The global medium-density fiberboard (MDF) market has experienced steady growth, driven by rising demand in construction, furniture, and interior design applications—particularly for moisture-resistant and waterproof variants. According to Grand View Research, the global MDF market size was valued at USD 69.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030, fueled by increasing urbanization and the shift toward cost-effective, engineered wood products. Mordor Intelligence also projects robust growth, noting that the Asia Pacific region dominates production and consumption due to rapid industrialization and infrastructure development. As sustainability and durability become key purchasing factors, waterproof MDF—treated with moisture-resistant resins and waxes—has emerged as a preferred alternative to traditional wood panels in high-humidity environments. This growing demand has spurred innovation and competition among manufacturers aiming to deliver high-performance, eco-friendly solutions. Below are the top 9 waterproof MDF manufacturers leading the market through technological advancement, global reach, and certified product quality.

Top 9 Mdf Waterproof Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MDF

Domain Est. 1996

Website: uniboard.com

Key Highlights: Uniboard MDF is produced using the latest in manufacturing technology. From the 9-foot continuous press to super refining and the latest in sanding and cutting ……

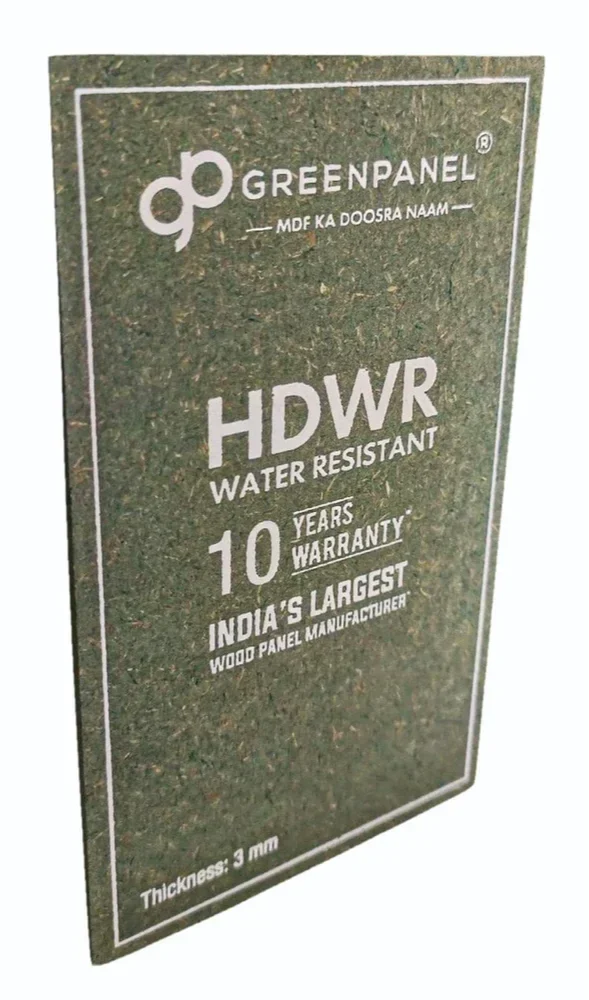

#2 Greenpanel : MDF Ka Doosra Naam

Domain Est. 2000

Website: greenpanel.com

Key Highlights: GREENPANEL – INDIA’S LARGEST MANUFACTURER OF WOOD PANELS · MEDIUM DENSITY FIBREBOARD · HDWR – High Density Water Resistant · WOODEN FLOORING · PRE-LAMINATED MDF….

#3 MDF Product Specifications

Domain Est. 1995

Website: weyerhaeuser.com

Key Highlights: This product is for interior use only, not “waterproof” and not intended for wet-area applications. Product Specifications. Plywood Core, Used as inner core ……

#4 Medium Density Fiberboard (MDF)

Domain Est. 1996

Website: roseburg.com

Key Highlights: Whether moisture-resistant, flame retardant or no-added formaldehyde (NAF), Roseburg has an MDF panel to suit every setting. Made from recycled content, all of ……

#5 Trupan Moisture

Domain Est. 1996

Website: na.arauco.com

Key Highlights: Trupan Moisture Resistant is an interior, moisture resistant MDF panel that is ideally suited for kitchen, bath and laboratory cabinets….

#6 MDF

Domain Est. 1997

Website: dixieply.com

Key Highlights: It is possible to waterproof Standard MDF by applying a latex primer and sealant or water-resistant paint to the panel’s surface. However, this only ……

#7 Moisture Resistant MDF Boards

Domain Est. 2001

Website: madar.com

Key Highlights: High-performance HMR E2 MDF boards with ≤18.6% thickness swelling. Ideal for kitchens, bathrooms & humid areas. EN & CARB compliant. Shop now!…

#8 MDF Board Manufacturer, MDF Sheet at Best Price in India

Domain Est. 2013

Website: vir-mdf.com

Key Highlights: India’s leading MDF Board manufacturer brand – VIRMDF. We are a supplier of MDF sheets at a competitive price which is available in different styles….

