The global Kevlar market, driven by growing demand for high-performance materials in marine, defense, and aerospace applications, is projected to expand at a CAGR of 6.3% from 2023 to 2030, according to Grand View Research. Within the marine sector, the adoption of Kevlar-reinforced composites has surged due to their exceptional strength-to-weight ratio, resistance to corrosion, and ability to withstand harsh oceanic environments. These properties make Kevlar a critical material for high-speed vessels, naval craft, and offshore structures requiring durability and impact resistance. As maritime industries prioritize lightweighting and fuel efficiency without compromising safety, the need for reliable Kevlar suppliers has intensified. This increasing demand has positioned key manufacturers at the forefront of innovation and production capacity in marine-grade aramid fibers. Based on market footprint, technological capability, and sector-specific solutions, the following six companies stand out as leading marine Kevlar manufacturers shaping the future of advanced marine composites.

Top 6 Marine Kevlar Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Point Blank Enterprises, Inc.

Domain Est. 2011

Website: pointblankenterprises.com

Key Highlights: Point Blank Enterprises, Inc. (PBE) is the worldwide leader in the development, manufacturing and distribution of high performance, protective solutions for ……

#2 Marine Composites

Domain Est. 1987

Website: dupont.com

Key Highlights: DuPontTM Kevlar® fiber helps deliver lightweight strength, stiffness, and impact resistance for the composites industry….

#3 Fibre Glast Developments Corp LLC

Domain Est. 1995

Website: fibreglast.com

Key Highlights: Fibre Glast is a leading supplier of fiberglass & composite materials. A source for Carbon Fiber, Kevlar, Fiberglass, Resin, Gel Coat & much more….

#4 Aramid Fiber Substrate

Domain Est. 1996

Website: trelleborg.com

Key Highlights: Kevlar®: Manufactured by DuPontTM, it is commonly known for its use in stab and bullet-proof vests. uses include protective clothing, helmets, sails, brake…

#5 U.S. Marine Corps Forces, Pacific

Website: marforpac.marines.mil

Key Highlights: As the Indo-Pacific region faces the challenges of the information age and the rise of technological warfare, Marines with 3d Cyber Warfare Company, III Marine ……

#6 Top 100 Kevlar Fabric Manufacturers in 2025

Domain Est. 2022

Website: ensun.io

Key Highlights: Teijin Aramid is a leading manufacturer of high-performance aramid materials, including Kevlar fabric, which is known for its durability and lightweight ……

Expert Sourcing Insights for Marine Kevlar

H2: Marine Kevlar Market Trends for 2026

The global Marine Kevlar market is projected to experience sustained growth and strategic evolution by 2026, driven by escalating demands for lightweight, high-strength, and durable materials across naval, commercial, and recreational marine sectors. Key trends shaping the market include:

1. Accelerated Adoption in Naval & Defense Applications

- Lightweight Armor Integration: Naval forces globally are prioritizing weight reduction without compromising protection. Kevlar’s high strength-to-weight ratio makes it essential for ballistic protection in crew compartments, bulkheads, and critical equipment housings on next-generation vessels and patrol boats.

- Vessel Survivability Enhancements: Kevlar-reinforced composite hulls and decks are increasingly used to improve blast and fragmentation resistance, directly contributing to mission success and crew safety.

- Rising Defense Budgets: Geopolitical tensions are driving increased defense spending, particularly in the Asia-Pacific and North America, fueling investments in advanced naval platforms where Kevlar is a critical component.

2. Growth in Commercial & Offshore Marine Sectors

- Offshore Wind and Oil & Gas Expansion: Kevlar is used in high-performance mooring lines, risers, and umbilical cables due to its resistance to fatigue, UV radiation, and seawater corrosion. The global push toward offshore renewable energy is a key growth catalyst.

- High-Speed Craft Demand: Ferries, patrol boats, and crew transfer vessels (CTVs) in the offshore wind industry benefit from Kevlar composites for reduced weight, improved fuel efficiency, and higher speeds.

