The global dust collection systems market is experiencing robust growth, driven by tightening environmental regulations, rising industrialization, and increasing focus on workplace health and safety. According to a report by Mordor Intelligence, the market was valued at USD 4.5 billion in 2023 and is projected to grow at a CAGR of over 6.2% from 2024 to 2029. This expansion reflects heightened demand across key sectors such as manufacturing, pharmaceuticals, food processing, and mining, where efficient air quality management is critical. As industries strive to meet emission standards and optimize operational efficiency, investments in advanced dust collection technologies are becoming essential. This has spurred innovation among leading manufacturers focused on energy efficiency, low maintenance, and smart monitoring capabilities. In this landscape, identifying top-performing manufacturers that deliver measurable improvements in system performance is crucial for businesses aiming to reduce downtime, lower energy costs, and ensure regulatory compliance.

Top 10 Maximizing Dust Collection System Efficiency Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Superior Filtration, Industrial Dust and Mist Collector

Domain Est. 1995

Website: parker.com

Key Highlights: We offer a range of efficient and cost-effective air pollution control solutions, including industrial DustHog dust and Smoghog mist collectors….

#2 AAF Dust Collection Solutions

Domain Est. 1997

Website: info.aafintl.com

Key Highlights: Efficient system maximizes filtration performance; Robust construction ensures long-term durability; Proven technology delivers reliable results across ……

#3 Dust Collector Manufacturers

Domain Est. 2000

Website: dustcollectingsystems.com

Key Highlights: We offer a wide selection of dust collectors, mist collectors, welding booths, work containment booths, cyclones, electrostatic filters, air cleaning and ……

#4 Importance of Investing in a Dust Collector Maintenance Program

Domain Est. 2013

Website: camfilapc.com

Key Highlights: Learn why a structured industrial dust collector maintenance program is far more effective than reactive repairs….

#5 Optimizing Dust Collection Systems for Efficiency and Sustainability

Domain Est. 2014

Website: adamscorp.com

Key Highlights: Discover how optimizing dust collection systems with modern valve technology can save energy, reduce costs, and boost sustainability….

#6 Baghouse Filter Efficiency

Domain Est. 1998

Website: cpef.com

Key Highlights: The best way to manage airflow and maximize energy efficiency is by installing a variable frequency drive (VFD) on the fan motor. A VFD will help mitigate dust ……

#7 Maximizing the Efficiency and Lifespan of Your Dustcontrol …

Domain Est. 2002

Website: dustcontrol.us

Key Highlights: Each Service Kit is thoughtfully designed with high-quality components specifically made for Dustcontrol machines. A standard Service Kit ……

#8 Maximizing Dust Collection System Efficiency

Domain Est. 2006

Website: airbestpractices.com

Key Highlights: In this article, we review the operating principles of both basic types of pulse-jet dust collectors — bag (sock), and reverse flow filter ……

#9 Maximizing Dust Collection System Efficiency

Domain Est. 2008

Website: actdustcollectors.com

Key Highlights: Discover practical tips to improve your dust collection system’s efficiency. Learn how to optimize airflow, reduce maintenance, and ensure cleaner, ……

#10 Is It Time to Update Your Dust Collection Equipment?

Domain Est. 2015

Website: foodindustryexecutive.com

Key Highlights: Updating dust collection systems can save energy, extend the life of production equipment and help food production companies meet sustainability ……

Expert Sourcing Insights for Maximizing Dust Collection System Efficiency

Maximizing Dust Collection System Efficiency: 2026 Market Trends

As industrial processes continue to prioritize safety, sustainability, and operational efficiency, dust collection systems are undergoing significant technological and strategic advancements. The global market for dust collection is projected to grow robustly by 2026, driven by stricter environmental regulations, rising awareness of air quality, and innovations in smart manufacturing. Below are key 2026 market trends shaping the optimization of dust collection system efficiency.

