The global adhesives and sealants market, driven by rising demand in automotive, electronics, construction, and industrial manufacturing sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2028, reaching an estimated value of USD 81.3 billion by 2028, according to Mordor Intelligence. A key contributor to this expansion is the increasing need for high-performance bonding solutions capable of joining dissimilar materials—particularly metals and plastics—in applications requiring durability, temperature resistance, and structural integrity. As lightweight materials gain prominence in product design, the demand for specialized metal and plastic adhesives has surged, prompting innovation and competition among manufacturers. This growth trajectory, supported by technological advancements and stringent environmental regulations influencing adhesive formulations, has positioned the sector as a critical enabler of modern manufacturing. In this evolving landscape, a select group of manufacturers leads in product performance, R&D investment, and global reach—shaping the future of industrial bonding.

Top 10 Metal And Plastic Glue Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Devcon Industrial Epoxy Adhesive

Domain Est. 2017

Website: itwperformancepolymers.com

Key Highlights: Devcon® is the best metal epoxy manufacturer & coating solutions provider. You can use the epoxy adhesives as metal bonding filler, epoxy plastic filler, ……

#2 Adhesives, Sealants and Coatings

Domain Est. 1996

Website: masterbond.com

Key Highlights: Master Bond is a leading manufacturer of epoxy adhesives, sealants, coatings, potting and encapsulation compounds. Master Bond specializes in epoxies, ……

#3 Weld

Domain Est. 2002

Website: weldon.com

Key Highlights: Weld-On products are globally- recognized as the premium products for joining plastic pipes and fittings. © 2026 Weld-On Adhesives, Inc. Weld-On Adhesives, Inc….

#4 High

Domain Est. 2016

Website: astraladhesives.com

Key Highlights: Astral Adhesives offers top bonding solutions, sealants &adhesive products designed for durability and performance in diverse industrial applications….

#5 MEGUM™

Domain Est. 1987

Website: dupont.com

Key Highlights: MEGUM™ rubber-to-substrate adhesives are used to bond a variety of elastomer compounds to metal and plastic substrates including steel, stainless steel ……

#6 Bonding Products and Assembly Solutions

Domain Est. 1988

Website: 3m.com

Key Highlights: 3M offers a wide range of bonding products to do just that across different industries, applications and substrates….

#7 J

Domain Est. 1995

Website: jbweld.com

Key Highlights: Discover the world’s strongest bond with J-B Weld products. Sort by and find the perfect solution for your job. Need help? We’ve got you covered….

#8 Permabond Adhesive

Domain Est. 1996

Website: permabond.com

Key Highlights: Permabond adhesives are noted for their ability to bond a large variety of different materials. Whether you are looking to bond plastics, metals, composites ……

#9 Franklin International

Domain Est. 1999

Website: franklininternational.com

Key Highlights: Franklin International provides the world with industry-leading construction adhesives, manufacturing adhesives, flooring adhesives, and woodworking glues….

#10 Structural Adhesives

Domain Est. 2000

Website: henkel-adhesives.com

Key Highlights: Find out more about our Structural Adhesives ✓ Epoxy, Acrylic, and Polyurethane Structural Adhesives for Metal, Wood, and Plastic Bonding….

Expert Sourcing Insights for Metal And Plastic Glue

H2: Market Trends for Metal and Plastic Glue in 2026

The global metal and plastic glue market is projected to experience significant transformation by 2026, driven by technological advancements, evolving industry demands, and sustainability imperatives. Key trends shaping the market include:

1. Rising Demand from Automotive and Electronics Sectors

The automotive industry continues to be a major consumer of metal and plastic adhesives, especially with the shift toward lightweight vehicle designs to improve fuel efficiency and meet emission standards. Similarly, the electronics sector relies heavily on high-performance adhesives for compact, durable assembly of devices. By 2026, increasing production of electric vehicles (EVs) and smart electronics will fuel demand for thermally conductive, electrically insulating, and vibration-resistant glue formulations.

2. Growth in Industrial Automation and Robotics

Automation in manufacturing processes demands reliable bonding solutions that ensure precision and durability. Metal and plastic glues with fast curing times, high shear strength, and compatibility with automated dispensing systems are becoming essential. This trend is expected to accelerate through 2026, particularly in sectors like aerospace, consumer goods, and industrial equipment.

