The global marine air compressor market is experiencing steady growth, driven by increasing demand for efficient onboard compression systems in commercial shipping, offshore operations, and defense vessels. According to Grand View Research, the global marine compressor market size was valued at USD 1.48 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. Factors such as rising maritime trade, stricter environmental regulations, and the modernization of aging fleets are accelerating adoption of advanced, energy-efficient air compressors. Additionally, Mordor Intelligence forecasts consistent growth in marine air compressor demand, attributing it to expanding shipbuilding activities in Asia-Pacific and the increasing installation of compressors in auxiliary and safety systems like starting engines, pneumatic controls, and dive operations. As the industry evolves, a handful of manufacturers have emerged as leaders, combining innovation, reliability, and global reach to capture significant market share. Here are the top 10 marine air compressor manufacturers shaping the future of maritime operations.

Top 10 Marine Air Compressor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sperre

Domain Est. 1996

Website: sperre.com

Key Highlights: Sperre has researched, developed and maintained durable air power technology to the marine industry. The result? A life cycle partner….

#2 Marine Air Compressor System Manufacturer

Domain Est. 1996

Website: us.kaeser.com

Key Highlights: KAESER offers a complete range of rotary screw compressors, blowers, and air treatment products specifically designed for marine compressed air use….

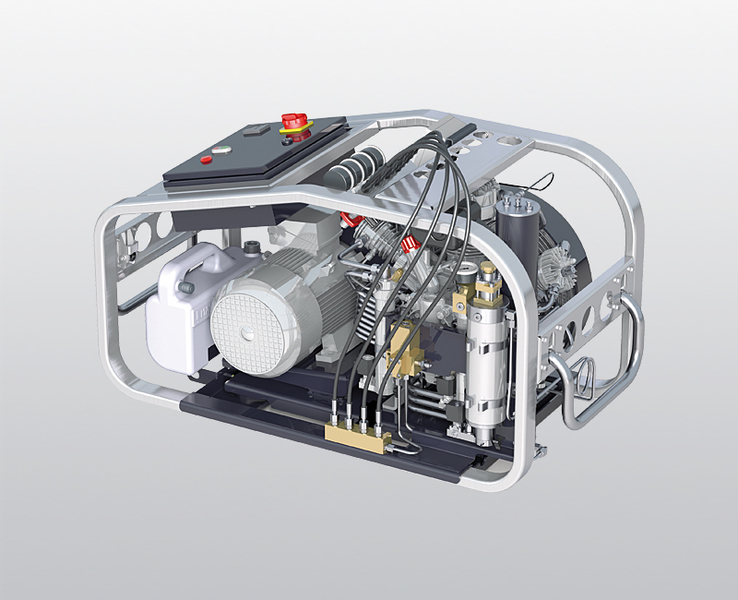

#3 Bauer Compressors: High

Domain Est. 1997

Website: bauercomp.com

Key Highlights: Bauer Compressors manufactures a broad range of compressor systems for various breathing-air and industrial applications….

#4 Standard & Custom Air & Gas Products

Domain Est. 2000

Website: uapc.com

Key Highlights: Universal Air & Gas Products Corp. is a designer & manufacturer of air & gas compressors. Ask about filtration & drying system installation & maintenance….

#5 Air Compressors

Domain Est. 2001

Website: ingersollrand.com

Key Highlights: Ingersoll Rand offers high-quality industrial air compressors and compressed air services for a wide range of industries….

#6 TANABE PNEUMATIC MACHINERY CO., LTD.

Website: tanacomp.co.jp

Key Highlights: Class approved air & gas compressors from a single source. Exemplary after-sales support including reasonably available at realistic prices….

#7 Full marine compressor range

Domain Est. 1995

Website: atlascopco.com

Key Highlights: Full range of sturdy marine compressors. Reliable, energy efficient and equipped to the highest standards. For a steady air flow in the harshest ……

#8 TMC Compressors

Domain Est. 1997

Website: tmc.com

Key Highlights: We produce the only true marine compressor: Reliable under extreme conditions; Market-leading support system; Certified by all the marine classification ……

#9 RIX Industries

Domain Est. 1997

Website: rixindustries.com

Key Highlights: RIX Industries provides precision compressor solutions, gas generation systems, and cryogenic technologies for critical infrastructure markets….

