The global ladder manufacturing market is experiencing steady growth, driven by rising construction activities, infrastructure development, and increasing demand for safety-compliant equipment across residential, commercial, and industrial sectors. According to a report by Mordor Intelligence, the global ladders market was valued at USD 3.67 billion in 2023 and is projected to reach USD 4.68 billion by 2029, growing at a CAGR of 4.15% during the forecast period. This expansion is particularly evident in masonry applications, where durable, high-load-bearing ladders are essential for bricklaying, stonework, and facade construction. With the construction sector modernizing and prioritizing worker safety and efficiency, demand for specialized masonry ladders—known for their robust design and stability on uneven surfaces—has intensified. As a result, leading manufacturers are innovating with lightweight yet resilient materials, anti-slip features, and modular designs to meet rigorous job site demands. Based on market presence, product quality, and industry reputation, the following seven companies stand out as top manufacturers of masonry ladders globally.

Top 7 Masonry Ladder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

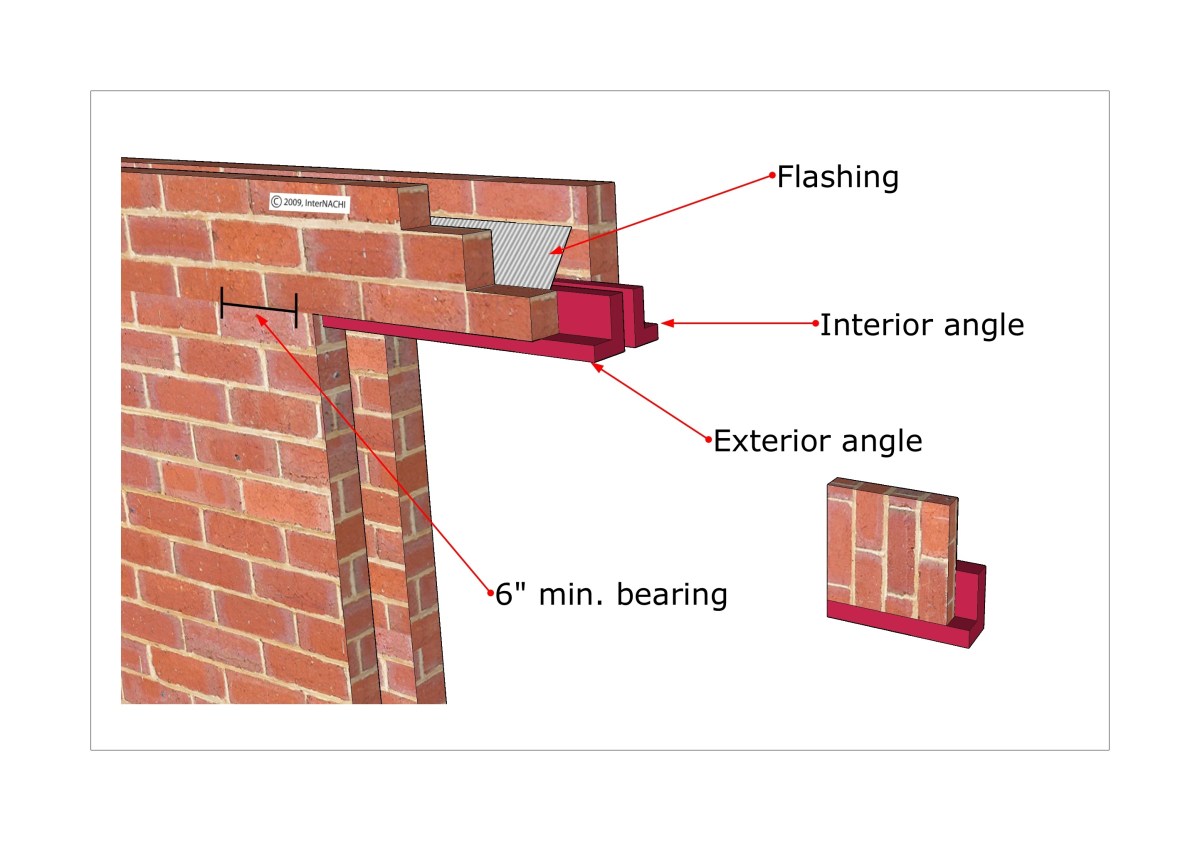

#1 Steel Lintels

Domain Est. 1998

Website: powerssteel.com

Key Highlights: Powers Steel &p Wire, Inc. is a manufacturer of innovative steel construction components including our patented steel lintels and carport solar frames….