1. Integration of Smart Sensors and IoT Technology

By 2026, the integration of Internet of Things (IoT) sensors into dust collection systems is becoming standard across manufacturing, woodworking, and pharmaceutical industries. Real-time monitoring of filter pressure drop, airflow velocity, particulate concentration, and system performance enables predictive maintenance and immediate troubleshooting. These smart systems reduce downtime, extend filter life, and optimize energy consumption by dynamically adjusting fan speeds based on actual dust loads.

2. Adoption of Energy-Efficient Fan and Motor Systems

Energy costs remain a major operational concern, prompting a shift toward high-efficiency motors (e.g., IE4 and IE5), variable frequency drives (VFDs), and aerodynamically optimized fan designs. In 2026, over 60% of new dust collection installations are expected to include VFDs to match airflow to real-time demand, significantly lowering electricity usage. Modular fan systems and regenerative blowers are also gaining traction in smaller or specialized applications.

3. Advanced Filter Media and Nanofiber Technologies

Filter clogging and frequent replacements are key inefficiencies in traditional systems. The 2026 market sees widespread adoption of nanofiber and hybrid filter media, which offer higher dust holding capacity, lower pressure drop, and improved release of particulates during cleaning cycles. These materials enhance filtration efficiency (reaching near-HEPA levels) while reducing compressed air consumption in pulse-jet cleaning systems.

4. Rise of Centralized and Modular System Designs

Customizable, modular dust collection units are growing in popularity, especially in facilities with evolving production needs. These systems allow for easy scalability and reconfiguration. Simultaneously, centralized systems with zoned collection networks are being optimized using AI-driven duct balancing algorithms to maintain consistent suction across multiple workstations, minimizing energy waste.

5. Emphasis on Compliance and Indoor Air Quality (IAQ)

With tightening global emissions standards—such as updated EPA and EU directives—industrial operators are investing in high-efficiency dust collectors to meet permissible exposure limits (PELs). In 2026, systems with integrated air quality monitors and closed-loop feedback mechanisms are increasingly required, particularly in food processing, pharmaceuticals, and metal fabrication, where worker health and product purity are critical.

6. Sustainability and Waste-to-Energy Integration

Sustainability initiatives are driving innovation in dust disposal and recovery. By 2026, efficient dust collectors are being paired with material recovery systems that reclaim valuable particulates (e.g., metal fines, wood flour) for reuse. Additionally, some systems incorporate thermal recovery units that capture heat from dust-laden air streams, contributing to facility-wide energy efficiency.

7. AI and Machine Learning for Predictive Optimization

Artificial intelligence is revolutionizing maintenance scheduling and system tuning. Machine learning algorithms analyze historical performance data to predict filter failure, optimize cleaning cycles, and recommend configuration changes. In 2026, AI-powered digital twins of dust collection systems are being deployed to simulate performance under different operating conditions, enabling proactive efficiency improvements.

8. Focus on Worker Safety and Noise Reduction

Beyond particulate control, modern dust collection systems are designed with ergonomics and safety in mind. Low-noise fans, vibration dampening, and automated lockout/tagout (LOTO) features are becoming standard. These enhancements not only improve workplace conditions but also reduce long-term liability and increase compliance with OSHA and similar regulatory bodies.

Conclusion

By 2026, maximizing dust collection system efficiency will depend on a holistic approach combining smart technology, energy-conscious design, advanced materials, and regulatory foresight. Companies that adopt these trends will achieve not only cleaner, safer environments but also significant cost savings and competitive advantages in an increasingly eco-conscious market.

Common Pitfalls When Sourcing for Maximizing Dust Collection System Efficiency (Quality, IP)

When sourcing components and systems for dust collection, organizations often encounter challenges that compromise both the quality and Ingress Protection (IP) rating of the final installation—critical factors for long-term efficiency and safety. Avoiding these common pitfalls ensures optimal performance, regulatory compliance, and reduced maintenance costs.

