The global conductor plate market, a critical segment within the electrical and automotive components industry, is experiencing steady growth driven by rising demand for reliable power distribution systems in transportation and infrastructure. According to Mordor Intelligence, the global busbar and conductor plate market was valued at USD 7.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This expansion is fueled by advancements in electric mobility, increasing infrastructure investments, and the need for efficient current conduction in high-performance applications—particularly in rail and electric vehicle systems where brands like Mercedes rely on precision-engineered conductor plates for optimal performance. As Mercedes integrates more electrified and automated technologies into its vehicles and transportation solutions, the demand for high-quality conductor plate manufacturers capable of meeting stringent German engineering standards has intensified. In this competitive landscape, a select group of manufacturers has emerged as key suppliers, demonstrating excellence in conductivity, durability, and compliance with OEM specifications. Below are the top 9 conductor plate manufacturers serving the Mercedes ecosystem, recognized for their technical capabilities, global reach, and innovation in materials and manufacturing processes.

Top 9 Mercedes Conductor Plate Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OEM 10 0209 51

Domain Est. 1998

Website: newparts.com

Key Highlights: Trusted by automotive professionals, this conductor plate is compatible with various Dodge and Mercedes-Benz models. … Manufacturer Part #. 10 0209 51….

#2 OEM 1402701161 Automatic Transmission Conductor Plate

Domain Est. 2000

Website: eeuroparts.com

Key Highlights: Replace your Mercedes-Benz transmission component with OEM 1402701161 Conductor Plate. Enjoy seamless compatibility and easy installation. Shop now….

#3 I received the conductor plate

Domain Est. 2001

Website: benzworld.org

Key Highlights: So, I purchased a conductor plate. On the merchant (importec, euro part) web site, it was marked as made by O.E.M. I guess the manufacturer ……

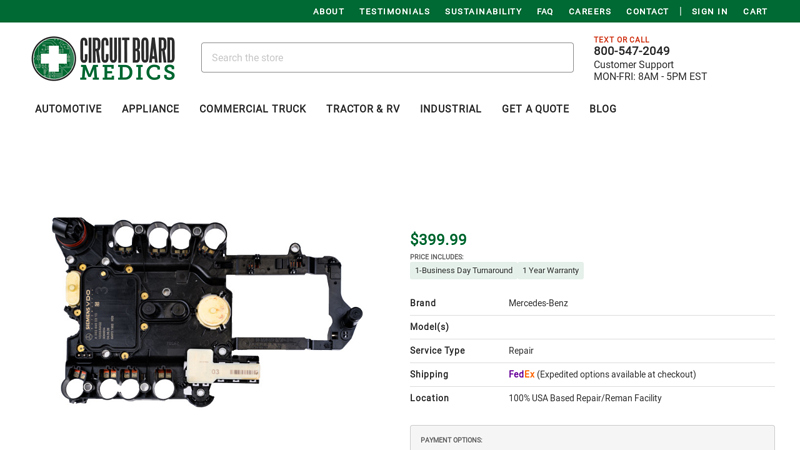

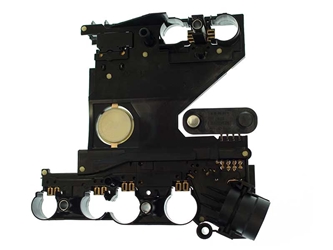

#4 Mercedes Transmission Conductor Plate

Domain Est. 2010

Website: fcpeuro.com

Key Highlights: High Quality Genuine & OEM Mercedes-Benz parts. Free Shipping and available now! See OE cross references for OES-000270260080….

#5 New OEM 5 Speed Transmission Conductor Plate (Round D/Stick Gu

Domain Est. 2011

Website: sussexautos.com

Key Highlights: 30-day returnsThis genuine OE Mercedes-Benz conductor plate is designed for 722.6 automatic gearboxes, which are commonly fitted to most rear-wheel-drive Mercedes vehicles….

#6 OEM Transmission Valve Body Electric Conductor Plate for …

Domain Est. 2017

Website: inkfrenzy.com

Key Highlights: In stock Rating 4.3 (52) 7 days ago · OEM Transmission Valve Body Electric Conductor Plate for Mercedes 722.6 ; New $61.30 (tax included) Number of stocks: 1 ; Number of stocks ·…

#7 Mercedes C240 Transmission Conductor Plate Parts

Domain Est. 1998

#8 Automatic Transmission Conductor Plate (722.6, 5

Domain Est. 2009

Website: europaparts.com

Key Highlights: In stock Rating 4.5 (1) This conductor plate is attached to the valve body in the automatic transmission and designed for the 722.6 automatic transmissions….

