The global market for magnetic materials, particularly advanced magnets used in conjunction with stainless steel applications, is experiencing steady growth driven by rising demand in industrial manufacturing, automotive, and electronics sectors. According to Mordor Intelligence, the global permanent magnets market was valued at approximately USD 20.5 billion in 2023 and is projected to grow at a CAGR of over 7.5% through 2029. This expansion is fueled by the increasing need for efficient magnetic solutions in challenging environments—such as those involving stainless steel, which is typically non-magnetic due to its austenitic structure. As a result, specialized magnetic technologies capable of adhering to or interacting with stainless steel surfaces have become critical across logistics, fabrication, and automation industries. Manufacturers are now focusing on rare-earth-based and flexible magnetic systems engineered to overcome the low permeability of stainless steel, positioning innovation at the core of market competition. This report identifies the top 8 magnet manufacturers leading this niche with high-performance, application-specific solutions.

Top 8 Magnet For Stainless Steel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 BasicLift™ Magnets

Domain Est. 1995

Website: magnetics.com

Key Highlights: Featuring a lightweight and durable Stainless Steel design, the BasicLift has a full-width cam to release the magnet from the steel surface and a tall lift lug ……

#2 Stainless Mounting Magnets

Domain Est. 1998

Website: stanfordmagnets.com

Key Highlights: Stainless Mounting Magnets completely encased in stainless steel (AISI304 / AISI316(L)). Great for applications where corrosion is a concern….

#3 Stainless Steel Magnets

Domain Est. 1994

Website: mcmaster.com

Key Highlights: Choose from our selection of stainless steel magnets in a wide range of styles and sizes. Same and Next Day Delivery….

#4 Magnet Company

Domain Est. 1997

Website: adamsmagnetic.com

Key Highlights: Adams Magnetic Products is a leading custom magnet company specializing in custom assemblies and prefabricated magnetic products. Get a quote….

#5 GN 50.8 Retaining Magnets

Domain Est. 1997

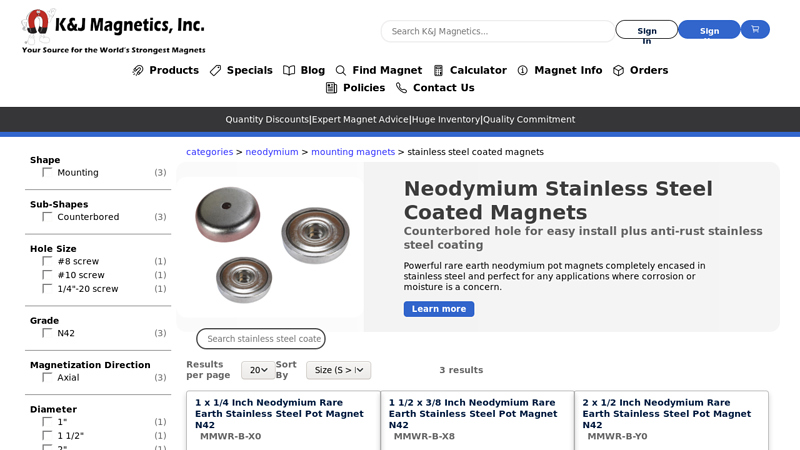

#6 Strong Neodymium Stainless Steel Pot Magnets for Sale

Domain Est. 2003

Website: kjmagnetics.com

Key Highlights: Strong rare earth neodymium stainless steel coated magnets. Corrosion resistance and versatility to be used in many applications….

#7 Ferrite Channel Magnets

Domain Est. 2007

Website: first4magnets.com

Key Highlights: 4–6 day deliveryFerrite Channel Magnet – 61kg Pull – Ideal for heavy-duty applications. Stainless Steel Ferrite Channel Magnet – Durable and resistant to rust. Magnetic Cable ……

