The global laser marking machine market is experiencing robust expansion, driven by increasing demand for permanent, high-precision marking across industries such as automotive, electronics, and medical devices. According to Grand View Research, the global laser marking market was valued at USD 2.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. This growth is fueled by advancements in fiber laser technology, rising adoption of automation in manufacturing, and stringent regulatory requirements for product traceability. In this evolving landscape, manufacturers of marcatori laser—Italian for “laser markers”—are playing a pivotal role in delivering reliable, efficient, and scalable marking solutions. From Italian engineering excellence to German precision and Asian innovation, the top nine laser marker manufacturers have distinguished themselves through technological leadership, global reach, and strong R&D investment, positioning them at the forefront of industrial digitalization and smart manufacturing trends.

Top 9 Marcatori Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Homepage

Founded: 1940

Website: automator.com

Key Highlights: Since 1940, Automator Marking Systems has been a world leader in industrial marking solutions, with an unwavering commitment to customer-centric innovation….

#2 Marcatori Laser Industriali

Website: markem-imaje.com

Key Highlights: Marcatori laser Markem-Imaje per codici permanenti di alta qualità, senza sostanze chimiche. Disponibili fibra, UV o CO2, per ablazione, incisione, ……

#3 Domino Printing

Website: domino-printing.com

Key Highlights: Discover Domino Printing’s award-winning, innovative printers, coders and markers for a wide range of industries – from product to pallet….

#4 Marcatura Laser

Website: arcalasermarking.com

Key Highlights: The laser is the most modern, efficient and effective marking and coding system. An investment with a certain and easily quantifiable return….

#5 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#6 Sisma S.p.A.

Website: sisma.com

Key Highlights: Sisma S.p.A. è un riferimento a livello mondiale per la progettazione e produzione di macchinari e sistemi laser di altissima precisione….