Selecting Components Without Verifying IP Ratings

A frequent oversight is assuming that all dust collection equipment meets the required IP standards for the operating environment. Sourcing motors, control panels, or sensors without confirming their IP65 or IP66 ratings (for dust-tight and water-resistant protection) can result in premature failures due to dust ingress or moisture exposure. Always validate IP certifications with manufacturer documentation and ensure compatibility with the facility’s environmental conditions.

Prioritizing Cost Over Build Quality

Opting for lower-cost filtration units or ductwork made from substandard materials may seem economical initially but leads to reduced filtration efficiency, shorter component lifespan, and frequent replacements. Thin-gauge steel or poorly constructed filters degrade quickly under constant dust loads, increasing downtime and total cost of ownership. Invest in high-quality, durable materials like reinforced polypropylene filters or powder-coated carbon steel housings.

Overlooking Filter Media Specifications

Not all filter cartridges or bags are created equal. Sourcing filters without considering micron rating, dust cake release properties, or anti-static features can drastically reduce collection efficiency. For fine or combustible dusts, using standard filter media instead of specialized options (e.g., nanofiber or conductive filters) increases fire risk and emissions. Always match filter specs to dust type and process requirements.

Ignoring System Compatibility and Integration

Integrating components from multiple vendors without verifying compatibility—such as mismatched flange sizes, airflow rates (CFM), or pressure drops—leads to bottlenecks and inefficiencies. Poorly matched fans, collectors, and ducts create imbalanced airflow, reducing suction at pickup points. Ensure all sourced parts are designed to work together within a unified system specification.

Failing to Validate Supplier Certifications and Testing Data

Relying on marketing claims without requesting independent test reports (e.g., CE, UL, or ISO certifications) or third-party efficiency data (like BIA or EPA test results) risks installing underperforming systems. Reputable suppliers should provide performance validation under real-world conditions. Always demand verifiable quality assurance documentation before procurement.

Neglecting Maintenance and Service Support

Even high-efficiency systems degrade without proper maintenance. Sourcing from suppliers who lack local service networks or spare parts availability leads to prolonged downtimes. Consider post-purchase support, training, and diagnostic tools when evaluating vendors—long-term efficiency depends on timely upkeep.

By addressing these sourcing pitfalls, organizations can ensure their dust collection systems maintain high efficiency, meet IP standards, and deliver reliable performance throughout their operational lifecycle.

Logistics & Compliance Guide for Maximizing Dust Collection System Efficiency

Ensuring optimal performance of your dust collection system requires a strategic approach that integrates efficient logistics with strict adherence to regulatory compliance. This guide outlines key steps to enhance system efficiency while meeting all safety and environmental standards.

Assess Facility Layout and Dust Generation Points

Begin by mapping all dust-generating processes within your facility. Identify the location, volume, and type of particulate matter produced at each station. This assessment informs the logistics of ductwork design and collector placement, minimizing airflow resistance and ensuring effective capture at the source. Proper zoning helps in routing ducts efficiently, reducing pressure drops and energy consumption.

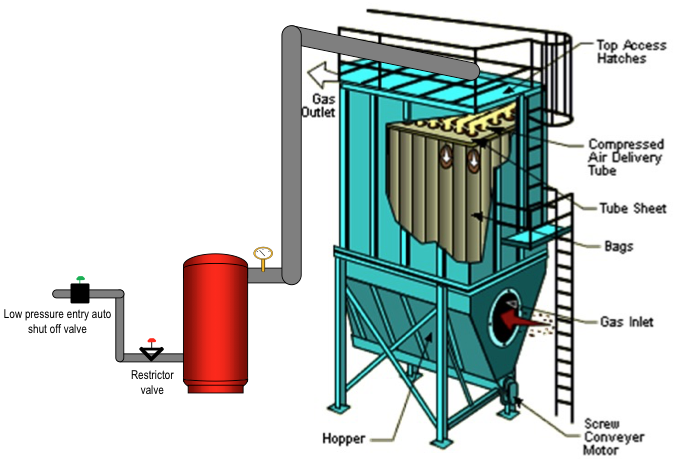

Select the Right Dust Collector Type and Sizing

Choose a dust collector (e.g., baghouse, cartridge, cyclone) based on dust characteristics such as particle size, combustibility, and chemical composition. Oversized or undersized systems lead to inefficiency and increased maintenance. Use air-to-cloth ratio calculations and required airflow (CFM) to properly size the system, ensuring it meets both operational demand and regulatory airflow standards.

