The global material handling equipment market is experiencing robust expansion, driven by increasing automation in logistics, warehousing, and manufacturing sectors. According to a 2023 report by Mordor Intelligence, the material handling equipment market was valued at USD 173.5 billion in 2022 and is projected to grow at a CAGR of 6.8% from 2023 to 2028. Conveyor systems, a critical component within this ecosystem, are witnessing heightened demand due to their role in improving operational efficiency, reducing labor costs, and enabling seamless integration in automated production lines. Grand View Research further supports this trend, noting that the global conveyor systems market size reached USD 7.2 billion in 2022 and is expected to expand at a CAGR of 6.3% through 2030. Amid rising e-commerce fulfillment needs, Industry 4.0 adoption, and lean manufacturing principles, conveyor manufacturers are innovating with smart, energy-efficient, and modular solutions. In this evolving landscape, identifying the top material handling conveyor manufacturers becomes essential for businesses aiming to optimize throughput and future-proof their supply chains.

Top 10 Material Handling Conveyors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 QC Conveyors

Domain Est. 2013

Website: qcconveyors.com

Key Highlights: QC Conveyors is a trusted conveyor manufacturer providing custom systems for industrial and automation applications. Fast lead times and expert support….

#2 Handling Systems & Conveyors

Domain Est. 1998

Website: hsc-lr.com

Key Highlights: Handling Systems & Conveyors (HSC) is an Industry leading manufacturer of assembly and process material handling systems in North America. We offer a full ……

#3 Custom Conveyor Systems

Domain Est. 2003 | Founded: 1927

Website: mheus.com

Key Highlights: Build durable, heavy-duty conveyor systems for cement, steel, and mining with Materials Handling Equipment Co. ; trusted U.S. manufacturer since 1927….

#4 Dorner Conveyors

Domain Est. 2007

Website: dornerconveyors.com

Key Highlights: Dorner offers a wide variety of industrial, aluminum frame and sanitary, stainless steel frame conveyors. With fabric belt, modular belt, and flexible chain ……

#5 FMH Conveyors: Conveyor Manufacturer

Domain Est. 2014

Website: fmhconveyors.com

Key Highlights: FMH Conveyors is a leading conveyor company improving your truck loading and unloading efficiency, productivity, and safety in conveyance solutions….

#6 Span Tech Conveyors

Domain Est. 2017

Website: spantechconveyors.com

Key Highlights: Explore Span Tech’s custom conveyors for packaging, food, pharma, and more—built for efficiency, flexibility, and increased productivity….

#7 Flexlink

Domain Est. 1997

Website: flexlink.com

Key Highlights: FlexLink is a leading company in the production of automated conveyors systems and robotic palletizing cells for several industries….

#8 Bulk Material Handling Solutions

Domain Est. 1997

Website: hapman.com

Key Highlights: Welcome to Hapman, where the design and manufacturing of the best material handling equipment is driven by your specific application needs….

#9 Kornylak Corporation

Domain Est. 1998

Website: kornylak.com

Key Highlights: Kornylak manufactures conveyor systems, metal belt conveyors, rubber belt, steel slat conveyors, metal slat, roller conveyors, gravity flow and gravity powered ……

#10 Conveyor Systems

Domain Est. 2013

Website: nerconconveyors.com

Key Highlights: Nercon designs and manufactures conveyor systems to keep consumer packaged goods moving in ways that are faster, more reliable and more efficient. About Us….

Expert Sourcing Insights for Material Handling Conveyors

H2: 2026 Market Trends for Material Handling Conveyors

The material handling conveyor market is poised for significant transformation by 2026, driven by rapid technological advancements, evolving supply chain demands, and increasing automation across industries. As global logistics networks expand and e-commerce continues to surge, conveyor systems are becoming more intelligent, efficient, and integrated. Key trends shaping the 2026 landscape include the rise of smart conveyors, sustainability initiatives, modular designs, and heightened demand in emerging markets.

One of the most prominent trends is the integration of Industry 4.0 technologies. By 2026, smart conveyors equipped with IoT sensors, real-time monitoring, and predictive maintenance capabilities will dominate industrial applications. These systems enhance operational efficiency by reducing downtime, optimizing throughput, and enabling seamless integration with warehouse management systems (WMS) and enterprise resource planning (ERP) platforms. AI-driven analytics will allow operators to anticipate bottlenecks and adjust workflows dynamically.

Another major trend is the growing emphasis on energy efficiency and sustainability. Manufacturers are increasingly adopting eco-friendly conveyor materials and energy-saving drive systems to meet stringent environmental regulations and corporate ESG (Environmental, Social, and Governance) goals. Lightweight conveyor components and regenerative drive technologies are expected to see heightened adoption, particularly in Europe and North America.

Modularity and flexibility are also gaining traction. With fluctuating consumer demands and the need for rapid reconfiguration in warehouses and distribution centers, modular conveyor systems allow businesses to scale operations quickly and cost-effectively. Plug-and-play designs and standardized components will drive faster deployment and reduced maintenance costs by 2026.

