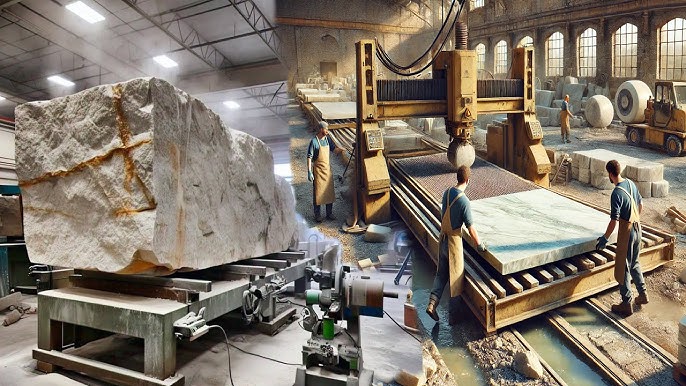

The global stone processing machinery market, driven by rising demand in construction and architectural applications, is projected to grow at a CAGR of 4.8% from 2023 to 2028, according to Mordor Intelligence. A key component within this sector is the marble cutting machine segment, which has seen increased adoption due to advancements in precision engineering and automation. With marble retaining its prominence in high-end interior design and infrastructure projects, the need for efficient, durable, and technologically advanced marble cutters has surged. This growth is further supported by expanding urbanization and infrastructure development in regions like Asia-Pacific and the Middle East. As demand intensifies, a handful of manufacturers have emerged as industry leaders, combining innovation, reliability, and scalable production to dominate the competitive landscape. Based on market presence, technological capabilities, and global reach, the following six companies represent the forefront of marble cutter manufacturing today.

Top 6 Marble Cutter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 1550W High Power 110mm Marble Cutter

Domain Est. 2012

Website: kynko.com.cn

Key Highlights: KD75 is KYNKO new generation 110MM Marble Cutter with 1550W strong power and new technology. No water spray during operation. More convenient for operation….