#9 Mercedes

Domain Est. 2010

Expert Sourcing Insights for Mercedes Conductor Plate

H2: Analysis of 2026 Market Trends for Mercedes Conductor Plate

As of 2026, the market for Mercedes Conductor Plates—critical electrical components used in power distribution systems within commercial and industrial vehicles, particularly in Mercedes-Benz commercial fleets—is undergoing significant transformation driven by electrification, digitalization, and sustainability demands. These trends are reshaping product design, supply chain dynamics, and market competition.

1. Electrification of Commercial Fleets

Mercedes-Benz has accelerated its transition toward full electrification, with the eActros and eSprinter leading the charge in the heavy-duty and light commercial vehicle segments. As a result, conductor plates—traditionally designed for internal combustion engine (ICE) architectures—are being redesigned for high-voltage electric drivetrains. In 2026, conductor plates are expected to feature enhanced thermal management, higher current-carrying capacity, and improved insulation materials to support 800V architectures, aligning with the broader industry shift toward faster charging and increased efficiency.

2. Integration with Smart Power Management Systems

Conductor plates are no longer passive components. By 2026, Mercedes is integrating sensor-embedded conductor plates that communicate with onboard energy management systems. These “smart” conductor plates monitor current flow, temperature, and connection integrity in real time, enabling predictive maintenance and reducing downtime. This integration supports Mercedes’ broader digital ecosystem, including Fleetboard telematics and cloud-based diagnostics.

3. Material Innovation and Lightweighting

To improve energy efficiency and reduce vehicle weight, Mercedes is adopting advanced composite and aluminum-based conductor plates. These materials offer comparable conductivity to traditional copper with significantly lower mass. In 2026, supplier partnerships are focusing on recyclable and sustainable materials, reflecting Mercedes’ commitment to a circular economy and reduced lifecycle emissions.

4. Supply Chain Localization and Resilience

Geopolitical instability and trade uncertainties have prompted Mercedes to localize key component production. In 2026, conductor plate manufacturing is increasingly regionalized, with production hubs in Germany, North America, and China to serve regional EV assembly lines. This shift reduces logistics costs and ensures faster response to demand fluctuations, especially given the surge in electric van and truck orders.

5. Regulatory and Safety Standards

Stringent global safety and EMC (electromagnetic compatibility) regulations are influencing conductor plate design. In 2026, Mercedes conductor plates must comply with updated ISO and UN ECE standards for high-voltage components, including enhanced fire resistance, arc flash protection, and shielding against electromagnetic interference—critical for vehicle and occupant safety.

6. Market Competition and Aftermarket Growth

While Mercedes produces many conductor plates in-house or through Tier 1 suppliers like Bosch and ZF, the growing EV aftermarket is opening opportunities for third-party manufacturers. However, strict OEM certification requirements limit unauthorized replacements, preserving Mercedes’ control over quality and performance. Nonetheless, demand for retrofit conductor plates for fleet electrification projects is rising.

Conclusion:

By 2026, the Mercedes conductor plate market is evolving from a commodity component to a high-tech, integrated system element. Driven by electrification, digitalization, and sustainability, these components are central to the performance and safety of next-generation electric commercial vehicles. Mercedes’ strategy focuses on innovation, supply chain resilience, and ecosystem integration, positioning conductor plates as a key enabler of its zero-emission future.

Common Pitfalls Sourcing Mercedes Conductor Plate (Quality, IP)

Sourcing a Mercedes conductor plate—often a critical electrical or mechanical component in vehicles or industrial systems—can be fraught with risks, particularly concerning quality inconsistencies and intellectual property (IP) violations. Failing to address these pitfalls can lead to safety hazards, legal liabilities, and supply chain disruptions.

Poor Quality Control and Counterfeit Components

One of the most significant risks when sourcing conductor plates branded for or compatible with Mercedes is encountering substandard or counterfeit parts. Many third-party suppliers offer lower-cost alternatives that mimic original equipment manufacturer (OEM) specifications but fail under real-world conditions. These components may use inferior materials (e.g., incorrect alloy compositions or inadequate plating thickness), leading to premature wear, overheating, or electrical failure. Inadequate quality control during manufacturing—such as inconsistent tolerances or poor surface finishes—can compromise performance and safety, especially in high-voltage or high-stress applications.

Moreover, counterfeit parts often lack proper testing and certification, making them undetectable without rigorous incoming inspection. Buyers may unknowingly integrate these into end products, risking recalls, warranty claims, and reputational damage.

Intellectual Property Infringement and Legal Exposure

Another major pitfall is the risk of IP infringement. Mercedes-Benz holds trademarks, design patents, and technical specifications related to its components, including conductor plates. Sourcing parts that bear Mercedes branding, logos, or part numbers without authorization constitutes trademark infringement. Even reverse-engineered components that closely replicate patented designs may violate utility or design patents.

