The global metal bracket support market is experiencing steady growth, driven by rising demand across construction, industrial manufacturing, and infrastructure development sectors. According to Grand View Research, the global structural supports market was valued at USD 15.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by increasing construction activities, stringent safety regulations, and the need for durable load-bearing solutions in commercial and industrial applications. Metal bracket supports—critical for enhancing structural integrity, enabling modular construction, and ensuring long-term reliability—are at the heart of this expansion. As demand intensifies, manufacturers are focusing on innovation in materials, load capacity, and corrosion resistance to meet evolving engineering requirements. Based on market presence, production capabilities, product range, and technological advancements, the following ten companies have emerged as leading manufacturers of metal bracket supports worldwide.

Top 10 Metal Bracket Support Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Steel Brackets, Tabs, & Miscellaneous

Domain Est. 1999

Website: industrialmetalsupply.com

Key Highlights: 30-day returnsSteel brackets and industrial metal power tabs are manufactured from premium materials and are used with other components to create various finished products….

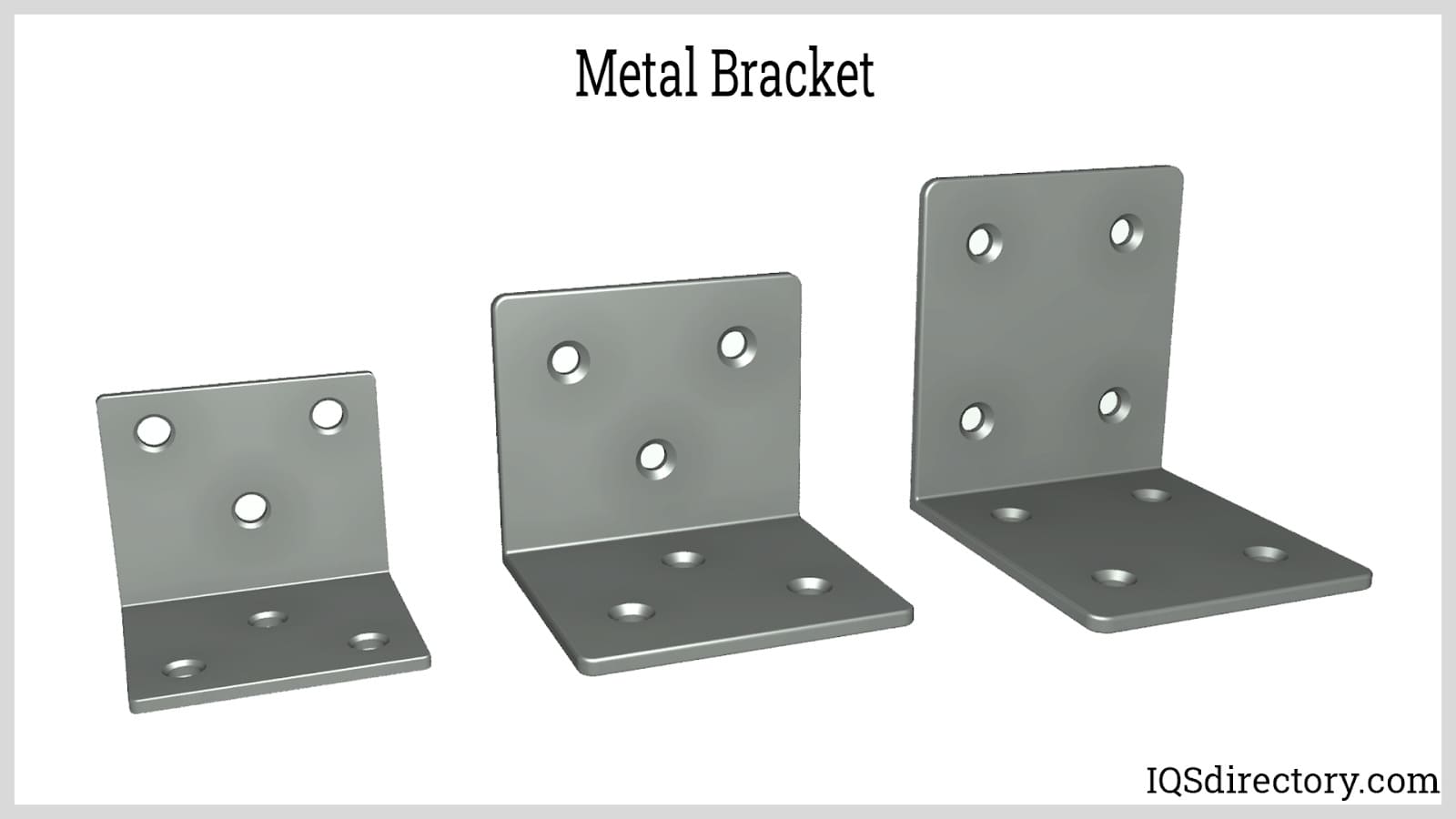

#2 Leading Metal Bracket Manufacturers

Domain Est. 2001

Website: metalstamper.net

Key Highlights: World-class fabricators from the leading metal bracket companies can be found on this site. Easily connect with the top metal bracket manufacturer….

