The global material handling equipment market is experiencing robust growth, driven by increasing automation in manufacturing, warehousing, and logistics sectors. According to a report by Mordor Intelligence, the material handling equipment market was valued at USD 177.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2029. A significant portion of this expansion is attributed to conveyor systems, which are pivotal in improving operational efficiency, reducing labor costs, and enhancing throughput in distribution centers and production lines. As e-commerce continues to surge and industries adopt Industry 4.0 practices, the demand for intelligent, scalable, and energy-efficient conveyor solutions has intensified. This evolving landscape has positioned leading manufacturers at the forefront of innovation, offering modular designs, integration with warehouse management systems (WMS), and advanced automation capabilities. Based on market penetration, technological leadership, and global footprint, we present the top 10 material handling conveyor systems manufacturers shaping the future of material flow automation.

Top 10 Material Handling Conveyor Systems Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 QC Conveyors

Domain Est. 2013

Website: qcconveyors.com

Key Highlights: QC Conveyors is a trusted conveyor manufacturer providing custom systems for industrial and automation applications. Fast lead times and expert support….

#2 Handling Systems & Conveyors

Domain Est. 1998

Website: hsc-lr.com

Key Highlights: Handling Systems & Conveyors (HSC) is an Industry leading manufacturer of assembly and process material handling systems in North America. We offer a full ……

#3 Custom Conveyor Systems

Domain Est. 2003 | Founded: 1927

Website: mheus.com

Key Highlights: Build durable, heavy-duty conveyor systems for cement, steel, and mining with Materials Handling Equipment Co. ; trusted U.S. manufacturer since 1927….

#4 Dorner Conveyors

Domain Est. 2007

Website: dornerconveyors.com

Key Highlights: Dorner offers a wide variety of industrial, aluminum frame and sanitary, stainless steel frame conveyors. With fabric belt, modular belt, and flexible chain ……

#5 Span Tech Conveyors

Domain Est. 2017

Website: spantechconveyors.com

Key Highlights: Explore Span Tech’s custom conveyors for packaging, food, pharma, and more—built for efficiency, flexibility, and increased productivity….

#6 Shuttleworth

Domain Est. 1996

Website: shuttleworth.com

Key Highlights: Shuttleworth designs and manufactures conveyor systems & material handling systems for a variety of industries & applications….

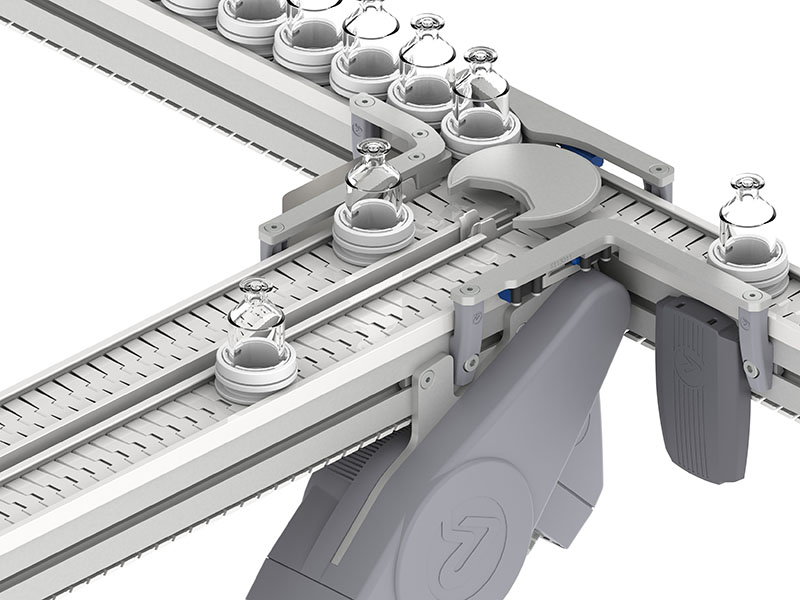

#7 Flexlink

Domain Est. 1997

Website: flexlink.com

Key Highlights: FlexLink is a leading company in the production of automated conveyors systems and robotic palletizing cells for several industries….

