammable materials, moisture, and extreme weather conditions. Elevate barrels off the ground using pallets or racks to prevent bottom corrosion. Keep lids closed when not in use to minimize debris and moisture entry. If stored outdoors, cover with a durable, waterproof tarp that allows ventilation to reduce condensation buildup.

Regulatory Compliance

Compliance with local, state, and federal regulations is essential when using a metal burn barrel. Many jurisdictions prohibit or restrict open burning due to air quality concerns under regulations such as the Clean Air Act. Before use, verify with local fire departments or environmental protection agencies whether burn barrel usage is permitted. In areas where allowed, only burn dry, untreated wood or approved materials—never plastics, rubber, painted or treated lumber, or household waste, as these release toxic fumes.

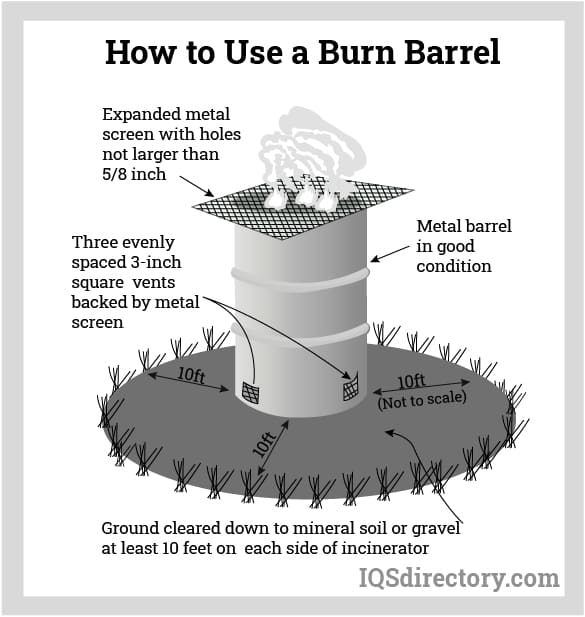

Environmental and Safety Standards

Metal burn barrels must meet safety design standards to minimize fire hazards and emissions. Units should feature adequate ventilation (e.g., air intake holes near the base) and be constructed from thick-gauge steel to withstand high temperatures. Always operate the burn barrel on a non-combustible surface such as dirt, gravel, or concrete, and maintain a minimum 10-foot clearance from structures, vegetation, and property lines. Keep a fire extinguisher, garden hose, or sand nearby during use.

Disposal and Decommissioning

At end-of-life, dispose of metal burn barrels in accordance with local scrap metal recycling guidelines. If the barrel is contaminated with hazardous residues (e.g., from burning treated materials), consult a hazardous waste disposal service. Never abandon or illegally dump used burn barrels. For decommissioning, fully extinguish any remaining embers, allow the unit to cool, and dismantle or recycle responsibly.

Documentation and Recordkeeping

Maintain records of purchase, intended use, and compliance checks with local ordinances. Businesses using burn barrels for waste management may be required to keep logs of burn dates, materials burned, and weather conditions. These records support regulatory audits and demonstrate responsible operational practices.

In conclusion, sourcing a metal burn barrel requires careful consideration of material quality, size, local regulations, and safety standards. It is essential to select a durable, heat-resistant barrel—preferably made from thick steel—and to verify compliance with local environmental and burn regulations to avoid legal or safety issues. Whether purchasing from industrial suppliers, online marketplaces, or local fabricators, vetting the source for reliability and product specifications is crucial. Additionally, implementing proper safety measures such as stable placement, ventilation, and fire prevention will ensure responsible and effective use. By thoroughly researching and selecting the right burn barrel from a reputable source, users can achieve a long-lasting, safe, and efficient solution for controlled waste disposal.