#2 Masonry Wire Ladder Mesh

Domain Est. 2002

Website: ocm-inc.com

Key Highlights: Description: OCM, Inc’s Masonry Wire Ladder Mesh is fabricated for embedment in horizontal mortar joints. Features: Ladder Design allows for Core Clearance….

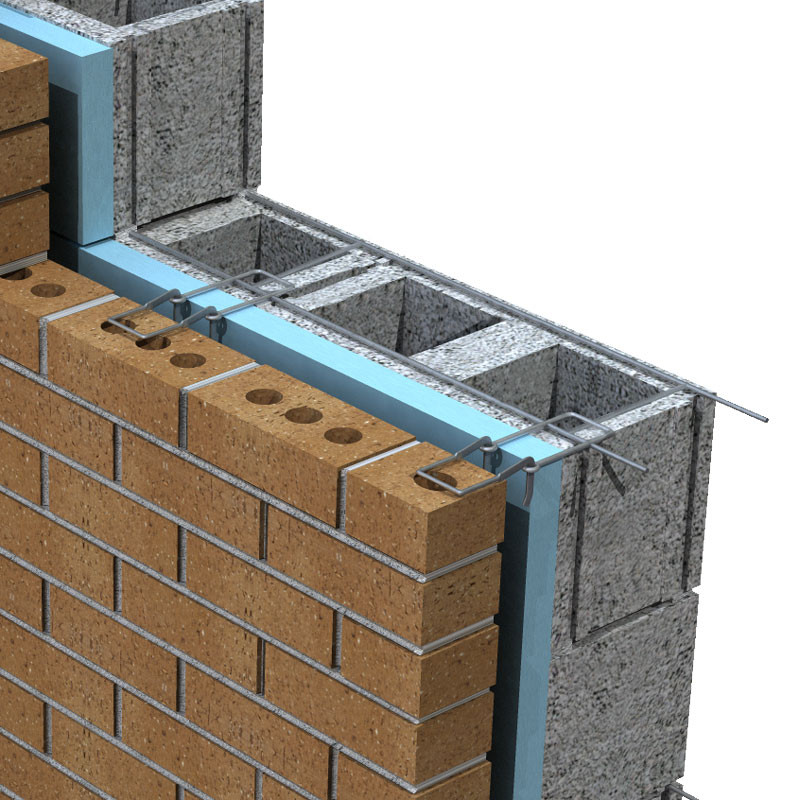

#3 220 Ladder

Domain Est. 1997

Website: h-b.com

Key Highlights: Hohmann & Barnard’s 220 Ladder-Mesh provides superior masonry wall performance with continuous joint reinforcement embedded in horizontal mortar joints….

#4 Ladder

Domain Est. 1997

Website: heckmannbuildingprods.com

Key Highlights: Our Ladder Type Wall Reinforcement is for vertical rebar, as its cross wires are spaced to match block cores. Learn more about this masonry wire….

#5 Ladder Wire

Domain Est. 1999

Website: southatlanticllc.com

Key Highlights: We offer several sizes of 9 GA ladder wire for reinforcing brick and block walls. All South Atlantic ladder wire is hot-dip galvanized….

#6 Masonry Ladder Frames

Domain Est. 1999

Website: scaffoldsales.com

Key Highlights: Universal’s Masonry Ladder Frames come in a variety of needed sizes in order to complete the necessary job. Universal carries them in 42″ wide or 5′ wide sets….

#7 Block Ladder Mesh

Domain Est. 2001

Website: madar.com

Key Highlights: Block Ladder Mesh is designed to provide superior reinforcement for masonry walls, ensuring enhanced stability, crack resistance, and structural integrity….

Expert Sourcing Insights for Masonry Ladder

H2: Masonry Ladder Market Trends in 2026

The masonry ladder market is poised for notable transformation by 2026, driven by advancements in construction technology, evolving safety regulations, and increasing demand for efficient masonry tools. As global infrastructure development accelerates—particularly in emerging economies—the need for durable, lightweight, and safe access equipment in brick and stone construction remains critical. Masonry ladders, essential for scaffolding setups and vertical access during wall construction, are adapting to these market dynamics through innovation and material optimization.

