The global marble mesh market has experienced steady growth, driven by rising construction activities and increased demand for high-performance building materials. According to Grand View Research, the global natural stone market—including marble—was valued at USD 34.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A significant portion of this demand stems from the use of marble mesh in enhancing the structural integrity of marble slabs during transportation and installation, particularly in residential and commercial cladding applications. Additionally, Mordor Intelligence projects that infrastructure development in emerging economies, along with modern architectural trends favoring natural stone finishes, will further fuel market expansion through 2028. As demand grows, a select group of manufacturers has risen to prominence by offering durable, flexible, and corrosion-resistant marble mesh solutions that meet stringent industry standards.

Top 7 Marble Mesh Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Marble slabs reinforcement

Domain Est. 1999

Website: gavazzispa.it

Key Highlights: Gavazzi has developed a wide variety of meshes with sophisticated weaving and finishing techniques to ensure optimal bonding with the various types of resins ……

#2 Arizona Tile

Domain Est. 1999

Website: arizonatile.com

Key Highlights: Explore Our Products · Quartzite Slab · Della Terra Quartz Slabs · Marble & Dolomite Slab · Glass Tile · Porcelain & Ceramic Tile · Granite Slab · Kitchen · Bathroom ……

#3 Marble Mesh

Domain Est. 2003

Website: stonecontact.com

Key Highlights: Marble Mesh : You can find out different kinds of Marble Meshwith high quality products at low price, like and so on….

#4 Vertex® Mesh for Marble and Mosaic

Domain Est. 2012

Website: eu.adfors.com

Key Highlights: Vertex® Mesh is commonly used in marble slab reinforcement – by bonding fiberglass mesh to one side of the slab, the material can be strengthened….

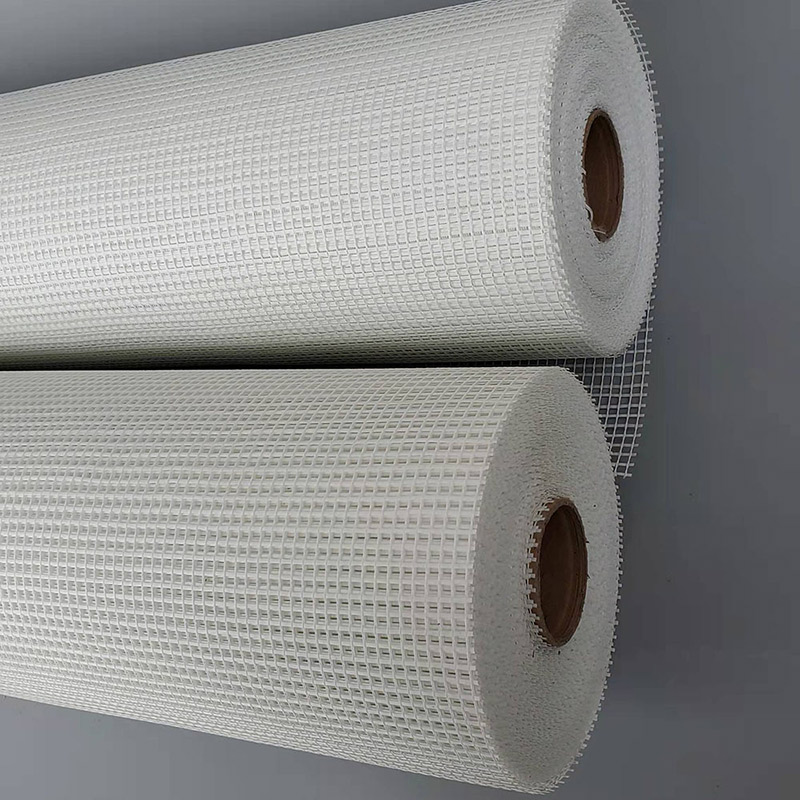

#5 Sinpro Fiberglass mesh for wall or marble reinforcement

Domain Est. 2022

Website: sinpro-fiberglass.com

Key Highlights: Short Description: Fiberglass alkaline resistant mesh is woven by C-glass or E-glass yarn, coated with alkali resistant polymer emulsion….

#6 Marble: A Multimodal World Model

Domain Est. 2023

Website: worldlabs.ai

Key Highlights: Marble can create 3D worlds from text, images, video, or coarse 3D layouts; Marble also lets you interactively edit, expand, and combine worlds….

#7 MarbleRun

Website: edgeless.systems

Key Highlights: MarbleRun is the control plane for confidential computing. Easy-to-use: you can deploy, scale, and verify your confidential microservices on vanilla ……

Expert Sourcing Insights for Marble Mesh

2026 Market Trends for Marble Mesh

The marble mesh market is poised for significant transformation by 2026, driven by evolving architectural aesthetics, sustainability imperatives, and technological advancements. This analysis explores the key trends expected to shape the sector in the coming years.

Growing Demand for Sustainable and Eco-Friendly Materials

Sustainability will be a dominant driver in the 2026 marble mesh market. Architects and developers are increasingly prioritizing low-carbon, recyclable, and responsibly sourced materials. Marble mesh—especially when produced using recycled marble offcuts or bonded with eco-resins—aligns with green building certifications like LEED and BREEAM. Expect heightened demand for suppliers offering transparent sourcing and carbon footprint disclosures, with a shift toward circular economy models in production.

