The global meat processing equipment market is experiencing robust growth, driven by rising demand for packaged meat, increasing automation in food production, and stringent hygiene regulations. According to Grand View Research, the market was valued at USD 11.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. Similarly, Mordor Intelligence reports a CAGR of approximately 6.5% during the forecast period of 2023–2028, citing technological advancements and growing meat consumption in emerging economies as key growth catalysts. As processors seek greater efficiency, food safety compliance, and scalability, investment in advanced slicing, grinding, mixing, and packaging equipment continues to rise. In this evolving landscape, a select group of manufacturers are leading innovation, setting benchmarks in reliability, automation, and sustainability. Here’s a data-driven look at the top 10 meat equipment manufacturers shaping the future of the industry.

Top 10 Meat Equipment Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Metalquimia

Domain Est. 1997

Website: metalquimia.com

Key Highlights: Leader in technology and manufacturing of turnkey complete lines and industrial equipment for the processing of meat products….

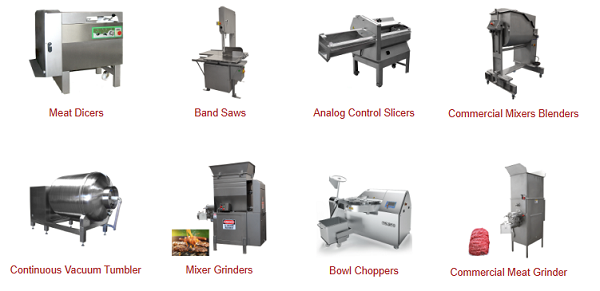

#2 PIECO

Domain Est. 1996

Website: pieco.com

Key Highlights: PIECO is a manufacturer and supplier of meat grinding products, safety equipment, and specialized tools for the commercial meat processing industry….

#3 Kentmaster

Domain Est. 1997

Website: kentmaster.com

Key Highlights: Kentmaster is the world’s leading manufacturer of the finest quality tools for the meat industry. Kentmaster tools are used daily in the most modern high ……

#4 Talsa

Domain Est. 1998 | Founded: 1900

Website: talsanet.com

Key Highlights: Talsa – Manufacturer of machinery for the meat industry. World Leader within the Food Industry. Founded in 1900….

#5 Biro Manufacturing Food Equipment known for Reliability since 1921

Domain Est. 1996

Website: birosaw.com

Key Highlights: BIRO designs, manufactures, and markets safe, durable, and reliable power operated, stainless steel, food and meat processing machinery….

#6 Marel

Domain Est. 1996

Website: marel.com

Key Highlights: Marel is full-line supplier of innovative solutions, services and software for the poultry, meat and fish processing industries, alongside alternative ……

#7 Reliable Food Manufacturing Equipment

Domain Est. 1999

Website: fpec.com

Key Highlights: FPEC designs and manufactures industry-trusted equipment for food processing. Our meat grinders, tumblers, cookers, and other specialized equipment are ……

#8 GASER

Domain Est. 2000

Website: gaser.com

Key Highlights: INDUSTRIAS GASER SL has become a leader in the manufacture of complete production lines for making meatballs and croquettes, as well as other auxiliary ……

#9 MEAT! Your Maker

Domain Est. 2017

#10 Kitchen Equipment

Domain Est. 2021

Website: hakkabros.com

Key Highlights: Hakka Brothers Corp ; Food Processing Equipment. Sausage Stuffer. Meat Grinder. Meat Mixer. Meat Tenderizers ; Smoker & Food Dehydrator. Electric Smoker Grill….

Expert Sourcing Insights for Meat Equipment

H2: 2026 Market Trends for Meat Processing Equipment

The global meat processing equipment market is poised for significant transformation by 2026, driven by technological innovation, evolving consumer preferences, sustainability demands, and regulatory shifts. As the food industry adapts to rising protein demand and heightened food safety standards, several key trends are shaping the future of meat equipment technology and investment.

-

Automation and Smart Manufacturing

By 2026, automation will dominate meat processing facilities, with increased adoption of robotics, AI-driven quality control systems, and IoT-enabled equipment. Automated deboning, portioning, and packaging systems improve precision, reduce labor costs, and enhance throughput. Smart sensors and real-time monitoring are becoming standard for predictive maintenance and hygiene compliance, reducing downtime and ensuring consistent product quality. -

Growth in Alternative Protein Influence

While traditional meat remains dominant, the rise of plant-based and lab-grown proteins is pushing equipment manufacturers to develop hybrid systems. Multi-functional machines capable of handling both conventional meat and alternative proteins are gaining traction. This flexibility allows processors to pivot quickly in response to shifting market demands without overhauling entire production lines. -