#9 Moisture

Domain Est. 1997

Website: forestplywood.com

Key Highlights: Moisture-resistant MDF, sometimes called MR MDF, is engineered to withstand damp or humid conditions better than traditional MDF….

Expert Sourcing Insights for Mdf Waterproof

2026 Market Trends for MDF Waterproof

The medium-density fiberboard (MDF) industry is undergoing a transformative shift, particularly in the segment of waterproof or moisture-resistant MDF. As construction, interior design, and furniture manufacturing continue to evolve, demand for durable, sustainable, and cost-effective materials is driving innovation in MDF technology. The year 2026 is poised to reflect significant growth and transformation in the waterproof MDF market, shaped by technological advancements, environmental regulations, and shifting consumer preferences.

Rising Demand Across Key Sectors

By 2026, the waterproof MDF market is expected to experience robust growth, especially in the residential and commercial construction sectors. Increasing urbanization in emerging economies and a surge in renovation activities in developed regions are key drivers. Waterproof MDF is increasingly favored for use in kitchens, bathrooms, and high-humidity environments due to its resistance to swelling and warping. The furniture industry is also adopting waterproof variants to meet consumer demands for long-lasting and low-maintenance products.

Additionally, the modular and prefabricated construction trend is accelerating the adoption of engineered wood products like waterproof MDF. Its uniformity, ease of machining, and compatibility with laminates and coatings make it ideal for mass-produced interior components.

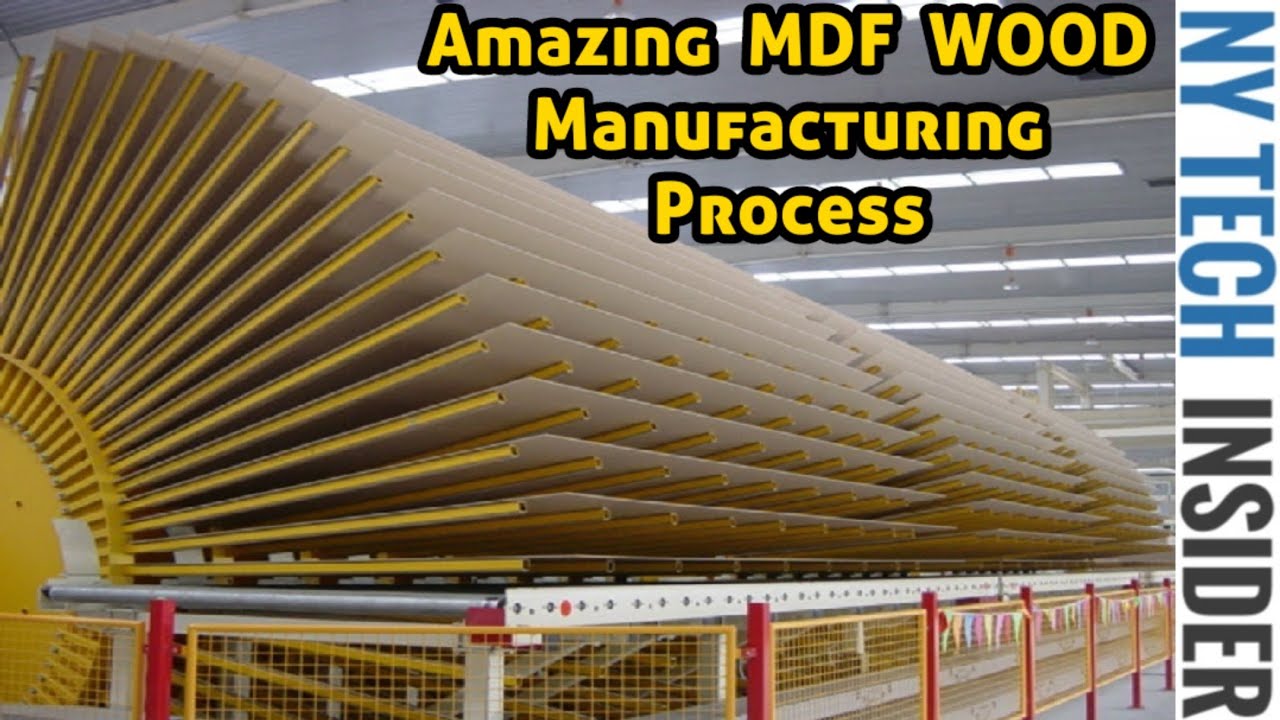

Technological Innovations Enhancing Performance

A major trend shaping the 2026 landscape is the integration of advanced resin systems and nano-coatings to improve moisture resistance. Traditional MDF is highly susceptible to water damage, but new formulations using acrylics, wax emulsions, and isocyanate-based binders (such as PMDI) significantly enhance water repellency. Manufacturers are investing in R&D to develop hybrid composites that combine wood fibers with thermoplastics or mineral additives, further improving durability.