3. Emphasis on Sustainable and Eco-Friendly Formulations

Environmental regulations and corporate sustainability goals are pushing manufacturers to develop low-VOC (volatile organic compound), solvent-free, and bio-based adhesives. By 2026, eco-conscious consumers and B2B buyers are anticipated to favor green alternatives, prompting leading producers to innovate with recyclable packaging and biodegradable adhesive chemistries.

4. Advancements in Adhesive Technology

Innovations such as UV-curable, cyanoacrylate, epoxy, and structural acrylic adhesives are enhancing bonding performance between dissimilar materials—crucial as hybrid material usage grows. Nanotechnology integration is also expected to improve adhesive strength, temperature resistance, and durability, particularly in high-stress applications.

5. Regional Market Expansion

Asia-Pacific, led by China, India, and Southeast Asia, is expected to dominate market growth by 2026 due to rapid industrialization, expanding manufacturing bases, and increased infrastructure development. North America and Europe will maintain strong demand, supported by advanced R&D and stringent quality standards.

6. Supply Chain Resilience and Raw Material Volatility

Ongoing fluctuations in petrochemical prices and geopolitical tensions may impact raw material availability. As a result, adhesive manufacturers are likely to invest in localized sourcing and alternative feedstocks to ensure supply chain stability by 2026.

In summary, the 2026 metal and plastic glue market will be characterized by innovation, sustainability, and increased application diversity. Companies that adapt to these H2 trends—particularly in performance, environmental responsibility, and automation compatibility—are poised for competitive advantage.

Common Pitfalls When Sourcing Metal and Plastic Glue: Quality and Intellectual Property Risks

Sourcing adhesives for bonding metal and plastic involves more than just finding a low price. Overlooking quality consistency and intellectual property (IP) concerns can lead to costly failures, legal disputes, and reputational damage. Here are key pitfalls to avoid:

Inconsistent or Substandard Quality

One of the most frequent issues when sourcing metal and plastic glue—especially from new or low-cost suppliers—is inconsistent product quality. Adhesives with variable viscosity, cure time, bond strength, or temperature resistance can lead to product failures in the field. Suppliers may cut corners by altering formulations or using inferior raw materials to meet price points, resulting in batches that don’t meet technical specifications. Without rigorous quality control and third-party testing, companies risk production delays, warranty claims, and safety hazards.

Lack of Technical Documentation and Traceability

Many generic or unbranded adhesives come with incomplete or misleading technical data sheets (TDS) and safety data sheets (SDS). This lack of transparency makes it difficult to verify performance claims such as shear strength, thermal stability, or chemical resistance. Additionally, poor batch traceability complicates root cause analysis during failure investigations and can hinder compliance with industry standards (e.g., ISO, ASTM, or REACH).

Intellectual Property Infringement Risks

Sourcing low-cost alternatives, particularly from regions with weak IP enforcement, increases the risk of inadvertently using counterfeit or cloned products. Some suppliers may replicate proprietary formulations from leading brands (e.g., Loctite, 3M, or Permabond) without authorization. While these knock-offs may appear identical, they often lack the rigorous R&D, testing, and certification of authentic products. Using such adhesives can expose your company to IP litigation, especially if your end product incorporates the glue and is sold in regulated markets.

Misrepresentation of Performance and Compatibility

Suppliers may overstate an adhesive’s compatibility with specific metals (e.g., aluminum, stainless steel) or challenging plastics (e.g., polypropylene, polyethylene). Without access to independent adhesion testing under real-world conditions, companies may discover too late that the glue fails under stress, humidity, or thermal cycling. This can compromise the structural integrity of assemblies and lead to costly recalls.

Supply Chain and Regulatory Non-Compliance

Unverified suppliers may not comply with environmental, health, and safety regulations such as RoHS, REACH, or VOC restrictions. Using non-compliant adhesives can result in import delays, product seizures, or liability issues. Furthermore, poor supply chain practices—such as unreliable lead times or lack of scalability—can disrupt production schedules and increase inventory costs.

