The global demand for reliable and cost-effective electrical cabling solutions continues to rise, driven by rapid urbanization, infrastructure development, and the expansion of the construction and industrial sectors. According to Mordor Intelligence, the global electrical wires and cables market was valued at USD 167.12 billion in 2022 and is projected to grow at a CAGR of 5.8% over the forecast period (2023–2028). A significant segment of this growth is attributed to non-metallic sheathed cables—commonly known as NM-B (or Romex) and BX (armored) cables—used extensively in residential and commercial wiring. With increasing regulatory standards and performance expectations, selecting the right manufacturer has become critical. Based on market presence, product innovation, compliance with UL and NEC standards, and global distribution, the following eight manufacturers stand out in the Mc (NM-B) and BX cable space.

Top 8 Mc Vs Bx Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Why Choose Metal

Domain Est. 1996

Website: servicewire.com

Key Highlights: Contractors who use Type MC armored cable report 50-70% combined labor and material savings versus traditional pipe and wire….

#2 AFC Cable Systems

Domain Est. 2010 | Founded: 1926

Website: atkore.com

Key Highlights: AFC Cable Systems, founded in 1926, is an industry-leading brand of pre-wired armored and metal-clad cables (AC & MC), We manufacture standard Type MC Cables,…

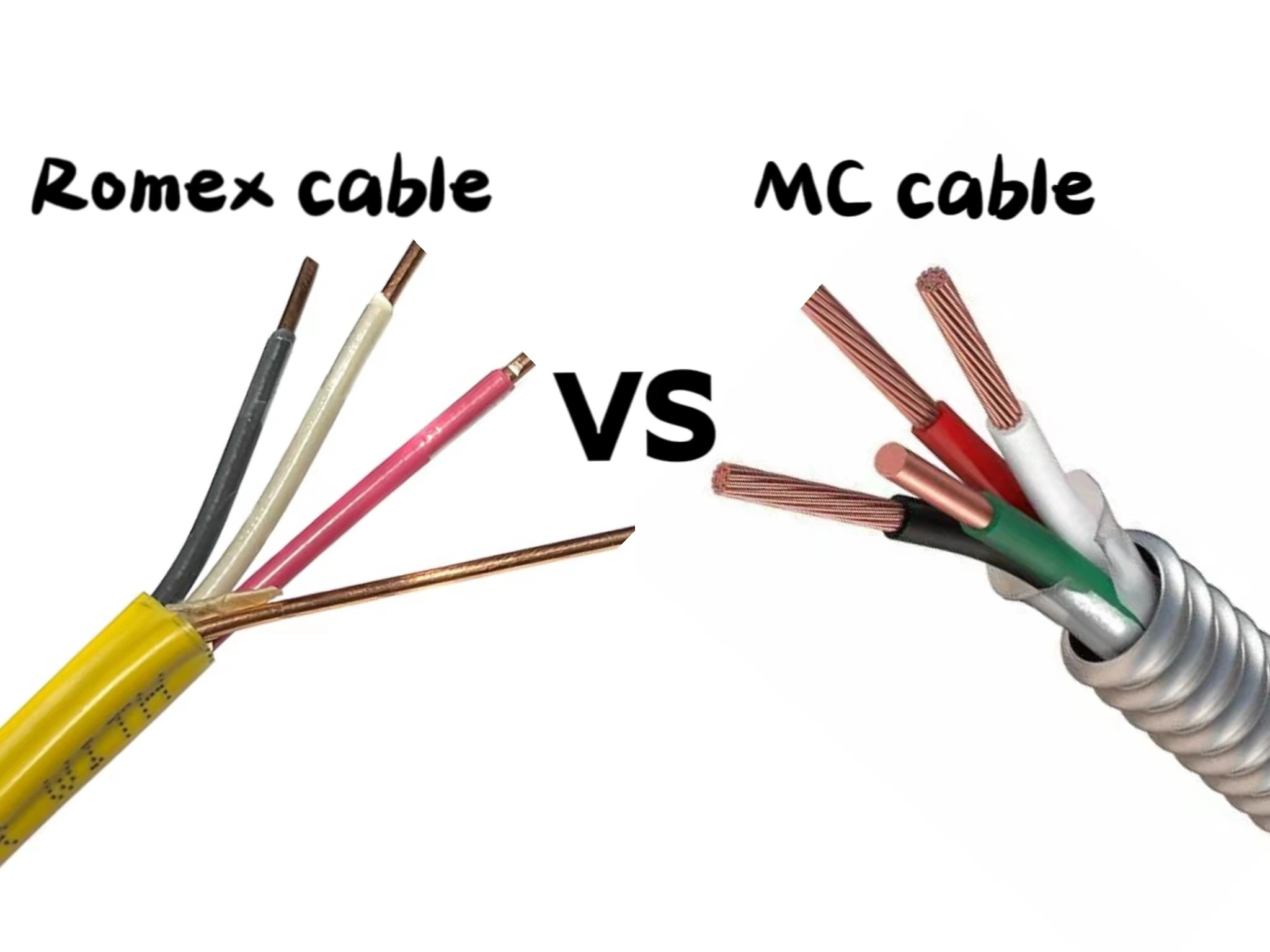