Additionally, the expansion of e-commerce and omnichannel retail is fueling demand for high-speed sorting and conveying solutions. Automated sortation conveyors, cross-belt systems, and tilt-tray conveyors will be critical in handling the growing volume of parcel shipments. This demand is especially strong in Asia-Pacific, where countries like India and Vietnam are investing heavily in logistics infrastructure.

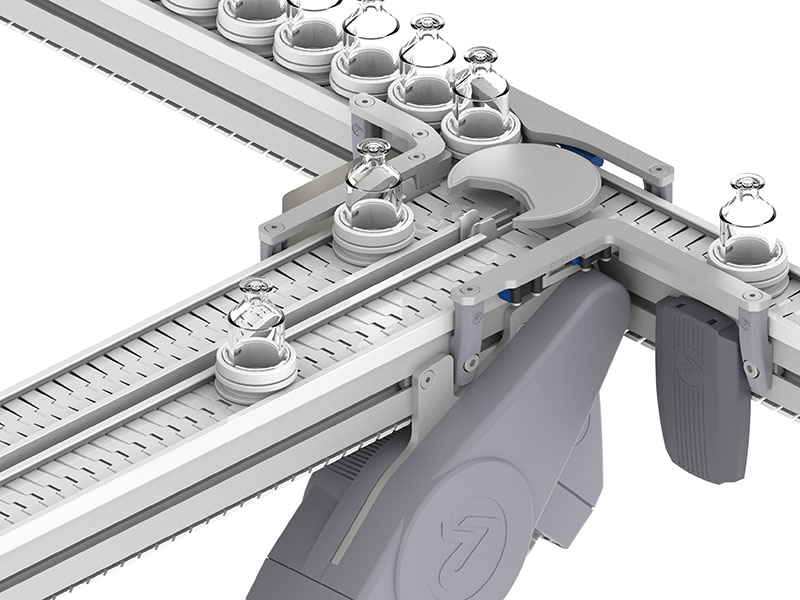

Lastly, the adoption of conveyors in non-traditional sectors—such as food and beverage, pharmaceuticals, and cold chain logistics—is accelerating. Hygienic, corrosion-resistant conveyor designs that comply with strict sanitation standards are becoming essential, particularly in light of heightened health and safety regulations post-pandemic.

In summary, by 2026, the material handling conveyor market will be defined by intelligence, sustainability, adaptability, and sector diversification. Companies that embrace innovation and align with these trends will be best positioned to capitalize on emerging opportunities in a highly competitive global market.

Common Pitfalls When Sourcing Material Handling Conveyors (Quality, IP)

Sourcing material handling conveyors involves more than just finding a supplier with the lowest bid. Overlooking key quality and intellectual property (IP) considerations can lead to operational inefficiencies, safety risks, and legal complications. Below are critical pitfalls to avoid.

Inadequate Quality Verification

Many buyers focus on upfront costs and neglect to validate the actual build quality and durability of conveyor systems. This can result in premature wear, frequent breakdowns, and increased maintenance expenses. Always request third-party certifications, conduct factory audits, and review material specifications to ensure the conveyor meets industry standards and site-specific requirements.

Lack of Customization Documentation

When conveyors are customized for unique workflows or environments, failure to obtain complete design documentation—including CAD files, schematics, and specifications—can create dependency on the original supplier. Without proper documentation, future modifications, repairs, or replication become difficult and costly, potentially infringing on the supplier’s IP.

Overlooking Intellectual Property Rights

Suppliers may retain ownership of designs, even for custom-built conveyors, unless explicitly transferred in the contract. This can restrict your ability to duplicate, modify, or service the equipment. Always clarify IP ownership terms before signing agreements and ensure any custom designs are assigned to your organization if needed.

Assuming Standard Components Are Generic

While many conveyors use standard components (motors, rollers, belts), integrating them into a proprietary system may still involve protected designs or configurations. Assuming these are freely replicable can lead to unintentional IP infringement. Verify the scope of any proprietary elements and ensure your use complies with licensing terms.

Insufficient Supplier Vetting for IP Compliance

Some suppliers may use third-party designs or components without proper licensing. If your company procures and operates such equipment, you could face liability for IP violations. Conduct due diligence on the supplier’s design sources and require warranties confirming IP compliance in the procurement contract.

Failure to Secure Service and Spare Parts Rights

Even with quality equipment, long-term operations depend on accessible support. Some suppliers restrict access to spare parts or technical service unless under exclusive service agreements. Ensure your contract includes rights to third-party servicing and availability of spare parts to avoid operational downtime and vendor lock-in.

Ignoring Future Scalability and Integration

Conveyors sourced without considering future expansion may not integrate with upcoming automation systems due to proprietary protocols or closed software architectures. This limits scalability and can result in costly replacements. Choose systems with open interfaces and documented APIs to maintain flexibility and protect your long-term investment.