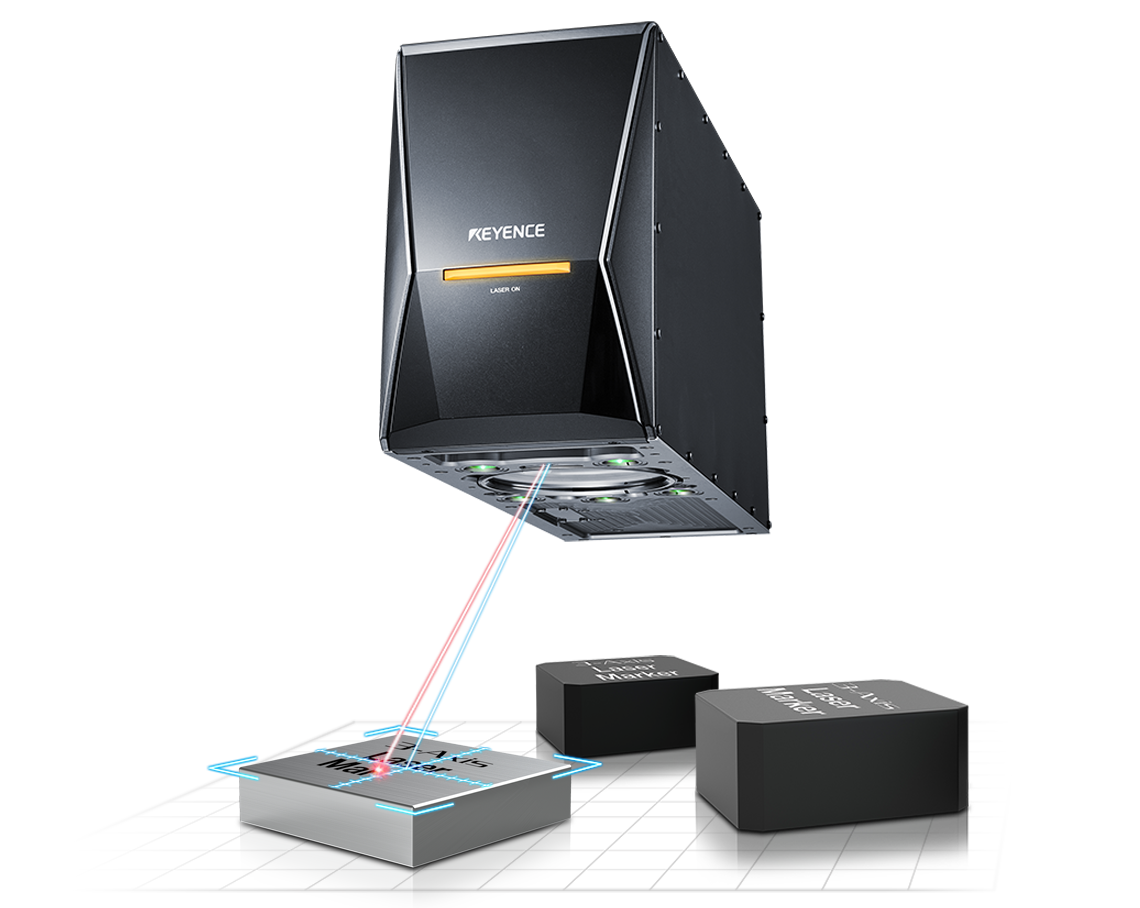

#7 KEYENCE ITALIA S.p.A.

Website: keyence.it

Key Highlights: Nuovi Prodotti · Marcatore laser UV a 3 assi · Deionizzatore ad altissima velocità e massima efficienza · Marcatore ad alta risoluzione per imballaggi in cartone….

#8 Industria Fine Linea

Website: arcalabelingmarking.com

Key Highlights: Marcatori laser CO2 e Fiber, per la codifica indelebile: numero di lotto, data di scadenza, codici a barre/ 2D. Direttamente su bottiglie di plastica, PET, ……

#9 Le nostre industrie

Website: telesis.com

Key Highlights: Le macchine Telesis Technologies hanno la capacità di marcare materiali da un’ampia gamma di settori. Aiutiamo a svolgere attività con facilità….

Expert Sourcing Insights for Marcatori Laser

H2 2026 Market Trends Analysis for Marcatori Laser (Laser Marking Systems)

The global laser marking systems market is poised for significant transformation in H2 2026, driven by technological advancements, evolving industry demands, and macroeconomic shifts. For companies like Marcatori Laser, understanding these trends is crucial for strategic positioning and growth. Here’s an analysis of the key trends expected in the second half of 2026:

1. Accelerated Adoption of Ultrafast Lasers (Femtosecond & Picosecond):

* Trend: Demand for ultra-precise, high-contrast, and damage-free marking on sensitive materials (e.g., medical devices, semiconductors, thin films, consumer electronics) will surge. Picosecond lasers are becoming more cost-effective, while femtosecond lasers penetrate new applications.

* Impact on Marcatori Laser: Requires significant R&D investment in integrating advanced ultrafast sources and developing application-specific software/processes. Presents a premium market opportunity but intensifies competition from established players like Trumpf, IPG, and Coherent. Focus on demonstrating superior process stability and ROI will be key.

2. Deepening Integration of AI and Machine Learning:

* Trend: AI will move beyond predictive maintenance to real-time process optimization, quality control, and adaptive marking. ML algorithms will analyze sensor data (cameras, spectrometers) to automatically adjust laser parameters for varying material conditions or detect marking defects instantly.

* Impact on Marcatori Laser: Systems will need built-in AI capabilities or seamless integration with factory AI platforms. Data collection and processing become critical assets. Offers a major differentiator: “Smart Markers” that guarantee quality and minimize waste. Requires expertise in AI/ML and robust data infrastructure.

3. Expansion of “Green” and Sustainable Manufacturing Focus:

* Trend: Regulatory pressure (e.g., EU Green Deal, circular economy mandates) and corporate ESG goals will drive demand for energy-efficient lasers and processes that minimize waste and environmental impact. Traceability of materials (including marking for recycling) becomes paramount.

* Impact on Marcatori Laser: Need to highlight energy efficiency (kW/h per mark) and low consumable use of their systems. Develop capabilities for marking materials critical to recycling streams (e.g., plastics with high pigment load, composites). Offer solutions enabling full product lifecycle traceability.