#10 Burckhardt Compression

Domain Est. 2000

Website: burckhardtcompression.com

Key Highlights: We – Burckhardt Compression – are a leading provider of reciprocating compressor systems and services. Discover our innovative solutions for various ……

Expert Sourcing Insights for Marine Air Compressor

H2: 2026 Market Trends for Marine Air Compressors

The marine air compressor market is poised for significant transformation by 2026, driven by regulatory shifts, technological innovation, and evolving maritime industry demands. Key trends shaping the market include the global push for decarbonization, digitalization of marine systems, rising demand for energy-efficient solutions, and the expansion of offshore and shipping activities.

1. Regulatory Compliance and Environmental Standards

By 2026, the International Maritime Organization’s (IMO) EEDI (Energy Efficiency Design Index) and CII (Carbon Intensity Indicator) regulations will be more stringently enforced. These policies are compelling shipbuilders and operators to adopt energy-efficient auxiliary systems, including advanced marine air compressors. Compressors with lower energy consumption and reduced emissions—especially those compatible with alternative fuels—are expected to see increased demand. Manufacturers are investing in oil-free and low-lubricant models to meet Tier III NOx and IMO 2030/2050 emission targets.

2. Growth in LNG and Alternative Fuel Vessels

The rising adoption of Liquefied Natural Gas (LNG), hydrogen, and methanol-fueled ships is creating a specialized need for compressors in fuel supply and inert gas systems. Marine air compressors are critical in LNG carriers for cargo handling, vapor recovery, and pneumatic control systems. By 2026, the market is projected to witness strong demand for compressors designed for cryogenic and high-pressure applications, particularly in dual-fuel and hybrid vessels.

3. Digitalization and Predictive Maintenance

Smart marine systems integrated with IoT sensors and AI-driven analytics are becoming standard. Marine air compressors equipped with condition monitoring systems, remote diagnostics, and predictive maintenance capabilities are gaining traction. By 2026, OEMs are expected to offer “connected compressors” that transmit real-time performance data, reducing downtime and improving operational efficiency. This trend is particularly significant for large shipping fleets and offshore platforms seeking to optimize lifecycle costs.

4. Expansion in Offshore and Specialized Vessels

Growth in offshore wind farms, subsea exploration, and offshore oil & gas projects is increasing demand for support vessels and offshore platforms—many of which rely heavily on reliable air compression systems for drilling, diving operations, and control systems. The rise in offshore renewables, especially in Europe and Asia-Pacific, will drive demand for compact, corrosion-resistant compressors capable of operating in harsh marine environments.

5. Regional Market Dynamics

Asia-Pacific—led by China, South Korea, and Japan—will remain the largest market due to high shipbuilding activity and government investments in green shipping infrastructure. Europe will follow closely, driven by stringent environmental regulations and the growth of short-sea shipping and ferry electrification. North America will see moderate growth, primarily in offshore energy and naval applications.

6. Technological Advancements and Materials Innovation

By 2026, manufacturers are expected to shift toward lightweight composite materials, advanced coatings for corrosion resistance, and variable speed drive (VSD) compressors to improve energy efficiency. Integration with shipboard automation systems and compatibility with digital twins will become key differentiators in product offerings.

Conclusion

The marine air compressor market in 2026 will be characterized by a strong focus on sustainability, digital integration, and operational efficiency. Companies that innovate in energy-saving technologies, comply with environmental regulations, and offer smart, connected solutions will lead the market. With global trade and marine energy sectors evolving rapidly, marine air compressors will play a critical role in enabling safer, cleaner, and more efficient maritime operations.

H2: Common Pitfalls When Sourcing Marine Air Compressors (Quality and Intellectual Property)

Sourcing marine air compressors requires careful evaluation to ensure reliability, compliance, and long-term operational safety. Two critical areas where procurement often goes wrong are quality assurance and intellectual property (IP) concerns. Below are the common pitfalls in these domains:

1. Compromising on Quality for Short-Term Cost Savings

- Pitfall: Selecting low-cost compressors from unverified suppliers without proper certification.

- Risk: Poor-quality compressors may fail prematurely in harsh marine environments (saltwater, humidity, vibration), leading to downtime, safety hazards, and costly repairs.

- Solution: Insist on compressors certified to international marine standards such as ISO 8573, DNV-GL, ABS, LR, or IEC 60092. Verify material specifications (e.g., corrosion-resistant alloys) and conduct factory acceptance tests (FAT).