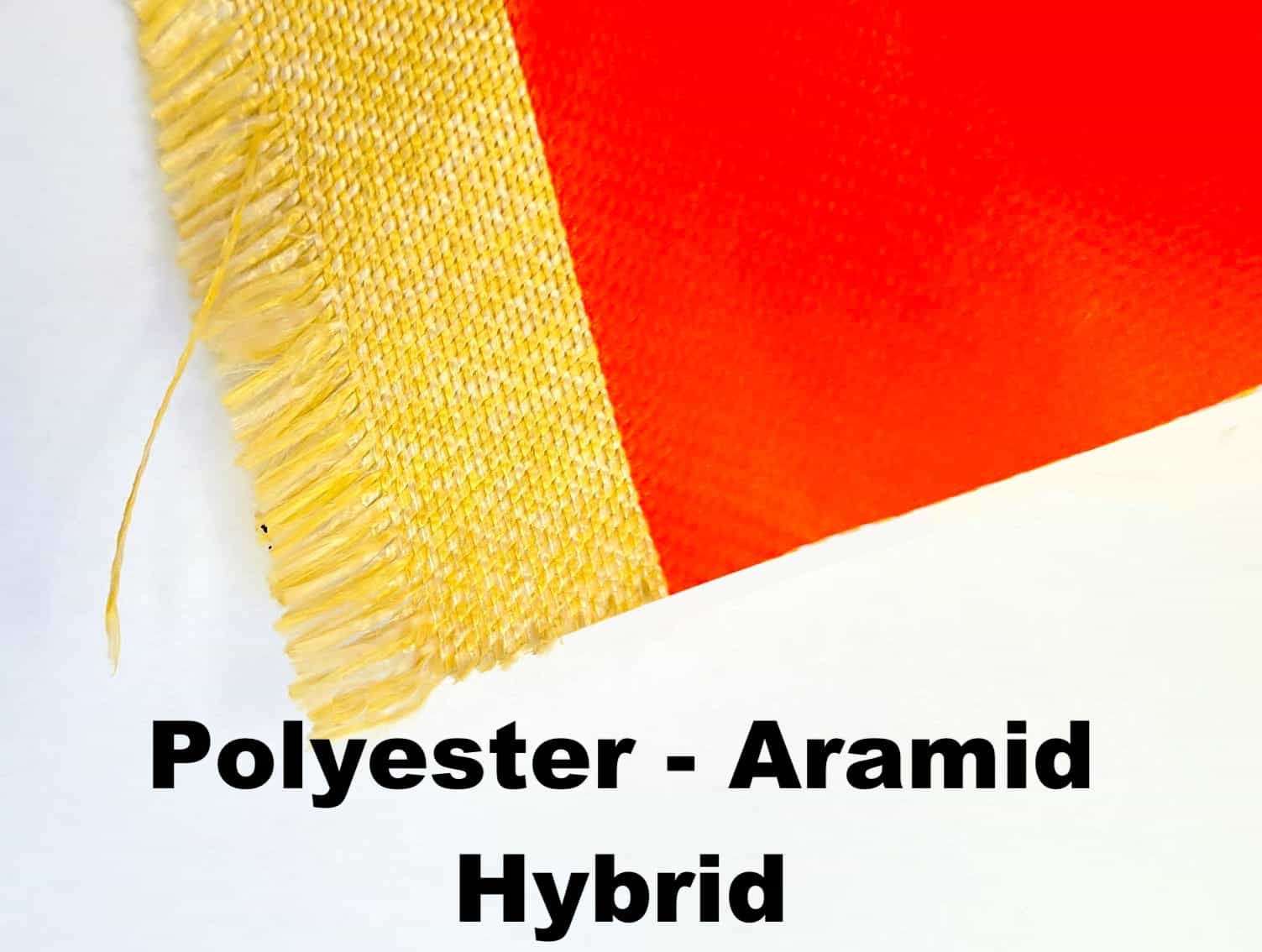

3. Technological Advancements and Hybrid Composites

- Kevlar-Carbon/E-Glass Hybrids: Manufacturers are increasingly combining Kevlar with carbon fiber or E-glass to optimize cost, strength, stiffness, and impact resistance. These hybrid solutions are becoming standard in premium marine applications.

- Improved Resin Systems: Development of marine-grade epoxy and vinyl ester resins enhances Kevlar’s interfacial bonding, reducing moisture ingress and delamination—critical for long-term durability.

- Automated Manufacturing: Adoption of automated fiber placement (AFP) and resin transfer molding (RTM) is improving production efficiency and consistency of Kevlar-based structures.

4. Sustainability and Lifecycle Considerations

- Longevity and Reduced Maintenance: Kevlar’s resistance to corrosion and fatigue reduces lifecycle costs, making it attractive despite higher upfront costs—aligning with industry trends toward sustainable and low-maintenance designs.

- Recycling Challenges: Limited recycling infrastructure for aramid composites remains a challenge. However, R&D into chemical recycling and reclamation methods is gaining momentum, potentially influencing material choices by 2026.

5. Regional Market Dynamics

- Asia-Pacific Dominance: Countries like China, South Korea, and Japan are leading shipbuilding hubs with growing investments in defense and offshore infrastructure, positioning the region as the fastest-growing market for Marine Kevlar.

- North America and Europe: Mature markets with strong defense sectors and offshore wind initiatives (e.g., U.S. East Coast, North Sea) continue to drive steady demand.