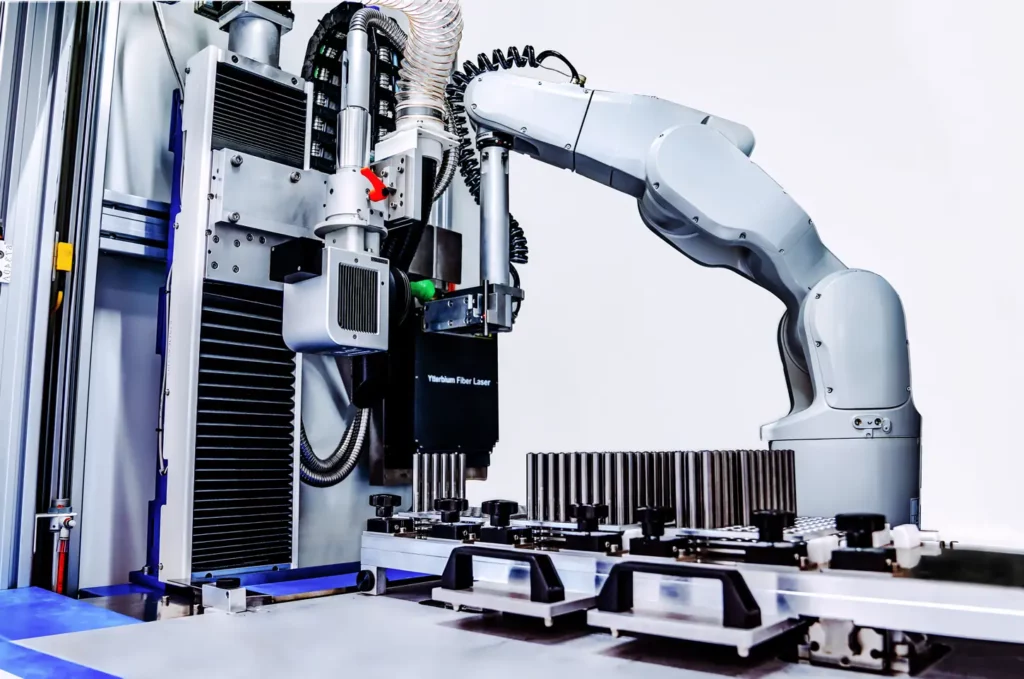

4. Growth in High-Volume, Automated Production Lines:

* Trend: Demand for laser markers seamlessly integrated into fully automated production cells (robotics, conveyors, vision systems) will increase, especially in automotive, electronics, and pharmaceuticals. Speed, reliability, and communication (Industry 4.0) are non-negotiable.

* Impact on Marcatori Laser: Systems must offer robust IIoT connectivity (OPC UA, MQTT), easy integration with PLCs and robots, and high throughput/reliability. Focus shifts from standalone machines to process solutions. Partnerships with automation integrators become vital.

5. Rising Demand for Permanent, Tamper-Proof Traceability (Serialization & Anti-Counterfeiting):

* Trend: Regulations (e.g., DSCSA, EU Falsified Medicines Directive) and brand protection needs will drive demand for high-resolution, unique marking (2D Data Matrix codes, micro-text, covert features) on diverse materials.

* Impact on Marcatori Laser: Expertise in high-resolution marking (especially with fiber and UV lasers) and developing solutions for challenging substrates (dark plastics, anodized metals, ceramics) is essential. Potential to offer integrated verification systems.

6. Supply Chain Resilience & Regionalization:

* Trend: Ongoing geopolitical tensions and lessons from past disruptions will push manufacturers towards more regionalized supply chains. “Nearshoring” and “friendshoring” will influence equipment purchasing decisions.

* Impact on Marcatori Laser: Opportunities may arise in regions seeking to build domestic manufacturing capacity (e.g., parts of Europe, North America, India). Requires flexible manufacturing and supply chains. Local service and support networks become a competitive advantage.

7. Intensifying Competition & Price Pressure (Especially in Mid-Range):

* Trend: The market for standard fiber laser markers will become increasingly commoditized, with strong competition from Asian manufacturers offering lower prices. Differentiation through software, service, and specialized applications will be critical.

* Impact on Marcatori Laser: Risk of margin erosion in core product lines. Necessitates a clear value proposition beyond the hardware: superior software, application support, reliability, and service. Strategic focus on high-value niches (e.g., medical, aerospace, luxury goods) is essential.

Strategic Implications for Marcatori Laser:

- Double Down on Innovation: Prioritize R&D in ultrafast lasers, AI integration, and specialized applications to avoid commoditization.

- Embrace Software & Services: Transform from a hardware vendor to a solutions provider. Offer subscription-based software, advanced analytics, and comprehensive service packages.

- Strengthen Ecosystem Partnerships: Collaborate with automation integrators, material suppliers, and software platforms to offer complete turnkey solutions.

- Focus on Sustainability & Traceability: Make these core tenets of product development and marketing.

- Optimize Global Footprint: Balance cost efficiency with the need for regional presence, service, and supply chain resilience.

- Target High-Growth Verticals: Allocate resources strategically towards medical devices, EVs/batteries, advanced electronics, and aerospace.