#3 Federal Brace

Domain Est. 2009

Website: federalbrace.com

Key Highlights: Federal Brace manufactures a full line of support products for various residential, commercial, and industrial applications….

#4 Simpson Strong

Domain Est. 1995

Website: strongtie.com

Key Highlights: Welcome to the Simpson Strong-Tie homepage showcasing our resources, products and services designed to help people build safer, stronger structures….

#5 Metal Brackets

Domain Est. 2009

Website: ekenamillwork.com

Key Highlights: Rating 4.8 (233) View our entire collection of heavy-duty, sleek and modern metal brackets. Available in stainless and unfinished steel, iron, and designer painted options….

#6 Custom Support Brackets

Domain Est. 2013

#7 Brackets Custom Metal Stainless Steel

Domain Est. 2015

Website: metalfabgroup.com

Key Highlights: When you need a custom bracket, brace, hanger, mount, or support connector, we can fabricate them in a variety of metals including steel, stainless steel, ……

#8 Metal Shelf Brackets

Domain Est. 2017

#9 Heavy Duty L Brackets – Strong Shelf Brackets

Domain Est. 2017

Website: rightonbracket.com

Key Highlights: In stock 30-day returnsExtremely Strong Right Angle Brackets – Steel Brackets Give The Best Support For Any Wood, Glass, or Metal Shelf – Available In Many Sizes – USA Made!…

#10 FIG 199 199 Heavy Welded Steel Bracket

Domain Est. 2020

Website: asc-es.com

Key Highlights: Material: Carbon steel. Finish: Plain or Hot-Dip Galvanized. Service: Recommended for the support of loads from above or below bracket….

