The global man lift elevator market is experiencing robust growth, driven by rising construction activities, increasing demand for worker safety, and the expansion of infrastructure projects worldwide. According to a 2023 report by Mordor Intelligence, the aerial work platform (AWP) market—which includes man lift elevators—is projected to grow at a CAGR of 6.8% from 2023 to 2028, reaching an estimated value of USD 16.2 billion by 2028. This growth is further fueled by technological advancements such as electric-powered models and smart safety features, as well as stringent occupational safety regulations across developed and emerging economies. With North America and Europe leading in adoption due to high construction standards, and Asia-Pacific witnessing accelerated demand due to urbanization and industrial expansion, the competitive landscape is evolving rapidly. In this dynamic environment, selecting the right manufacturer is critical for durability, compliance, and operational efficiency. Below, we present the top 10 man lift elevator manufacturers shaping the industry through innovation, global reach, and proven performance.

Top 10 Man Lift Elevator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Elevators, Escalators, Lifts & Moving Walks

Domain Est. 1994

Website: otis.com

Key Highlights: Otis is a leading manufacturer and maintainer of Elevators, Escalators, Moving Walkways with world class modernization tools & service packages for ……

#2 JLG Industries

Domain Est. 1995

Website: jlg.com

Key Highlights: JLG is a leading manufacturer of access equipment. Get up-to-date news, events, tech tips and even machine sightings. Where will you find JLG?…

#3

Domain Est. 1995

Website: genielift.com

Key Highlights: Genie® articulated boom lifts, telescopic boom lifts, scissor lifts and telehandler products are used in a wide range of industries around the world….

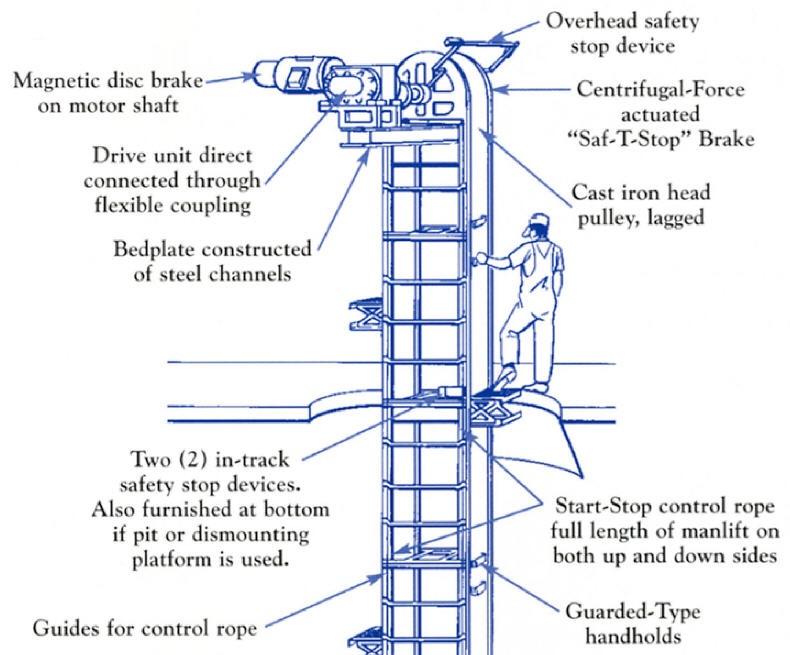

#4 Humphrey Manlift

Domain Est. 1998

Website: humphrey-manlift.com

Key Highlights: The Humphrey Manlift is a belt manlift built on tradition and recognized as an outstanding value for any type of facility needing to move people up or down ……

#5 Manlift

Domain Est. 1999

Website: schumacherelevator.com

Key Highlights: Schumacher Special Purpose Personnel Elevator (SPPE) systems feature a rugged design, low maintenance, quiet operation, and easy installation….

#6 Skyjack

Domain Est. 2000

Website: skyjack.com

Key Highlights: Simple & reliable. Learn more. Designed for rental. Learn more. Quality of service. Learn more. Easy to do business with. Learn more….