Digital manufacturing technologies, including CNC machining and automated finishing lines, are also enabling precise customization of waterproof MDF panels, supporting the growth of made-to-order furniture and architectural millwork.

Sustainability and Regulatory Pressures

Environmental concerns are influencing the waterproof MDF market profoundly. By 2026, stricter emissions standards—such as CARB (California Air Resources Board) Phase 2 and EPA TSCA Title VI—are pushing manufacturers toward formaldehyde-free or ultra-low-emitting binders. Bio-based resins derived from soy, lignin, or tannins are gaining traction as eco-friendly alternatives.

Moreover, recyclability and sourcing transparency are becoming critical selling points. Consumers and B2B buyers are increasingly demanding certifications like FSC (Forest Stewardship Council) and PEFC, which will shape branding and market positioning strategies for leading MDF producers.

Regional Market Dynamics

Asia-Pacific is expected to dominate the waterproof MDF market in 2026, driven by rapid infrastructure development in countries like India, Vietnam, and Indonesia. China remains a major producer and consumer, although environmental crackdowns are pushing manufacturers toward greener production methods.

In Europe, the renovation wave and emphasis on energy-efficient buildings are boosting demand for high-performance building materials, including moisture-resistant MDF. North America is witnessing steady growth, primarily in the DIY and premium furniture segments, supported by home improvement trends and e-commerce expansion.

Competitive Landscape and Strategic Moves

The market is becoming increasingly competitive, with key players such as Kronospan, Norbord (now part of West Fraser), EGGER, and Arauco expanding their waterproof MDF offerings. Strategic partnerships with coating specialists and technology providers are becoming common to differentiate product lines. Vertical integration and investment in smart factories are enabling cost control and faster time-to-market.

E-commerce platforms and digital distribution channels are also emerging as critical tools for reaching end-users directly, especially in the DIY and small contractor segments.

Conclusion

By 2026, the waterproof MDF market will be defined by innovation, sustainability, and expanding applications. As industries seek resilient and environmentally responsible materials, waterproof MDF is set to play a pivotal role in shaping the future of interior construction and design. Companies that invest in green technologies, performance enhancement, and market responsiveness will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing MDF Waterproof (Quality, IP)

Sourcing waterproof Medium Density Fiberboard (MDF) can present several challenges, particularly when evaluating quality and ensuring the product meets appropriate Ingress Protection (IP) standards. Below are common pitfalls to avoid:

Misunderstanding Waterproof vs. Water-Resistant

One of the most frequent mistakes is assuming that “waterproof” MDF is completely impervious to water. In reality, most waterproof MDF is actually water-resistant, meaning it can withstand moisture exposure for limited periods but is not fully waterproof. Buyers should clarify technical specifications with suppliers and verify performance under expected environmental conditions.

Overlooking Core Composition and Resin Quality

The quality of the resin (typically moisture-resistant resins like melamine-urea-formaldehyde) used in the MDF core greatly affects durability. Low-quality resins or inadequate resin distribution reduce water resistance and structural integrity. It’s essential to request material data sheets and verify compliance with standards such as EN 622-5 for humid conditions.

Ignoring Surface Sealing and Edge Treatment

Even high-quality waterproof MDF requires proper sealing at edges and joints to maintain its IP rating. Poor installation or lack of sealant can compromise performance. Buyers should ensure that the supplied product includes or is compatible with appropriate edge banding and surface coatings.

Confusing IP Ratings with Moisture Resistance

Ingress Protection (IP) ratings typically apply to electrical enclosures and do not directly assess a material’s moisture resistance. Waterproof MDF used in construction or cabinetry is not usually assigned an IP code. Relying on IP ratings can mislead purchasers; instead, focus on industry standards like ASTM D1037 for water absorption and thickness swelling tests.

Sourcing from Unverified Suppliers

Many suppliers claim their MDF is “waterproof” without third-party certification. This can lead to substandard materials that degrade prematurely. Always request test reports, certifications (e.g., CARB, E1, or F**** for formaldehyde emissions and moisture resistance), and conduct factory audits if sourcing in bulk.