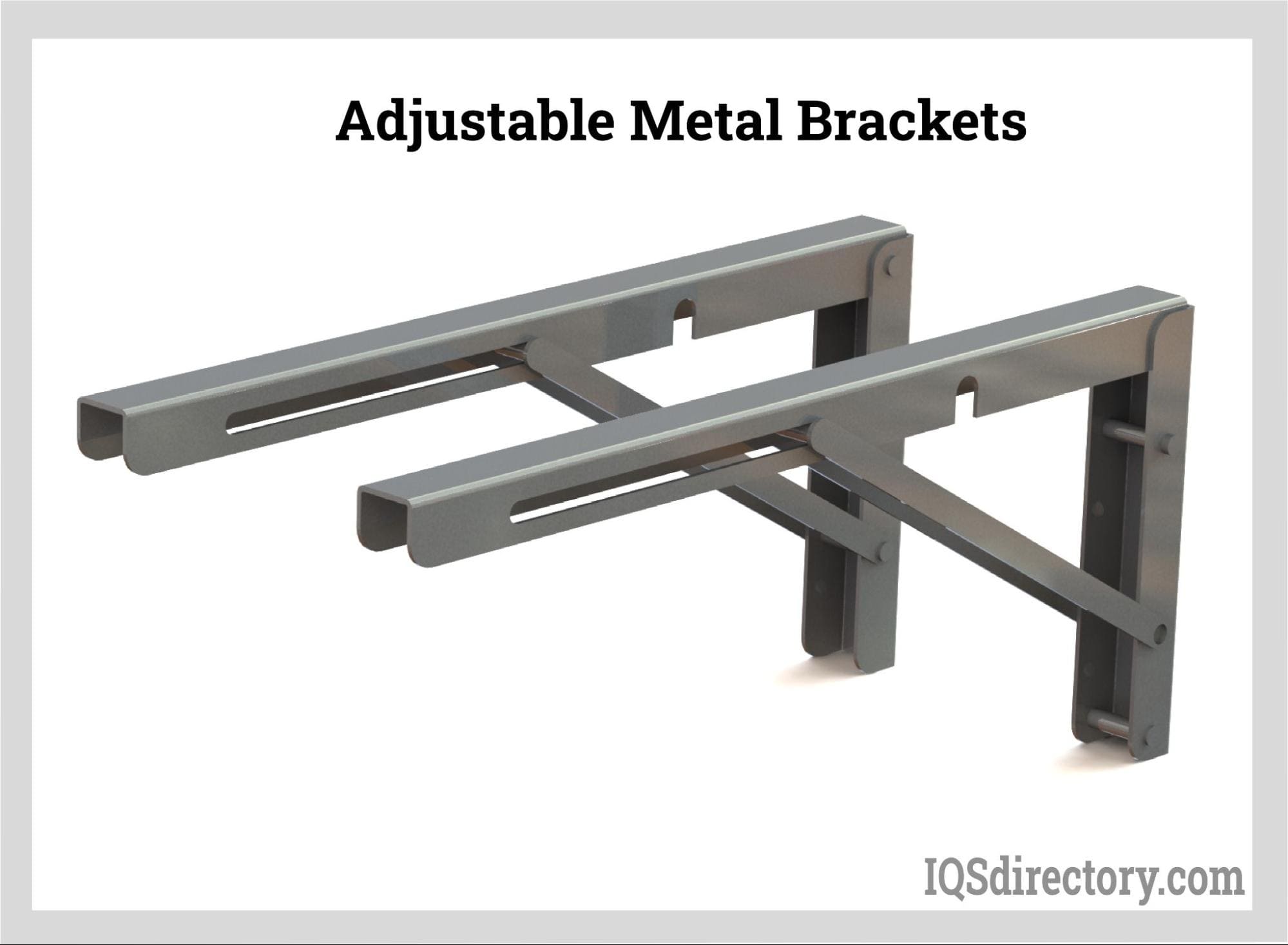

Expert Sourcing Insights for Metal Bracket Support

H2: 2026 Market Trends for Metal Bracket Support

The global market for metal bracket supports is poised for significant transformation by 2026, driven by evolving industrial demands, technological advancements, and shifts in construction and manufacturing practices. Below is an analysis of key trends expected to shape the metal bracket support sector in 2026:

-

Increased Demand in Construction and Infrastructure

With governments worldwide investing heavily in infrastructure development—especially in emerging economies—the demand for durable and load-bearing metal bracket supports is projected to rise. Urbanization, smart city projects, and the need for earthquake-resistant structures will boost the use of high-strength steel and aluminum brackets in both commercial and residential construction. -

Adoption of Smart and Modular Building Techniques

The growth of modular and prefabricated construction will drive innovation in bracket design. Metal brackets are being engineered for quick assembly, reusability, and compatibility with digital building information modeling (BIM) systems. By 2026, smart brackets embedded with sensors for structural health monitoring may begin entering high-end construction markets. -

Sustainability and Recyclability Focus

Environmental regulations and corporate sustainability goals are pushing manufacturers toward using recyclable metals like aluminum and recycled steel. Lightweight yet strong alloys are gaining traction, reducing carbon footprints in transportation and installation. Bracket producers are expected to emphasize low-impact manufacturing processes and eco-friendly coatings. -

