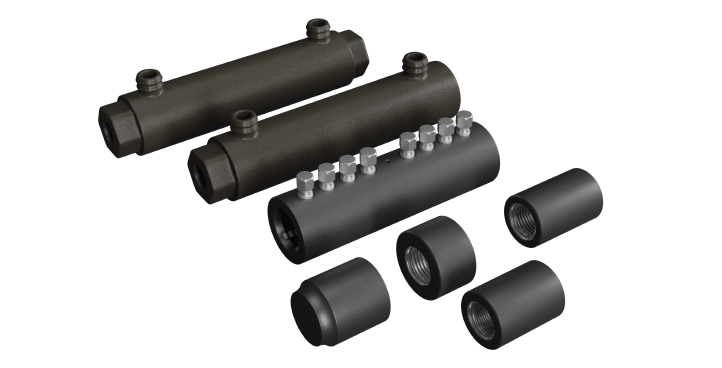

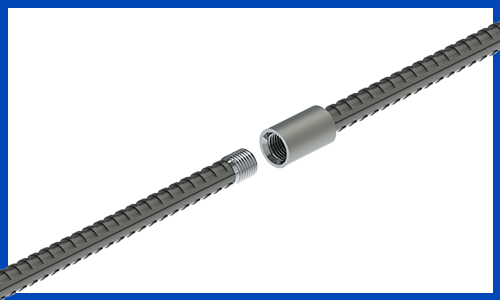

The global rebar couplers market is experiencing robust growth, driven by increasing demand for sustainable and efficient construction practices in infrastructure and high-rise building projects. According to Mordor Intelligence, the rebar couplers market was valued at USD 2.1 billion in 2023 and is projected to grow at a CAGR of over 6.8% from 2024 to 2029. This expansion is fueled by the shift toward modular construction, seismic resilience requirements, and the need to reduce steel congestion and construction time on site. Mechanical rebar couplers—known for their ability to provide high-strength, reliable splicing solutions while minimizing material waste—are gaining prominence across bridges, tunnels, skyscrapers, and nuclear facilities. As urbanization accelerates and building codes become more stringent, manufacturers specializing in high-performance coupler systems are playing a pivotal role in modern construction efficiency. In this evolving landscape, the following eight companies have emerged as leading mechanical rebar coupler manufacturers, combining innovation, global reach, and technical excellence to meet the demands of large-scale projects worldwide.

Top 8 Mechanical Rebar Couplers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Barsplice Products

Domain Est. 1998

Website: barsplice.com

Key Highlights: Barsplice Products, Inc. designs and manufactures American-made rebar couplers and mechanical splicing systems for the reinforcing steel industry….

#2 Leviat US

Domain Est. 2010

Website: leviat.com

Key Highlights: Leviat is a global source for lifting, connecting and anchoring technologies for the construction and industrial sectors….

#3 Rebar Couplers, Rebar Coupler Manufacturers, Rebar couplers …

Domain Est. 2020

Website: vruddhicouplers.com

Key Highlights: Leading manufacturer, supplier and exporter of Rebar Couplers backed by vast experience and expertise. An ISO-9001:2015 accredited company providing ……

#4 Coupler systems

Domain Est. 1996

Website: halfen.com

Key Highlights: HALFEN Coupler systems from Leviat provide reliable and efficient solutions for all connections of reinforcement bars….

#5 Bar Lock® Couplers System

Domain Est. 1996

Website: daytonsuperior.com

Key Highlights: The Dayton Superior Bar Lock® Coupler System provides a simple, quick, cost effective method for splicing deformed rebar in tension and/or compression ……

#6 Nucor Rebar Fabrication & Installation Services and Projects

Domain Est. 1997

Website: nucor.com

Key Highlights: Nucor Rebar Fabrication: expertise in rebar fabrication and installation services and products with projects and locations across North America….

#7 Griptec® Rebar Splicing System

Domain Est. 1999

Website: dextragroup.com

Key Highlights: Griptec® by Dextra is the original high-performance rebar splicing system trusted for critical construction worldwide….