#8 Kornylak Corporation

Domain Est. 1998

Website: kornylak.com

Key Highlights: Kornylak manufactures conveyor systems, metal belt conveyors, rubber belt, steel slat conveyors, metal slat, roller conveyors, gravity flow and gravity powered ……

#9 Conveyor Handling Company

Domain Est. 1999

Website: conveyorhandling.com

Key Highlights: CONVEYOR HANDLING COMPANY. CHC is a full line material handling systems integrator, providing custom designed solutions for those material handling challenges….

#10 Material Handling Systems Integrators, Distributors, Conveyor …

Domain Est. 2009

Website: taylormhc.com

Key Highlights: We proudly carry many of the finest name brands in material handling and conveyor systems for our customers. We are an authorized retailer, dealer, reseller, ……

Expert Sourcing Insights for Material Handling Conveyor Systems

H2: Market Trends in Material Handling Conveyor Systems for 2026

As the global logistics, manufacturing, and e-commerce sectors continue to evolve, Material Handling Conveyor Systems are undergoing significant transformation. By 2026, several key trends are expected to shape the market, driven by technological innovation, labor dynamics, sustainability demands, and supply chain resilience. Below is an analysis of the most influential trends projected to define the Material Handling Conveyor Systems landscape in 2026.

1. Increased Adoption of Automation and Smart Conveyors

Automation remains a dominant force in the conveyor systems market. By 2026, smart conveyors equipped with IoT sensors, real-time monitoring, and predictive maintenance capabilities will be standard in advanced facilities. These intelligent systems enable seamless integration with Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) platforms, improving operational efficiency and reducing downtime. The push for labor optimization—especially in regions facing workforce shortages—will accelerate this trend.

2. Growth in E-Commerce Drives Flexible Conveyor Solutions

The exponential growth of e-commerce continues to demand highly adaptable and scalable material handling systems. Conveyor systems in 2026 will increasingly feature modular designs that allow for quick reconfiguration to meet fluctuating order volumes and product types. High-speed sorting conveyors, cross-belt sorters, and shoe sorters will be in high demand, particularly in last-mile distribution centers.

3. Integration with Robotics and AGVs

The convergence of conveyor systems with Autonomous Guided Vehicles (AGVs) and robotic arms will redefine material flow in warehouses and production lines. Hybrid systems that combine fixed conveyor routes with mobile robotics offer greater flexibility and responsiveness. By 2026, integrated solutions enabling seamless handoffs between conveyors and robots will become a competitive differentiator for system providers.

4. Focus on Energy Efficiency and Sustainability

Sustainability regulations and corporate ESG (Environmental, Social, and Governance) goals are pushing manufacturers to develop energy-efficient conveyor systems. Trends include the use of low-friction components, regenerative braking systems, and solar-powered operations. Lightweight materials and recyclable components will also gain traction, reducing the environmental footprint across the product lifecycle.

5. Regional Market Expansion and Localization

While North America and Europe remain strong markets due to high automation rates, Asia-Pacific—particularly China, India, and Southeast Asia—is expected to see the fastest growth. Rising industrialization, urbanization, and government investments in smart manufacturing (e.g., “Make in India,” “Smart Factory” initiatives) will drive demand for advanced conveyor systems. Localization of production and service networks will become essential for global suppliers.

6. Advanced Materials and Design Innovation

New materials such as high-performance polymers and composites are being adopted to reduce weight, increase durability, and lower maintenance needs. Conveyor designs will prioritize hygiene (especially in food and pharma) and noise reduction, with features like silent chains and sealed bearings. Customization will be key, as industries demand conveyors tailored to specific product handling requirements.

7. Cybersecurity and Data Integration

As conveyor systems become more connected, cybersecurity will emerge as a critical concern. By 2026, manufacturers will need to ensure that their systems comply with industrial cybersecurity standards to protect against data breaches and operational disruptions. Secure data integration will be essential for enabling real-time analytics and AI-driven optimization.