Growth in Renewable Energy Installations

Solar panel mounting systems and wind turbine support structures rely heavily on precision-engineered metal brackets. With renewable energy capacity expanding globally, especially in regions like Asia-Pacific and North America, demand for corrosion-resistant and weather-durable brackets will surge through 2026. -

Automation and Precision Manufacturing

The integration of automation, CNC machining, and robotic welding in production is improving the consistency and complexity of bracket designs. Customization capabilities are increasing, enabling OEMs to offer tailored solutions for niche applications in automotive, aerospace, and industrial machinery. -

Regional Market Shifts

Asia-Pacific is expected to dominate the metal bracket support market by 2026, led by China, India, and Southeast Asian countries due to rapid industrialization and construction activity. Meanwhile, North America and Europe will focus on high-performance, compliant brackets meeting stringent safety and energy efficiency standards. -

Material Innovation and Lightweighting

To meet efficiency demands in automotive and aerospace sectors, manufacturers are developing advanced high-strength steels (AHSS) and hybrid metal-composite brackets. These materials offer superior strength-to-weight ratios, supporting fuel efficiency and emission reduction goals. -

Supply Chain Resilience and Localization

Post-pandemic supply chain challenges have prompted companies to localize production. By 2026, more metal bracket manufacturers are expected to establish regional production hubs to reduce lead times, mitigate trade risks, and respond quickly to market demands.

In conclusion, the 2026 market for metal bracket supports will be defined by innovation, sustainability, and adaptability across industries. Companies that invest in R&D, embrace digital manufacturing, and align with global infrastructure and environmental trends will be best positioned for growth.

Common Pitfalls When Sourcing Metal Bracket Supports (Quality and Intellectual Property)

Sourcing metal bracket supports may seem straightforward, but overlooking critical quality and intellectual property (IP) aspects can lead to significant risks, including product failure, legal disputes, and reputational damage. Below are key pitfalls to avoid:

1. Inadequate Material Specification and Verification

One of the most common quality pitfalls is failing to clearly define and verify the material composition of the metal brackets. Suppliers may use lower-grade alloys (e.g., substituting 304 stainless steel with 201) to cut costs, resulting in reduced strength, corrosion resistance, or durability. Always specify exact material grades and require material test reports (MTRs) or certificates of conformance (CoC).

2. Poor Dimensional Accuracy and Tolerances

Metal brackets often interface with other components, making precise tolerances critical. Sourcing from manufacturers without proper quality control (QC) processes can lead to inconsistent dimensions, misalignment in assembly, or fitment issues. Ensure drawings include detailed GD&T (Geometric Dimensioning and Tolerancing) and require first-article inspections (FAI) before full production.

3. Inconsistent Surface Finish and Coating Quality

Corrosion resistance and aesthetic requirements depend heavily on surface treatments like powder coating, anodizing, or galvanization. Poorly applied or uneven coatings can lead to premature rust, chipping, or non-compliance with environmental standards. Audit supplier finishing processes and request samples for salt spray testing.

4. Lack of Traceability and Documentation

Without proper traceability (e.g., batch numbers, heat numbers), identifying the source of defective parts during a failure becomes difficult. Insist on full documentation for materials and manufacturing steps, especially for regulated industries like aerospace, medical, or automotive.

5. Ignoring Intellectual Property Rights

Using bracket designs that are patented or protected by industrial design rights without authorization exposes your company to IP infringement lawsuits. Even reverse-engineered designs can pose legal risks. Always verify IP ownership and consider having your own designs protected before sharing them with suppliers.

6. Unlicensed or Unauthorized Production

Some suppliers may subcontract production to unauthorized third parties, increasing the risk of counterfeit parts or deviation from specifications. This also complicates IP enforcement. Conduct factory audits and include contractual clauses prohibiting unauthorized subcontracting.

7. Overlooking Design Ownership in Contracts

When custom brackets are developed with a supplier, ownership of the design may default to the manufacturer unless explicitly assigned in writing. This can limit your ability to source from alternate vendors or modify the design. Always include IP assignment clauses in supplier agreements.