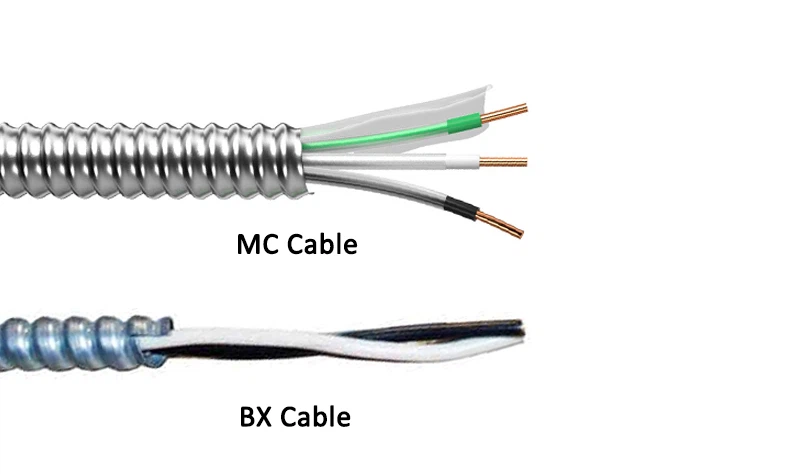

#3 MC Cable and BX Cable: What Is It?

Domain Est. 2010

Website: fibersavvy.com

Key Highlights: BX cable and MC cable are both referring to armored cable. BX cable is actually a branded name for AC or armored cable. MC cable is easier to remember. BX ……

#4 In

Domain Est. 2012

Website: idealind.com

Key Highlights: 30-day returnsIDEAL® In-Sure® MC-PCS wire connectors use a simple push-in action to securely splice control and signal conductor pairs in MC-PCS cables….

#5 BX Cable vs. MC Cable: What Are They

Domain Est. 2015

Website: fiber-mart.com

Key Highlights: The most important foundational knowledge is that both BX cable and MC cable are specific types of armored cable. The term “BX” is a branded ……

#6 What Is BX Cable and Its Complete Usage

Domain Est. 2023

Website: centralwires.com

Key Highlights: BX cables do not have a ground wire, whereas MC cables have a ground wire and are therefore suitable for different applications….

#7 Romex vs. MC Cable vs. THHN

Domain Est. 2023

Website: expertce.com

Key Highlights: While they look similar, BX cable relies on the combination of its metal armor and a thin bonding wire for grounding, whereas MC cable contains ……

#8 The Difference Between MC Cable And BX Cable

Domain Est. 2024

Website: greaterwire.com

Key Highlights: BX Cable is simpler in structure and lower in cost, so it. BX Cable is prone to rust in humid environments floors, and ceilings….

