The global metal brackets market is experiencing steady expansion, driven by rising demand across industrial, automotive, and construction sectors. According to Grand View Research, the global structural metal components market was valued at USD 1.37 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030. This growth is fueled by increasing infrastructure development, advancements in manufacturing technologies, and the need for durable, high-performance fastening solutions. Metal brackets, as critical components in assembly and structural support systems, are benefiting from this upward trend. Additionally, Mordor Intelligence forecasts sustained demand in North America and Asia-Pacific, where industrial automation and building & construction activities are accelerating. As competition intensifies, a select group of manufacturers are leading the market through innovation, scalability, and stringent quality standards—setting the benchmark for performance and reliability.

Top 10 Metal Braket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom Metal Brackets

Domain Est. 1999

Website: monarchmetal.com

Key Highlights: Custom Brackets Buy all sizes of corner guards in one place, manufacturer direct, with the product often shipping out the same day the order is placed….

#2 Custom Metal Brackets Made in the USA

Domain Est. 1996

Website: valcocleve.com

Key Highlights: As a metal bracket manufacturer, we work closely with our customers to streamline the manufacturing process and meet their project needs. At ……

#3 Steel Brackets, Tabs, & Miscellaneous

Domain Est. 1999

Website: industrialmetalsupply.com

Key Highlights: 30-day returnsSteel brackets and industrial metal power tabs are manufactured from premium materials and are used with other components to create various finished products….