2. Inadequate Testing and Lack of Traceability

- Pitfall: Accepting units without full performance documentation or third-party testing reports.

- Risk: Hidden defects or substandard components (e.g., seals, motors) may not surface until after installation.

- Solution: Require full documentation including pressure tests, burst ratings, duty cycle validation, and material traceability (e.g., mill certificates). Conduct on-site audits of the manufacturer if feasible.

3. Ignoring Environmental and Operational Suitability

- Pitfall: Procuring compressors not designed for the specific vessel type or duty (e.g., main engine start, instrument air, diving operations).

- Risk: Mismatched performance leads to inefficiency or system failure under load.

- Solution: Clearly define operational parameters (pressure, flow rate, ambient temperature, duty cycle) and ensure the compressor is rated for marine use with appropriate IP (Ingress Protection) ratings (e.g., IP55 or higher for salt-laden environments).

4. Intellectual Property (IP) Infringement Risks

- Pitfall: Sourcing from manufacturers that replicate branded designs without licensing (e.g., counterfeit or “copycat” products).

- Risk: Legal exposure, lack of technical support, voided warranties, and poor reliability due to reverse-engineered flaws.

- Solution: Verify OEM authenticity through official distributors, check for registered trademarks and patents, and avoid suppliers offering “equivalent” models at suspiciously low prices.

5. Lack of After-Sales Support and Spare Parts Availability

- Pitfall: Choosing suppliers with no local service network or unclear spare parts policy.

- Risk: Extended downtime during breakdowns, especially in remote locations.

- Solution: Prioritize suppliers with global support, documented spare parts lists, and accessible technical documentation—ensure IP rights do not restrict third-party servicing.

6. Misunderstanding Warranty and Liability in IP-Based Designs

- Pitfall: Assuming warranty coverage extends to cloned or modified designs.

- Risk: OEMs may deny support if IP is violated, leaving the buyer without recourse.

- Solution: Confirm warranty terms are valid and enforceable. Avoid modified or uncertified variants that may infringe on protected engineering.

Conclusion

To mitigate risks in sourcing marine air compressors, prioritize certified quality, environmental resilience, and legitimate IP compliance. Conduct due diligence on suppliers, demand full technical and legal transparency, and avoid shortcuts that compromise safety or regulatory compliance.

Logistics & Compliance Guide for Marine Air Compressor

Overview

Marine air compressors are critical components in shipboard operations, providing compressed air for engine starting, pneumatic controls, and various auxiliary systems. Due to their operational importance, safety implications, and international maritime regulations, their logistics and compliance requirements are strictly governed. This guide outlines key considerations for the safe, efficient, and compliant transportation, handling, installation, and operation of marine air compressors.

Regulatory Compliance

International Maritime Organization (IMO) Regulations

Marine air compressors must comply with relevant IMO standards, particularly under the Safety of Life at Sea (SOLAS) Convention. Key requirements include:

– SOLAS Chapter II-1: Mandates the provision and performance of air starting systems for main and auxiliary engines.

– SOLAS Chapter III: Requires reliable operation of compressed air systems for lifesaving appliances (e.g., davit systems).

– Components must be constructed and tested in accordance with recognized standards such as ISO 1217 or ISO 5389.

Classification Society Certification

Marine air compressors must be certified by recognized classification societies (e.g., ABS, DNV, LR, BV, NK) to ensure compliance with structural, mechanical, and safety standards. Certification typically involves:

– Type approval of design and materials.

– Factory acceptance testing (FAT) including pressure, endurance, and performance tests.

– Onboard installation and commissioning verification.

Environmental & Emission Standards

- IMO MARPOL Annex VI: Governs emissions from shipboard machinery; while air compressors are not direct emission sources, associated lubricants must be environmentally acceptable.

- Use of non-toxic, biodegradable lubricants may be required in sensitive marine areas.

- Noise emissions must comply with IMO Resolution MSC.337(91) on noise levels onboard ships.

Pressure Equipment Directive (PED) – EU Market

For compressors installed on vessels flagged in the European Economic Area (EEA):

– Compliance with EU Directive 2014/68/EU (Pressure Equipment Directive) is mandatory.

– CE marking required based on equipment category and pressure-volume criteria.

– Involves conformity assessment procedures, technical file documentation, and notified body involvement where necessary.

Logistics & Transportation

Packaging & Handling

- Compressors must be securely crated with moisture barriers and desiccants to prevent corrosion during transit.