Sustainability and Energy Efficiency

Environmental concerns are reshaping equipment design. By 2026, there will be a strong market preference for energy-efficient, water-saving, and low-emission processing equipment. Manufacturers are integrating closed-loop water recycling, heat recovery systems, and eco-friendly refrigerants into new models. Equipment with lower carbon footprints will be a competitive advantage, especially in regions with stringent environmental regulations. -

Emphasis on Food Safety and Traceability

Regulatory bodies are tightening food safety standards worldwide. In response, meat processing equipment is incorporating advanced sanitation features such as Clean-in-Place (CIP) systems, antimicrobial surfaces, and automated hygiene validation. Blockchain integration for traceability is also influencing equipment design, with data collection capabilities built directly into processing lines. -

Regional Market Diversification

Demand for meat processing equipment is growing unevenly across regions. Asia-Pacific, particularly China and India, is expected to lead market expansion due to rising meat consumption and modernization of slaughterhouses. Meanwhile, North America and Europe are focused on upgrading legacy systems with smart technologies. Latin America and Africa are emerging as new frontiers, driven by investments in food infrastructure. -

Customization and Modular Equipment

As meat processors cater to niche markets and specialty products (e.g., organic, halal, or premium cuts), modular and customizable equipment is gaining popularity. Flexible systems allow quick reconfiguration for different product types, enabling small and medium enterprises (SMEs) to remain competitive without large capital investments. -

Supply Chain Resilience and Localization

Post-pandemic, meat processors are prioritizing supply chain resilience. This has led to increased demand for domestically manufactured equipment and localized service networks. Equipment suppliers are responding by establishing regional production hubs and offering faster maintenance support, reducing dependency on global logistics.

Conclusion

By 2026, the meat processing equipment market will be defined by intelligent automation, sustainability, and adaptability. Companies that invest in innovative, future-ready equipment will gain a strategic edge in efficiency, compliance, and responsiveness to consumer trends. As the global protein landscape evolves, the integration of advanced technologies into meat processing infrastructure will be critical for long-term competitiveness.

Common Pitfalls Sourcing Meat Equipment (Quality, IP)

Sourcing meat processing equipment involves significant investment and long-term operational impact. Overlooking critical factors related to quality and intellectual property (IP) can lead to costly mistakes, compliance issues, and operational inefficiencies. Below are common pitfalls to avoid:

Poor Quality Standards and Material Specifications

One of the most frequent issues is selecting equipment made from substandard materials or lacking compliance with food safety standards. Equipment must be constructed from food-grade stainless steel (typically 304 or 316) and meet hygienic design standards such as EHEDG or 3-A Sanitary Standards. Failure to verify these specifications can result in contamination risks, frequent breakdowns, and increased cleaning times.

Inadequate Validation of Manufacturer Claims

Suppliers may overstate performance, durability, or compliance capabilities. Without independent verification or third-party certifications, buyers risk acquiring equipment that fails under real-world conditions. Always request test reports, references from existing clients, and on-site demonstrations before finalizing purchases.

Ignoring Intellectual Property Rights

Using equipment that infringes on patented designs or proprietary technology can expose your business to legal action. Some suppliers, especially in regions with lax IP enforcement, may copy or reverse-engineer branded machinery. Ensure the equipment does not violate existing patents and request documentation proving the supplier’s right to manufacture and sell the product.

Lack of Documentation and Technical Support

Low-cost suppliers may provide insufficient technical documentation, operating manuals, or after-sales support. This becomes problematic during installation, maintenance, or troubleshooting. Ensure the supplier delivers complete technical drawings, maintenance guides, and accessible customer support—especially critical for complex meat processing lines.

Non-Compliance with Regional Regulatory Requirements

Meat equipment must comply with local food safety and electrical regulations (e.g., USDA, CE, FDA). Sourcing from international suppliers without confirming compliance can result in import delays, fines, or equipment rejection. Verify that the equipment meets all relevant certifications for your operating region.

Overlooking Long-Term Maintenance and Spare Parts Availability

Inexpensive equipment may have hidden long-term costs due to the unavailability of spare parts or lack of service networks. Confirm that the supplier can provide spare parts for at least 10 years and has a reliable service infrastructure, either directly or through local partners.

Failure to Audit Supplier Facilities

Relying solely on brochures or online claims without conducting on-site audits increases the risk of receiving low-quality or counterfeit equipment. Whenever possible, audit the manufacturer’s production facility to assess their quality control processes, material sourcing, and adherence to industry standards.

By proactively addressing these pitfalls—focusing on verified quality, regulatory compliance, and legitimate IP—you can ensure a reliable, safe, and legally sound investment in meat processing equipment.