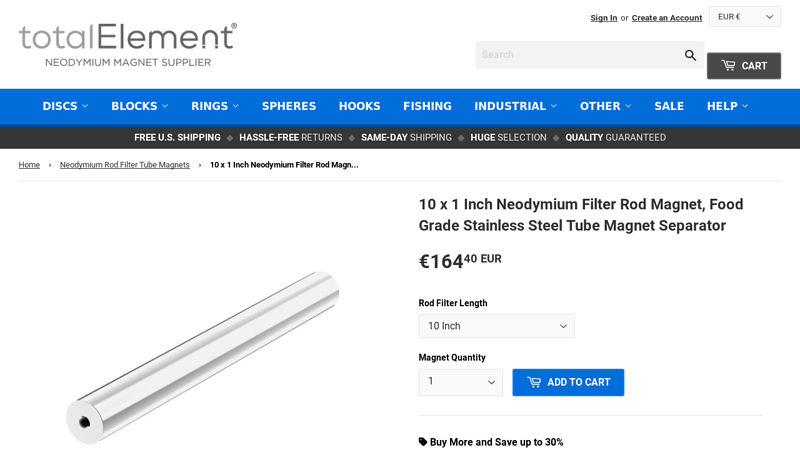

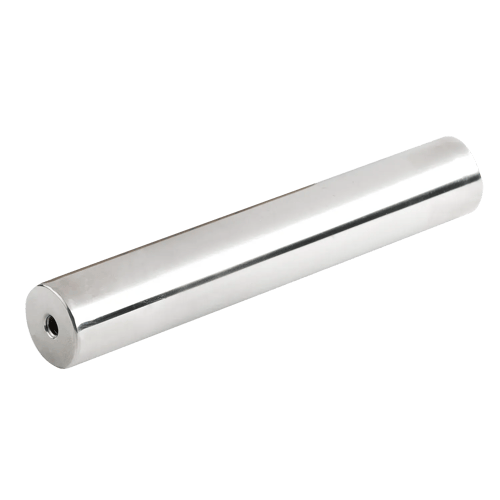

#8 10 x 1 Inch Neodymium Filter Rod Magnet, Food Grade Stainless …

Domain Est. 2012

Expert Sourcing Insights for Magnet For Stainless Steel

H2: Projected Market Trends for Magnets for Stainless Steel in 2026

The global market for magnets used in conjunction with stainless steel is expected to undergo significant transformation by 2026, driven by technological advancements, evolving industrial applications, and growing demand across key sectors. Although stainless steel is generally non-magnetic due to its austenitic structure, certain grades (such as ferritic and martensitic) exhibit magnetic properties, enabling the use of magnets in applications like holding, lifting, separation, and sensing. Below are the key market trends anticipated for 2026:

-

Increased Demand in Industrial Automation and Robotics

The expansion of smart manufacturing and Industry 4.0 is fueling demand for magnetic systems that integrate with stainless steel components. Magnetic grippers, sensors, and actuators used in robotic arms often rely on permanent magnets (e.g., neodymium) that adhere to magnetic stainless steel parts. By 2026, the push for automation in automotive, electronics, and pharmaceutical manufacturing will boost the need for high-performance magnets compatible with stainless steel environments. -

Growth in Magnetic Separation Technologies

The food & beverage, pharmaceutical, and chemical industries increasingly use magnetic separators to remove ferrous contaminants from products processed in stainless steel equipment. With stricter hygiene and safety regulations, demand for high-strength magnets—such as rare-earth types—used in stainless steel housings is expected to rise, especially in emerging markets. -

Advancements in Permanent Magnet Materials

Innovations in magnet technology, including improved corrosion-resistant coatings and temperature-stable neodymium-iron-boron (NdFeB) magnets, will enhance compatibility with stainless steel applications in harsh environments. By 2026, manufacturers will increasingly offer hybrid solutions where magnets are embedded or bonded to stainless steel for durability and performance. -

Rise in Sustainable and Hygienic Design

Stainless steel’s corrosion resistance and cleanability make it ideal for sanitary applications. Magnets designed for use with stainless steel in cleanrooms, medical devices, and kitchen appliances will benefit from growing emphasis on sustainability and hygiene. Magnetic closures, latches, and mounting systems made with stainless steel and rare-earth magnets are expected to gain traction in consumer and commercial products. -

Regional Market Shifts and Supply Chain Dynamics

Asia-Pacific—particularly China, Japan, and South Korea—is projected to dominate the magnet for stainless steel market in 2026 due to robust manufacturing infrastructure and strong domestic demand. However, geopolitical factors and supply chain diversification efforts may lead to increased regional production in North America and Europe, especially for high-grade magnets used in critical applications. -

Impact of Electric Vehicles (EVs) and Renewable Energy

While not directly related to stainless steel magnetism, the proliferation of EVs and wind turbines will indirectly affect the magnet market. High-performance magnets used in motors and generators often require stainless steel components for structural and protective purposes. This synergy will support continued R&D in magnet-stainless steel integration. -

Price Volatility and Material Substitution

Fluctuations in rare-earth element prices (e.g., neodymium, dysprosium) may drive innovation in alternative magnet materials or hybrid designs. Some manufacturers may explore ferrite or alnico magnets for less demanding stainless steel applications to reduce costs, though high-performance sectors will continue to favor rare-earth variants.