Rise of Digital Fabrication and Customization

Advancements in digital design and fabrication will enable hyper-customization of marble mesh products by 2026. Using CAD/CAM and robotic cutting technologies, manufacturers can offer bespoke patterns, scales, and textures tailored to specific architectural visions. This trend supports the growing preference for unique, statement-making façades and interior features in high-end commercial and residential projects.

Integration with Smart Building Systems

By 2026, marble mesh is expected to evolve beyond aesthetics into functional building components. Integration with smart systems—such as embedded sensors for temperature, humidity, or structural monitoring—will add value. Additionally, marble mesh could be combined with photovoltaic elements or used in ventilated façade systems that enhance energy efficiency, merging natural beauty with intelligent building performance.

Expansion in Commercial and Hospitality Applications

The commercial and hospitality sectors will remain primary adopters of marble mesh in 2026. Its durability, elegance, and versatility make it ideal for lobbies, feature walls, room dividers, and façades in hotels, offices, and retail spaces. The post-pandemic emphasis on biophilic design—incorporating natural materials to enhance well-being—will further boost its appeal in premium developments.

Innovation in Composite and Hybrid Materials

Market growth will be fueled by innovation in composite marble mesh systems. By combining thin marble veneers with high-strength polymer or fiberglass meshes, manufacturers can produce lighter, more flexible, and impact-resistant products. These hybrids reduce structural load and installation costs, making marble mesh viable for retrofitting and high-rise applications where weight is a concern.

Geographic Market Shifts and Emerging Economies

While Europe and North America will maintain strong demand due to renovation projects and high design standards, emerging markets in Asia-Pacific (particularly China, India, and Southeast Asia) and the Middle East will experience accelerated growth. Rapid urbanization, luxury construction booms, and government investments in infrastructure will drive adoption in these regions.

Challenges: Cost and Skilled Labor Shortages

Despite positive trends, the marble mesh market faces challenges. High material and installation costs may limit adoption in budget-sensitive projects. Additionally, the need for specialized labor for precise installation could constrain scalability, especially in regions lacking trained technicians. Automation in production and modular installation systems may help mitigate these issues by 2026.

In summary, the 2026 marble mesh market will be defined by sustainability, technological integration, and design innovation. Companies that invest in eco-conscious production, digital customization, and smart material solutions will be best positioned to capitalize on these emerging opportunities.

Common Pitfalls Sourcing Marble Mesh (Quality, IP)

Sourcing marble mesh—whether referring to fiberglass mesh embedded in marble slabs for reinforcement or decorative mesh used in marble-like finishes—can present several challenges, particularly concerning quality inconsistencies and intellectual property (IP) risks. Being aware of these pitfalls helps ensure you receive a reliable product while avoiding legal complications.

Poor Material Quality and Inconsistent Performance

One of the most frequent issues is receiving marble mesh with substandard materials. Low-quality fiberglass mesh may lack sufficient tensile strength, leading to cracking or delamination in marble slabs during transportation or installation. Additionally, inconsistent resin coating or improper mesh weave can compromise adhesion and structural integrity. Buyers often encounter variations in mesh weight (e.g., 160g/m² vs. 200g/m²), aperture size, and alkali resistance, which directly impact performance. Without clear specifications and third-party testing, it’s easy to end up with a product that fails under real-world conditions.

Misrepresentation of Technical Specifications

Suppliers may exaggerate or falsify product claims, such as stating higher tensile strength, UV resistance, or compatibility with specific resins or adhesives. Some may advertise “premium-grade” or “imported” mesh without providing verifiable test reports (e.g., ISO or ASTM certifications). This misrepresentation can result in material failure, costly project delays, or safety hazards, especially in structural or exterior applications.

Lack of Quality Control and Batch Inconsistencies

Inconsistent manufacturing processes, particularly with overseas suppliers, can lead to significant batch-to-batch variations. One shipment might meet specifications, while the next fails basic performance tests. Absence of rigorous in-house quality control and failure to implement standardized production protocols increase the risk of receiving defective or non-uniform mesh.

Intellectual Property (IP) Infringement Risks

When sourcing marble mesh—especially if it involves proprietary weaves, coating technologies, or branded products—there’s a risk of inadvertently purchasing counterfeit or IP-infringing materials. Some suppliers may replicate patented mesh designs or use protected trademarks without authorization. If your company uses such materials in finished goods, you could face legal liability, product recalls, or damage to your brand reputation. This is particularly prevalent when sourcing from regions with lax IP enforcement.

Inadequate Documentation and Traceability

Many suppliers fail to provide comprehensive documentation, such as material safety data sheets (MSDS), certificates of conformance, or origin tracing. This lack of transparency makes it difficult to verify compliance with industry standards or to address quality issues post-purchase. It also complicates efforts to ensure that the product is free from IP violations.