Conclusion:

H2 2026 presents both significant challenges and opportunities for Marcatori Laser. Success will depend on moving beyond being a provider of laser marking tools towards becoming an enabler of intelligent, sustainable, and traceable manufacturing. The winners will be those who leverage AI, focus on high-value applications, offer seamless integration, and provide demonstrable ROI through enhanced quality, efficiency, and compliance. Navigating the price pressure in the mid-market while capturing premium segments with advanced technology will be the key strategic balancing act.

Common Pitfalls When Sourcing Laser Marking Machines (Quality and Intellectual Property)

Sourcing laser marking machines (Marcatori Laser) from international suppliers, especially in cost-sensitive markets, can present significant challenges related to both product quality and intellectual property (IP) risks. Being aware of these pitfalls is crucial to ensuring a reliable, compliant, and sustainable investment.

Quality Inconsistencies and Substandard Components

One of the most prevalent issues when sourcing laser markers is inconsistent product quality. Suppliers may offer machines that appear identical on paper but differ drastically in real-world performance. Key quality pitfalls include:

- Use of Low-Grade Lasers and Optics: Some manufacturers substitute high-performance lasers (e.g., IPG or SPI fiber lasers) with cheaper, less reliable alternatives that degrade quickly, resulting in inconsistent marking depth, speed, and longevity.

- Poor Mechanical Build Quality: Inadequate frame rigidity, substandard linear guides, or weak enclosures can lead to misalignment, vibration, and premature wear, affecting marking accuracy and machine lifespan.

- Insufficient Cooling and Thermal Management: Overheating can shorten laser diode life and cause system shutdowns. Budget machines often lack adequate cooling systems, especially in continuous-use applications.

- Inadequate Software and Controls: Proprietary software may be outdated, non-intuitive, or lack essential features like barcode integration, job logging, or remote diagnostics, increasing downtime and maintenance costs.

Intellectual Property (IP) Infringement Risks

Another critical concern is the potential for IP violations, particularly when sourcing from regions with lax enforcement of intellectual property laws:

- Counterfeit or Cloned Systems: Some suppliers replicate the design, firmware, or software of well-known brands (e.g., Trumpf, Keyence, or Trotec) without authorization. These clones may infringe on patents, trademarks, or copyrighted software, exposing the buyer to legal liability.

- Unauthorized Use of Licensed Components: Machines may include components (such as laser sources or control boards) that are legally licensed only for specific manufacturers. Unauthorized integration can void warranties and lead to supply chain disruptions.

- Lack of Transparency in Firmware and Software: Closed-source or modified firmware may contain pirated software or unauthorized modifications that compromise system security and compliance.

- Exposure to Legal Action: End users or system integrators incorporating infringing equipment into their production lines may face cease-and-desist orders, customs seizures, or lawsuits, especially in IP-strict jurisdictions like the EU or North America.

Mitigation Strategies

To avoid these pitfalls:

- Verify Component Origins: Request detailed specifications and origin documentation for critical components like the laser source, galvanometer, and control software.

- Conduct On-Site Audits or Third-Party Inspections: Evaluate the manufacturer’s facilities, quality control processes, and supply chain transparency.

- Require IP Compliance Certifications: Ask for proof of licensing agreements, software authenticity, and design originality.

- Test Machines Under Real Conditions: Perform endurance and performance testing before full-scale procurement.

- Use Legal Contracts with IP Clauses: Include warranties, indemnification for IP infringement, and clear liability terms in procurement agreements.

By proactively addressing quality and IP concerns, buyers can safeguard their operations, ensure long-term reliability, and avoid costly legal or operational setbacks.

Logistics & Compliance Guide for Marcatori Laser

This guide outlines essential logistics and compliance considerations for the import, export, distribution, and operation of laser marking machines (Marcatori Laser). Adherence to these guidelines ensures legal compliance, operational safety, and efficient supply chain management.

Regulatory Compliance

Laser marking machines are subject to strict international and national regulations due to their use of high-intensity laser radiation. Compliance is mandatory to ensure product safety and legal market access.

Laser Safety Standards

- IEC 60825-1: International standard for the safety of laser products. Classifies lasers by hazard level (Class 1 to Class 4).

- FDA 21 CFR Part 1040.10 (USA): Requires laser products to comply with performance standards, including labeling, safety interlocks, and reporting to the FDA.

- CE Marking (EU): Mandatory for placing laser equipment on the European market. Requires compliance with directives including the Machinery Directive (2006/42/EC) and the Low Voltage Directive (2014/35/EU), as well as IEC 60825.

Product Certification & Documentation

- Ensure all Marcatori Laser units are certified to applicable regional standards.

- Maintain technical files including risk assessments, design schematics, and test reports.