8. Inadequate Testing and Compliance Validation

Assuming brackets meet performance standards without independent testing is risky. Suppliers may provide falsified test reports. Validate critical performance metrics (load capacity, fatigue resistance, etc.) through third-party labs, especially for safety-critical applications.

9. Supply Chain Transparency Gaps

Complex supply chains can obscure the origin of raw materials and manufacturing steps, making it difficult to ensure ethical sourcing or regulatory compliance (e.g., conflict minerals, environmental regulations). Require transparency and conduct supplier due diligence.

10. Failure to Protect Custom Tooling and Fixtures

Custom molds, jigs, or dies used for bracket production may remain the supplier’s property unless specified otherwise. This can lead to increased costs or delays if switching suppliers. Clearly define tooling ownership and storage terms in contracts.

By proactively addressing these pitfalls—through robust specifications, supplier vetting, legal safeguards, and quality assurance—you can mitigate risks and ensure reliable, compliant, and legally secure sourcing of metal bracket supports.

Logistics & Compliance Guide for Metal Bracket Support

Product Classification and Documentation

Ensure accurate classification of the Metal Bracket Support under the appropriate Harmonized System (HS) code for international shipping. Typically, metal brackets fall under HS Code 7326.90 (Other Articles of Iron or Steel), but verify based on material composition, function, and regional tariff schedules. Maintain detailed product specifications, including material type (e.g., stainless steel, carbon steel), dimensions, weight, and intended use, to support customs declarations and regulatory compliance.

Export and Import Regulations

Adhere to export control regulations such as EAR (Export Administration Regulations) if applicable, particularly if the brackets are destined for restricted countries or end-uses. Confirm that no International Traffic in Arms Regulations (ITAR) restrictions apply unless the brackets are used in defense applications. Importers must comply with local customs requirements, including duties, taxes, and conformity assessments in the destination country.

Packaging and Labeling Requirements

Package Metal Bracket Supports securely to prevent damage during transit, using materials that comply with ISPM 15 standards for wooden packaging (if applicable). Clearly label each package with essential information: product name, quantity, weight, HS code, country of origin, and handling instructions (e.g., “Fragile,” “This Side Up”). Include barcodes or RFID tags if required by the logistics partner or customer.

Transportation and Handling

Use freight carriers experienced in handling industrial metal components. For international shipments, provide commercial invoices, packing lists, and bills of lading/air waybills accurately and in advance. Ensure compliance with IATA, IMDG, or ADR regulations if transporting via air, sea, or road, even if the product is non-hazardous. Confirm stacking and load limits to prevent deformation during transit.

Environmental and Safety Compliance

Verify that the manufacturing process and materials comply with environmental standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), especially for shipments to the European Union. Provide a Declaration of Conformity (DoC) if required. Ensure workplace safety standards (e.g., OSHA in the U.S.) are followed during packaging and handling operations.

Recordkeeping and Audits

Maintain records of all shipments, compliance documents, certifications, and correspondence for a minimum of five years, in accordance with customs and regulatory requirements. Conduct periodic internal audits to ensure ongoing compliance with logistics and regulatory standards. Prepare for potential inspections by customs or regulatory bodies with readily accessible documentation.

Conclusion for Sourcing Metal Bracket Support

After a comprehensive evaluation of potential suppliers, material options, manufacturing capabilities, cost structures, and quality standards, the sourcing strategy for metal bracket supports has been finalized. The selected supplier offers a strong balance of cost-efficiency, consistent product quality, and reliable lead times, meeting both technical specifications and volume requirements. Key factors such as material durability (e.g., stainless steel or aluminum), corrosion resistance, load-bearing capacity, and compliance with industry standards were prioritized throughout the selection process.

Additionally, considerations around supply chain resilience, geographic proximity, and the supplier’s track record for on-time delivery supported the final decision. Ongoing performance monitoring, including quality audits and feedback loops, will ensure long-term reliability and continuous improvement.

In conclusion, the chosen sourcing approach ensures a sustainable, scalable, and cost-effective supply of metal bracket supports, aligning with project timelines, quality objectives, and overall operational goals.