One key trend shaping the 2026 market is the shift toward lightweight composite and aluminum materials. Traditional steel masonry ladders, while sturdy, are heavy and prone to corrosion. In response, manufacturers are increasingly adopting high-strength aluminum alloys and fiberglass-reinforced polymers that reduce weight without compromising load capacity. This transition improves worker mobility, reduces fatigue, and enhances job site efficiency—factors highly valued in modern construction practices.

Another significant trend is the integration of modular and adjustable designs. Modular masonry ladders allow for quick assembly, disassembly, and adaptability to varying wall heights and configurations. By 2026, demand for customizable ladder systems will grow, especially in regions with diverse construction styles such as Europe and Southeast Asia. These designs also align with the broader industry push toward reusable and sustainable scaffolding solutions, reducing material waste and long-term project costs.

Safety compliance will also influence the masonry ladder market in 2026. Regulatory bodies such as OSHA (U.S.) and the EU’s Construction Products Regulation are tightening standards for fall protection and structural integrity. As a result, manufacturers are incorporating anti-slip rungs, improved anchoring mechanisms, and compliance labeling into their products. Ladders that meet ISO 14122 and EN 131 standards are expected to dominate in international markets.

Additionally, digitalization and supply chain optimization are affecting market dynamics. Leading suppliers are leveraging data analytics to forecast demand, streamline inventory, and offer just-in-time delivery—crucial for large-scale construction projects. E-commerce platforms are also expanding access to specialized masonry equipment, enabling smaller contractors to source high-quality ladders more efficiently.

Finally, regional growth patterns will shape the 2026 outlook. Asia-Pacific, led by China, India, and Indonesia, will account for the largest market share due to rapid urbanization and government-funded infrastructure projects. Meanwhile, North America and Western Europe will see steady growth, supported by renovation activities and stricter safety enforcement.

In conclusion, the 2026 masonry ladder market will be characterized by innovation in materials, design flexibility, regulatory alignment, and digital integration. Companies that prioritize safety, sustainability, and adaptability will be best positioned to capture value in this evolving landscape.

Common Pitfalls When Sourcing Masonry Ladders (Quality and Intellectual Property)

Sourcing masonry ladders—specialized equipment used in construction for accessing scaffolding and working at heights—can be fraught with challenges, particularly concerning product quality and intellectual property (IP) risks. Avoiding these pitfalls is essential to ensure worker safety, regulatory compliance, and protection against legal or financial liabilities.

Poor Material Quality and Construction

One of the most significant risks in sourcing masonry ladders is receiving products made from substandard materials. Low-quality aluminum or steel can compromise structural integrity, leading to bending, cracking, or even collapse under load. Inferior welding techniques and lack of proper reinforcement in critical stress points further exacerbate safety hazards. These issues often arise when sourcing from suppliers who prioritize low cost over compliance with international safety standards such as EN 131 (Europe) or OSHA/ANSI A14 (North America).

Lack of Safety Certifications and Compliance

Many suppliers, particularly in unregulated markets, offer masonry ladders without proper third-party testing or certification. Purchasing non-compliant ladders exposes contractors and project owners to legal liability in the event of an accident. Always verify that the product carries legitimate certifications and has been tested for load capacity, durability, and slip resistance. Absence of documentation should be a red flag.

Inconsistent Product Dimensions and Design Flaws

Offshore manufacturers may produce ladders that deviate from specified dimensions or ergonomic designs, affecting usability and safety. Misaligned rungs, incorrect angles, or inadequate anti-slip features can increase the risk of falls. These inconsistencies often stem from poor quality control processes and can lead to delays or rework on job sites.

Intellectual Property Infringement

Sourcing masonry ladders from certain regions may inadvertently involve IP violations. Some manufacturers replicate patented designs, logos, or branding from established brands without authorization. Purchasing counterfeit or IP-infringing products can expose your company to legal action, customs seizures, and reputational damage. Always conduct due diligence on suppliers and request proof of IP ownership or licensing for branded designs.

Inadequate After-Sales Support and Warranty

Low-cost suppliers may offer limited or non-existent warranties and customer service. If a ladder fails or requires maintenance, the lack of spare parts or technical support can disrupt operations. Ensure that suppliers provide clear warranty terms and have a support structure in place before finalizing procurement.

