The global marble slabs market has experienced steady growth over the past decade, driven by rising demand in construction, luxury residential development, and high-end interior design. According to Mordor Intelligence, the global natural stone market — with marble as a leading segment — was valued at USD 37.48 billion in 2022 and is projected to grow at a CAGR of 6.8% from 2023 to 2028. This expansion is fueled by increasing infrastructure investments in emerging economies and a growing preference for premium building materials in both commercial and residential spaces. As demand surges, wholesale manufacturers play a pivotal role in meeting supply needs with consistent quality, large-scale production, and competitive pricing. With key players concentrated in countries like Italy, Turkey, India, and China — known for their rich marble reserves and advanced processing technologies — the competitive landscape is evolving to prioritize sustainability, digital showrooms, and just-in-time logistics. In this context, identifying the top wholesale manufacturers becomes essential for importers, fabricators, and developers aiming to balance cost-efficiency with aesthetic and material excellence.

Top 10 Marble Slabs Wholesale Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Marble of the World: Top Tile and Stone Supplier

Domain Est. 1998

Website: marbleoftheworld.com

Key Highlights: Explore luxury surfaces, exotic stone slabs & gallery-style showrooms. Walk in or schedule a visit in Pompano Beach, Miami or Stuart….

#2 MarbleWarehouse.com

Domain Est. 1998

Website: marblewarehouse.com

Key Highlights: 60-day returnsMarbleWarehouse is the best online store and supplier in USA who offer the best selection of online natural stone marble, tiles, sheet and slab on direct ……

#3 OHM Intl.

Domain Est. 2002

Website: ohmintl.com

Key Highlights: OHM International is a leading natural stone, marble & granite supplier & distributor of high-quality stone surface materials in 9 east coast locations….

#4 StoneContact.com: Stone, Marble, Granite

Domain Est. 2003

Website: stonecontact.com

Key Highlights: Stone portal website(StoneContact.com) is the world leading B2B stone website.We offer abundant stone products, prices, pictures, suppliers, such as marble,…

