The global solar photovoltaic (PV) market is experiencing robust expansion, driven by declining technology costs, supportive government policies, and increasing demand for clean energy. According to Grand View Research, the global solar panel market size was valued at USD 157.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.9% from 2024 to 2030. This surge is further bolstered by rising energy security concerns and the urgent need to reduce carbon emissions. Mordor Intelligence forecasts similar momentum, anticipating continued growth as utility-scale installations and residential adoption accelerate across North America, Europe, and Asia-Pacific. With over 1,000 GW of solar capacity now installed worldwide—and increasing—selecting high-performance, reliable solar panels has never been more critical. As the market evolves, a select group of manufacturers are leading innovation, scalability, and quality, shaping the future of solar energy. Here are the top 10 solar panel manufacturers driving this transformation.

Top 10 Of Solar Panels Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Boviet Solar

Domain Est. 2017

Website: bovietsolar.com

Key Highlights: Boviet Solar is a solar energy technology company specializing in manufacturing top-performing solar PV modules for solar projects….

#2 Solar panel manufacturer, trusted since 1996

Domain Est. 2004

Website: recgroup.com

Key Highlights: REC Group is a solar panel manufacturer, trusted for almost three decades. Since its founding in 1996, REC has been a true pioneer in the solar industry….

#3 Suniva

Domain Est. 2005 | Founded: 2007

Website: suniva.com

Key Highlights: Suniva is America’s oldest and largest monocrystalline solar cell manufacturer in North America. Suniva was founded in 2007….

#4 Illuminate USA

Domain Est. 2019

Website: illuminateusa.com

Key Highlights: Illuminate USA is the largest single-site solar panel manufacturer in North America, using advanced manufacturing to supply the American solar market….

#5 First Solar

Domain Est. 1999

#6 Solar Manufacturing Map

Domain Est. 1999

Website: energy.gov

Key Highlights: This map provides information about all of the solar photovoltaic (PV) manufacturing facilities in the United States and how they contribute to the solar ……

#7 Canadian Solar

Domain Est. 2001

Website: canadiansolar.com

Key Highlights: Over 20 solar & energy storage manufacturing facilities. in Asia & Americas. Canadian Solar closely examines our supply chains to ensure goods imported are ……

#8 PowerFilm Solar

Domain Est. 2005

Website: powerfilmsolar.com

Key Highlights: PowerFilm designs and manufactures custom solar cells, panels, and power solutions for energy harvesting, portable, and remote power applications….

#9 Heliene

Domain Est. 2009

Website: heliene.com

Key Highlights: We manufacture high quality solar photovoltaic modules in our American facilities. The supply chains are short, and our modules are never held up in port or ……

#10 Silfab Solar

Domain Est. 2023

Website: silfabsolarsc.com

Key Highlights: Bringing new high-skilled jobs and opportunities to York County with our state-of-the-art cell and solar panel manufacturing facility. WHO WE ARE….

Expert Sourcing Insights for Of Solar Panels

H2: Solar Panel Market Trends in 2026

As the global push toward clean energy intensifies, the solar panel market in 2026 is shaped by rapid technological advancements, evolving policy landscapes, and shifting economic dynamics. This analysis explores the key trends driving the solar industry during this pivotal year.

1. Cost Parity and Grid Competitiveness

By 2026, solar photovoltaic (PV) systems have reached or surpassed grid parity in most regions worldwide. The levelized cost of electricity (LCOE) for utility-scale solar continues to decline, averaging $0.02–$0.04 per kWh in favorable geographies. Technological improvements in manufacturing, reduced balance-of-system (BOS) costs, and economies of scale have contributed to solar becoming the lowest-cost source of new electricity generation in over 90 countries.

2. Advancements in PV Technology

Solar panel efficiency has seen significant gains, with mainstream commercial panels achieving 22–24% efficiency. The market increasingly adopts next-generation technologies:

- Perovskite-Silicon Tandem Cells: Commercialized at scale in 2025, these tandem modules now deliver over 30% efficiency in real-world applications, with major manufacturers like LONGi and Oxford PV leading deployment.

- Bifacial Modules: Now standard in utility-scale projects, bifacial panels increase energy yield by up to 15% by capturing reflected light.

- Thin-Film Innovations: Flexible and lightweight solar solutions gain traction in building-integrated photovoltaics (BIPV) and transportation applications.