Conclusion

By 2026, the Material Handling Conveyor Systems market will be defined by intelligence, flexibility, and sustainability. Companies that invest in smart technologies, modular designs, and integrated automation will lead the market. As supply chains become more complex and customer expectations rise, conveyor systems will no longer be simple transport mechanisms but strategic enablers of agility and efficiency across industries.

Common Pitfalls When Sourcing Material Handling Conveyor Systems: Quality and Intellectual Property (IP) Concerns

Sourcing material handling conveyor systems involves more than just selecting the right configuration and price. Overlooking quality and intellectual property (IP) aspects can lead to long-term operational, legal, and financial risks. Below are key pitfalls to avoid in these critical areas.

Compromised Component Quality

One of the most common pitfalls is selecting a conveyor system based solely on initial cost, which often leads to suppliers using substandard materials or components. Low-quality rollers, bearings, motors, or structural frames may fail prematurely, increasing downtime and maintenance costs. Always verify material specifications, request third-party certifications (e.g., ISO, CE), and inspect samples before full procurement.

Lack of Manufacturing Process Oversight

Without direct oversight or audits of the manufacturer’s facility, buyers risk receiving systems produced with inconsistent quality control practices. Poor welding, misaligned components, or inadequate testing can go unnoticed until installation or operation. Conduct factory acceptance tests (FAT) and request documentation on manufacturing processes to ensure consistency and compliance.

Inadequate Documentation and Traceability

Poor documentation—such as missing schematics, operation manuals, or material traceability reports—compromises long-term maintenance and compliance. This is especially critical in regulated industries. Ensure suppliers provide complete technical documentation, including component serial numbers and certifications, to support quality assurance and future troubleshooting.

Unverified Design Ownership and IP Infringement

When customizing conveyor systems, there is a risk that the supplier may reuse or incorporate designs protected by third-party intellectual property. This exposes the buyer to potential IP litigation. Always confirm in writing that the supplier owns the design or has proper licensing for any proprietary technology used in the system.

Ambiguous IP Rights in Custom Solutions

If your organization commissions a custom conveyor solution, failing to define IP ownership in the contract can result in losing rights to the design. Suppliers may retain rights to reuse or resell your custom design to competitors. Clearly specify in the contract that all IP developed for your project is assigned to your company.

Use of Counterfeit or Unlicensed Software

Modern conveyor systems often include control systems with proprietary software. Some suppliers may use unlicensed or pirated software to cut costs, exposing buyers to cybersecurity risks and legal liability. Require proof of software licensing and ensure firmware and control systems are authentic and supported by the original developer.

Failure to Protect Internal Process IP

During the sourcing process, buyers often share sensitive information about workflows, layouts, and production requirements. Without proper non-disclosure agreements (NDAs) and data protection clauses, this proprietary operational information could be exposed or misused. Always enforce strict confidentiality agreements with all potential suppliers.

By proactively addressing these quality and IP-related pitfalls, organizations can ensure they procure reliable, legally compliant conveyor systems that support long-term operational success.

Logistics & Compliance Guide for Material Handling Conveyor Systems

System Design and Layout Compliance

Ensure conveyor system designs adhere to recognized safety standards such as ISO 10218 (for industrial robots and integrated systems), ANSI/RIA R15.06, and OSHA 29 CFR 1910 Subpart O (Powered Industrial Trucks) and Subpart N (Materials Handling). Conveyor layouts must include adequate guarding, emergency stop placement, and safe access points. Design considerations should address load capacity, speed, environmental conditions (e.g., washdown, explosive atmospheres), and integration with other material handling equipment.

Safety and Guarding Requirements

Install fixed and interlocked guards around pinch points, drive components, and moving parts as required by ANSI B15.1 – Safety Standard for Conveyors and Related Equipment. Emergency stop cords or buttons must be accessible within 5 feet of any conveyor operator station and at transfer points. Regular safety audits and risk assessments should be conducted to ensure compliance with local and international regulations such as the EU’s Machinery Directive 2006/42/EC.