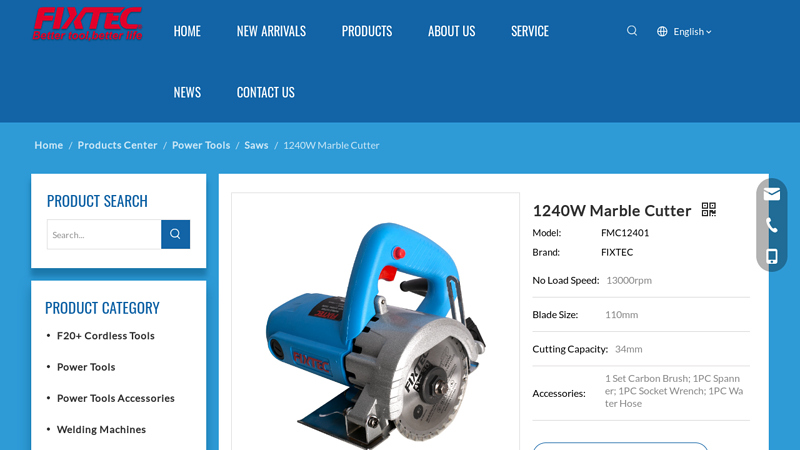

#2 1240W Marble Cutter

Domain Est. 2014

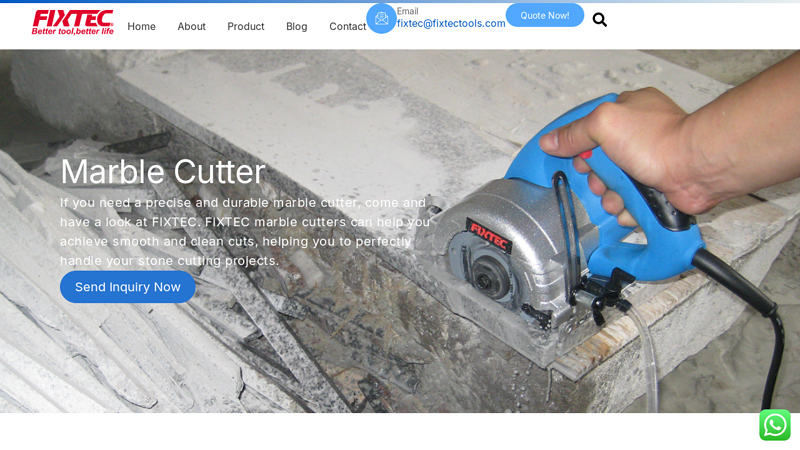

Website: fixtectools.com

Key Highlights: This 1240W Marble Cutter can be used in construction, renovation site, stone factory and road maintenance. Ready stock for rapid delivery….

#3 Marble tile cutters

Domain Est. 1996

Website: rubi.com

Key Highlights: RUBI’s DCX-250 Xpert range of professional cutters is designed for intensive cutting of porcelain stoneware tiles (BIA) and any other type of ceramic tile….

#4 Cutting Machines

Domain Est. 2019

Website: ibelltools.com

Key Highlights: Free deliveryiBELL gets you the most advanced Marble Cutter for cutting different types of materials like marble, wood, etc. Its ergonomic design facilitates g… View ……

#5 Marble Cutter

Domain Est. 2021

Website: delitoolsglobal.com

Key Highlights: Ideal for cutting marble, granite, ceramic, and other hard stone materials, DELI marble cutter is widely used in tile shaping, countertop fabrication, ……

#6 Marble Cutter

Website: fixtectool.com

Key Highlights: A marble cutter is a power tool designed for precision cutting of marble, granite, and tile. Equipped with a powerful motor and diamond blade, it delivers….

Expert Sourcing Insights for Marble Cutter

H2: 2026 Market Trends for Marble Cutters

The marble cutter market in 2026 is poised for significant transformation, driven by technological innovation, evolving industry demands, and sustainability imperatives. Here’s a comprehensive analysis of the key trends shaping the sector:

1. Automation and Smart Technology Integration

By 2026, automation will be a cornerstone of marble processing. Advanced CNC (Computer Numerical Control) marble cutters with AI-driven optimization algorithms will dominate, enabling precision cuts, reduced waste, and minimal human intervention. Integration with IoT platforms allows for real-time monitoring of machine performance, predictive maintenance, and remote diagnostics—boosting operational efficiency and reducing downtime.

2. Increased Demand for Precision and Customization

Architectural and interior design trends continue to favor bespoke stone elements. This drives demand for marble cutters capable of intricate detailing, complex geometries, and high repeatability. Multi-axis cutting systems and waterjet technologies will gain traction, allowing manufacturers to produce custom countertops, flooring, and decorative panels with minimal error margins.

3. Sustainability and Energy Efficiency

Environmental regulations and consumer awareness are pushing manufacturers toward greener solutions. Marble cutters in 2026 will feature improved dust suppression systems, water recycling units, and energy-efficient motors. The industry will increasingly adopt circular practices, including recycling marble slurry into construction materials, reducing the environmental footprint of stone fabrication.

4. Growth in Emerging Markets

Regions like Southeast Asia, the Middle East, and parts of Africa are witnessing rapid urbanization and infrastructure development, fueling demand for natural stone in construction and luxury interiors. This expansion will boost the adoption of mid-range and entry-level marble cutters, leading to localized production and after-sales service networks.

5. Digitalization of Design and Production Workflows

The integration of CAD/CAM software with marble cutting machinery will streamline the design-to-production pipeline. Designers will be able to simulate cuts and layouts digitally before production, minimizing material waste and accelerating project timelines. Cloud-based platforms will enable seamless collaboration between architects, fabricators, and clients.

6. Focus on Operator Safety and Ergonomics

Regulatory standards and corporate responsibility will drive the development of safer machines. Features such as automated loading/unloading systems, enhanced guarding, real-time safety alerts, and ergonomic control panels will become standard, reducing workplace injuries and improving user experience.