Expert Sourcing Insights for Mc Vs Bx Cable

H2: 2026 Market Trends for MC vs BX Cable

As the electrical construction and building infrastructure sectors evolve, the competition between Metal-Clad (MC) and BX (a type of armored cable) continues to reflect shifting preferences driven by technological advancements, regulatory standards, labor efficiency, and cost considerations. By 2026, several key market trends are expected to influence the adoption and demand for MC versus traditional BX cable:

-

Growing Preference for MC Cable in Commercial and Industrial Applications

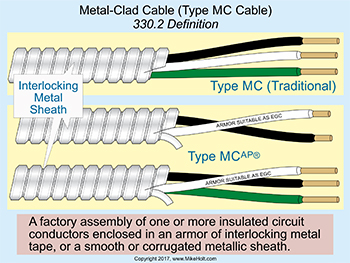

Metal-Clad (MC) cable is projected to dominate the market in commercial, industrial, and institutional construction projects by 2026. Its flexibility, integrated grounding conductor, and superior fire resistance make it ideal for environments requiring high safety standards and ease of installation. The increasing emphasis on arc fault protection and compliance with NEC (National Electrical Code) requirements, particularly Article 330, is driving contractors toward MC cable for its code-compliant design. -

Decline in BX Cable Usage Due to Regulatory and Safety Concerns

BX cable, while historically popular for residential use, is seeing reduced adoption due to limitations in grounding reliability and its inability to meet the latest NEC standards without modification. By 2026, stricter enforcement of electrical safety codes—especially in new construction and retrofit projects—will likely accelerate the phase-out of BX in favor of more modern alternatives. The absence of a dedicated equipment grounding conductor (EGC) in older BX designs is a key disadvantage in markets prioritizing safety and liability reduction. -

Labor Efficiency and Installation Speed Favoring MC Cable

With rising labor costs and a growing skilled labor shortage, contractors are prioritizing installation efficiency. MC cable, which often includes pre-assembled components and easier termination methods, reduces labor time compared to BX, which may require additional grounding measures. This efficiency advantage positions MC as the preferred choice in time-sensitive projects, further widening its market lead by 2026. -

Sustainability and Material Innovation

Manufacturers are investing in lightweight, aluminum-jacketed MC cables that reduce material costs and environmental impact. These innovations align with green building trends and support LEED certification goals, giving MC an edge in sustainable construction markets. In contrast, BX cable technology has seen minimal innovation, limiting its appeal in eco-conscious projects. -

Regional Market Variations

While MC cable adoption is strong nationwide, especially in urban and code-strict regions (e.g., California, Northeast U.S.), some rural or residential retrofit markets may still use BX due to lower material costs and familiarity among local electricians. However, even in these areas, the long-term trend points toward MC as training and awareness improve. -

Impact of Smart Buildings and Power Over Ethernet (PoE)

The rise of smart buildings and increased demand for PoE systems require reliable, shielded, and code-compliant wiring solutions. MC cable’s superior EMI shielding and compatibility with low-voltage systems make it better suited for these applications than BX, further boosting its relevance in the evolving infrastructure landscape.

Conclusion:

By 2026, MC cable is expected to hold a dominant position in the market, driven by safety regulations, labor efficiency, and technological adaptability. BX cable will likely remain in niche or legacy applications but will continue to lose ground overall. Electrical contractors, specifiers, and developers are increasingly favoring MC for its compliance, performance, and future-readiness, marking a clear trend toward modernization in electrical infrastructure.

Common Pitfalls Sourcing MC vs BX Cable (Quality, IP)

When sourcing electrical cables like MC (Metal-Clad) and BX (a common term historically used for armored cables, often referring to AC or Type AC cable), understanding the differences and potential pitfalls is critical for ensuring safety, compliance, and long-term performance. Below are key pitfalls related to quality and IP (Ingress Protection) considerations when choosing between MC and BX/AC cable.

Misunderstanding Cable Types and Standards

A major pitfall is confusing MC cable with BX or AC cable due to outdated terminology. BX is a legacy term originally used for early forms of armored cable, but today’s electrical codes typically refer to AC (Armored Cable) rather than BX. MC cable is a more modern, code-compliant product with broader applications. Sourcing the wrong type due to terminology confusion can lead to code violations and safety hazards.

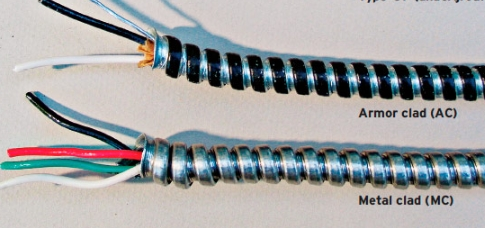

Overlooking Armor Construction and Grounding

MC cable features a continuous interlocking metal armor that acts as the equipment grounding conductor, provided it meets NEC (National Electrical Code) requirements. In contrast, older AC/BX cable relies on an internal bonding strip for grounding. Sourcing AC/BX without verifying the presence and integrity of the bonding strip can result in inadequate grounding, posing serious safety risks. Inferior quality AC cables may lack or damage this strip during installation.