Failure to Verify Supplier Credentials

Engaging with unverified or uncertified suppliers increases exposure to both quality and IP risks. Without due diligence—such as auditing manufacturing facilities, checking business licenses, or reviewing customer references—buyers may unknowingly partner with counterfeiters or subpar producers.

Conclusion

To mitigate these pitfalls, conduct thorough supplier vetting, demand third-party test reports, specify technical requirements in contracts, and consult legal experts when sourcing proprietary technologies. Ensuring quality and IP compliance from the outset protects your projects, timelines, and brand integrity.

Logistics & Compliance Guide for Marble Mesh

Overview of Marble Mesh Products

Marble mesh refers to reinforced stone mesh sheets composed of natural marble fragments bonded with a polymer resin and supported by a fiberglass or stainless steel backing. These products are widely used in architectural cladding, interior design, and decorative applications due to their durability, flexibility, and aesthetic appeal. This guide provides key logistics and compliance considerations for the safe and legal handling, transportation, and installation of marble mesh products.

Regulatory Compliance Requirements

Compliance with international, national, and regional regulations is essential when distributing marble mesh. Key regulatory areas include:

– REACH (EU): Ensure that resins and binders used in the mesh comply with registration, evaluation, and restriction of chemical substances.

– LEED and GREENGUARD Certification: Verify low VOC emissions for indoor applications to support sustainable building standards.

– Building Codes (e.g., IBC, NFPA 285): Confirm flame spread and smoke development ratings appropriate for installation environments.

– Import/Export Regulations: Declare accurate HS codes (typically under 6810 or 6802 for artificial stone or marble制品) and comply with customs documentation, including Certificates of Origin and Material Safety Data Sheets (MSDS).

Packaging and Handling Guidelines

Proper packaging minimizes damage during transit:

– Rolls or panels should be wrapped in waterproof, UV-resistant plastic with corner protectors.

– Palletized loads must be securely strapped and labeled with handling instructions (e.g., “Fragile,” “This Side Up”).

– Avoid direct ground contact; use pallets and store indoors or under cover if held in temporary storage.

– Handle with mechanical aids (e.g., forklifts) to prevent edge chipping or mesh tearing.

Transportation and Freight Considerations

- Mode of Transport: Marble mesh is typically shipped via containerized ocean freight (FCL/LCL), air freight for urgent orders, or ground transport for regional distribution.

- Weight and Dimensions: Standard rolls range from 1.2m to 1.5m wide and up to 50m in length; pallet weights vary between 30–60 kg. Confirm carrier weight limits and loading constraints.

- Temperature & Humidity: Avoid extreme temperatures (>40°C or <0°C) and high humidity to prevent resin degradation or adhesive failure.

- Insurance: Shipments should be fully insured against damage, loss, or delay, especially for high-value architectural projects.

Documentation and Traceability

Maintain accurate documentation throughout the supply chain:

– Commercial Invoice, Packing List, and Bill of Lading/Air Waybill

– MSDS/SDS (Safety Data Sheet) for resin components

– Certificate of Compliance (CoC) for material quality and regulatory adherence

– Batch traceability logs for quality control and recalls, if necessary

Installation and On-Site Compliance

- Only trained personnel should install marble mesh using manufacturer-recommended adhesives and substrates.

- Conduct site inspections to ensure substrate stability, moisture levels, and environmental conditions meet specifications.

- Follow fire-rated assembly guidelines if used in commercial or high-rise buildings.

- Dispose of off-cuts and packaging in accordance with local waste regulations (e.g., non-hazardous construction waste).

Environmental and Sustainability Practices

- Optimize shipping routes to reduce carbon footprint.

- Use recyclable or reusable packaging materials where possible.

- Partner with suppliers who adhere to responsible quarrying and resin sourcing practices.

- Support end-of-life recycling programs for composite stone materials where available.

Audits and Continuous Improvement

- Conduct annual compliance audits to verify adherence to safety, environmental, and quality standards.

- Maintain records of training, incident reports, and supplier certifications.

- Update logistics protocols in response to regulatory changes or new project requirements.

By following this guide, stakeholders in the marble mesh supply chain can ensure safe, compliant, and efficient operations from production to installation.

Conclusion for Sourcing Marble Mesh:

Sourcing high-quality marble mesh is a critical step in ensuring the durability, structural integrity, and aesthetic finish of marble installations. After evaluating suppliers, material specifications, pricing, and logistical considerations, it is evident that selecting a reliable and experienced provider is essential. Key factors such as mesh tensile strength, compatibility with adhesives and setting materials, resistance to moisture and alkaline environments, and adherence to international standards (e.g., ISO, ASTM) must be prioritized.

Additionally, sustainability, ethical sourcing practices, and timely delivery play an increasingly important role in supplier selection. By establishing strong partnerships with reputable manufacturers—preferably those offering technical support and product consistency—project stakeholders can minimize risks such as breakage, delamination, or installation failure.

In conclusion, a strategic and well-researched approach to sourcing marble mesh not only enhances the performance and longevity of marble applications but also contributes to cost-efficiency and overall project success. Continuous evaluation and quality control throughout the supply chain are recommended to maintain high standards in both residential and commercial stone projects.