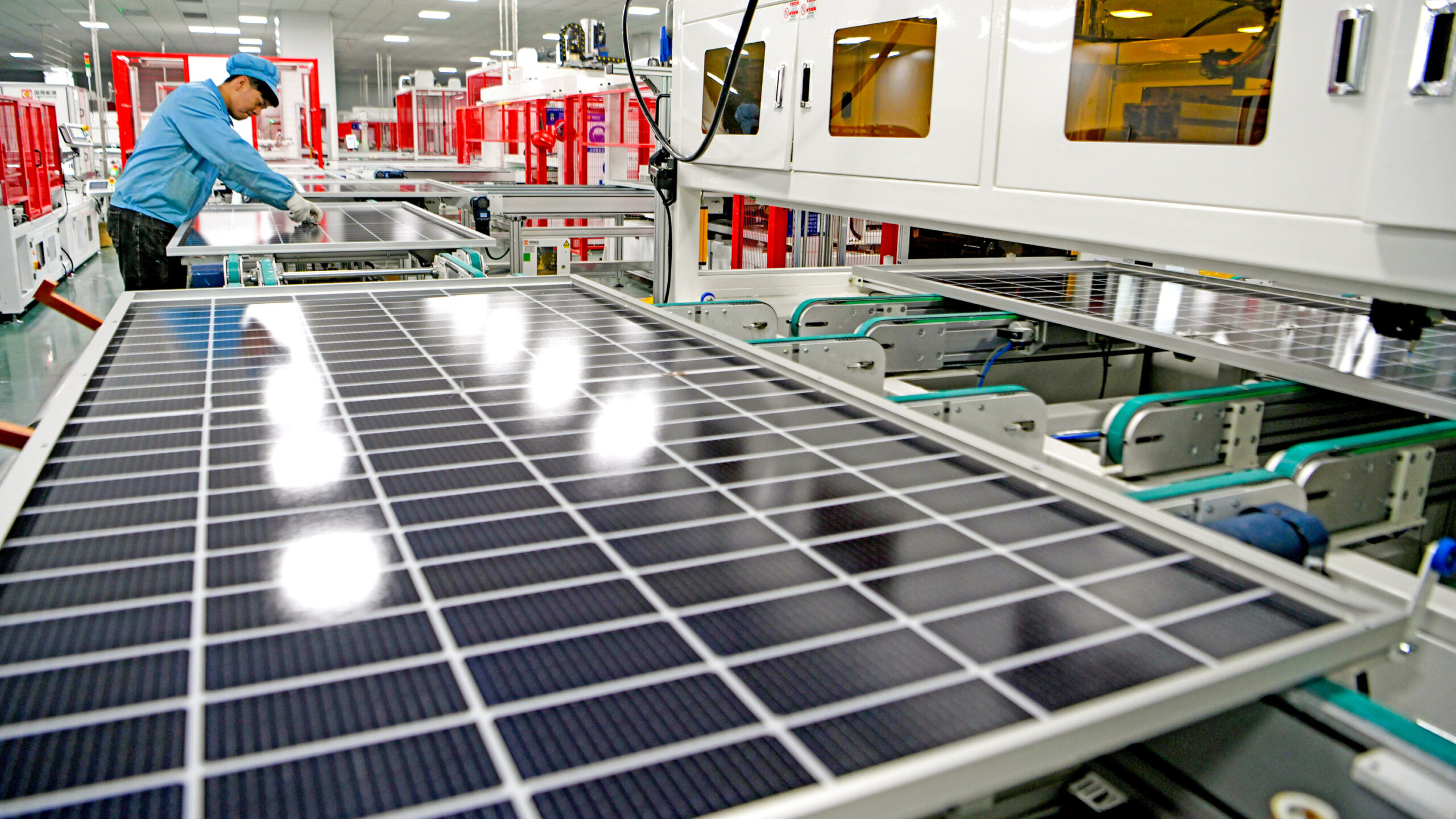

3. Supply Chain Resilience and Regionalization

Geopolitical concerns have accelerated the regionalization of solar manufacturing. In 2026:

- The U.S. and European Union have significantly expanded domestic PV manufacturing capacity, driven by incentives like the U.S. Inflation Reduction Act (IRA) and the EU Green Deal Industrial Plan.

- China remains the dominant producer, but its global market share has decreased from over 80% in 2023 to around 65%, as India, Southeast Asia, and North Africa emerge as key manufacturing hubs.

- Supply chains are more diversified, with increased transparency and traceability to comply with environmental, social, and governance (ESG) standards.

4. Policy and Regulatory Support

Government policies remain a key catalyst:

- Over 130 countries have strengthened renewable energy targets under updated Nationally Determined Contributions (NDCs), with solar accounting for over 60% of new renewable capacity.

- Net metering reforms and dynamic pricing models in markets like California, Germany, and Australia are improving grid integration and rewarding prosumers.

