The global laser marking plastics market is witnessing robust expansion, driven by increasing demand for permanent, high-precision labeling across industries such as automotive, healthcare, electronics, and consumer goods. According to Grand View Research, the global laser marking machines market size was valued at USD 1.47 billion in 2022 and is expected to grow at a CAGR of 6.3% from 2023 to 2030, with plastic material applications representing a significant share. This growth is fueled by the rising need for traceability, product authentication, and regulatory compliance, particularly in pharmaceutical and medical device packaging. As manufacturers prioritize non-contact, eco-friendly marking solutions that ensure durability and clarity, laser technology has emerged as the preferred choice over traditional methods. In response to these trends, a select group of companies have distinguished themselves through innovation, reliability, and technical expertise in laser marking for plastic substrates. Based on market presence, technological capabilities, and customer reviews, the following nine manufacturers are leading the charge in the Marcatura Laser Plastica space.

Top 9 Marcatura Laser Plastica Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

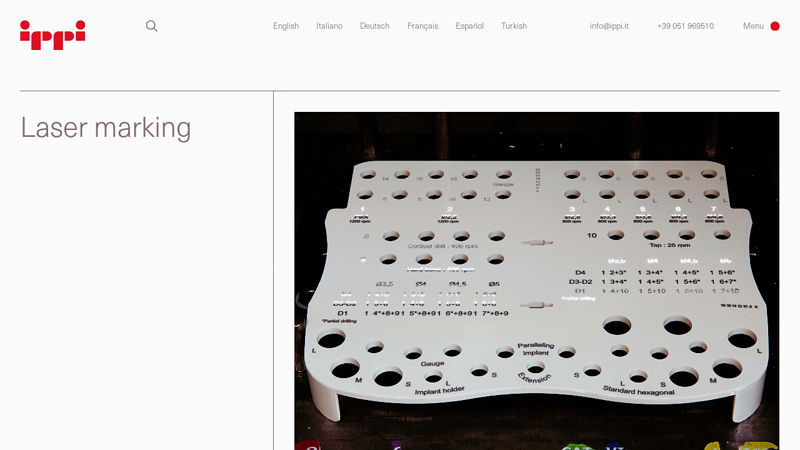

#1 Industrial laser marking of plastic

Website: ippi.it

Key Highlights: We perform industrial laser marking of plastic and metal for many different sectors. We customize standard products and designed products….

#2 Marcatura laser su tutti i materiali

Website: lasit.it

Key Highlights: La marcatura laser è lo strumento ideale per garantire la tracciabilità e la durabilità di loghi e disegni su tutti i materiali….

#3 Homepage

Founded: 1940

Website: automator.com

Key Highlights: Since 1940, Automator Marking Systems has been a world leader in industrial marking solutions, with an unwavering commitment to customer-centric innovation….

#4 Marking and engraving of Plastics

Website: laserevo.com

Key Highlights: Lasers with CO2 source are used for the engraving of the material. By removing the surface layer, a deep marking is obtained, without color contrast….

#5 Le nostre industrie

Website: telesis.com

Key Highlights: Le macchine Telesis Technologies hanno la capacità di marcare materiali da un’ampia gamma di settori. Aiutiamo a svolgere attività con facilità….

#6 Macchine taglio laser

Website: seilaser.com

Key Highlights: Progettiamo e produciamo macchine da taglio e marcatura basate sulla tecnologia laser. SEI Laser: vicini a chi guarda lontano!…

#7 Marcatura della plastica con il laser

Website: epiloglaser.com

Key Highlights: Un laser a fibra Epilog è la scelta migliore per eseguire la marcatura di componenti in plastica con codici a barre, numeri di serie e loghi….

#8 Marcatura laser di materia plastica

Website: trumpf.com

Key Highlights: Le marcature laser su superfici in materia plastica sono sempre resistenti a strofinamento e usura. Di base si distinguono tre procedimenti per la marcatura ……

#9 Produttore italiano di marcatori laser

Website: mpix.it

Key Highlights: M-Pix offre sistemi di marcatura laser compatti e All-in-One, per incisioni permanenti ad alto contrasto su metalli, plastiche, ceramica, vetro e molto altro….

Expert Sourcing Insights for Marcatura Laser Plastica

H2: Market Trends for Marcatura Laser Plastica in 2026

The plastic laser marking (Marcatura Laser Plastica) industry is poised for significant transformation by 2026, driven by technological advancements, regulatory demands, and evolving industrial needs. Several key trends are expected to shape the market landscape, creating both opportunities and challenges for manufacturers, system integrators, and end-users.

1. Rising Demand for Sustainable and Traceable Packaging

Environmental regulations and consumer demand for transparency are pushing industries—especially food & beverage, pharmaceuticals, and consumer goods—to adopt permanent, non-toxic marking solutions. Laser marking offers a chemical-free alternative to ink-based systems, aligning with sustainability goals. By 2026, the need for tamper-proof, traceable product identification will drive adoption of laser systems capable of high-resolution 2D codes, QR codes, and serialized data on plastic packaging.