Logistics & Compliance Guide for Meat Equipment

Overview

This guide outlines essential logistics and compliance considerations when transporting, importing, exporting, installing, and operating meat processing equipment. Adherence to regulatory, sanitary, and safety standards is critical to ensure food safety, equipment integrity, and legal compliance across the supply chain.

Regulatory Compliance

Food Safety Standards

Meat processing equipment must comply with food safety regulations such as:

– FDA (U.S. Food and Drug Administration): Equipment must meet 21 CFR standards for food contact surfaces, including material safety and cleanability.

– USDA FSIS (Food Safety and Inspection Service): Equipment used in federally inspected meat facilities must be approved and listed in the USDA’s Equipment Acceptance Program.

– EU Regulation (EC) No 852/2027: Requires equipment to be designed for hygiene, cleanability, and prevention of cross-contamination in EU member states.

– HACCP (Hazard Analysis and Critical Control Points): Equipment design and operation must support HACCP-based food safety plans.

International Standards

- CE Marking (Europe): Equipment must meet Machinery Directive 2006/42/EC and relevant harmonized standards (e.g., EN 1672-2 for hygiene in food machinery).

- CSA/ANSI Standards (Canada/USA): Compliance with safety and electrical standards for industrial equipment.

- ISO 14159: Hygiene requirements for the design of machinery in meat and poultry processing.

Equipment Design & Materials

Hygienic Design Requirements

- Surfaces in contact with meat must be non-porous, corrosion-resistant (e.g., AISI 304 or 316 stainless steel), and free of crevices.

- Equipment should allow for full drainage, disassembly, and clean-in-place (CIP) or wash-down capability.

- Seals, gaskets, and bearings must be protected from direct product contact or designed for easy cleaning.

Certification & Documentation

- Maintain equipment documentation including:

- Declaration of Conformity (CE or other regional standards)

- USDA Equipment Acceptance Letter (if applicable)

- Material certifications (e.g., mill test reports for stainless steel)

- Sanitation and maintenance manuals

Logistics & Transportation

Packaging & Protection

- Use weatherproof, sealed packaging to prevent moisture, dust, and contamination during transit.

- Secure equipment with anti-vibration mounts and protective covers for sensitive components (e.g., sensors, control panels).

- Include desiccants in enclosed spaces to reduce condensation risk.

Shipping Requirements

- Clearly label equipment with handling instructions: “Fragile,” “This Side Up,” “Do Not Stack.”

- Comply with international shipping regulations (e.g., ISPM 15 for wooden pallets).

- Use temperature-controlled transport if required (e.g., for equipment with sensitive electronics or lubricants).

Import/Export Compliance

- Ensure compliance with customs regulations, including:

- Harmonized System (HS) codes for meat processing machinery

- Import permits or sanitary certificates (where required)

- FDA Prior Notice (for U.S. imports of food contact equipment)

- Verify that equipment meets destination country’s electrical and safety standards (e.g., voltage, plug types, CE vs. UL certification).

Installation & Commissioning

Site Preparation

- Verify that facility infrastructure (electrical, water, drainage, ventilation) meets equipment specifications.

- Ensure installation area complies with sanitary zoning (e.g., separation of raw and cooked product areas).

Commissioning & Validation

- Perform equipment installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ) as part of validation.

- Conduct sanitation validation to confirm cleanability and absence of harborage points.

- Train personnel on safe operation, cleaning procedures, and maintenance.

Maintenance & Ongoing Compliance

Preventive Maintenance

- Follow manufacturer-recommended maintenance schedules.

- Keep records of all servicing, part replacements, and sanitation logs.

- Use only food-grade lubricants and replacement parts.

Audits & Inspections

- Prepare for regular audits by regulatory bodies (e.g., USDA, local health departments) and third-party auditors (e.g., SQF, BRCGS).

- Maintain an up-to-date equipment compliance file including certifications, manuals, and maintenance records.

Conclusion

Proper logistics and compliance management for meat equipment ensures food safety, operational efficiency, and regulatory adherence. From design and shipping to installation and maintenance, each phase must follow stringent standards to protect public health and support a robust food processing operation.

In conclusion, sourcing meat processing equipment requires careful consideration of several key factors, including equipment quality, compliance with food safety and regulatory standards, scalability, supplier reliability, and total cost of ownership. Choosing the right equipment not only enhances operational efficiency and product consistency but also supports long-term business growth and consumer trust. Conducting thorough research, obtaining quotes from multiple suppliers, and verifying equipment suitability for specific processing needs are essential steps in making informed procurement decisions. Ultimately, investing in reliable, well-maintained, and technologically appropriate meat equipment lays the foundation for a safe, efficient, and profitable meat processing operation.