Logistics & Compliance Guide for Material Handling Conveyors

Introduction

Material handling conveyors are critical components in manufacturing, warehousing, distribution, and production environments. Efficient logistics and strict compliance with safety, environmental, and industry standards ensure operational reliability, worker safety, and regulatory adherence. This guide outlines essential logistics considerations and compliance requirements for the deployment, operation, and maintenance of conveyor systems.

Design and Engineering Compliance

Ensure conveyor systems are engineered to meet relevant industry standards:

– ISO 14119: Safety of machinery – Interlocking devices associated with guards.

– ANSI/RIA R15.06: Industrial robot safety standard (if integrated with robotics).

– CE Marking (EU): Compliance with Machinery Directive 2006/42/EC for safety, electromagnetic compatibility (EMC), and low-voltage directives.

– OSHA 29 CFR 1910.212: General requirements for all machines, including guarding and point-of-operation protection.

Design must include emergency stops, guarding, overload protection, and proper labeling.

Safety and Operational Standards

Prioritize worker safety and system reliability:

– Install emergency stop buttons at accessible intervals (typically every 15–30 feet).

– Use proper guarding around pinch points, drive chains, and rollers.

– Implement lockout/tagout (LOTO) procedures per OSHA 29 CFR 1910.147.

– Conduct regular risk assessments and safety audits.

– Train all personnel on safe operation, maintenance, and emergency procedures.

Electrical and Control System Compliance

Electrical components must adhere to local and international codes:

– NFPA 70 (NEC): National Electrical Code for wiring, grounding, and circuit protection in the U.S.

– IEC 60204-1: Safety of machinery – Electrical equipment of machines.

– Use control systems with proper overload relays, short-circuit protection, and motor starters.

– Ensure control panels are labeled with voltage, current ratings, and emergency procedures.

Installation and Site Logistics

Proper planning ensures smooth setup and long-term performance:

– Verify floor loading capacity supports conveyor weight and material loads.

– Allow adequate clearance for maintenance, airflow, and personnel movement.

– Coordinate with facility engineers for power supply, data connectivity, and integration with existing systems.

– Follow manufacturer’s installation manual and torque specifications.

– Conduct a commissioning checklist before full operation.

Maintenance and Inspection Protocols

Scheduled maintenance prevents downtime and ensures compliance:

– Perform daily visual inspections for wear, misalignment, or damage.

– Lubricate bearings, chains, and gears according to manufacturer guidelines.

– Keep detailed logs of maintenance, repairs, and part replacements.

– Use predictive maintenance tools (e.g., vibration analysis, thermal imaging) where feasible.

– Replace worn components promptly to avoid failure and safety risks.

Environmental and Sustainability Considerations

Adhere to environmental regulations and promote sustainability:

– Use energy-efficient motors (e.g., IE3 or IE4 class) to reduce power consumption.

– Minimize noise emissions in accordance with local ordinances (e.g., OSHA permissible noise exposure limits).

– Recycle worn conveyor belts and metal components responsibly.

– Prevent fluid leaks (e.g., lubricants) with drip trays and containment systems.

Transportation and Handling During Delivery

Ensure safe and compliant delivery of conveyor systems:

– Secure components on transport vehicles using straps, braces, and blocking.

– Protect sensitive electronics and drive systems from moisture and shock.

– Verify shipping documentation includes material safety data sheets (MSDS), compliance certificates, and installation manuals.

– Use appropriate lifting equipment (e.g., forklifts, cranes) during unloading.

Documentation and Recordkeeping

Maintain comprehensive records for compliance and traceability:

– Keep copies of design schematics, compliance certifications, and inspection reports.

– Store training records for operators and maintenance staff.

– Update as-built drawings after any modifications.

– Retain records for minimum periods as required by local regulations (e.g., OSHA mandates 5-year retention for certain safety records).

Conclusion

Effective logistics and strict compliance are essential for the safe, efficient, and legal operation of material handling conveyors. By adhering to engineering standards, safety regulations, and maintenance best practices, organizations can optimize performance, protect workers, and avoid costly penalties. Regular training, audits, and documentation ensure long-term success and regulatory readiness.

Conclusion for Sourcing Material Handling Conveyors

Sourcing material handling conveyors is a critical decision that directly impacts operational efficiency, labor costs, product flow, and long-term scalability. After evaluating various factors such as throughput requirements, facility layout, product characteristics, automation needs, and total cost of ownership, it becomes evident that selecting the right conveyor system requires a strategic approach. Partnering with experienced suppliers who offer customizable, reliable, and energy-efficient solutions ensures not only seamless integration into existing operations but also adaptability for future growth.

It is essential to conduct thorough due diligence, including supplier assessments, site visits, and lifecycle cost analysis, to avoid costly downtime or system limitations down the line. Additionally, integrating modern technologies such as IoT-enabled monitoring, modular designs, and sustainable materials can enhance performance and support lean manufacturing principles.

In conclusion, a well-sourced material handling conveyor system serves as the backbone of efficient logistics and production operations. By aligning technical specifications with business objectives and leveraging expert vendor partnerships, organizations can achieve improved productivity, reduced operational risks, and a strong return on investment.