Purchasers—even if unintentionally—can become liable for contributory infringement by incorporating such parts into their systems or reselling them. Legal consequences may include cease-and-desist orders, financial penalties, or seizure of goods by customs authorities. Additionally, using non-authorized supplier networks increases exposure to IP violations, as many gray-market vendors operate without proper licensing agreements.

To mitigate these risks, buyers must verify supplier credentials, request material certifications (e.g., RoHS, ISO 9001), and ensure components are sourced through authorized distribution channels or licensed manufacturers. Conducting due diligence on IP rights and specifying technically equivalent but non-branded alternatives can also reduce exposure.

Logistics & Compliance Guide for Mercedes Conductor Plate

Overview

The Mercedes Conductor Plate is a specialized electrical component used in high-voltage systems within Mercedes-Benz commercial and electric vehicles. Proper logistics and compliance handling are essential to ensure safety, regulatory adherence, and supply chain integrity throughout transportation, storage, and installation.

Regulatory Compliance

All shipments of the Mercedes Conductor Plate must comply with international and regional regulations governing the transport of electrical components, particularly those used in electric vehicles (EVs). Key compliance standards include:

– ADR/RID/IMDG/IATA: Applicable for road, rail, sea, and air transport of hazardous goods (if applicable due to battery or high-voltage content).

– REACH & RoHS: Compliance with EU regulations for restricted substances in electrical equipment.

– UN 38.3: Required if the conductor plate is part of a system classified as a lithium battery assembly.

– ECE R100: Ensures electromagnetic compatibility and electrical safety in electric vehicles.

Ensure all documentation, including Safety Data Sheets (SDS), Certificates of Conformity (CoC), and test reports, are up to date and accompany shipments.

Packaging & Handling Requirements

The Conductor Plate must be packaged to prevent mechanical damage, electrostatic discharge (ESD), and environmental exposure:

– Use ESD-safe packaging materials (e.g., conductive foam, shielded bags).

– Secure the plate in rigid, labeled containers to avoid movement during transit.

– Clearly label packages with “Fragile,” “Electrostatic Sensitive Device,” and “Do Not Stack” indicators as needed.

– Avoid exposure to moisture, extreme temperatures (below -20°C or above 70°C), and corrosive atmospheres.

Storage Conditions

Store the Conductor Plate in a controlled indoor environment with the following parameters:

– Temperature: 15°C to 30°C

– Relative Humidity: 30% to 60%

– Clean, dry area free from dust and conductive contaminants

– Maximum storage duration: 12 months from manufacturing date unless otherwise specified in technical documentation.

Transportation Guidelines

- Use climate-controlled vehicles when transporting over long distances or through extreme climates.

- Avoid abrupt shocks, vibrations, or tilting during loading/unloading.

- Secure loads to prevent shifting; use anti-vibration padding if necessary.

- For international shipments, verify customs requirements and ensure Harmonized System (HS) code 8537.10 (control panels for electrical machinery) is correctly applied.

Traceability & Documentation

Each Conductor Plate must be traceable via a unique serial number or QR code. Required documentation includes:

– Bill of Lading (BoL)

– Packing List

– Certificate of Origin

– Customs Declaration (for cross-border shipments)

– Mercedes-Benz Parts Compliance Certificate (if specified)

Maintain records for a minimum of 10 years in accordance with automotive industry standards.

Returns & Non-Conformance

Defective or non-compliant units must be reported immediately to the Mercedes-Benz Logistics Support Team. Returns require:

– A completed Return Material Authorization (RMA) form

– Original packaging and labeling

– Detailed failure description and photos (if applicable)

– Secure packaging to prevent further damage during return shipment

Do not attempt repair or modification of the Conductor Plate; return to authorized service centers only.

Contact & Support

For logistics or compliance inquiries, contact:

Mercedes-Benz Commercial Vehicle Parts Logistics

Email: [email protected]

Phone: +49 711 17-30000 (Global Support Line)

Reference: Conductor Plate – Part No. A 007 152 66 01 (example)

Ensure all communications include shipment reference numbers and relevant documentation.

Conclusion for Sourcing Mercedes Conductor Plate:

In conclusion, sourcing the Mercedes conductor plate requires a strategic approach that balances quality, authenticity, cost-efficiency, and supply chain reliability. It is essential to partner with certified suppliers or OEM-approved vendors to ensure compatibility, durability, and adherence to Mercedes-Benz specifications. Conducting thorough due diligence—verifying material standards, production capabilities, and compliance with automotive industry regulations—will mitigate risks related to performance and safety.

Additionally, evaluating total cost of ownership, including logistics, lead times, and after-sales support, contributes to long-term operational efficiency. By establishing strong supplier relationships and implementing rigorous quality control processes, sourcing the conductor plate can support consistent vehicle performance and uphold Mercedes-Benz’s reputation for engineering excellence. Ultimately, a well-structured sourcing strategy ensures reliable supply, technical compliance, and alignment with the brand’s high standards.