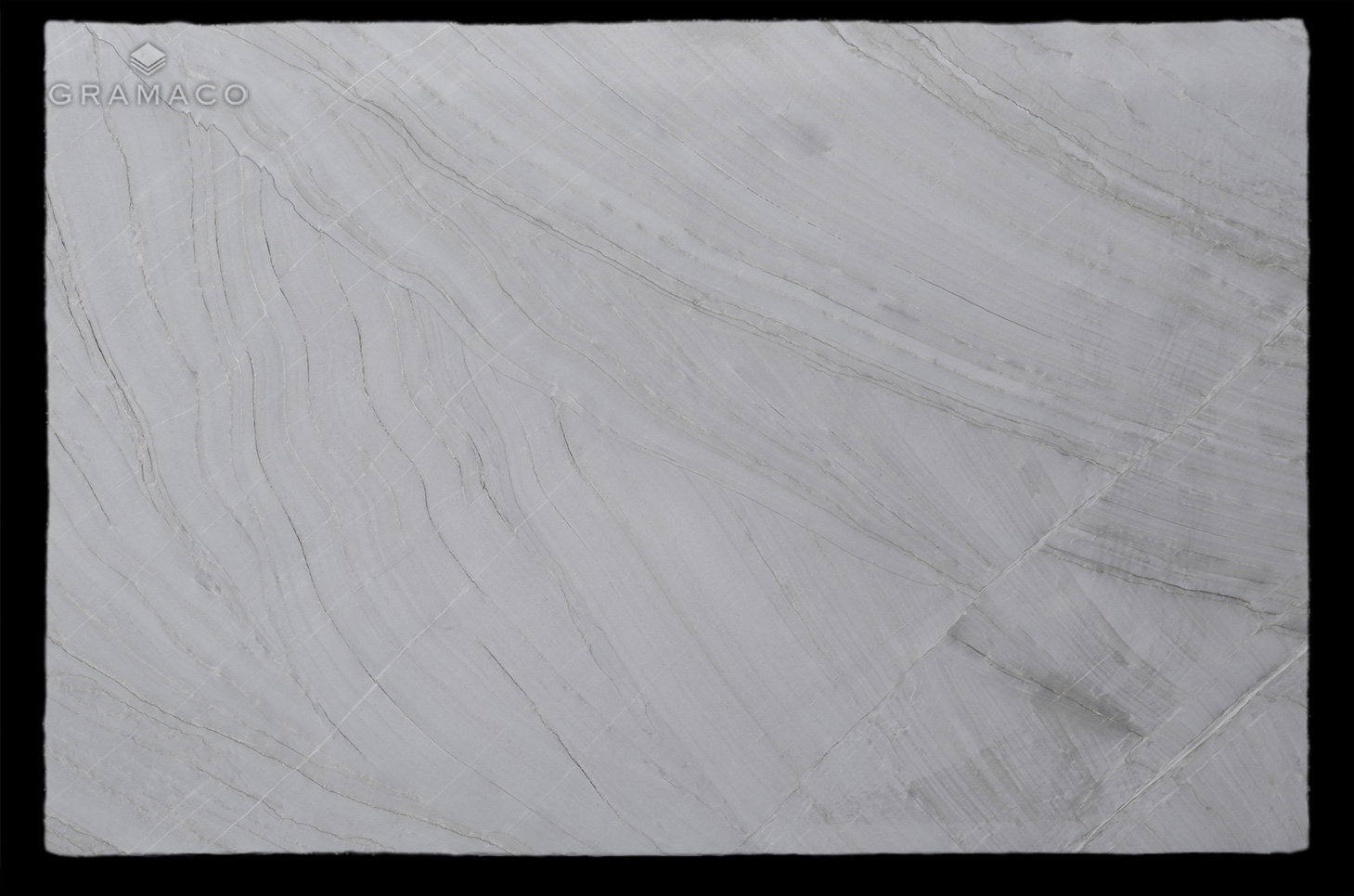

#5 Gramaco

Domain Est. 2003 | Founded: 2005

Website: gramaco.com

Key Highlights: Since 2005, GRAMACO has become a reference in importing and providing the highest quality slabs of natural and engineered stone….

#6 Stone Slabs

Domain Est. 2003

Website: mandarinstone.com

Key Highlights: Mandarin Stone offers a range of pre-cut natural stone slabs perfect for bringing your design ideas to life. Transform into marble tops, pool surrounds and ……

#7 Marble Express

Domain Est. 2007

Website: marbleexpresslv.com

Key Highlights: No one has a better selection of in-stock natural stone than Marble Express. With over 700 types of stones and literally thousands of slabs to choose from….

#8 Verona Marble Company

Domain Est. 2007

Website: vmcstone.com

Key Highlights: We specialize in providing high-quality marble, granite, quartzite, and quartz materials for a variety of residential and commercial projects….

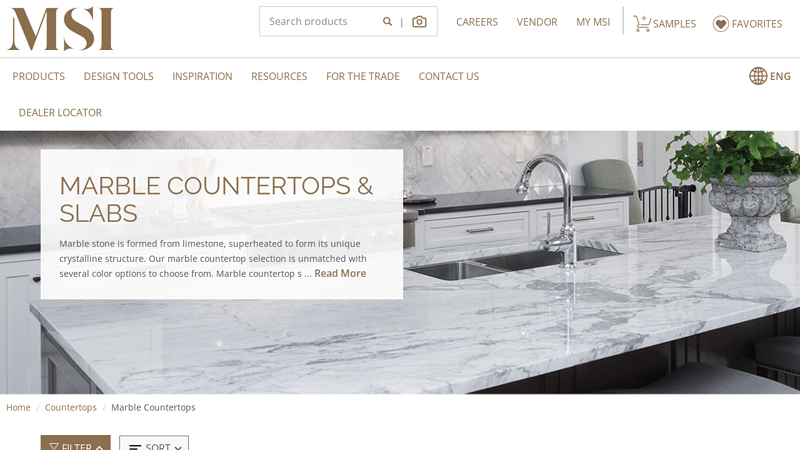

#9 Marble Countertops & Slabs

Domain Est. 2012

Website: msisurfaces.com

Key Highlights: MSI Surfaces is the leading U.S. importer and wholesale supplier of Marble countertops and slabs with a variety of marble colors to choose from….

#10 ARCA WW

Domain Est. 2022

Website: arcaww.com

Key Highlights: Free deliveryStone Slabs ; Calacata Viola Honed 3/4 in Marble Slab. Honed Marble | $110.00 per ; Grand Antique Honed 3/4in Marble Slab BL056025. Honed Marble | $132.00 per ……

Expert Sourcing Insights for Marble Slabs Wholesale

2026 Market Trends for Marble Slabs Wholesale

Rising Demand for Sustainable and Ethically Sourced Materials

By 2026, sustainability will be a dominant driver in the marble slabs wholesale market. End consumers and commercial developers are increasingly demanding transparency in sourcing, favoring suppliers who can verify ethical quarrying practices and low environmental impact. Wholesale distributors that partner with quarries using water recycling systems, renewable energy, and fair labor standards will gain a competitive edge. Certifications such as ISO 14001 and membership in sustainable stone initiatives will become critical differentiators.