Ignoring Environmental and IP Ratings

MC cables are often available with additional jackets (e.g., PVC) that provide moisture and chemical resistance, offering higher effective IP ratings (e.g., protection against dust and water ingress). Standard AC/BX cable typically lacks such a jacket, making it unsuitable for damp, wet, or outdoor locations. Sourcing AC/BX for environments requiring moisture protection leads to premature failure and non-compliance with IP standards.

Compromising on Quality and Material Thickness

Low-cost MC or AC cables may use thinner aluminum or steel armor, reducing mechanical protection and durability. Inferior interlocking armor can kink or separate during installation, exposing conductors. Additionally, substandard materials may corrode faster, especially in harsh environments. Buyers focusing solely on cost may end up with cables that fail under stress or do not meet code requirements.

Assuming Interchangeability in Applications

MC cable is approved for a wider range of applications than AC/BX, including outdoor use, direct burial (with proper jacketing), and in commercial/industrial settings. AC cable is generally limited to dry indoor locations. Sourcing AC/BX for applications requiring MC cable results in non-compliant installations and potential insurance or inspection issues.

Neglecting Third-Party Certification and Documentation

A common quality pitfall is sourcing cables without proper certification (e.g., UL, ETL). Counterfeit or uncertified MC/AC cables may not have undergone rigorous testing for fire resistance, armor strength, or electrical safety. Always verify certification marks and request test reports to ensure compliance with NEC and IP-related performance standards.

Inadequate Attention to Jacket Integrity for IP Protection

For environments requiring dust or moisture resistance (e.g., IP54 or higher), the outer jacket of MC cable plays a crucial role. Sourcing MC cable without a robust outer jacket—or selecting AC cable, which lacks one—results in insufficient ingress protection. Always confirm the cable’s jacket material and thickness when IP ratings are a concern.

Conclusion

To avoid these pitfalls, clearly define project requirements, use correct terminology (MC vs. AC, not BX), source from reputable suppliers, and verify certifications. Prioritize cables with appropriate armor, grounding provisions, and jacketing to meet both quality and IP protection needs.

Logistics & Compliance Guide for MC vs. BX Cable

Understanding the differences between Metal-Clad (MC) and BX (Armored Cable) cables is essential for proper logistics planning and regulatory compliance in construction and electrical installations. This guide outlines key considerations for handling, transporting, storing, and installing both cable types in accordance with industry standards.

Definition and Key Differences

MC Cable (Metal-Clad Cable)

MC cable is a factory-assembled assembly consisting of one or more insulated conductors enclosed in a flexible, interlocking metal sheath. It typically includes an internal bonding strip or equipment grounding conductor. MC cable is designed for both indoor and outdoor use and meets modern National Electrical Code (NEC) requirements.

BX Cable (Armored Cable)

BX cable is an older type of armored cable that also features insulated conductors wrapped in a flexible metal armor. However, it lacks a dedicated internal bonding strip or grounding conductor. BX cable relies on the armor itself for grounding, which can be less reliable and is often not compliant with current NEC standards in many applications.

Regulatory and Code Compliance

National Electrical Code (NEC) Requirements

– MC Cable: Approved under NEC Article 330. It is suitable for a wide range of applications, including commercial, industrial, and residential settings. Requires proper grounding via an internal bonding conductor.

– BX Cable: Covered under NEC Article 320 (for Type AC cable, the modern equivalent). Traditional BX cable without an internal bonding strip may not meet grounding requirements and is generally not permitted in new installations unless it includes a listed bonding strip.

OSHA and Workplace Safety Standards

– Both cables must be installed in accordance with OSHA regulations (29 CFR 1926, Subpart K) for electrical safety.

– MC cable is preferred due to its consistent compliance and built-in grounding features.