2. Advancements in Laser Technology

Fiber and UV laser systems are becoming more efficient, compact, and cost-effective. Innovations in picosecond and femtosecond lasers allow for precise, high-contrast marking on sensitive or complex plastic substrates without damaging the material. These advancements will expand applications in medical devices and electronics, where precision and material integrity are critical.

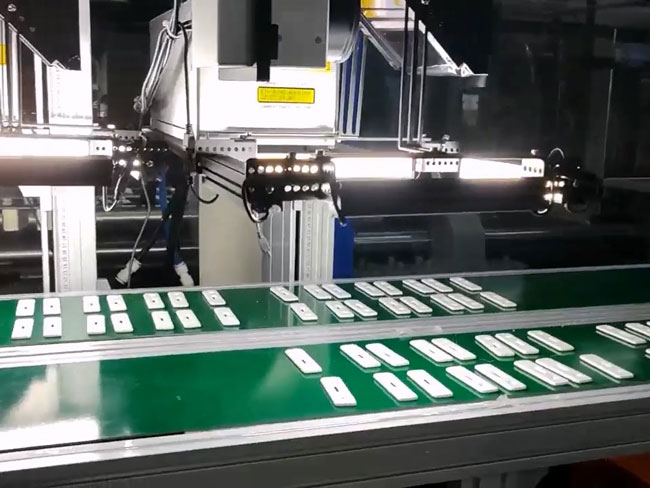

3. Growth in Industrial Automation and Industry 4.0 Integration

The integration of laser marking systems into smart manufacturing environments is accelerating. By 2026, laser markers will increasingly feature IoT connectivity, enabling real-time monitoring, predictive maintenance, and seamless data exchange with MES (Manufacturing Execution Systems) and ERP platforms. This trend supports traceability, quality control, and operational efficiency across production lines.

4. Expansion in Automotive and Electronics Sectors

Automotive and electronics industries are adopting laser marking for part identification, anti-counterfeiting, and compliance with global standards (e.g., UL, CE, RoHS). As electric vehicles (EVs) and advanced electronics grow, so will the need for durable, high-speed marking on plastic components such as connectors, housings, and circuit boards.

5. Regional Market Growth and Regulatory Influence

Europe and North America will remain key markets due to strict labeling regulations (e.g., EU Medical Device Regulation, FDA UDI requirements). Meanwhile, Asia-Pacific—especially China, India, and Southeast Asia—is expected to see rapid growth, fueled by expanding manufacturing capabilities and rising automation investment.

6. Customization and Brand Protection

Brands are leveraging laser marking for aesthetic and security purposes—creating unique textures, logos, and covert security features. This trend supports anti-counterfeiting efforts and enhances brand value, particularly in luxury goods and high-value consumer products.

Conclusion

By 2026, the Marcatura Laser Plastica market will be shaped by a convergence of sustainability, digitalization, and regulatory compliance. Companies that invest in advanced, flexible laser solutions and integrate them into broader smart manufacturing ecosystems will gain a competitive edge. The future lies in precision, connectivity, and eco-friendly performance—positioning laser marking as an indispensable technology in modern industrial production.

Common Pitfalls Sourcing Marcatura Laser Plastica (Quality, IP)

Sourcing laser marking services for plastic components—known as Marcatura Laser Plastica—can present several challenges, especially when balancing quality, cost, and intellectual property (IP) protection. Below are common pitfalls to avoid in these areas.

Quality-Related Pitfalls

Inconsistent Marking Results

Different plastic materials react uniquely to laser energy. Using the wrong laser type (fiber, UV, CO2) or incorrect settings can lead to poor contrast, surface damage, or fading over time. Suppliers may lack the expertise to optimize parameters for your specific resin (e.g., ABS, polycarbonate, or polypropylene), resulting in inconsistent or non-compliant markings.

Lack of Process Validation

Some suppliers do not perform rigorous testing under real-world conditions (e.g., exposure to UV light, chemicals, or abrasion). This can result in markings that degrade prematurely, failing durability or regulatory requirements such as UL, medical device, or automotive standards.

Poor Traceability and Documentation

Inadequate record-keeping of laser parameters, machine calibration, and material batches can compromise quality control and hinder root cause analysis in case of defects. This is especially critical in regulated industries where full traceability is mandatory.

Intellectual Property (IP) Risks

Insufficient IP Protection Agreements

When sharing design files (e.g., logos, serial numbers, or 2D data matrix codes), suppliers may not have robust confidentiality agreements (NDAs) or data handling procedures. This exposes your proprietary designs or product information to unauthorized use or leakage.