Growth in Prefabricated and Engineered Marble Solutions

While natural marble remains popular, the market is seeing accelerated adoption of engineered marble slabs—composites made from marble dust and resin. These products offer greater consistency in color, increased durability, and lower costs. In 2026, wholesalers who diversify their inventory to include high-quality engineered options will meet rising demand from mid-tier residential and hospitality projects where budget and design flexibility are key.

Digital Transformation in B2B Procurement

The wholesale marble trade is embracing digital platforms. By 2026, expect widespread use of AI-powered visualization tools, virtual showrooms, and blockchain-based provenance tracking. Online B2B marketplaces will streamline ordering, allowing architects and contractors to browse, customize, and order slabs remotely. Wholesalers investing in user-friendly digital interfaces, 3D rendering, and real-time inventory systems will outperform traditional players reliant on physical showrooms alone.

Regional Shifts in Supply and Demand

Asia-Pacific, particularly India and China, will remain major suppliers due to cost-effective quarrying and processing. However, geopolitical factors and trade policies may encourage nearshoring in North America and Europe. In 2026, regional distribution hubs in Turkey, Greece, and Brazil will grow in importance. Meanwhile, demand will surge in emerging markets across Southeast Asia and the Middle East, driven by luxury real estate and infrastructure development.

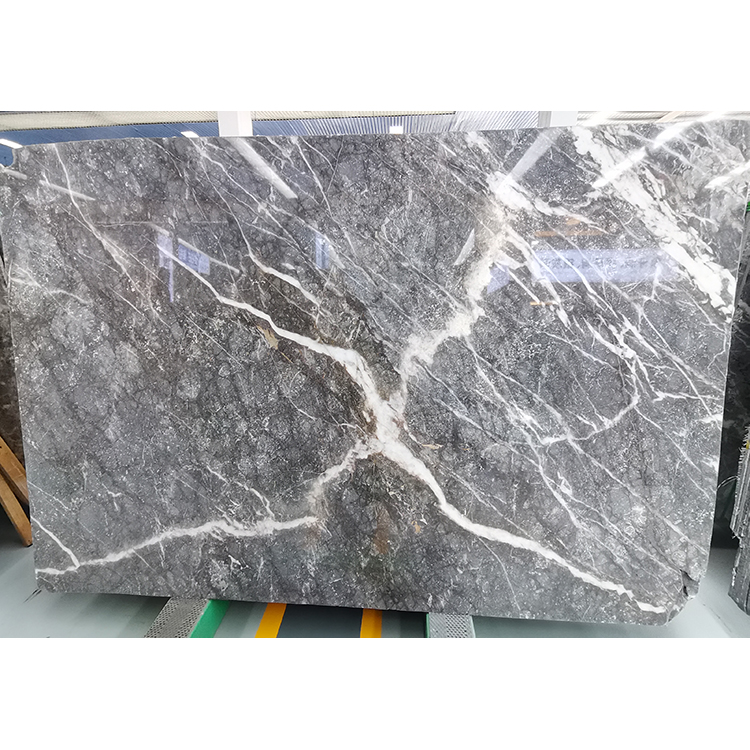

Premiumization and Customization Trends

High-end residential and boutique commercial projects will fuel demand for rare and exotic marble varieties—such as Calacatta Viola, Nero Marquina, and Rosa Beta. Wholesalers offering curated collections, custom finishes (e.g., honed, leathered, filled), and value-added services like templating and fabrication will capture premium margins. Personalization and unique aesthetics will outweigh cost concerns in luxury segments.

Impact of Supply Chain Resilience

Following disruptions from past global events, marble wholesalers in 2026 will prioritize supply chain resilience. This includes diversified sourcing, strategic inventory buffering, and partnerships with logistics providers offering end-to-end tracking. Companies leveraging predictive analytics to anticipate demand fluctuations and mitigate shipping delays will maintain reliability and customer trust.

Conclusion

The 2026 marble slabs wholesale market will be shaped by sustainability, digitalization, and shifting global dynamics. Wholesalers who adapt by embracing ethical sourcing, hybrid product lines, and technology-driven distribution will thrive amid increasing competition and evolving customer expectations.

Common Pitfalls Sourcing Marble Slabs Wholesale (Quality, IP)

Sourcing marble slabs wholesale can offer significant cost advantages, but it comes with risks—particularly concerning quality inconsistencies and intellectual property (IP) issues. Being aware of these pitfalls helps buyers make informed decisions and avoid costly mistakes.