Conclusion

To mitigate these risks, prioritize suppliers with proven quality management systems (e.g., ISO 9001), robust IP policies, and transparent technical support. Conduct supplier audits, request sample testing, and verify compliance documentation before full-scale procurement. Investing in reliable, legally sound adhesive sourcing protects both product performance and your company’s long-term reputation.

Logistics & Compliance Guide for Metal and Plastic Glue

Product Classification and Regulatory Overview

Metal and plastic glue is typically classified as an adhesive containing chemical compounds such as cyanoacrylates, epoxies, or solvent-based polymers. These substances may be regulated under international, national, and regional frameworks due to flammability, toxicity, or environmental hazards. Proper classification under systems like the Globally Harmonized System (GHS) is essential for safe handling and legal transport.

Hazard Identification and Safety Data Sheets (SDS)

All metal and plastic glue products must be accompanied by a Safety Data Sheet (SDS) compliant with GHS standards. The SDS provides critical information on:

– Physical and chemical properties (e.g., flash point, volatility)

– Health hazards (e.g., skin irritation, respiratory sensitization)

– First-aid and firefighting measures

– Accidental release procedures

Ensure SDS documents are up to date (typically revised every 3–5 years or after formulation changes) and accessible to all handlers and emergency responders.

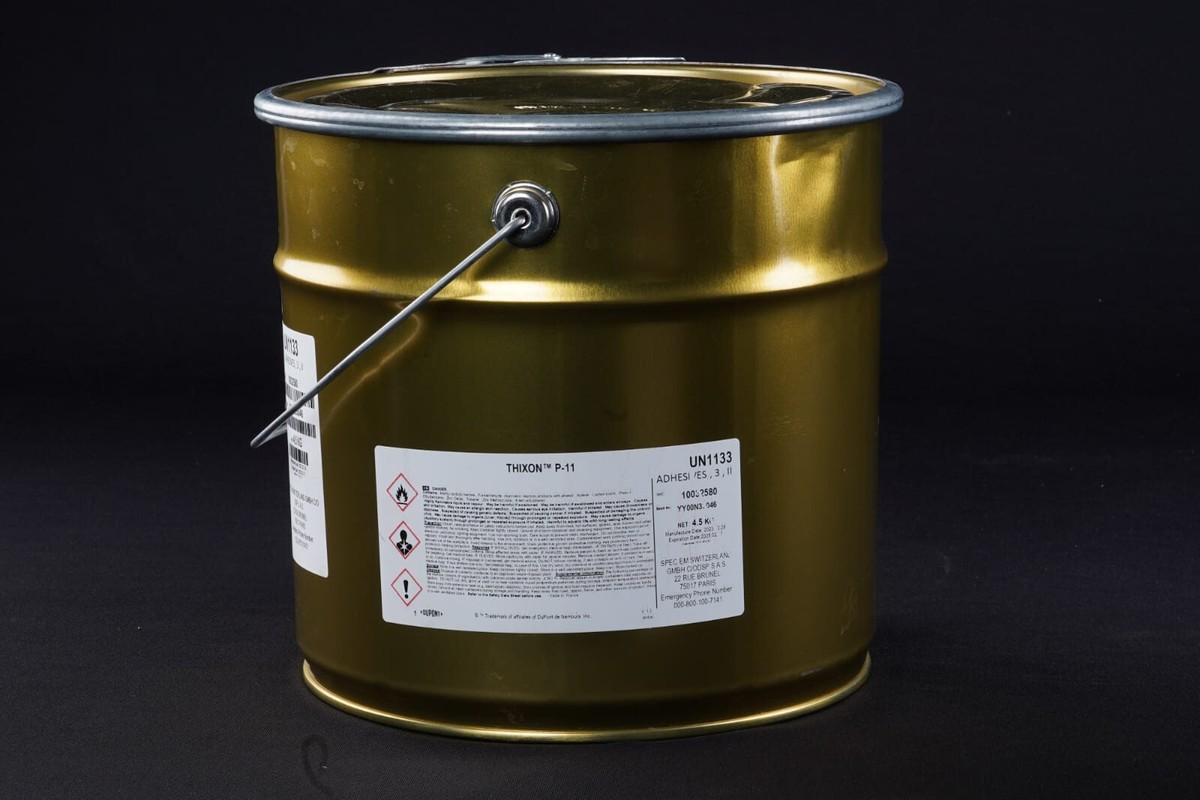

Packaging and Labeling Requirements

Adhesives must be packaged in leak-proof, chemically resistant containers suitable for the formulation (e.g., HDPE bottles with tamper-evident seals). Labels must include:

– Product identifier and manufacturer details

– GHS pictograms (e.g., flame, corrosion, health hazard)

– Signal word (e.g., “Danger” or “Warning”)

– Hazard and precautionary statements

– Batch/lot number and expiration date

Labels must be durable and legible under transport and storage conditions.

Transportation Regulations (Air, Sea, Ground)

Transport of metal and plastic glue is governed by:

– IATA (air): Classified based on flash point and quantity; many adhesives fall under UN1133 (Adhesives, flammable) or UN3506 (Adhesives, non-flammable).

– IMDG (sea): Requires proper UN number, hazard class (usually Class 3 for flammable liquids), and marine pollutant designation if applicable.

– ADR/RID (road/rail in Europe): Adhesives with flash points ≤ 60°C are typically Class 3 hazardous goods.

Ensure transport documents include emergency contact information and proper shipping names.

Storage Conditions and Handling

Store metal and plastic glue in a cool, dry, well-ventilated area away from direct sunlight and incompatible materials (e.g., oxidizers, strong acids). Recommended conditions:

– Temperature: 10–25°C (50–77°F)

– Humidity: Below 60% to prevent moisture degradation (especially for cyanoacrylates)

– Fire safety: Keep away from ignition sources; use explosion-proof storage cabinets for flammable types

Employees must use appropriate PPE (gloves, goggles, ventilation) during handling.

Import and Export Compliance

When shipping internationally:

– Verify destination country regulations (e.g., REACH in the EU, TSCA in the US)

– Provide accurate HS (Harmonized System) codes (e.g., 3506.91 for non-reactive adhesives)

– Submit required documentation (commercial invoice, packing list, SDS, certificate of origin)

– Confirm whether the adhesive contains restricted substances (e.g., VOC limits under EU Directive 2004/42/EC)

Environmental and Disposal Regulations

Dispose of expired or waste adhesive according to local hazardous waste regulations. Do not pour down drains or dispose of in regular trash. Options include:

– Recycling through licensed chemical waste handlers

– Incineration in permitted facilities

– Neutralization (if approved by SDS)

Follow RCRA (US), Waste Framework Directive (EU), or equivalent local laws to prevent soil and water contamination.

Training and Documentation

Personnel involved in logistics and handling must receive training on:

– GHS labeling and SDS interpretation

– Spill response and emergency procedures

– Safe handling and storage practices

Maintain records of training, SDS access, shipping manifests, and incident reports for audit and compliance verification.

Emergency Preparedness

Establish protocols for:

– Chemical spills: Use absorbent materials (e.g., vermiculite) and contain area

– Fire: Use CO₂, dry chemical, or foam extinguishers (avoid water jets for flammable types)

– Exposure: Flush skin/eyes with water; seek medical attention if ingested or inhaled

Display emergency contact numbers and provide spill kits in storage and handling areas.

Conclusion: Sourcing Metal and Plastic Glue

In conclusion, sourcing the right adhesive for bonding metal and plastic requires careful consideration of several key factors, including the specific materials involved, the operating environment (e.g., exposure to heat, moisture, or chemicals), required bond strength, curing time, and application method. There is no one-size-fits-all solution; therefore, selecting a versatile, high-performance adhesive such as epoxy, cyanoacrylate (super glue), or a specialized two-part polyurethane is essential for durable and long-lasting results.

Reliable suppliers offering quality-tested products, clear technical data sheets, and compliance with industry standards (e.g., ISO, RoHS) should be prioritized. Additionally, evaluating cost-effectiveness, availability, and logistical considerations ensures a consistent supply chain. By combining thorough research, supplier vetting, and small-scale testing, businesses and individuals can identify the optimal metal and plastic glue solution that balances performance, reliability, and value. Ultimately, the right adhesive not only ensures structural integrity but also enhances the longevity and functionality of the bonded components.