International and Local Jurisdictional Codes

– Verify local amendments to the NEC, as some jurisdictions may restrict or prohibit the use of BX cable.

– MC cable is widely accepted globally when compliant with IEC or other regional standards.

Handling and Transportation

Packaging and Spooling

– Both MC and BX cables are typically shipped on reels or in coiled bundles.

– Ensure packaging is intact to prevent kinking or crushing during transit.

Load Securing and Vehicle Requirements

– Secure cable reels to prevent rolling or shifting during transport.

– Use padded straps and avoid sharp edges that could damage the metal sheath.

– MC cable reels may be heavier due to additional grounding components—confirm weight limits for handling equipment.

Environmental Protection During Transit

– Protect cables from moisture, extreme temperatures, and UV exposure, especially for outdoor-rated MC cable with non-metallic jackets.

– Use tarps or enclosed trailers when transporting in adverse weather.

Storage and Inventory Management

Indoor vs. Outdoor Storage

– Store both cable types indoors when possible, in a dry, temperature-controlled environment.

– If outdoor storage is necessary, elevate reels off the ground and cover with waterproof tarps, ensuring ventilation to prevent condensation.

Shelf Life and Inspection

– Inspect cables before use for signs of corrosion, dents, or damaged sheathing.

– MC cable with polymer jackets has a longer shelf life than older BX types, which may degrade over time.

Labeling and Traceability

– Maintain clear labeling of cable type, gauge, length, and compliance markings (e.g., UL, NEC Article 330).

– Use inventory logs to track lot numbers and expiration dates where applicable.

Installation Best Practices

Grounding and Bonding

– MC Cable: Connect the internal bonding conductor to grounding terminals at each fitting.

– BX Cable: Only use if it includes a listed bonding strip; otherwise, it may not provide effective grounding.

Bending Radius and Support

– Follow manufacturer specifications for minimum bending radius (usually 5–7 times the cable diameter).

– Support cables every 3–6 feet, depending on cable size and type, per NEC requirements.

Use in Hazardous or Exposed Locations

– MC cable is preferred in corrosive, high-vibration, or exposed environments due to robust construction.

– BX cable is generally not recommended in harsh environments or where code compliance is strictly enforced.

Disposal and Environmental Compliance

Recycling Metal Components

– Both MC and BX cables contain recyclable steel armor and copper conductors.

– Partner with certified e-waste or scrap metal recyclers.

Hazardous Material Considerations

– Older BX cables may contain materials subject to environmental regulations (e.g., lead-based coatings).

– Confirm material safety data sheets (MSDS) for disposal guidelines.

Compliance with EPA and Local Regulations

– Follow EPA and local waste disposal codes for electronic and metal waste.

– Document recycling efforts for sustainability reporting.

Summary and Recommendations

For modern electrical projects, MC cable is the recommended choice due to its compliance with current NEC standards, built-in grounding conductor, durability, and versatility. BX cable should be used only in repair or legacy system maintenance, and only if it meets local code requirements. Proper logistics planning—covering transport, storage, handling, and disposal—ensures safety, compliance, and project efficiency. Always consult the latest NEC edition and local authorities having jurisdiction (AHJ) before specifying or installing either cable type.

Conclusion: Sourcing MC vs. BX Cable

When deciding between sourcing MC (Metal-Clad) cable and BX (an older type of armored cable), it is important to consider code compliance, safety, performance, and application requirements. While BX cable was historically used for electrical installations, it lacks a dedicated grounding conductor and does not meet current National Electrical Code (NEC) standards for grounding, making it obsolete and unsuitable for new construction or upgrades.

In contrast, MC cable is a modern, code-compliant solution that includes a full ground wire, superior armor protection, and greater flexibility in installation. It is suitable for both residential and commercial applications, offering enhanced safety, durability, and ease of use. Additionally, MC cable is widely available from reputable suppliers and preferred by electricians and inspectors alike.

Therefore, MC cable is the recommended choice over BX cable for all new installations and renovations. Sourcing MC cable ensures compliance with current electrical codes, improved safety, and long-term reliability. Given the obsolescence and safety limitations of BX, it should only be considered in rare cases of historical restoration, and even then, with proper evaluation and code exceptions. Ultimately, investing in MC cable is a safer, more efficient, and future-ready decision.