#7 snorkellifts.com

Domain Est. 2004

Website: snorkellifts.com

Key Highlights: Operating from the North East of England, Snorkel has established a reputation for delivering top-notch powered access solutions, from low-level lifts to robust ……

#8 MEC Aerial Work Platforms

Domain Est. 2004

Website: mecawp.com

Key Highlights: Reach 20 ft platform height with 800 lb lift capacity. Built to boost performance in tight spaces. Compact. Powerful. Capable. Award Winning Design Micro2032 ……

#9 KLEEMANN Lifts

Domain Est. 2006

Website: kleemannlifts.com

Key Highlights: KLEEMANN is one of the major lift companies in the European and global market, producing all types of elevators. KLEEMANN products provide flexible ……

#10 ManLift USA Lift Machines

Domain Est. 2022 | Founded: 2000

Website: manliftusa.com

Key Highlights: Man Lift has been providing lifts and access equipment for the most unique, hazardous, and challenging environments since 2000….

Expert Sourcing Insights for Man Lift Elevator

H2: 2026 Market Trends for Man Lift Elevators

The man lift elevator market is poised for significant transformation by 2026, driven by technological innovation, growing infrastructure demands, and an increased emphasis on workplace safety and efficiency. As industries continue to modernize, man lift elevators—also known as personnel lifts or vertical personnel platforms—are becoming essential across construction, manufacturing, warehousing, and maintenance sectors. Below are the key trends expected to shape the market in 2026:

-

Rise in Automation and Smart Technology Integration

By 2026, man lift elevators are expected to incorporate advanced automation features such as IoT-enabled sensors, real-time monitoring systems, and predictive maintenance capabilities. These technologies will enhance operational efficiency, reduce downtime, and improve safety by alerting operators to potential malfunctions or hazardous conditions. Integration with building management systems (BMS) will allow for seamless coordination in large facilities. -

Increased Demand in E-Commerce and Warehouse Expansion

The rapid growth of e-commerce continues to fuel the need for high-density warehousing and distribution centers. Man lift elevators are critical in these environments for transporting personnel safely between levels during inventory management and maintenance. As companies expand logistics infrastructure to meet consumer demand, the need for compact, efficient, and safe vertical access solutions will rise. -

Focus on Safety and Regulatory Compliance

Regulatory bodies such as OSHA and ANSI are expected to enforce stricter safety standards for elevated work platforms. In response, manufacturers will prioritize features like anti-slip platforms, fall protection systems, emergency stop mechanisms, and load-sensing technology. Certification and compliance will become key differentiators in the competitive landscape. -

Sustainability and Electric-Powered Models

Environmental concerns and corporate sustainability goals are accelerating the shift toward electric-powered man lift elevators. By 2026, battery-operated and energy-efficient models will dominate the market, especially in indoor applications where emissions control is crucial. Advances in lithium-ion battery technology will extend operational run times and reduce charging intervals. -

Customization and Modular Designs

Industries are demanding more flexible solutions tailored to specific operational needs. Modular man lift elevators that can be customized for height, load capacity, and footprint will gain popularity. This trend supports retrofitting in existing buildings and facilitates quick deployment in temporary or evolving workspaces. -

Growth in Emerging Markets

Asia-Pacific, Latin America, and parts of Africa are expected to see substantial infrastructure development, driving demand for man lift elevators. Urbanization, government investment in construction, and industrialization will open new market opportunities. Localized manufacturing and partnerships will help global suppliers meet regional regulations and cost expectations. -

Adoption in Renewable Energy and Maintenance Sectors

As wind and solar energy projects expand, man lift elevators are increasingly used for turbine and panel maintenance. Their compact design and vertical reach make them ideal for servicing tall structures in remote locations. This niche application is projected to grow steadily through 2026.

In conclusion, the 2026 man lift elevator market will be defined by smart, safe, and sustainable solutions tailored to evolving industrial needs. Companies that invest in innovation, comply with safety standards, and adapt to regional demands will be well-positioned to capture market share in this dynamic sector.

Common Pitfalls When Sourcing Man Lift Elevators: Quality and Intellectual Property Risks

Sourcing man lift elevators—especially from international or unfamiliar suppliers—can expose buyers to significant risks related to product quality and intellectual property (IP). Recognizing these pitfalls early is essential for ensuring safety, compliance, and long-term operational reliability.