Electrical and Control System Standards

All electrical components must comply with the National Electrical Code (NEC) Article 670 and IEC 60204-1 for safety of machinery. Control systems should incorporate safety relays, redundant circuits for critical functions, and proper labeling. Ensure compatibility with facility power systems and protection against overloads, short circuits, and voltage fluctuations. PLC programming must follow safety integrity level (SIL) guidelines when applicable.

Installation and Commissioning Procedures

Follow manufacturer specifications and project engineering plans during installation. Verify alignment, tensioning, and lubrication schedules per OEM guidelines. Conduct a pre-commissioning safety review including lockout/tagout (LOTO) procedures, grounding checks, and functionality tests. Document all installation steps and obtain sign-off from safety and operations teams before system activation.

Operational Training and Documentation

Provide comprehensive training for operators, maintenance personnel, and supervisors on safe operating procedures, emergency protocols, and maintenance routines. Training records must be maintained per OSHA and ISO standards. Supply detailed operation manuals, schematics, and maintenance logs with the system. Include multilingual documentation if required by workforce composition.

Maintenance and Inspection Compliance

Implement a preventive maintenance (PM) program aligned with manufacturer recommendations and regulatory requirements. Schedule regular inspections for wear, belt tracking, motor performance, and safety device functionality. Maintain logs of all maintenance activities and component replacements. Use condition monitoring tools (e.g., vibration analysis, thermal imaging) where justified by system criticality.

Environmental and Workplace Regulations

Ensure conveyor systems meet environmental standards such as EPA regulations for noise levels and emissions (e.g., from motors or lubricants). In food, pharmaceutical, or cleanroom applications, use conveyors made from food-grade or non-shedding materials compliant with FDA 21 CFR, USDA, or EHEDG standards. Address dust control and static discharge in flammable environments per NFPA 77 and ATEX/IECEx directives.

Transportation and Logistics Planning

Coordinate logistics for conveyor system delivery, considering component dimensions, weight, and site access limitations. Use certified rigging and lifting equipment during unloading and positioning. Protect sensitive components (e.g., sensors, control panels) from moisture, shock, and contamination during transit. Verify shipping documentation, including bills of lading and export/import compliance (e.g., CE marking, FCC declarations).

Regulatory Certification and Audits

Obtain necessary certifications prior to operation, including CE marking for EU markets, UL listing for North America, or CSA certification in Canada. Maintain up-to-date documentation for regulatory audits, including risk assessments, conformity declarations, and equipment history files. Schedule third-party inspections as required by local authorities or insurance providers.

Continuous Improvement and Compliance Monitoring

Establish a feedback loop for incident reporting, near-miss tracking, and performance metrics. Periodically review and update compliance procedures to reflect changes in regulations or operational scope. Conduct annual compliance audits and utilize findings to improve system safety, efficiency, and regulatory alignment.

Conclusion: Sourcing Material Handling Conveyor Systems

Sourcing material handling conveyor systems is a strategic decision that significantly impacts operational efficiency, productivity, and long-term cost management in manufacturing, warehousing, and distribution environments. A thorough evaluation of system requirements—considering factors such as throughput, product characteristics, facility layout, and future scalability—is essential to selecting the right conveyor solution.

Engaging with experienced suppliers and conducting comprehensive assessments of equipment quality, customization capabilities, service support, and total cost of ownership ensures that the chosen system aligns with current and future operational needs. Additionally, integrating automation and intelligent controls where appropriate can enhance flexibility, reduce labor costs, and improve accuracy in material flow.

Ultimately, investing time and resources into proper sourcing leads to a reliable, efficient, and adaptable material handling infrastructure that supports continuous improvement and competitive advantage. By prioritizing collaboration, technology integration, and lifecycle performance, organizations can achieve optimal return on investment and sustainable operational success.