Supply Chain and Lead Time Risks

Long lead times, inconsistent production schedules, and lack of transparency in the supply chain can delay project timelines. Some suppliers may overpromise delivery dates without the capacity to meet them, leading to costly downtime. Establish clear communication and include contractual clauses around delivery performance.

Conclusion

To mitigate these risks, buyers should conduct thorough supplier vetting, request product samples, verify certifications, and ensure clear contractual terms around quality, compliance, and IP rights. Partnering with reputable manufacturers and using independent inspection services can significantly reduce the chances of encountering these common pitfalls.

Logistics & Compliance Guide for Masonry Ladder

Product Overview

A masonry ladder, also known as a stilt or scaffold bracket, is a temporary support system used in bricklaying and masonry work to provide a stable platform for workers and materials at height. Proper logistics and compliance are critical to ensure safety, efficiency, and adherence to regulations during transportation, handling, and use.

Regulatory Compliance

Masonry ladders must comply with national and international safety standards. Key regulations include:

– OSHA 29 CFR 1926 Subpart L (Scaffolds) – Requires structural integrity, guardrails, and safe access.

– ANSI/ASSP A10.8 – Provides safety requirements for scaffold use in construction.

– EN 12811 (Europe) – Specifies performance criteria for temporary work equipment, including load capacity and stability.

Ensure all masonry ladders are certified and accompanied by manufacturer documentation verifying compliance.

Transportation & Handling

- Secure masonry ladders during transit using straps or load locks to prevent shifting.

- Transport in a horizontal position when possible to avoid bending or deformation.

- Use protective padding to prevent damage to ladder rungs or frame.

- Handle with care; avoid dropping or dragging to maintain structural integrity.

Storage Requirements

- Store in a dry, covered area to prevent rust and corrosion.

- Keep off the ground using pallets or racks to avoid moisture exposure.

- Stack vertically or horizontally with proper support to prevent warping.

- Separate from chemicals or abrasive materials that could degrade metal components.

Inspection & Maintenance

Conduct regular inspections before each use:

– Check for cracks, bends, or corrosion in frame and rungs.

– Verify pins, brackets, and locking mechanisms are intact and functional.

– Ensure non-slip feet are present and undamaged.

Maintain a log of inspections and retire damaged units immediately. Perform scheduled maintenance as per manufacturer guidelines.

Load Capacity & Usage Limits

- Never exceed the manufacturer-specified load rating (typically 250–500 lbs).

- Include the weight of workers, tools, and materials in load calculations.

- Distribute weight evenly across the platform.

- Use only on stable, level surfaces; avoid soft or sloped ground.

Fall Protection & Safety Measures

- Always use masonry ladders in conjunction with guardrails or personal fall arrest systems when working at heights over 6 feet (per OSHA).

- Ensure ladders are tied or secured to the structure to prevent tipping.

- Prohibit climbing on cross braces or using unstable objects to extend height.

- Train all workers on proper setup, use, and emergency procedures.

Documentation & Recordkeeping

Maintain the following records:

– Manufacturer’s compliance certificates

– Inspection and maintenance logs

– Worker training records

– Incident reports (if applicable)

These documents are essential for audits and regulatory inspections.

Environmental & Disposal Considerations

- Recycle damaged or obsolete masonry ladders through certified metal recycling facilities.

- Avoid open burning or landfill disposal to comply with environmental regulations.

- Follow local waste management guidelines for industrial metal disposal.

Conclusion

Adhering to logistics and compliance protocols for masonry ladders ensures operational safety, regulatory compliance, and equipment longevity. Regular training, proper handling, and documentation are key components of a successful masonry worksite safety program.

Conclusion for Sourcing a Masonry Ladder

In conclusion, sourcing a masonry ladder requires careful consideration of material quality, durability, safety standards, and suitability for specific construction applications. It is essential to partner with reputable suppliers who provide certified, high-load-bearing ladders designed to withstand the demanding conditions of masonry work. Evaluating factors such as ladder height, portability, corrosion resistance, and compliance with occupational safety regulations ensures both worker safety and project efficiency. By conducting thorough market research, comparing pricing and warranties, and prioritizing long-term value over initial cost, construction firms can secure reliable equipment that enhances productivity and maintains a safe working environment. Ultimately, a well-sourced masonry ladder is a critical investment in operational safety, workforce confidence, and overall project success.