Poor Build Quality and Substandard Materials

One of the most frequent issues when sourcing man lift elevators, particularly from low-cost manufacturers, is the use of inferior materials and poor workmanship. Components such as hydraulic systems, load-bearing frames, and safety mechanisms may not meet required industry standards (e.g., ASME A92, OSHA, or EN 280). This can result in frequent breakdowns, safety hazards, and costly downtime. Buyers often discover too late that the elevating mechanism lacks durability under continuous use or fails under load testing.

Lack of Compliance with Safety and Regulatory Standards

Many suppliers, especially in regions with lax enforcement, may not adhere to recognized safety certifications. A man lift elevator that is not compliant with local or international regulations can lead to legal liabilities, failed inspections, and workplace accidents. Buyers may assume certifications are valid without verifying documentation, allowing non-compliant products to enter worksites.

Inadequate or Missing Documentation

Reliable suppliers provide comprehensive technical documentation, including operation manuals, maintenance guides, CE or UL marks, and test reports. Sourcing from untrustworthy vendors often results in missing, falsified, or poorly translated documentation. This lack of transparency complicates installation, training, and regulatory compliance, and can void insurance coverage.

Intellectual Property Infringement

A significant but often overlooked risk is the potential for IP violations. Some manufacturers produce man lift elevators that closely mimic patented designs, control systems, or software from reputable brands without authorization. Purchasing such equipment—even unknowingly—can expose the buyer to legal action, especially if the infringing product is used in a jurisdiction with strong IP enforcement. Additionally, counterfeit parts and cloned control systems may lack reliability and software updates.

Limited After-Sales Support and Spare Parts Availability

Low-cost suppliers may offer attractive initial pricing but fail to provide reliable after-sales service, technical support, or access to genuine spare parts. When maintenance is required, delays in obtaining components can halt operations. In some cases, the supplier may disappear altogether, leaving the buyer with unsupported equipment.

Misrepresentation of Origin and Branding

Some vendors falsely claim that their man lift elevators are manufactured in countries known for high engineering standards (e.g., Germany or the USA) when, in reality, they are produced elsewhere with different quality controls. This misrepresentation undermines trust and can impact warranty validity and resale value.

Insufficient Testing and Quality Assurance Processes

Reputable manufacturers implement rigorous testing protocols, including load testing, cycle testing, and environmental stress testing. Sourcing from suppliers without documented QA processes increases the risk of receiving units that fail prematurely or under real-world conditions.

Conclusion

To mitigate these pitfalls, buyers should conduct thorough due diligence, including factory audits, third-party inspections, verification of certifications, and legal review of IP rights. Engaging with established distributors or original equipment manufacturers (OEMs) with a proven track record helps ensure both quality and IP integrity in man lift elevator procurement.

Logistics & Compliance Guide for Man Lift Elevator

Overview

Man lift elevators, also known as personnel lifts or vertical reciprocating conveyors (VRCs), are essential for transporting workers and materials between different levels in industrial, warehouse, and construction environments. Proper logistics planning and regulatory compliance are critical to ensure safe, efficient, and legal operations.

Regulatory Standards and Compliance

Man lift elevators must adhere to several national and international safety standards. Key compliance requirements include:

– ASME A17.1/CSA B44: Safety Code for Elevators and Escalators – governs design, construction, installation, operation, inspection, testing, and maintenance.

– OSHA 29 CFR 1910.68: Covers employee protection during use of man lifts, including fall protection, guardrails, and safe operating procedures.

– ANSI/ITSDF B56.4: Safety standards for low-lift and high-lift trucks, often referenced for integrated man lift platforms.

– Local Building and Fire Codes: Permits and inspections may be required based on jurisdiction.

Ensure documentation includes engineering certifications, equipment load ratings, and compliance labels.

Transportation and Delivery Logistics

Proper handling during transport prevents damage and ensures timely installation:

– Pre-shipment Inspection: Verify unit integrity, control systems, and safety components prior to dispatch.