7. Rise of Hybrid and Compact Systems

To meet the needs of small to medium enterprises (SMEs), compact and hybrid marble cutters—combining sawing, polishing, and drilling functions—will gain popularity. These modular systems offer flexibility, lower capital investment, and space efficiency without compromising on output quality.

Conclusion

By 2026, the marble cutter market will be defined by intelligent, sustainable, and highly adaptive machinery. Companies that invest in digital integration, eco-friendly technologies, and customer-centric innovation will lead the market, while traditional operators risk obsolescence without modernization. The convergence of precision, efficiency, and environmental responsibility will shape the future of stone fabrication.

Common Pitfalls When Sourcing a Marble Cutter (Quality and IP)

Sourcing a marble cutter—especially from international suppliers—can introduce significant risks related to product quality and intellectual property (IP) protection. Being aware of these pitfalls helps avoid costly mistakes, production delays, and legal complications.

Poor Build Quality and Material Substitution

One of the most frequent issues is receiving marble cutters made with substandard materials or inferior craftsmanship. Some suppliers may use low-grade motors, bearings, or steel frames that wear out quickly under heavy use. Components such as blades or dust extraction systems may also be undersized or poorly engineered, leading to inconsistent cuts, frequent breakdowns, and safety hazards.

Tip: Request detailed specifications, conduct factory audits, and insist on sample testing before bulk orders.

Inaccurate or Inconsistent Cutting Performance

Marble requires precision cutting to minimize waste and ensure smooth finishes. Low-quality machines may suffer from vibration, misalignment, or weak motor power, resulting in chipped edges, uneven surfaces, or inaccurate dimensions. This undermines the final product quality and increases material waste.

Tip: Verify machine calibration standards and request test-cut samples using your specific marble type.

Misrepresentation of Technical Specifications

Suppliers may exaggerate performance metrics such as cutting speed, depth, motor power (e.g., real vs. peak power), or IP (Ingress Protection) ratings. For instance, a machine advertised as “IP55” might not actually be tested or certified to that standard, leaving it vulnerable to dust and water damage in wet workshop environments.

Tip: Ask for third-party certification reports and conduct on-site verification of IP ratings.

Lack of Genuine Intellectual Property (IP) Compliance

Many marble cutter designs, especially advanced CNC models, are protected by patents, trademarks, or copyrights. Sourcing from suppliers who copy or reverse-engineer branded equipment can expose your business to legal liability, including customs seizures, fines, or lawsuits in your home market.

Tip: Conduct IP due diligence—verify original design rights and request proof of licensing if applicable.

Use of Counterfeit or Unauthorized Components

Some machines incorporate counterfeit motors, control systems, or safety devices that fail to meet international safety standards (e.g., CE, UL). These components not only compromise reliability but also create liability risks in case of accidents.

Tip: Require documentation for key components and perform compliance checks with certification bodies.

Inadequate After-Sales Support and Spare Parts Availability

Even high-quality machines require maintenance. Suppliers may disappear after delivery or fail to provide technical support, manuals, or spare parts. This leads to prolonged downtime and increased operational costs.

Tip: Negotiate service agreements and confirm spare parts inventory before finalizing the purchase.

Hidden Costs from Non-Compliant Equipment

Machines that don’t meet regional safety or environmental standards may be blocked at customs or require expensive retrofits. For example, a marble cutter lacking proper dust suppression may violate OSHA or EU workplace regulations.

Tip: Ensure the machine complies with the target market’s regulatory requirements before shipping.

By addressing these pitfalls proactively—through due diligence, clear contracts, and third-party verification—you can source a reliable, high-performance marble cutter while protecting your business from quality failures and IP risks.

Logistics & Compliance Guide for Marble Cutter

This guide outlines key logistics considerations and compliance requirements for the transportation, handling, and import/export of marble cutting equipment, such as bridge saws, CNC marble cutters, and handheld marble cutting tools.