Design Efficient Ductwork and Airflow Systems

Design ducts with minimal bends and proper diameter to maintain optimal transport velocity (typically 3,500–4,500 ft/min for most industrial dusts). Use smooth, sloped ducts to prevent dust buildup and ensure self-cleaning flow. Balance the system using dampers to equalize airflow across branches, preventing short-circuiting and ensuring uniform dust capture.

Implement Routine Maintenance and Filter Management

Establish a preventive maintenance schedule for filter inspection, cleaning, and replacement. Clogged or damaged filters reduce airflow and increase energy use. Use pressure drop monitors to determine cleaning cycles. For compliance, maintain logs of filter replacements and system inspections to demonstrate adherence to OSHA and EPA requirements.

Monitor System Performance with Instrumentation

Install key monitoring devices such as differential pressure gauges, airflow sensors, and explosion suppression systems where applicable. Real-time data allows for quick identification of performance drops or blockages. Automated alerts help in proactive maintenance, reducing downtime and ensuring continuous compliance with exposure limits (e.g., OSHA PELs).

Ensure Regulatory Compliance with Air Quality and Safety Standards

Verify that your system meets OSHA, EPA, and NFPA standards, particularly NFPA 654 (prevention of fire and dust explosions) and local air quality regulations. Conduct regular stack testing to ensure emissions are within permissible limits. Maintain documentation for inspections, employee training, and hazard assessments to pass audits and avoid penalties.

Train Personnel on Safe Operation and Emergency Protocols

Provide comprehensive training for operators on system startup, shutdown, maintenance, and emergency response (e.g., dust explosions, filter leaks). Include lockout/tagout (LOTO) procedures and proper use of personal protective equipment (PPE). Document training sessions to meet OSHA compliance and promote a culture of safety.

Optimize Energy Use and Sustainability Practices

Evaluate fan motor efficiency and consider variable frequency drives (VFDs) to match airflow to production needs, reducing energy consumption. Explore options for dust recycling or safe disposal in compliance with RCRA regulations. Energy-efficient systems not only lower operating costs but also support environmental compliance goals.

Conduct Regular Audits and Continuous Improvement

Schedule annual system audits to assess efficiency, compliance, and safety. Use findings to update maintenance schedules, upgrade components, or reconfigure ductwork. Engage with certified industrial hygienists or consultants to ensure ongoing alignment with evolving regulations and industry best practices.

By integrating logistical precision with robust compliance measures, facilities can maximize dust collection efficiency, protect worker health, reduce operational costs, and maintain regulatory readiness.

Conclusion: Maximizing Dust Collection System Efficiency through Strategic Sourcing

Optimizing the efficiency of a dust collection system begins with intelligent and strategic sourcing of components, materials, and technologies. By carefully selecting high-performance filters, correctly sized fans, durable ductwork, and advanced control systems from reputable suppliers, organizations can significantly enhance system performance, reduce energy consumption, and extend equipment lifespan. Furthermore, incorporating industry-specific requirements, considering total cost of ownership, and prioritizing compatibility and maintenance accessibility during the sourcing process ensures long-term operational effectiveness.

Investing in high-quality, properly matched components—not just the lowest-cost options—leads to improved air quality, regulatory compliance, and worker safety. When combined with proactive maintenance and continuous monitoring, a well-sourced dust collection system delivers maximum efficiency, minimizes downtime, and supports sustainable manufacturing practices. Ultimately, strategic sourcing is not merely a procurement decision—it is a critical component of an integrated approach to industrial hygiene and operational excellence.