– Crating and Packaging: Use robust, weather-resistant packaging for outdoor or long-distance shipments. Include lift points and handling instructions.

– Freight Mode Selection: Choose flatbed trucks or enclosed trailers depending on size and environmental exposure. Notify carriers of oversized load requirements if applicable.

– Site Access Assessment: Confirm delivery route, door clearances, floor load capacity, and crane/hoist availability for unloading.

Coordinate delivery with site supervisors to minimize downtime.

Installation and Site Requirements

Successful installation depends on proper site preparation:

– Foundation and Structural Support: Ensure the floor can support static and dynamic loads (refer to manufacturer specs). Reinforce if needed.

– Power Supply: Provide correct voltage, phase, and amperage; dedicated circuits are recommended. Include grounding and surge protection.

– Clearance and Enclosures: Maintain required overhead and side clearances. Install safety gates or interlocked doors per OSHA and ASME standards.

– Permitting: Obtain necessary building, electrical, and elevator permits before installation begins.

All installation must be performed by certified technicians.

Inspection and Certification

Routine inspections are legally mandated and essential for ongoing compliance:

– Initial Inspection: Conducted by a certified elevator inspector after installation. Includes load testing and safety device validation.

– Monthly Visual Checks: Performed by site personnel—verify cables, controls, emergency stops, and warning labels.

– Annual Comprehensive Inspection: Required by ASME A17.1; includes mechanical, electrical, and safety system evaluations.

– Maintenance Logs: Maintain detailed records of all inspections, repairs, and component replacements.

Only authorized service providers should perform major maintenance.

Training and Operational Safety

Proper training reduces accident risk and ensures regulatory adherence:

– Operator Certification: Train all users on startup, operation, emergency procedures, and load limits. Maintain training records.

– Fall Protection: Enforce use of harnesses and lanyards when working at height, especially on open platforms.

– Load Management: Never exceed rated capacity. Distribute weight evenly and secure loose materials.

– Emergency Protocols: Clearly post emergency stop locations, rescue procedures, and contact information. Conduct drills periodically.

Prohibit unauthorized or untrained personnel from operating the lift.

Maintenance and Recordkeeping

A structured maintenance program extends equipment life and ensures compliance:

– Preventive Maintenance Schedule: Follow manufacturer guidelines (e.g., monthly lubrication, quarterly brake checks, annual cable inspection).

– Spare Parts Inventory: Keep critical components (fuses, sensors, brake pads) on-site to minimize downtime.

– Documentation: Retain service reports, inspection certificates, incident logs, and compliance audits for a minimum of 5 years.

– Decommissioning: If removing from service, follow lockout/tagout (LOTO) procedures and update safety plans accordingly.

Regular upkeep prevents violations and enhances reliability.

Conclusion

Adhering to logistics best practices and compliance standards ensures the safe and efficient use of man lift elevators. By integrating proper planning, certified installation, ongoing maintenance, and staff training, organizations can maintain regulatory compliance, protect personnel, and optimize operational performance. Always consult the manufacturer’s manual and local authorities for site-specific requirements.

Conclusion for Sourcing Man Lift Elevator:

Sourcing a man lift elevator is a strategic decision that significantly enhances workplace safety, operational efficiency, and productivity, especially in industries requiring frequent access to elevated work areas such as construction, warehousing, maintenance, and manufacturing. After evaluating various suppliers, models, lifting capacities, platform sizes, and safety features, it is evident that selecting the right man lift involves balancing cost, reliability, and suitability for specific job site requirements.

Opting for reputable suppliers who offer certified, well-maintained equipment—whether through purchase or rental—ensures compliance with safety standards (such as OSHA and ANSI) and reduces the risk of accidents. Additionally, considering factors like mobility (self-propelled vs. trailer-mounted), power source (electric vs. engine-driven), and ease of maintenance contributes to long-term operational success.

In conclusion, investing in the appropriate man lift elevator through careful sourcing not only improves job site efficiency but also demonstrates a commitment to worker safety and regulatory compliance. A thorough evaluation of needs, vendor credibility, and total cost of ownership will lead to a smart, sustainable solution that supports current and future project demands.