Product Classification and Harmonized System (HS) Codes

Identify the correct HS code for your marble cutter to ensure accurate customs declarations and tariff assessments. Typical classifications may fall under:

- HS 8464: Machines for working stone, ceramics, or concrete (e.g., sawing, cutting, milling).

- Specific subcodes may vary by country (e.g., 8464.20 for stone sawing machines in the U.S.).

- Confirm classification with local customs authorities or a licensed customs broker.

Packaging and Handling Requirements

Marble cutters are heavy, precision machinery requiring secure packaging:

- Use wooden crates or reinforced pallets with shock-absorbing materials.

- Secure all moving parts and blades to prevent damage during transit.

- Clearly label packages with “Fragile,” “This Side Up,” and weight indicators.

- Include handling instructions to prevent tipping or improper lifting.

Shipping and Transportation

Select appropriate freight methods based on equipment size and destination:

- Sea Freight: Recommended for large industrial cutters; use FCL (Full Container Load) or break-bulk for oversized units.

- Air Freight: Suitable for urgent shipments of smaller units or spare parts; higher cost but faster delivery.

- Land Freight: Use for regional distribution; ensure vehicles have proper lifting equipment (e.g., forklifts, cranes).

- Choose carriers experienced in heavy machinery logistics.

Import and Export Documentation

Ensure all required documentation is complete and accurate:

- Commercial Invoice

- Packing List

- Bill of Lading (or Air Waybill)

- Certificate of Origin

- Import/Export License (if required by country)

- Equipment Compliance Certificates (e.g., CE, UL)

- Dangerous Goods Declaration (if applicable for batteries or coolant)

Regulatory Compliance

Meet safety and environmental standards in both origin and destination countries:

- CE Marking: Required for sale in the European Economic Area (EEA); confirms compliance with EU health, safety, and environmental standards.

- UL/CSA Certification: Required in the U.S. and Canada for electrical safety.

- RoHS and REACH Compliance: Ensure materials used meet EU restrictions on hazardous substances.

- EPA and OSHA Standards: U.S. requirements for emissions and workplace safety.

Customs Duties and Taxes

- Research applicable import duties, VAT, or GST in the destination country.

- Leverage free trade agreements (e.g., USMCA, EU free trade pacts) if eligible.

- Use a customs broker to calculate landed costs and manage duty payments.

Installation and On-Site Compliance

- Provide installation guidelines and safety manuals in the local language.

- Ensure compliance with local electrical codes and workplace safety regulations (e.g., noise levels, dust extraction).

- Offer training or certification for operators where required by local law.

Warranty and After-Sales Service Logistics

- Establish a service network or partner with local technicians for maintenance and repairs.

- Ship spare parts efficiently using tracked courier services.

- Maintain compliance with local consumer protection laws regarding warranties.

Environmental and Disposal Regulations

- Comply with WEEE (Waste Electrical and Electronic Equipment) directives in the EU for end-of-life equipment.

- Provide guidance for proper disposal of blades, coolants, and electronic components.

Adhering to this logistics and compliance guide ensures smooth international operations, reduces delays, and supports long-term market success for marble cutter products.

Conclusion on Sourcing a Marble Cutter:

After thorough evaluation of available options, it is evident that sourcing a marble cutter requires careful consideration of cutting technology, material specifications, production capacity, and total cost of ownership. Whether choosing a semi-automatic bridge saw, a CNC stone processing machine, or a handheld tile cutter, the selection should align with the specific demands of the project—be it precision, volume, or versatility.

Key factors such as blade quality, machine durability, supplier reputation, after-sales support, and compliance with safety standards play a crucial role in ensuring long-term efficiency and operational safety. Sourcing from reputable manufacturers, preferably with proven experience in stone processing equipment, will help minimize downtime and maintenance issues.

In conclusion, investing in a reliable and appropriately sized marble cutter—sourced from a trusted supplier—will enhance productivity, improve cut quality, and deliver a strong return on investment. Future-proofing the procurement with scalability and technological advancements in mind ensures adaptability to evolving project requirements.