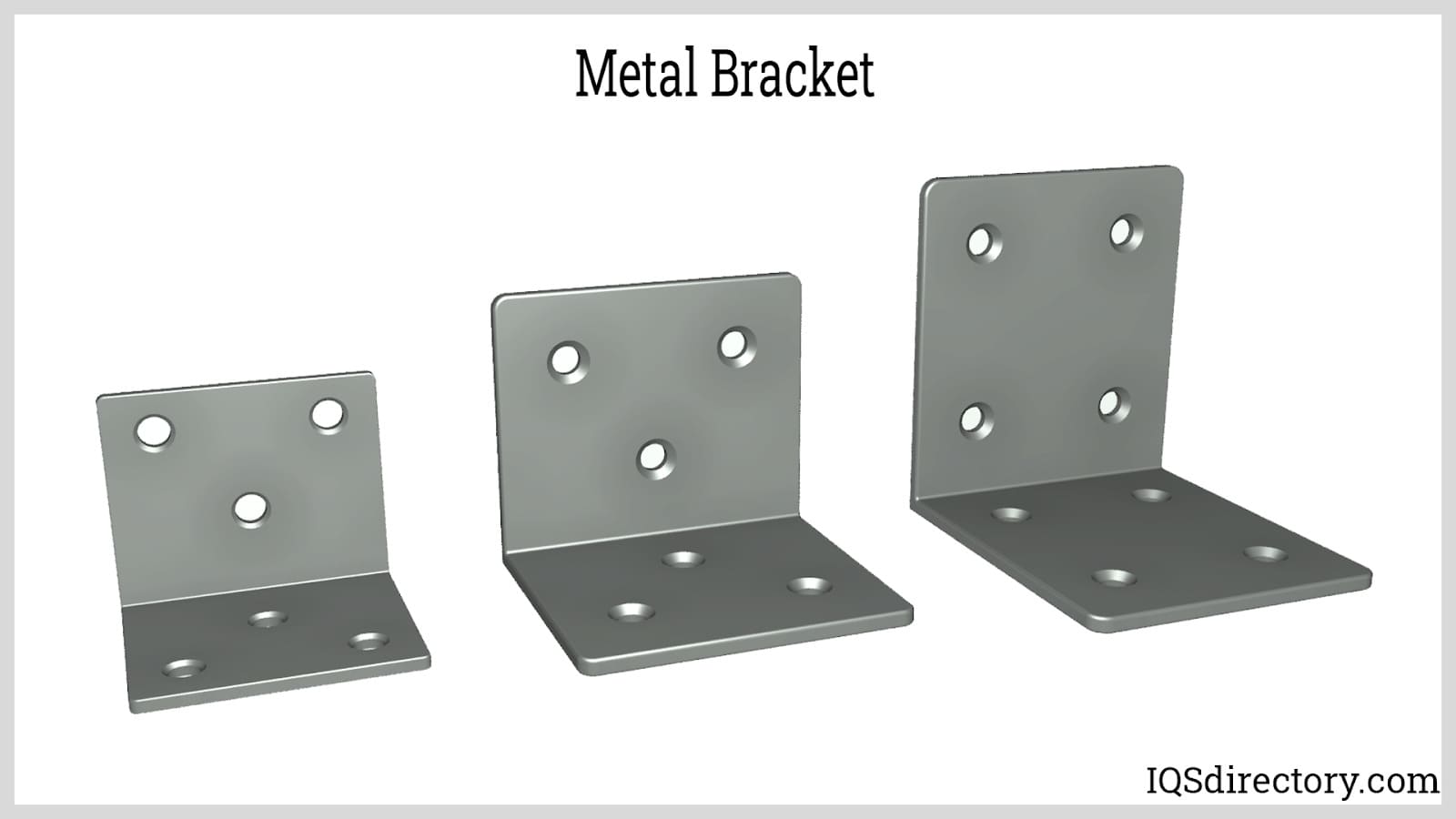

#4 Leading Metal Bracket Manufacturers

Domain Est. 2001

Website: metalstamper.net

Key Highlights: World-class fabricators from the leading metal bracket companies can be found on this site. Easily connect with the top metal bracket manufacturer….

#5 Federal Brace

Domain Est. 2009

Website: federalbrace.com

Key Highlights: Federal Brace manufactures a full line of support products for various residential, commercial, and industrial applications….

#6 Simpson Strong

Domain Est. 1995

Website: strongtie.com

Key Highlights: Welcome to the Simpson Strong-Tie homepage showcasing our resources, products and services designed to help people build safer, stronger structures….

#7 Custom Metal Brackets

Domain Est. 1998

Website: keatsmfg.com

Key Highlights: Keats Manufacturing’s custom metal bracket capabilities include various design options, materials, and finishes to meet the needs of many applications….

#8 Custom Sheet

Domain Est. 2001

Website: protocase.com

Key Highlights: Get custom sheet metal brackets exactly how you need them. Protocase offers full customization, fast lead times and no minimum order requirements….

#9 ClarkDietrich Building Systems

Domain Est. 2011

Website: clarkdietrich.com

Key Highlights: From framing to finishing, from interior to exterior, from digital tools to engineering expertise, our leading products and services work as a system. A system ……

#10 Brackets Custom Metal Stainless Steel

Domain Est. 2015

Website: metalfabgroup.com

Key Highlights: Our dedicated staff at MetalFab Group can manufacture custom brackets from your sketch or drawing, including DXF, DWG and solid models….

Expert Sourcing Insights for Metal Braket

H2: 2026 Market Trends for Metal Brackets

As we approach 2026, the global market for metal brackets is poised for transformative growth and innovation, driven by advancements in manufacturing technologies, evolving industrial demands, and a heightened focus on sustainability. Metal brackets—essential components in construction, automotive, aerospace, electronics, and consumer goods—are undergoing significant shifts in material selection, design optimization, and production methodologies. Below is an analysis of the key trends expected to shape the metal bracket market in 2026.

-

Increased Demand from Construction and Infrastructure

With governments worldwide investing heavily in infrastructure modernization and smart city development, the construction sector continues to be a primary driver of metal bracket demand. In 2026, increased use of prefabricated and modular construction techniques will boost the need for standardized, durable metal brackets that ensure structural integrity and faster assembly. Regions such as Asia-Pacific and Africa, experiencing rapid urbanization, will see particularly high growth. -

Advancements in Lightweight and High-Strength Alloys

The automotive and aerospace industries are demanding lighter yet stronger components to improve fuel efficiency and reduce emissions. By 2026, the adoption of advanced materials such as high-strength aluminum alloys, titanium, and high-performance steel composites in bracket manufacturing is expected to rise significantly. These materials offer superior strength-to-weight ratios, corrosion resistance, and longevity, making them ideal for safety-critical applications. -

Growth in Automation and Precision Manufacturing

The integration of automation, robotics, and computer-aided manufacturing (CAM) systems is revolutionizing metal bracket production. In 2026, smart factories equipped with AI-driven quality control and real-time monitoring will dominate the market. This shift enables tighter tolerances, reduced waste, and faster turnaround times—particularly important for industries like electronics and medical devices that require miniaturized, highly precise brackets. -

Expansion of 3D Printing and Additive Manufacturing

Additive manufacturing is gaining traction for producing complex, customized metal brackets that are difficult or costly to fabricate using traditional methods. By 2026, 3D printing technologies such as Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) will be more widely adopted, especially in aerospace, defense, and medical applications. This trend supports on-demand production, design flexibility, and supply chain resilience. -