Neglecting Environmental and Installation Conditions

Waterproof MDF performs differently in continuously humid environments (e.g., bathrooms, kitchens) versus occasional moisture exposure. Failing to match the product grade to the application leads to premature failure. Specify MDF designed for high-humidity environments and ensure proper ventilation in the installation area.

Cost-Cutting Compromises

Opting for cheaper alternatives may result in MDF that swells, delaminates, or off-gasses harmful compounds. Investing in certified, high-performance waterproof MDF reduces long-term maintenance and replacement costs.

By recognizing these pitfalls and conducting thorough due diligence, buyers can ensure they source high-quality, truly water-resistant MDF suitable for their application.

Logistics & Compliance Guide for MDF Waterproof

Product Overview

Medium Density Fiberboard (MDF) Waterproof is an engineered wood product treated with water-resistant resins to enhance moisture resistance. Commonly used in kitchens, bathrooms, and outdoor applications, it requires careful handling and compliance with international standards during transportation and distribution.

Packaging Requirements

- Moisture Protection: Use waterproof wrapping or sealed plastic film to prevent exposure to humidity during transit.

- Edge Protection: Apply corner protectors or edge banding to prevent chipping and structural damage.

- Palletization: Secure sheets on sturdy wooden pallets with strapping or shrink wrap to prevent shifting.

- Labeling: Clearly mark packages with product details, moisture-sensitive icons, and handling instructions (e.g., “Do Not Stack,” “Protect from Rain”).

Storage Guidelines

- Environment: Store indoors in a dry, well-ventilated area with controlled humidity (ideally 40–60% RH).

- Elevation: Keep pallets off the ground using skids to prevent moisture absorption.

- Stacking: Limit stack height to avoid compression damage; follow manufacturer recommendations.

- Rotation: Implement FIFO (First In, First Out) inventory management to reduce long-term storage risks.

Transportation Considerations

- Vehicle Type: Use enclosed, dry trucks or containers to protect against weather exposure.

- Loading/Unloading: Handle with forklifts or mechanical aids; avoid dragging or dropping panels.

- Climate Control: For long-distance or international shipments, consider climate-controlled logistics in high-humidity regions.

- Documentation: Include packing lists, delivery notes, and certificates of conformity with each shipment.

Regulatory Compliance

- REACH & RoHS (EU): Confirm that resins and binders comply with EU chemical safety regulations.

- CARB Phase 2 (USA): Ensure formaldehyde emissions meet California Air Resources Board standards.

- FSC or PEFC Certification: Provide chain-of-custody documentation if sourcing from sustainably managed forests.

- Import/Export Regulations: Verify customs requirements, including phytosanitary certificates if applicable (e.g., ISPM 15 for wood packaging materials).

Safety & Handling

- PPE: Workers should wear gloves, masks, and eye protection when cutting or sanding to minimize exposure to dust.

- Ventilation: Ensure adequate airflow in processing areas to reduce airborne particulate concentration.

- Disposal: Follow local regulations for disposal of off-cuts and waste; do not incinerate without emission controls.

Quality Assurance & Documentation

- Batch Tracking: Maintain lot numbers and production dates for traceability.

- Test Reports: Provide moisture resistance, density, and emission test results upon request.

- Compliance Labels: Affix certification marks (e.g., E0/E1 formaldehyde class, CE marking) on product or packaging.

Incident Management

- Damage Protocol: Inspect upon delivery; document and report any moisture damage or structural defects immediately.

- Recall Procedures: Establish a process for product recalls in case of non-compliance or safety issues.

- Customer Support: Offer technical documentation and compliance data to distributors and end-users.

Conclusion

Proper logistics and compliance practices are essential for maintaining the integrity and safety of Waterproof MDF throughout the supply chain. Adhering to packaging, storage, transportation, and regulatory standards ensures product performance and legal compliance across global markets.

In conclusion, sourcing waterproof MDF requires careful consideration of product specifications, supplier reliability, and intended application. Unlike standard MDF, waterproof or moisture-resistant MDF is specially engineered to withstand humid or damp environments, making it ideal for use in bathrooms, kitchens, and outdoor applications when properly sealed. When sourcing, it is essential to verify that the material meets relevant industry standards (such as BS EN 622-5 for humidity-resistant fiberboards), and to choose reputable suppliers who provide certification and consistent quality.

Additionally, understanding the differences between moisture-resistant MDF, fully waterproof composite boards, and alternative materials like marine-grade plywood or WBP (water-boil-proof) boards can help ensure the right choice for durability and performance. Cost, availability, and environmental certifications (such as FSC or CARB compliance) should also factor into the decision.

Ultimately, successful sourcing of waterproof MDF hinges on balancing performance requirements with budget and sustainability goals, ensuring long-term satisfaction and structural integrity in moisture-prone environments.