- Carbon pricing mechanisms and renewable portfolio standards (RPS) have made solar investments more attractive across commercial and industrial sectors.

5. Rise of Solar-Plus-Storage Systems

The integration of solar with energy storage is now the default for new residential and commercial installations. Falling battery costs—lithium-ion prices have dropped to $60–$80/kWh—make solar-plus-storage economically viable even in regions with less solar irradiance. Virtual power plants (VPPs) and peer-to-peer (P2P) energy trading platforms are growing, enhancing grid stability and consumer empowerment.

6. Sustainability and Recycling

End-of-life management has become a critical focus. In 2026, the first wave of early solar installations is reaching decommissioning age, prompting:

- Mandatory recycling policies in the EU and several U.S. states.

- Advancements in panel recycling technologies that recover over 95% of glass, aluminum, and silicon.

- Increased demand for low-carbon, recyclable solar panels, influencing procurement decisions.

7. Emerging Applications and Markets

Beyond rooftops and solar farms, solar panels are finding new applications:

- Agrivoltaics: Dual-use solar farms that combine agriculture with energy generation are expanding in Europe, Japan, and the U.S., improving land-use efficiency.

- Floating Solar (FPV): With over 20 GW installed globally, floating PV on reservoirs and lakes mitigates land constraints and reduces evaporation.

- Solar in Developing Economies: Off-grid and mini-grid solar solutions are powering rural electrification in Sub-Saharan Africa and South Asia, supported by international climate finance.

Conclusion

The solar panel market in 2026 is characterized by maturity, innovation, and global scalability. With solar firmly established as a cornerstone of the energy transition, continued investment in R&D, supply chain resilience, and supportive policy frameworks will be essential to sustain growth and meet net-zero targets by 2050.

Common Pitfalls in Sourcing Solar Panels: Quality and Intellectual Property (IP) Concerns

When sourcing solar panels, especially for large-scale projects or commercial distribution, buyers often face significant challenges related to product quality and intellectual property (IP) risks. Failing to address these issues can lead to performance shortfalls, financial losses, legal disputes, and reputational damage. Below are the most common pitfalls in these two critical areas.

Quality-Related Pitfalls

1. Inconsistent Manufacturing Standards

Many solar panel manufacturers, particularly in regions with less stringent regulatory oversight, may not adhere to international quality standards such as IEC 61215 (performance) or IEC 61730 (safety). Panels from such sources often exhibit inconsistent cell quality, poor lamination, or inadequate weather resistance, leading to premature degradation.

2. Overstated Performance Specifications

Some suppliers inflate key performance metrics such as wattage, efficiency, and temperature coefficients. These exaggerated claims may look attractive on paper but result in underperforming installations that fail to meet energy production expectations.

3. Use of Recycled or Substandard Materials

Low-cost panels may incorporate recycled silicon cells, degraded encapsulants, or inferior frame materials. These components compromise durability and long-term reliability, increasing the risk of delamination, microcracks, and power output loss over time.

4. Lack of Third-Party Certification

Panels without certifications from recognized bodies like TÜV Rheinland, UL, or Intertek may not have undergone rigorous testing. Skipping certification checks opens the door to counterfeit or non-compliant products that pose safety hazards and may void system warranties.

5. Inadequate Warranty and Support

Some suppliers offer attractive warranties on paper but lack the financial stability or service infrastructure to honor them. Ambiguous warranty terms—such as prorated coverage or exclusion of labor costs—can leave buyers exposed to unexpected repair expenses.

Intellectual Property (IP) Pitfalls

1. Risk of Infringing Patented Technology

Solar panel designs, cell architectures (e.g., PERC, TOPCon), and manufacturing processes are often protected by patents. Sourcing from suppliers that use patented technology without proper licensing exposes buyers to legal liability, import bans, or forced product recalls.

2. Counterfeit or Cloned Products

Some manufacturers produce panels that closely mimic branded models, copying外观 (appearance), labeling, and even serial number formats. These counterfeit products not only violate IP rights but also lack reliability and traceability, posing significant risks to project integrity.

3. Unclear Ownership of Design and Technology

When working with OEM or private-label suppliers, buyers may assume they have rights to the product design or technology. However, without explicit agreements, the supplier may retain all IP rights, limiting customization, resale, or innovation downstream.

4. Exposure to Trade Sanctions and IP-Related Import Restrictions

Countries like the United States have imposed import restrictions (e.g., Uyghur Forced Labor Prevention Act) on solar products linked to certain regions or companies with IP or ethical violations. Sourcing without due diligence can result in shipment seizures or compliance penalties.