6. Supply Chain and Cost Factors

- Raw Material Volatility: Fluctuations in precursor chemical prices and geopolitical supply chain risks may impact Kevlar pricing. However, long-term contracts and vertical integration by key players (e.g., DuPont, Teijin) help stabilize supply.

- Local Production Growth: Regional manufacturing of Kevlar-based composites is increasing to reduce lead times and logistics costs, especially in emerging shipbuilding centers.

Conclusion:

By 2026, the Marine Kevlar market will be characterized by deeper integration into advanced marine platforms, driven by defense modernization, offshore energy expansion, and material innovation. While cost and recyclability remain challenges, the unparalleled performance benefits of Kevlar in harsh marine environments ensure its continued strategic importance. Manufacturers and end-users who leverage hybrid materials and sustainable production practices will be best positioned to capitalize on emerging opportunities.

Common Pitfalls Sourcing Marine Kevlar: Quality and Intellectual Property Concerns

Sourcing Kevlar® for marine applications—such as high-performance hulls, ballistic protection, or reinforcement in composite structures—requires careful attention to both material quality and intellectual property (IP) integrity. Falling into common pitfalls can result in compromised safety, project delays, legal exposure, and reputational damage. Below are key challenges to avoid.

Quality Inconsistencies and Counterfeits

One of the most significant risks when sourcing Marine Kevlar is receiving substandard or counterfeit material. Kevlar® is a registered trademark of DuPont™, and genuine Kevlar® used in marine environments must meet stringent performance standards for tensile strength, UV resistance, and moisture stability.

- Non-Certified Suppliers: Procuring from unauthorized distributors increases the risk of receiving counterfeit or rebranded aramid fibers that do not meet marine-grade specifications. These materials may degrade rapidly under saltwater exposure or fail under impact.

- Lack of Traceability: Without mill certifications, batch traceability, or test reports (e.g., tensile strength, elongation at break), it’s difficult to verify that the Kevlar® meets required performance benchmarks.

- Improper Storage and Handling: Even genuine Kevlar® can degrade if improperly stored (e.g., exposed to moisture or UV light before integration). Suppliers lacking proper logistics controls may compromise material integrity before delivery.

Intellectual Property and Trademark Violations

Kevlar® is a proprietary product protected by patents and trademarks. Misrepresenting materials or sourcing from entities that infringe on IP rights can expose buyers to legal and compliance risks.

- Mislabeling and “Kevlar-like” Claims: Some suppliers market generic para-aramid fibers as “Kevlar-type” or “equivalent to Kevlar®,” which may mislead buyers and infringe on DuPont’s trademarks. These substitutes often underperform in marine conditions.

- Unauthorized Use of Branding: Using the Kevlar® name in marketing or technical documentation without authorization—even when sourcing genuine material through dubious channels—can lead to trademark infringement claims.

- Patent Circumvention Risks: Certain manufacturing processes or fiber treatments used in competitive aramid fibers may violate existing patents. Sourcing from suppliers with unclear IP practices could entangle your organization in litigation.

To mitigate these risks, always source through authorized DuPont distributors or certified partners, demand full material documentation, and conduct third-party verification when necessary. Additionally, consult legal counsel when referencing Kevlar® in product specifications or marketing to ensure compliance with trademark guidelines.

Logistics & Compliance Guide for Marine Kevlar

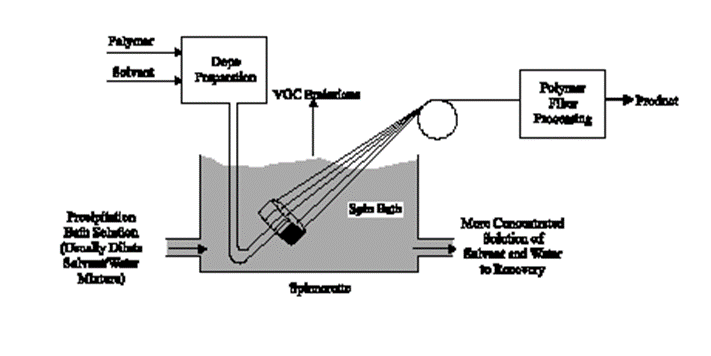

Overview of Marine Kevlar

Marine Kevlar refers to aramid fiber composite materials, primarily based on DuPont™ Kevlar®, specifically engineered or adapted for use in marine applications. These applications include high-performance boat hulls, protective panels, sail components, and reinforcement in marine structures. Due to its high strength-to-weight ratio and resistance to impact and abrasion, Kevlar is subject to specific logistics and regulatory compliance requirements.

International Shipping & Export Controls

Marine Kevlar is classified under dual-use goods due to its potential military applications. As such, it may be subject to export control regulations including:

– U.S. Export Administration Regulations (EAR): Kevlar and related composites may fall under ECCN (Export Control Classification Number) 1C010, which controls composite materials usable in rocket systems, unmanned aerial vehicles, or other defense applications.