#8 nVent LENTON

Domain Est. 2001

Website: nvent.com

Key Highlights: nVent LENTON is a world leader in advanced mechanical rebar splicing systems. Our Rebar Splicing Specialists understand the reinforced concrete business and ……

Expert Sourcing Insights for Mechanical Rebar Couplers

H2: Emerging 2026 Market Trends for Mechanical Rebar Couplers

The global Mechanical Rebar Couplers market is poised for significant transformation by 2026, driven by evolving construction practices, technological advancements, and shifting economic and regulatory landscapes. Key trends shaping the market include:

1. Accelerated Adoption Driven by High-Rise & Infrastructure Boom: The relentless global push for urbanization, particularly in Asia-Pacific (China, India, Southeast Asia) and the Middle East, will fuel demand for high-rise buildings, bridges, tunnels, and mass transit systems. Mechanical couplers offer critical advantages in these projects – faster construction cycles, reduced congestion in rebar cages, and improved seismic performance – making them increasingly indispensable. This infrastructure expansion, coupled with post-pandemic recovery investments in North America and Europe, will be the primary growth driver.

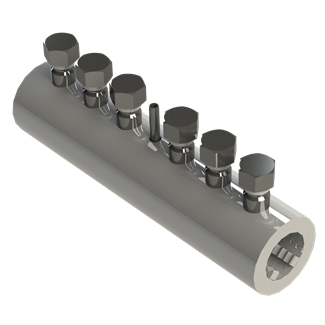

2. Dominance of Threaded Couplers (Parallel & Tapered) with Focus on Standardization: Threaded couplers, especially parallel-threaded types known for their ease of installation and reliability, will maintain market leadership. However, a critical trend is the push for global standardization (e.g., alignment with ISO 15835-1, ASTM A1044). Manufacturers will increasingly focus on producing couplers meeting stringent international codes and seismic requirements (like ACI 318), enhancing trust and facilitating cross-border project use. Compatibility with common threading machines will remain a key competitive factor.

3. Rise of Grout-Filled Couplers for Critical & Corrosive Environments: While threaded couplers dominate, grout-filled couplers will see significant growth, particularly in applications demanding the highest strength and ductility, such as nuclear facilities, major bridges in seismic zones, and marine structures. Their ability to provide a continuous, fully stressed rebar joint and superior corrosion protection (when using high-performance grouts) makes them ideal for critical infrastructure and harsh environments, aligning with increasing lifecycle cost considerations.

4. Integration of Smart Technology and Digitalization: The construction industry’s digital transformation will impact couplers. Expect the emergence of “smart” couplers incorporating RFID tags or QR codes for traceability, enabling real-time tracking of installation, inspection records, and quality assurance throughout the project lifecycle. BIM (Building Information Modeling) integration will become standard, allowing precise planning, clash detection, and automated quantity take-offs for couplers.

5. Sustainability and Material Efficiency Gaining Prominence: As sustainability becomes non-negotiable, the inherent advantages of mechanical couplers – reducing rebar lap splice lengths by up to 70%, minimizing steel waste, lowering transportation emissions (due to reduced rebar tonnage), and enabling faster construction (reducing on-site energy use) – will be a major selling point. Manufacturers will emphasize their products’ contribution to LEED or similar green building certifications.