In summary, by 2026, the market for magnets used with stainless steel will be shaped by the convergence of industrial digitization, regulatory standards, and material innovation. Companies that invest in R&D for durable, efficient, and application-specific magnetic solutions will be well-positioned to capitalize on expanding opportunities across multiple high-growth industries.

Common Pitfalls When Sourcing Magnets for Stainless Steel (Quality, IP)

Sourcing the right magnets for use with stainless steel requires careful attention to both material compatibility and performance standards—especially when quality and Ingress Protection (IP) ratings are critical. Overlooking key factors can lead to product failure, safety risks, or increased lifecycle costs. Below are common pitfalls to avoid:

1. Assuming All Stainless Steel Is Magnetic

One of the most frequent mistakes is assuming that all stainless steel is ferromagnetic and will bond well with standard magnets. In reality, common grades like 304 and 316 are austenitic and generally non-magnetic or only weakly magnetic. Using weak magnets (e.g., standard ferrite) results in poor adhesion or detachment under load. Always verify the stainless steel grade and choose high-strength rare-earth magnets like neodymium (NdFeB) designed for low-surface-field materials.

2. Overlooking Corrosion Resistance in Magnet Selection

Stainless steel is often chosen for its corrosion resistance, especially in outdoor, marine, or food-grade environments. However, standard neodymium magnets are prone to corrosion when exposed to moisture or chemicals. Sourcing uncoated or poorly coated magnets can lead to rust, compromising both the magnet and the application. Always specify IP-rated or fully encapsulated magnets with appropriate protective coatings (e.g., Ni-Cu-Ni, epoxy, or gold plating) to ensure long-term durability.

3. Ignoring IP Ratings for Environmental Protection

Ingress Protection (IP) ratings define a product’s resistance to dust and water. Failing to match the magnet’s IP rating to the operating environment can result in premature failure. For example, using an IP54-rated magnet in a washdown environment (requiring IP67 or higher) will likely lead to moisture ingress and corrosion. Ensure the entire magnetic assembly—including adhesives and housings—meets the required IP standard for the intended application.

4. Compromising on Magnet Quality to Reduce Cost

Low-cost magnets often use inferior raw materials, inconsistent manufacturing processes, or inadequate quality control. This can result in inconsistent magnetic strength, poor dimensional accuracy, or early demagnetization. Especially in critical applications, opting for cheap suppliers may lead to higher total costs due to rework, downtime, or product recalls. Source from reputable suppliers with certifications (e.g., ISO 9001) and request material test reports or performance data.

5. Neglecting Long-Term Performance Under Stress

Magnets used in dynamic or high-temperature environments may experience performance degradation over time. Neodymium magnets, for instance, can lose strength at elevated temperatures unless properly graded (e.g., N42SH for higher heat resistance). Sourcing magnets without considering operating temperature, mechanical stress, or vibration can result in unexpected failures. Always validate magnet performance under real-world conditions during prototyping.

6. Inadequate Adhesion or Mounting Method

Even the strongest magnet will fail if not properly mounted. Relying solely on magnetic attraction without mechanical backup (e.g., screws, adhesives, or housings) can be risky in high-vibration environments. Additionally, surface finish and flatness of the stainless steel impact adhesion. Ensure the magnet design includes a robust mounting strategy validated for the specific use case.

7. Overlooking Regulatory and Safety Standards

In industries like food processing, medical devices, or transportation, magnets must comply with specific safety and material regulations (e.g., FDA, RoHS, REACH). Sourcing non-compliant magnets can delay certifications or create liability issues. Always confirm that the magnet and its coatings meet relevant regulatory requirements for the target market.

By understanding and avoiding these common sourcing pitfalls, you can ensure reliable performance, durability, and compliance when integrating magnets with stainless steel in demanding applications.

Logistics & Compliance Guide for Magnets for Stainless Steel

Overview

Magnets used for stainless steel applications—commonly employed in industrial holding, lifting, separation, and magnetic filtration systems—require careful handling and adherence to regulations due to their strong magnetic fields, material composition, and potential safety risks. This guide outlines key logistics and compliance considerations to ensure safe, legal, and efficient transportation and use.