5. Lack of Transparency in Supply Chain

Complex supply chains can obscure the origins of cells and components. Panels assembled in one country may contain cells or technology sourced from IP-infringing manufacturers elsewhere, creating indirect liability for the buyer.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Require verified third-party certifications and test reports.

– Conduct factory audits and sample testing.

– Perform IP due diligence, including patent landscape reviews.

– Use legally binding contracts that specify quality, warranty, and IP rights.

– Partner with reputable suppliers and legal experts familiar with international trade regulations.

By proactively addressing quality and IP concerns, organizations can ensure reliable performance, regulatory compliance, and long-term success in their solar energy initiatives.

Logistics & Compliance Guide for Solar Panels

Transporting and installing solar panels involves careful planning to ensure safety, regulatory compliance, and efficiency. This guide outlines key considerations across logistics and compliance for solar panel shipments and deployments.

Transportation and Handling

Solar panels are fragile and must be handled with care during transit. Always ship panels in their original packaging or approved protective enclosures to prevent cracking or delamination. Panels should be transported vertically, secured firmly to prevent movement, and shielded from moisture, extreme temperatures, and direct sunlight. Use vehicles equipped with suspension systems suitable for delicate cargo, and avoid stacking heavy items on top of solar panel crates.

Packaging and Labeling Requirements

Proper packaging is essential to prevent damage. Each panel must be individually wrapped with corner protectors and placed in sturdy cardboard or wooden crates. Crates should be clearly labeled with “Fragile,” “This Side Up,” and “Do Not Stack” markings. Include essential shipping information such as model number, wattage, serial numbers, and quantity. Labels must be durable and resistant to weather conditions during transit.

Import and Export Regulations

Solar panels shipped internationally are subject to import/export controls. Ensure compliance with International Trade Commission (ITC) regulations and anti-dumping duties where applicable (e.g., tariffs on panels from certain countries). Obtain necessary export documentation, including commercial invoices, packing lists, and a bill of lading. Verify destination country requirements—some may require conformity assessments or certifications like CE (Europe), CCC (China), or INMETRO (Brazil).

Customs Clearance and Duties

Work with a licensed customs broker to facilitate smooth clearance. Provide Harmonized System (HS) codes for solar panels (typically 8541.40) to determine applicable tariffs and duties. Maintain detailed records of component origins—many countries offer reduced tariffs for panels made with locally sourced materials or under trade agreements (e.g., USMCA). Be prepared for customs inspections, particularly for large commercial shipments.

Safety and Environmental Compliance

Solar panels contain materials regulated under environmental laws. While most modern panels are lead-free or low-lead, compliance with RoHS (Restriction of Hazardous Substances) in the EU and similar regulations elsewhere is required. Ensure proper handling procedures are in place for damaged panels, which may release small amounts of toxic substances. Follow local regulations for disposal or recycling at end-of-life under WEEE (Waste Electrical and Electronic Equipment) directives.

Installation and Local Permitting

Before installation, secure necessary permits from local authorities. Building departments typically require structural assessments, electrical plans, and compliance with the National Electrical Code (NEC) in the U.S. or IEC standards internationally. Submit system designs for grid interconnection approval with utility providers. Inspections are usually required post-installation to verify code compliance and safety.

Certification and Standards

Solar panels must be certified by accredited bodies to meet performance and safety standards. Key certifications include:

– UL 61730 and UL 1703 (North America)

– IEC 61215 and IEC 61730 (international)

– IEEE 1547 for grid interconnection

Ensure all components—panels, inverters, racking—carry valid certifications and are listed in the relevant databases (e.g., California Energy Commission’s solar equipment list).

Documentation and Recordkeeping

Maintain comprehensive records for every shipment and installation, including:

– Certificates of compliance

– Test reports and datasheets

– Warranty documentation

– Bill of lading and customs forms

– Permit approvals and inspection reports

These documents are essential for audits, warranty claims, and regulatory compliance.

By adhering to these logistics and compliance practices, solar businesses can ensure safe delivery, legal operation, and long-term success in the renewable energy market.

In conclusion, sourcing solar panel manufacturers requires a comprehensive evaluation of several key factors, including product quality, certifications, production capacity, pricing, sustainability practices, and after-sales support. Prioritizing manufacturers with recognized certifications such as IEC, ISO, and UL ensures compliance with international standards and product reliability. Conducting on-site audits or third-party inspections can further validate manufacturing processes and quality control measures. Additionally, establishing long-term partnerships with manufacturers who demonstrate innovation, scalability, and ethical practices can provide a competitive advantage and support sustainable business growth. By carefully assessing both local and global suppliers and aligning their capabilities with your project or market requirements, you can secure a reliable and cost-effective solar panel supply chain that meets performance, durability, and environmental goals.