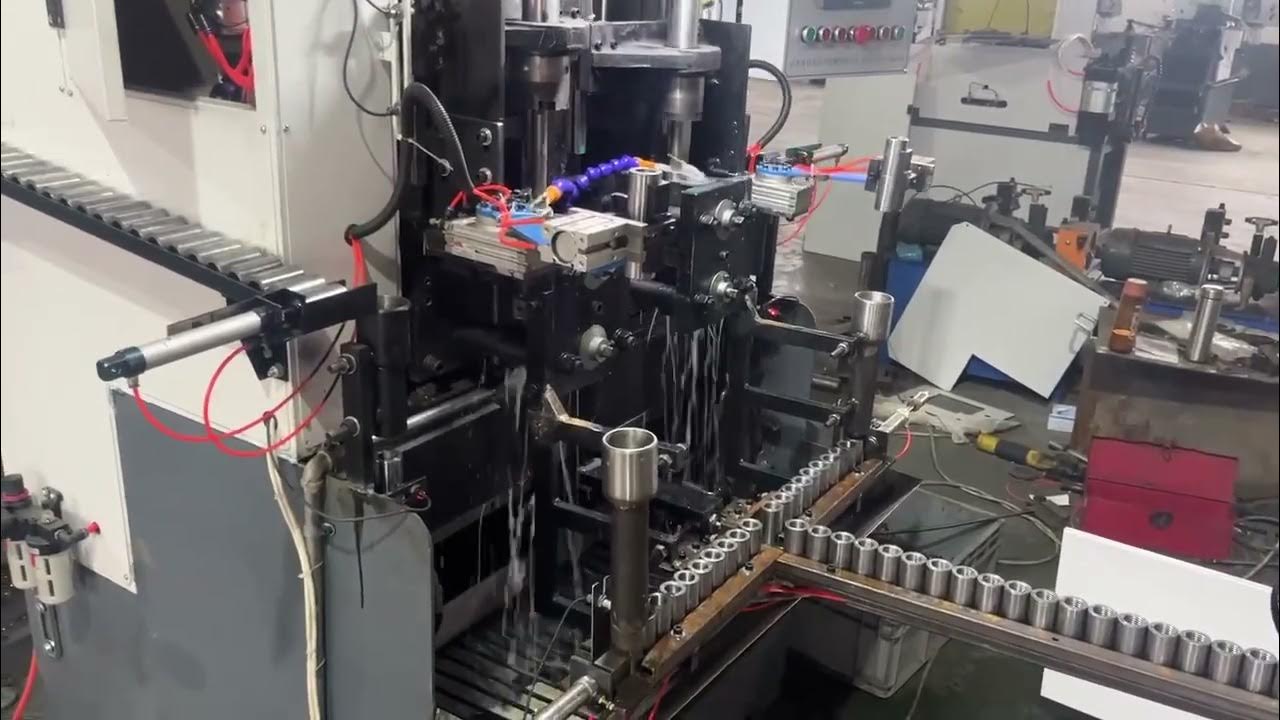

6. Intensifying Competition and Regional Manufacturing Shifts: Competition will intensify, particularly from established players in China and Turkey offering cost-effective solutions. However, global players will focus on innovation, quality assurance, and technical support. We may see a shift towards more regional manufacturing hubs closer to major growth markets (e.g., Southeast Asia, Middle East) to reduce logistics costs and tariffs, while maintaining quality control.

7. Focus on Seismic Resilience and Structural Performance: With increasing awareness of seismic risks, demand for couplers certified for high seismic performance (e.g., ACI 318-19/22, FIB Bulletins) will grow. Manufacturers will invest heavily in R&D to develop couplers offering superior energy dissipation, ductility, and reliability under cyclic loading, particularly for projects in earthquake-prone regions.

8. Labor Shortage Mitigation as a Key Value Proposition: The persistent global shortage of skilled rebar workers will amplify the value proposition of mechanical couplers. Their ease and speed of installation (often requiring less skilled labor compared to complex lap splicing) significantly reduce labor hours and dependency, making them a crucial tool for project managers facing workforce challenges.

Conclusion for 2026: By 2026, the mechanical rebar coupler market will be characterized by technology-driven standardization, a strong focus on performance and sustainability, and digital integration. Growth will be robust, fueled by infrastructure needs, but success will hinge on manufacturers’ ability to deliver high-quality, standardized, traceable, and application-specific solutions that address the industry’s core challenges of speed, safety, resilience, and environmental impact.