Sustainability and Circular Economy Pressures

Environmental regulations and corporate sustainability goals will drive the recycling and reuse of metal brackets. In 2026, manufacturers will prioritize eco-friendly processes, including energy-efficient machining, reduced emissions, and the use of recycled metals. Design for disassembly and life-cycle assessment (LCA) will become standard practices, especially in the EU and North America, where green procurement policies are tightening. -

Rising Adoption in Renewable Energy Infrastructure

The global push toward renewable energy sources—such as solar and wind—will increase demand for specialized metal brackets used in mounting systems and structural supports. By 2026, the solar panel racking market alone is expected to be a major growth segment, requiring corrosion-resistant, durable brackets capable of withstanding extreme weather conditions. -

Regional Market Dynamics

Asia-Pacific will remain the largest and fastest-growing market for metal brackets due to booming industrialization in countries like India, Vietnam, and Indonesia. Meanwhile, North America and Europe will focus on high-value, technologically advanced brackets for aerospace, automotive, and smart infrastructure. Emerging markets in Latin America and the Middle East will also see steady growth, supported by infrastructure investments.

In summary, the 2026 metal bracket market will be characterized by innovation in materials, manufacturing technologies, and sustainability. Companies that invest in R&D, adopt digital manufacturing tools, and align with global environmental standards will be well-positioned to capitalize on these trends and gain competitive advantage.

Common Pitfalls Sourcing Metal Brackets (Quality, IP)

Sourcing metal brackets may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to significant issues, including product failure, safety hazards, legal disputes, and reputational damage. Below are common pitfalls to avoid:

Quality-Related Pitfalls

Inadequate Material Specification

Failing to specify the exact metal grade, alloy composition, or treatment (e.g., stainless steel 304 vs. 316, galvanized vs. powder-coated) can result in brackets that corrode, deform, or fail under load. Always define material standards (e.g., ASTM, ISO) in procurement contracts.

Poor Dimensional Tolerances

Tight tolerances are critical for fit and function. Suppliers may cut corners on machining or stamping, leading to misalignment or assembly issues. Ensure detailed engineering drawings with clearly defined tolerances are provided and inspected.

Insufficient Surface Finish and Corrosion Protection

A subpar finish not only affects appearance but also long-term durability. Brackets exposed to moisture or harsh environments require proper coatings (e.g., zinc plating, anodizing). Verify coating thickness and salt spray test results before approving suppliers.

Lack of Load and Stress Testing

Assuming a bracket can handle required loads without verification is risky. Always require proof of mechanical testing (e.g., tensile, shear, fatigue) and validate performance under expected operating conditions.

Inconsistent Quality Control Processes

Suppliers with weak QC systems may deliver inconsistent batches. Audit supplier facilities or require third-party inspection reports (e.g., ISO 9001 certification) to ensure consistent quality.

Intellectual Property (IP)-Related Pitfalls

Unintentional IP Infringement

Sourcing brackets that replicate patented designs—even if modified—can expose your company to legal action. Conduct thorough IP due diligence, including patent searches, before procuring from third parties.

Lack of IP Ownership Clauses in Contracts

When custom brackets are designed, failing to secure IP rights in the contract means the supplier may retain ownership or resell the design to competitors. Clearly state that all IP developed for your project transfers to you.

Use of Counterfeit or Copycat Parts

Some suppliers offer “generic” versions of branded brackets that infringe on IP. These may be lower quality and legally risky. Source only from authorized or reputable manufacturers and verify design originality.

Insufficient Documentation for Regulatory Compliance

In regulated industries (e.g., medical, aerospace), brackets must meet strict standards. Using non-compliant or undocumented parts can violate IP and safety regulations. Require full traceability, material certifications, and compliance documentation.

Avoiding these pitfalls requires clear specifications, rigorous supplier vetting, and proactive IP management. Investing time upfront ensures reliable performance and legal safety throughout the product lifecycle.

Logistics & Compliance Guide for Metal Brackets

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and lawful handling, transportation, and documentation of metal brackets throughout the supply chain.

Product Classification & Specifications

Metal brackets are typically categorized as industrial hardware or fabricated metal components. Accurate classification is critical for compliance and logistics planning. Key specifications include material type (e.g., steel, aluminum, stainless steel), dimensions, weight, coating (e.g., galvanized, powder-coated), and load rating. Ensure technical data sheets (TDS) and material certifications (e.g., mill test reports) are available for traceability and quality assurance.