Inconsistent Slab Quality

One of the most prevalent challenges in wholesale marble sourcing is inconsistent quality across slabs. Natural stone varies inherently, but poor grading or lack of transparency from suppliers can lead to unexpected defects.

- Color and Vein Variation: Marble is a natural product, and variations in color, veining, and pattern are common. Some suppliers may not adequately showcase the full range of variation, leading to mismatched slabs in a single project.

- Hidden Defects: Cracks, fissures, pits, and soft spots may not be visible in photos or showroom samples. These flaws can become apparent only after installation, increasing waste and replacement costs.

- Inadequate Grading Standards: Not all suppliers adhere to consistent grading systems. A “Grade A” slab from one vendor might be equivalent to “Grade B” from another, leading to confusion and subpar material.

Lack of Quality Control and Verification

Wholesale suppliers—especially those overseas—may lack rigorous quality control procedures, resulting in damaged or substandard slabs arriving at the job site.

- Improper Packaging and Shipping Damage: Marble slabs are fragile and heavy. Inadequate crating or handling during transit can lead to chipping, cracking, or edge damage.

- No On-Site Inspection Rights: Buyers may not have the opportunity to inspect slabs before shipment, relying solely on photos that may be enhanced or misleading.

- Inconsistent Thickness and Dimensions: Slabs may vary in thickness (e.g., 2cm vs. 3cm), affecting fit and installation, especially in high-precision applications like countertops.

Intellectual Property and Design Infringement Risks

While less obvious, intellectual property concerns can arise when sourcing unique or branded marble patterns, particularly from international suppliers.

- Misrepresentation of Origin and Name: A common issue is the mislabeling of marble types. For example, a slab might be marketed as “Calacatta Gold” but is actually a lower-cost lookalike from a different region. This can mislead clients and damage a designer or contractor’s credibility.

- Trademarked Names and Branding: Names like “Statuario,” “Emperador,” or “Nero Marquina” are often trademarked or associated with specific quarries. Unauthorized use by suppliers can lead to legal complications if misrepresented in marketing or sales.

- Counterfeit or Replicated Patterns: Some suppliers digitally print patterns on lower-grade stone or engineered surfaces and pass them off as genuine rare marbles, especially in wholesale lots. This undermines authenticity and value.

Unreliable Supply Chain and Lead Times

Wholesale sourcing often involves longer and less predictable supply chains, which can impact project timelines.

- Quarry Availability Fluctuations: Natural stone supply depends on active quarrying, which can be affected by weather, political instability, or resource depletion.

- Extended Lead Times: Custom or exotic marbles may take weeks or months to procure and ship, with little flexibility for rush orders.

- Minimum Order Quantities (MOQs): Wholesale suppliers often require large MOQs, making it difficult for smaller projects or businesses to access premium materials without overstocking.

Lack of Traceability and Sustainability Certification

Increasingly, buyers demand transparency regarding the origin and ethical sourcing of materials.

- Unknown Quarry Origins: Without proper documentation, it’s difficult to verify where the marble was extracted, raising concerns about illegal mining or environmental harm.

- No Certification for Sustainability or Labor Practices: Reputable certifications (e.g., ISO, LEED-compliant sourcing) may be absent, exposing buyers to reputational risks.

Conclusion

To mitigate these pitfalls, buyers should:

– Request physical samples and full slabs for review.

– Work with reputable suppliers who provide certificates of authenticity and origin.

– Include quality specifications and inspection clauses in contracts.

– Verify branding and nomenclature to avoid IP issues.

– Consider third-party inspection services for international shipments.

Due diligence is essential when sourcing marble slabs wholesale—balancing cost savings with quality assurance and legal compliance.

Logistics & Compliance Guide for Marble Slabs Wholesale

Overview of Marble Slab Logistics

Marble slabs, due to their weight, fragility, and high value, require specialized handling, transportation, and storage. Effective logistics management ensures slabs arrive intact and on time, minimizing damage and delays. This guide outlines best practices for shipping, handling, documentation, and regulatory compliance in the wholesale marble trade.

Packaging and Crating Standards

Proper packaging is critical to protect marble slabs during transit. Slabs must be crated or bundled securely to prevent chipping, cracking, or scratching.

- Use wooden crates with internal supports and corner protectors.

- Place non-abrasive padding (e.g., foam, bubble wrap) between slabs.

- Seal crates with weather-resistant materials to protect against moisture.