Common Pitfalls Sourcing Mechanical Rebar Couplers (Quality, IP)

Sourcing mechanical rebar couplers involves significant risks related to both product quality and intellectual property (IP). Overlooking these aspects can lead to structural failures, project delays, legal disputes, and costly rework. Below are key pitfalls to avoid:

Poor Material Quality and Manufacturing Standards

One of the most frequent issues is receiving couplers made from substandard materials or manufactured without adherence to international standards (e.g., ISO 15835, ASTM A1044). Low-quality steel, improper heat treatment, or inconsistent thread precision can compromise structural integrity, especially under seismic loads. Buyers may unknowingly accept couplers that appear identical to certified products but fail performance tests due to inferior metallurgy or workmanship.

Lack of Third-Party Certification and Testing

Many suppliers claim compliance with industry standards but lack valid certifications from accredited laboratories. Relying solely on supplier-provided test reports—without independent verification—exposes projects to risk. Absence of mill test certificates, type test reports, or witnessed installation trials can result in non-compliant couplers being installed, potentially leading to safety hazards and liability issues.

Counterfeit or Copycat Products

The market includes counterfeit couplers that mimic patented designs from reputable manufacturers. These imitations often bypass rigorous quality control and may infringe on intellectual property rights. Using such products not only jeopardizes structural performance but can also lead to legal action against contractors or project owners for IP violations, even if unintentional.

Infringement of Intellectual Property (IP) Rights

Mechanical coupler designs are often protected by patents, trademarks, and technical know-how. Sourcing generic or unlicensed versions of patented systems can lead to infringement claims. Even if the coupler functions adequately, legal repercussions—including injunctions, fines, or project stoppages—can arise if the product copies a proprietary design without authorization.

Inadequate Technical Support and Installation Training

Low-cost suppliers may not provide comprehensive technical documentation, design assistance, or on-site training. Improper installation—such as incorrect rebar threading, inadequate torque application, or misalignment—can nullify the performance of even high-quality couplers. Without proper support, field errors are more likely, compromising joint strength and durability.

Inconsistent Product Traceability

Reputable suppliers offer batch traceability, including heat numbers and test records. Poor traceability makes it difficult to verify quality in case of failure or audit. This lack of transparency can hinder accountability and complicate quality assurance processes, especially in large infrastructure projects requiring full compliance documentation.

Choosing Solely on Price

Opting for the lowest bid often leads to compromised quality and elevated long-term risks. While cost-efficiency is important, excessively low prices may indicate corner-cutting in materials, manufacturing, or certification. The potential costs of structural failure, litigation, or remediation far outweigh initial savings from cheap couplers.

Ignoring Compatibility with Rebar Grades and Conditions

Not all couplers are suitable for high-strength rebars (e.g., Grade 60/500 or higher) or harsh environments (e.g., marine or seismic zones). Using incompatible couplers can result in reduced fatigue resistance, corrosion, or bond failure. Ensuring compatibility with project-specific requirements is essential but often overlooked during sourcing.

Logistics & Compliance Guide for Mechanical Rebar Couplers

Overview

Mechanical rebar couplers are critical components in reinforced concrete construction, enabling the splicing of reinforcing bars with high strength and reliability. Proper logistics and compliance with relevant standards ensure structural integrity, safety, and project efficiency. This guide outlines key considerations for the handling, transportation, storage, and regulatory compliance of mechanical rebar couplers.

Applicable Standards and Regulations

Mechanical rebar couplers must comply with recognized international and regional standards to ensure performance and safety. Key standards include:

– ASTM A1034/A1034M: Standard Specification for Mechanical Splices for Steel Reinforcing Bars

– ACI 318: Building Code Requirements for Structural Concrete (references splice performance)

– ISO 15835-1: Steel for the reinforcement of concrete — Mechanical couplers for reinforcing steel — Part 1: Requirements

– EN 14849-1: Mechanical couplers for steel reinforcing bars — Performance requirements and tests

– Local building codes and project-specific engineering specifications

Ensure all couplers are certified by an accredited third party and accompanied by test reports and material traceability documentation.