- Use of vibration-dampening materials to protect precision components.

- Clearly label packages with orientation indicators (e.g., “This Side Up”), weight, and handling instructions.

Shipping Documentation

Ensure the following documents accompany the shipment:

– Bill of Lading (B/L)

– Commercial Invoice

– Packing List

– Certificate of Origin

– Test Reports (e.g., pressure test, performance test)

– Classification Society Certificates (e.g., DNV Type Approval)

– CE Declaration of Conformity (if applicable)

International Transport Considerations

- Comply with IMDG Code if hazardous materials (e.g., lubricants) are shipped with the unit.

- Air freight: Declare as machinery; comply with IATA regulations for heavy or oversized cargo.

- Sea freight: Securely fasten in container or on deck; protect from saltwater exposure.

Customs & Import Clearance

- Verify import regulations in the destination country (e.g., import duties, VAT, local certification).

- Some countries require additional approvals (e.g., Russian Maritime Register of Shipping, CCS in China).

- Use a qualified freight forwarder experienced in marine equipment shipments.

Installation & Commissioning

Site Preparation

- Ensure foundation or mounting surface meets design specifications for load distribution and vibration isolation.

- Verify availability of electrical supply (voltage, frequency) and ventilation.

- Confirm compatibility with onboard air system (pressure, volume, piping standards).

Installation Procedures

- Follow manufacturer’s installation manual and classification society guidelines.

- Use certified personnel for mechanical and electrical connections.

- Install safety devices: pressure relief valves, moisture traps, and pressure gauges.

Testing & Commissioning

- Conduct leak tests on all piping and connections using air or nitrogen.

- Perform run-in tests under no load, followed by gradual load application.

- Verify auto-start/stop functionality and pressure switch calibration.

- Document test results and obtain sign-off from shipyard or class surveyor.

Maintenance & Operational Compliance

Routine Maintenance

- Follow manufacturer-recommended maintenance schedule (e.g., filter replacement, oil changes, valve inspections).

- Maintain logbook records of all servicing and repairs.

- Monitor for abnormal noise, vibration, or pressure fluctuations.

Regulatory Inspections

- Include air compressors in the vessel’s Planned Maintenance System (PMS).

- Subject to periodic surveys by classification societies (e.g., annual, intermediate, special surveys).

- SOLAS requires periodic testing of air starting systems during safety drills.

Spare Parts & Documentation

- Maintain an inventory of critical spares (filters, seals, valves).

- Keep onboard: Operation manual, spare parts list, class certificates, and compliance documentation.

Emergency & Safety Considerations

Pressure System Safety

- Never exceed maximum working pressure (MWP).

- Ensure pressure relief valves are correctly sized and regularly tested.

- Depressurize system before maintenance.

Fire & Explosion Risks

- Avoid oil accumulation in air receivers; perform regular draining.

- Use oil-free compressors in high-risk areas if required.

- Ensure proper ventilation in compressor room.

Conclusion

Proper logistics planning and strict adherence to international and classification standards are essential for the safe and compliant deployment of marine air compressors. From manufacturing certification to final commissioning and ongoing maintenance, each phase must align with regulatory frameworks to ensure reliability, safety, and operational continuity at sea. Always consult the latest IMO, class society, and manufacturer guidelines for specific vessel and operational contexts.

Conclusion on Sourcing a Marine Air Compressor

Sourcing a marine air compressor requires a careful evaluation of technical specifications, operational requirements, regulatory compliance, and long-term reliability. Given the critical role of air compressors in marine applications—such as starting engines, operating pneumatic tools, and supporting safety systems—it is essential to select a unit that meets international marine standards (e.g., ISO, SOLAS, and classification society approvals like DNV, ABS, or LR).

Key factors in the sourcing decision include the compressor’s capacity, pressure rating, duty cycle, resistance to saltwater corrosion, and suitability for the vessel’s operating environment. Additionally, energy efficiency, ease of maintenance, and availability of spare parts play a significant role in minimizing downtime and lifecycle costs.

Procuring from reputable manufacturers with proven marine experience, along with conducting thorough due diligence on warranty, after-sales support, and service network availability, ensures operational continuity and safety at sea. In conclusion, a strategic and well-informed sourcing approach will lead to the selection of a reliable, compliant, and cost-effective marine air compressor that supports safe and efficient vessel operations over its service life.