- Provide user manuals in local languages, including safety instructions, laser classification, and emergency procedures.

Import & Export Regulations

Cross-border movement of laser marking equipment requires adherence to customs, trade, and safety regulations.

Export Controls

- Check if the laser equipment falls under dual-use or strategic technology controls (e.g., EU Dual-Use Regulation, U.S. Export Administration Regulations – EAR).

- High-power lasers may require export licenses depending on power output, wavelength, and end-use.

- Verify destination country restrictions and end-user screening.

Import Requirements

- Confirm tariff classifications (HS Code – typically 8456.30 for laser cutting/marking machines).

- Prepare commercial invoices, packing lists, and certificates of origin.

- Some countries require import permits or pre-shipment inspections for industrial machinery.

Shipping & Transportation

Safe and secure transport of laser marking systems is critical due to their sensitive components and classification.

Packaging & Handling

- Use manufacturer-recommended packaging with shock absorption and moisture protection.

- Clearly label packages with “Fragile,” “This Way Up,” and “Laser Equipment” warnings.

- Secure optical components and laser heads to prevent misalignment during transit.

Hazard Classification

- Most industrial laser markers are not classified as hazardous goods for transport if powered off and without batteries.

- Batteries (if included) may be subject to IATA/IMDG regulations (e.g., lithium batteries).

- Confirm with freight forwarders whether special documentation (e.g., Material Safety Data Sheet) is needed.

Installation & Operational Compliance

Safe installation and usage are critical for regulatory compliance and user protection.

Workplace Safety

- Designate a controlled laser area with appropriate interlocks and warning signs (e.g., “Laser in Use”).

- Install protective enclosures and beam shielding to prevent exposure.

- Provide appropriate laser safety eyewear rated for the laser’s wavelength and power.

Training & Documentation

- Train operators on safe use, emergency shutdown procedures, and maintenance protocols.

- Maintain records of training, maintenance, and laser safety audits.

- Appoint a Laser Safety Officer (LSO) if required by local regulations (e.g., in the U.S. under ANSI Z136.1).

Environmental & Disposal Compliance

Environmental regulations govern the disposal of laser components and packaging.

Waste Electrical & Electronic Equipment (WEEE)

- In the EU, laser machines fall under WEEE Directive (2012/19/EU). Producers must register and support recycling.

- Provide customers with information on proper end-of-life disposal.

Hazardous Materials

- Some laser components (e.g., certain laser tubes, coolants, or batteries) may contain hazardous substances regulated under RoHS or REACH.

- Follow local disposal guidelines for electronic waste and chemical components.

Recordkeeping & Audits

Maintain comprehensive records to demonstrate compliance.

Required Documentation

- Product certification files (CE, FDA, etc.)

- Export/import documentation (licenses, customs declarations)

- Shipping logs and delivery confirmations

- Training records and maintenance logs

- Incident reports (if any laser exposure or malfunction occurs)

Audit Preparedness

- Conduct periodic internal audits of compliance procedures.

- Be prepared for inspections by regulatory bodies (e.g., FDA, EU market surveillance authorities).

Adhering to this Logistics & Compliance Guide ensures Marcatori Laser products are safely and legally distributed worldwide, protecting both users and the business. Always consult with legal and regulatory experts in target markets for up-to-date requirements.

Conclusion for Sourcing Laser Marking Machines (Marcatori Laser)

Sourcing laser marking machines (marcatori laser) requires a strategic approach that balances technical specifications, production needs, quality standards, and cost efficiency. After evaluating various suppliers, technologies (such as fiber, CO2, and UV lasers), and application requirements (e.g., material type, marking speed, durability), it becomes clear that selecting the right machine involves more than just price comparison.

Key factors to consider include reliability, after-sales service, warranty terms, availability of spare parts, and technical support—especially when sourcing internationally. Machines from established manufacturers in Italy, Germany, Japan, or the USA often deliver high precision and long-term durability, while options from Asian suppliers may offer cost advantages but require careful vetting for quality and support.

Ultimately, the optimal decision depends on the specific industrial application, volume of production, and long-term maintenance strategy. Conducting on-site demonstrations, requesting sample markings, and verifying supplier credentials can mitigate risks. Investing in a high-quality laser marker enhances product traceability, branding, and compliance with industry standards, delivering strong ROI over time.

In conclusion, prioritize supplier reliability and machine performance over initial cost savings. A well-sourced marcatori laser is not just a piece of equipment—it’s a long-term asset for enhancing manufacturing precision and competitiveness.