– International Traffic in Arms Regulations (ITAR): While most commercial marine Kevlar is not ITAR-controlled, certain high-performance variants may require review.

– Wassenaar Arrangement: As a member, the U.S. and many other countries regulate the export of Kevlar composites for national security reasons.

Ensure proper export classification is obtained prior to international shipment. A license may be required for destinations subject to sanctions or embargoes.

Packaging and Handling Requirements

Proper packaging is crucial to maintain the integrity of Marine Kevlar materials:

– Store and transport Kevlar fabrics, prepregs, or laminates in moisture-resistant, sealed packaging to prevent resin degradation or moisture absorption.

– Prepreg materials (resin-impregnated Kevlar) must be kept under refrigerated conditions (typically -18°C / 0°F) and shipped with dry ice or gel packs in insulated containers.

– Label packages clearly with handling instructions such as “Keep Cool,” “Fragile,” and “Protect from Moisture.”

– Avoid sharp bending or compression during transit to prevent fiber damage.

Transportation Regulations

- IATA/ICAO: When shipping by air, comply with IATA Dangerous Goods Regulations if transporting refrigerated or frozen materials (e.g., dry ice used for cooling prepregs). Dry ice is classified as UN 1845, Class 9 – Miscellaneous Dangerous Goods.

- IMDG Code: For maritime transport, follow the International Maritime Dangerous Goods (IMDG) Code if shipping temperature-controlled Kevlar prepregs or associated resins.

- DOT (USA): Ground shipments must comply with 49 CFR regulations, particularly when using hazardous materials for temperature control.

Customs and Import Compliance

- Provide accurate Harmonized System (HS) codes for customs declarations. Kevlar fibers and fabrics often fall under HS code 5906.14 (textile fabrics impregnated with plastics) or 5407.10 (woven fabrics of aramid yarn).

- Submit required documentation such as commercial invoices, packing lists, certificates of origin, and export licenses (if applicable).

- Be aware of import restrictions or tariffs in destination countries. Some nations impose duties or require import permits for advanced composite materials.

Storage and Inventory Management

- Store Marine Kevlar in a clean, dry, temperature-controlled environment, away from UV exposure and chemical contaminants.

- For prepreg materials, track shelf life and use a first-in, first-out (FIFO) inventory system.

- Maintain traceability of batch numbers and certifications (e.g., material test reports, compliance certificates) for quality and audit purposes.

Environmental, Health, and Safety (EHS) Considerations

- Kevlar dust generated during cutting or sanding can be an irritant. Use appropriate personal protective equipment (PPE) and implement dust control measures.

- Follow safe handling practices to minimize inhalation or skin contact with fibers.

- Dispose of waste Kevlar materials in accordance with local environmental regulations. While Kevlar is not classified as hazardous waste, proper disposal procedures should be followed.

Regulatory Certifications and Documentation

- Maintain documentation proving compliance with relevant standards, such as:

- ISO 9001 (Quality Management)

- REACH (EU Registration, Evaluation, Authorization, and Restriction of Chemicals)

- RoHS (Restriction of Hazardous Substances – if applicable)

- Provide Material Safety Data Sheets (MSDS/SDS) for all Kevlar-based products and associated resins.

Conclusion

Transporting and managing Marine Kevlar requires careful attention to export controls, proper handling, and regulatory compliance. Adhering to international shipping standards, maintaining accurate documentation, and following safety protocols ensures smooth logistics operations and legal compliance across global supply chains. Always consult with legal and compliance experts when shipping Kevlar composites internationally.

Conclusion for Sourcing Marine-Grade Kevlar

Sourcing marine-grade Kevlar requires a strategic approach that balances performance, durability, compliance, and cost. Due to the extreme conditions in marine environments—such as constant exposure to saltwater, UV radiation, mechanical stress, and abrasion—only high-quality, properly treated Kevlar specifically engineered for maritime applications should be considered. Successful sourcing involves identifying reputable suppliers with proven expertise in marine composites, verifying material certifications (such as ISO, ABS, or DNV-GL), and ensuring consistency in fiber treatment and coating technologies that enhance moisture resistance and long-term structural integrity.

Additionally, establishing long-term partnerships with suppliers who offer technical support and batch traceability can significantly reduce risks associated with material failure. While marine Kevlar may come at a premium compared to standard-grade variants, its superior strength-to-weight ratio, impact resistance, and longevity make it a critical investment for applications such as high-speed vessels, naval armor, offshore structures, and protective marine systems.

In conclusion, effective sourcing of marine Kevlar hinges on rigorous vetting of suppliers, adherence to industry standards, and a clear understanding of the operational demands of the intended application—ensuring safety, performance, and lifecycle value in demanding marine environments.