Unauthorized Use of Marking Data

Some suppliers may store or reuse marking patterns across customers, especially if they manage multiple clients in the same sector. Without strict data governance, your unique identifiers or branding elements could be replicated or reverse-engineered.

Weak Digital Security Measures

Digital workflows for laser marking often involve sending files via unsecured channels or storing them on poorly protected systems. Suppliers lacking cybersecurity protocols risk data breaches, potentially exposing sensitive product information or enabling counterfeiting.

Conclusion

To mitigate these risks, vet suppliers thoroughly—assess their technical capabilities, quality certifications (e.g., ISO 9001, ISO 13485), and IP protection policies. Require documented process validation and ensure data security compliance, particularly when handling proprietary designs or regulated products.

Logistics & Compliance Guide for Marcatura Laser Plastica

This guide outlines essential logistics and compliance considerations for laser marking on plastic materials, ensuring efficient operations and adherence to regulatory standards.

Material Compatibility and Selection

Ensure that the plastics intended for laser marking are suitable for the laser process. Some materials may emit hazardous fumes when exposed to laser energy. Verify material composition and consult safety data sheets (SDS) to confirm compatibility with CO2, fiber, or UV laser systems. Avoid halogenated plastics (e.g., PVC, PTFE) due to the risk of releasing toxic gases such as chlorine or fluorine compounds.

Emission Control and Workplace Safety

Install appropriate fume extraction systems equipped with HEPA and activated carbon filters to capture airborne particles and volatile organic compounds (VOCs) generated during laser marking. Conduct regular maintenance of filtration systems and ensure local exhaust ventilation (LEV) meets OSHA or equivalent regional standards. Provide operators with personal protective equipment (PPE), including safety glasses rated for laser wavelengths used.

Regulatory Compliance

Adhere to relevant international and local regulations, including:

– REACH and RoHS (EU): Confirm that marked plastic components do not contain restricted substances.

– FDA (USA): For medical or food-contact plastics, ensure the laser marking process does not compromise material safety or introduce contaminants.

– CE Marking: If placing equipment or marked products in the European market, ensure compliance with applicable directives (e.g., Machinery Directive, EMC Directive).

– Laser Safety Standards (IEC 60825-1): Classify laser systems appropriately and implement enclosure interlocks, warning labels, and access controls.

Traceability and Marking Requirements

Laser marking must produce permanent, high-contrast, and machine-readable identifiers (e.g., barcodes, QR codes, serial numbers) as required by industry standards such as:

– UDI (Unique Device Identification) for medical devices (FDA 21 CFR Part 801).

– IMDS (International Material Data System) compliance for automotive components.

Ensure markings remain legible throughout the product lifecycle under expected environmental conditions (e.g., UV exposure, abrasion, chemical contact).

Supply Chain and Packaging Logistics

Coordinate with suppliers to ensure incoming plastic parts are clean, free of contaminants, and correctly identified for batch traceability. Use anti-static packaging where necessary to prevent dust attraction, which can interfere with marking quality. Clearly label marked batches with date, shift, and equipment ID to support quality control and recall management.

Documentation and Record Keeping

Maintain comprehensive records including:

– Laser parameter settings (power, speed, frequency) for each material type.

– Calibration and maintenance logs for laser systems and extraction units.

– Operator training certifications.

– Compliance test results (e.g., adhesion, readability, chemical resistance).

These records support audits and demonstrate due diligence in regulatory compliance.

Environmental and Disposal Considerations

Dispose of collected filter waste and marked plastic scraps in accordance with local environmental regulations. Classify waste streams properly—some laser-generated particulates may be classified as hazardous. Partner with certified waste management providers to ensure compliant disposal or recycling.

By following this guide, businesses involved in marcatura laser plastica can ensure safe, compliant, and efficient operations across the logistics and production chain.

Conclusion on Sourcing Laser Marking for Plastics

Sourcing laser marking solutions for plastic materials requires a strategic approach that balances technical compatibility, production efficiency, and long-term cost-effectiveness. The selection of the appropriate laser technology—such as fiber, UV, or CO2 lasers—depends heavily on the specific type of plastic, desired mark quality, durability requirements, and production environment. UV lasers, for instance, are ideal for high-contrast, precise markings on sensitive plastics without causing thermal damage, while CO2 lasers are well-suited for organic materials and packaging applications.

When sourcing, it is essential to partner with experienced suppliers or integrators who can provide tailored solutions, technical support, and post-installation service. Evaluating factors such as marking speed, integration capabilities with existing production lines, maintenance needs, and regulatory compliance (e.g., food safety or medical device standards) ensures a seamless implementation.

Moreover, considering sustainability—such as energy consumption and the absence of inks or chemicals—adds value to environmentally responsible manufacturing. In conclusion, a well-informed sourcing strategy for laser marking on plastics enhances product traceability, brand protection, and operational efficiency, ultimately contributing to higher quality standards and competitiveness in the market.