Packaging & Unit Load Design

Proper packaging prevents damage during handling and transit. Metal brackets should be:

– Packed in sturdy corrugated cardboard boxes, wooden crates, or metal containers based on weight and fragility.

– Separated with protective materials (e.g., foam inserts, bubble wrap) to prevent scratching or deformation.

– Palletized using standard pallet sizes (e.g., 48” x 40” in North America) and secured with strapping or stretch wrap.

– Labeled with handling instructions (e.g., “Do Not Stack,” “Fragile,” “This Side Up”) and orientation arrows.

Hazardous Materials & Safety Compliance

Most metal brackets are non-hazardous. However, verify compliance with safety standards:

– Confirm absence of hazardous coatings or residues (e.g., lead-based paints) per OSHA and EPA regulations.

– If treated with oils or rust inhibitors, ensure compliance with GHS labeling and SDS (Safety Data Sheet) requirements.

– Adhere to workplace safety standards (e.g., OSHA 29 CFR 1910) for handling sharp or heavy components.

International Trade & Documentation

For cross-border shipments, ensure compliance with international trade regulations:

– Obtain a correct HS Code (e.g., 7326.90 for other articles of iron or steel) for customs clearance.

– Prepare commercial invoice, packing list, bill of lading, and certificate of origin.

– Comply with import/export controls such as EAR (Export Administration Regulations) if applicable.

– Verify adherence to trade agreements (e.g., USMCA, CE marking for EU) and country-specific standards.

Environmental & Regulatory Compliance

Metal brackets must meet environmental and industry-specific regulations:

– Comply with RoHS (Restriction of Hazardous Substances) and REACH (EU) if sold in Europe.

– Follow local environmental laws regarding metal waste and recycling.

– Ensure products meet industry standards such as ASTM, ISO, or DIN where required (e.g., ASTM A123 for zinc coatings).

Transportation & Carrier Requirements

Choose appropriate freight modes (road, rail, air, sea) based on volume, urgency, and destination:

– For ocean freight, use containers that prevent moisture exposure (consider desiccants).

– For air freight, respect weight and dimensional constraints.

– Use carriers compliant with applicable regulations (e.g., FMCSA in the U.S.).

– Implement tracking systems for real-time shipment visibility.

Customs Clearance & Duties

Facilitate smooth customs processing by:

– Providing accurate product descriptions and valuation.

– Ensuring correct tariff classification and duty rates.

– Submitting required permits or licenses if applicable (e.g., for strategic metals).

– Leveraging bonded warehouses or FTZs (Foreign-Trade Zones) to defer duties when possible.

Storage & Inventory Management

Store metal brackets in a dry, secure environment to prevent corrosion:

– Use racking systems that allow easy access and FIFO (First In, First Out) rotation.

– Protect from moisture and contaminants; elevate pallets off the floor.

– Monitor inventory levels using barcode or RFID systems for traceability.

Quality Assurance & Audit Readiness

Maintain compliance through regular audits and documentation:

– Keep records of inspections, test results, and supplier certifications.

– Implement a quality management system (e.g., ISO 9001).

– Prepare for third-party audits by regulatory bodies or customers.

Returns & Reverse Logistics

Establish a clear process for handling returns:

– Inspect returned brackets for damage or wear.

– Document reason for return and update inventory systems.

– Recycle or rework non-conforming items in compliance with environmental standards.

By following this guide, businesses can ensure the reliable and compliant movement of metal brackets from production to end-user, minimizing delays, costs, and regulatory risks.

Conclusion for Sourcing Metal Brackets

After a thorough evaluation of potential suppliers, material options, cost considerations, and quality standards, sourcing metal brackets can be successfully achieved by aligning supplier capabilities with project requirements. Key factors such as material durability (e.g., steel, aluminum, or stainless steel), precision in manufacturing, compliance with industry standards, and timely delivery play a crucial role in ensuring reliability and performance.

Opting for suppliers with proven quality certifications (e.g., ISO 9001), competitive pricing, and a track record of on-time delivery will help minimize risks and support long-term operational efficiency. Additionally, establishing strong supplier relationships and conducting periodic performance reviews can enhance supply chain resilience.

In conclusion, a strategic sourcing approach—balancing cost, quality, and reliability—will ensure the consistent supply of high-performance metal brackets necessary to meet production goals and maintain product integrity.