Procurement and Supplier Qualification

Select suppliers with proven experience and certifications. Key requirements:

– Valid ISO 9001 quality management certification

– Test reports demonstrating compliance with project specifications

– Traceability of raw materials (e.g., alloy steel grade, heat number)

– Factory production control (FPC) documentation where required

Include technical submittals in procurement, including drawings, installation procedures, and quality assurance plans.

Packaging and Labeling

Couplers must be packaged to prevent damage and corrosion during transport and storage:

– Use moisture-resistant packaging (e.g., sealed plastic wrap, desiccants)

– Clearly label each package with:

– Product type and size (e.g., 25mm parallel-thread coupler)

– Batch/lot number

– Material grade and standard (e.g., ASTM A706)

– Manufacturer name and certification mark

– Handling instructions (e.g., “Do Not Drop,” “Keep Dry”)

Color-coding or tagging may be used to differentiate sizes or thread types.

Transportation Requirements

- Use covered, dry transport vehicles to protect from rain and humidity

- Secure loads to prevent movement, impact, or deformation

- Avoid exposure to extreme temperatures or corrosive environments

- Segregate couplers from materials that may cause contamination (e.g., chemicals, chlorides)

Document shipment details, including date, carrier, and condition upon dispatch.

On-Site Handling and Storage

- Store in a dry, covered area off the ground (e.g., on pallets or racks)

- Protect from moisture, dirt, and direct sunlight

- Maintain separation between different sizes and types to avoid mix-ups

- Use first-in, first-out (FIFO) inventory management

- Inspect for damage or corrosion before use; reject damaged or rusted couplers

Avoid dragging or dropping couplers; use proper lifting equipment for bulk handling.

Installation and Quality Control

- Only trained and certified personnel should install couplers

- Verify bar ends are properly prepared (e.g., threaded, deburred, clean)

- Use calibrated tools (e.g., torque wrenches, thread gauges) as per manufacturer instructions

- Conduct periodic inspections and witness testing, including:

- Visual inspection of threads and engagement

- Torque verification

- Pull tests per ASTM A1034 or project requirements

Maintain installation logs with location, date, installer, and inspection results.

Documentation and Traceability

Maintain a complete compliance dossier, including:

– Material test reports (MTRs)

– Third-party certification documents

– Installation records and inspection reports

– Non-conformance reports (NCRs) and corrective actions

– As-built drawings showing coupler locations

Ensure all documentation is retained for project closeout and audit purposes.

Environmental, Health, and Safety (EHS) Considerations

- Provide appropriate PPE (gloves, eye protection) during handling and installation

- Manage metal shavings and waste from threading operations

- Follow safe lifting practices to prevent musculoskeletal injuries

- Comply with local EHS regulations for storage and disposal

Conclusion

Effective logistics and strict compliance with technical standards are essential for the successful use of mechanical rebar couplers. By following this guide, project teams can ensure structural performance, regulatory adherence, and long-term durability of reinforced concrete structures. Always consult manufacturer guidelines and project-specific engineering requirements for optimal results.

Conclusion for Sourcing Mechanical Rebar Couplers

In conclusion, sourcing mechanical rebar couplers requires a comprehensive approach that balances quality, cost, technical specifications, and supplier reliability. These couplers play a critical role in ensuring structural integrity, particularly in seismic zones and high-rise construction, where reinforcement continuity is vital. Therefore, selecting couplers that meet international standards (such as ISO, ASTM, or BS) and are certified by recognized testing authorities is essential.

Key factors to consider include material compatibility, ease of installation, load transfer efficiency, and long-term durability. Engaging with reputable suppliers who provide technical support, product traceability, and consistent quality assurance helps mitigate risks associated with structural failure. Additionally, evaluating total lifecycle costs—beyond initial pricing—can lead to more sustainable and economical outcomes.

Ultimately, a strategic sourcing process that involves thorough vetting of manufacturers, on-site testing when possible, and collaboration with engineering teams ensures the selection of high-performance mechanical rebar couplers that contribute to safer, more efficient, and code-compliant construction projects.