- Label each crate with handling instructions (e.g., “Fragile,” “This Side Up,” “Do Not Stack”).

- Bundle slabs on wooden pallets with steel or plastic strapping when crating is not used.

Transportation and Freight Methods

Selecting the appropriate transportation method ensures cost-efficiency and product safety.

- Flatbed Trucks: Ideal for domestic shipments; slabs must be secured with straps and covered with waterproof tarps.

- Container Shipping (FCL/LCL): Standard for international orders. Use 20′ or 40′ dry containers with proper lashing and blocking.

- Reefer Containers: Required if shipping through extreme climates to avoid thermal shock.

- Specialized Freight Carriers: Partner with carriers experienced in handling heavy stone materials.

Handling and Storage Protocols

Improper handling is a leading cause of slab damage. Follow these protocols at all stages:

- Store slabs vertically in racks at a 5–10 degree angle to prevent bowing.

- Avoid direct ground contact; use pallets or racks to prevent moisture absorption.

- Keep storage areas dry, clean, and free of vibrations.

- Use suction lifters or forklifts with soft rubber pads when moving slabs.

- Limit stacking height; never exceed manufacturer recommendations.

International Trade Compliance

Wholesale marble import/export must comply with international regulations.

- Harmonized System (HS) Code: Use HS 6802.91 or 6802.92 for natural marble blocks and slabs.

- Certificates of Origin: Required for customs clearance and duty determination.

- CITES Compliance: Not typically required for marble, but verify if the stone is sourced from protected geological areas.

- Import/Export Licenses: Obtain necessary permits based on country-specific regulations (e.g., U.S. Customs and Border Protection, EU import rules).

Documentation Requirements

Accurate documentation ensures smooth customs processing and legal compliance.

- Commercial Invoice (with detailed product description, weight, value)

- Packing List (itemized by slab size, quantity, weight, and packaging type)

- Bill of Lading (BOL) or Air Waybill (AWB)

- Certificate of Origin

- Insurance Certificate (recommended for high-value shipments)

- Import Declaration (completed by the buyer or customs broker)

Quality Control and Inspection

Conduct inspections before shipment to maintain compliance and customer satisfaction.

- Verify slab dimensions, thickness, edge finish, and surface quality.

- Check for cracks, pits, or discoloration.

- Use standardized grading (e.g., Premium, Standard, Commercial) consistently.

- Provide digital images or samples upon request.

- Third-party inspection services (e.g., SGS, Bureau Veritas) recommended for large orders.

Environmental and Ethical Sourcing Compliance

Increasingly, customers demand sustainable and ethically sourced materials.

- Source marble from quarries compliant with local environmental regulations.

- Request quarry certifications (e.g., ISO 14001 for environmental management).

- Avoid suppliers involved in illegal mining or deforestation.

- Disclose country of origin and quarry location transparently.

Insurance and Risk Management

Marble shipments are high-risk due to value and fragility.

- Purchase all-risk cargo insurance covering breakage, theft, and transit delays.

- Declare accurate shipment value to avoid underinsurance.

- Include clauses for “warehousing risk” if storage is involved pre-shipment.

- Document all damages immediately upon delivery for claims processing.

Return and Damage Resolution Policy

Establish clear policies for damaged or incorrect shipments.

- Require buyers to inspect and document damage within 24–48 hours of delivery.

- Provide claim forms and photo submission requirements.

- Offer replacement, repair, or refund based on damage severity.

- Retain shipping records and inspection reports for audit purposes.

Recordkeeping and Audit Readiness

Maintain organized records to support compliance and traceability.

- Archive all shipping, customs, and inspection documents for at least 5 years.

- Use digital systems to track batch numbers, origins, and shipment history.

- Prepare for customs audits with readily accessible compliance documentation.

By adhering to this logistics and compliance guide, marble slab wholesalers can ensure safe, legal, and efficient operations across domestic and international markets.

In conclusion, sourcing marble slabs wholesale offers significant advantages for contractors, fabricators, designers, and retailers seeking high-quality natural stone at competitive prices. By partnering with reliable suppliers, buyers can access a diverse range of marble varieties, ensure consistent supply for large projects, and achieve substantial cost savings through bulk purchasing. However, success in wholesale sourcing depends on thorough due diligence—assessing supplier credibility, verifying material quality, understanding logistics and import regulations (if applicable), and considering long-term relationships for better terms and priority access. With careful planning and strategic supplier selection, wholesale marble sourcing can enhance profitability, project quality, and customer satisfaction in the competitive stone and construction markets.