Classification & Regulatory Framework

Magnets for stainless steel are typically permanent magnets (e.g., neodymium, ferrite, or alnico) and may be classified under various international and national regulations based on their magnetic strength and material content. Key frameworks include:

– IMDG Code (International Maritime Dangerous Goods): Strong magnets are often classified as Class 9 – Miscellaneous Dangerous Goods (UN2803, Magnetized Material) when their magnetic field strength exceeds 0.159 A/m (0.002 Gauss) at a distance of 2.1 meters from the package.

– IATA Dangerous Goods Regulations (for air transport): Similar to IMDG, strong magnets must be declared as Class 9 if they meet magnetic field thresholds.

– OSHA & REACH/ROHS (for workplace and environmental safety): Compliance may be required if magnets contain restricted substances (e.g., nickel coatings that may pose allergen risks under REACH).

Packaging & Labeling Requirements

Proper packaging is essential to prevent demagnetization, physical damage, and interference with transport systems:

– Shielding: Use ferromagnetic shielding (e.g., steel plates or containers) to contain magnetic fields and prevent attraction to nearby metal objects.

– Secure Packaging: Magnets must be immobilized within packaging to avoid movement during transit. Non-magnetic spacers and cushioning materials (e.g., foam, wood) are recommended.

– Marking & Labeling:

– Affix Class 9 Miscellaneous Dangerous Goods labels if applicable.

– Include “Magnetized Material” on outer packaging.

– Provide orientation arrows if required (e.g., for sensitive equipment).

– Include shipper/consignee details and handling instructions (e.g., “Keep Away from Electronic Devices”).

Transportation Considerations

- Air Freight: Subject to strict IATA limits. Magnetic field measurements must be documented via a magnetic field report (typically using a gauss meter). Airlines may require special approvals.

- Sea Freight: Follow IMDG guidelines; ensure container stowage avoids proximity to navigation equipment or sensitive cargo.

- Ground Transport (ADR/RID in Europe, DOT in USA): Class 9 classification applies when thresholds are exceeded. No special placarding required for small quantities below reporting limits, but documentation must still reflect the hazard.

Handling & Safety Precautions

- Personal Safety: Strong magnets can cause pinching injuries or attract loose metal objects at high speed. Workers should wear protective gloves and avoid wearing magnetic-sensitive devices (e.g., pacemakers).

- Separation Distance: Store and transport magnets away from electronics, credit cards, medical devices, and other magnetic materials.

- Temperature Sensitivity: Neodymium magnets may lose magnetism or corrode at high temperatures; ensure climate-controlled environments if necessary.

Customs & Import/Export Compliance

- HS Codes: Commonly classified under 8505.11 (permanent magnets) or 8505.90 (magnetic assemblies). Confirm country-specific codes.

- Export Controls: Some high-performance magnets (especially rare-earth types) may be subject to export restrictions due to strategic material regulations (e.g., U.S. EAR or EU dual-use controls).

- Documentation: Include commercial invoices, packing lists, and, when required, Material Safety Data Sheets (MSDS/SDS) and non-hazardous or hazardous goods declarations.

Environmental & End-of-Life Compliance

- Recycling: Rare-earth magnets should be recycled to recover valuable materials. Comply with WEEE (Waste Electrical and Electronic Equipment) directives if applicable.

- Disposal: Do not incinerate neodymium magnets—risk of toxic fumes. Follow local hazardous waste regulations for disposal.

Best Practices Summary

- Test magnetic field strength before shipping to determine classification.

- Use certified dangerous goods packaging when required.

- Train personnel in safe handling and emergency procedures.

- Maintain documentation for audits and customs inspections.

- Partner with experienced freight forwarders familiar with magnetic cargo.

Adherence to this guide ensures regulatory compliance, reduces risk, and supports the reliable delivery of magnets for stainless steel applications worldwide.

Conclusion for Sourcing Magnets for Stainless Steel Applications

Sourcing the right magnet for use with stainless steel requires careful consideration of the specific grade and properties of the stainless steel involved. Since many stainless steels—particularly austenitic grades like 304 and 316—are non-magnetic or only weakly magnetic, standard magnets may not adhere effectively. Therefore, selecting high-strength rare earth magnets, such as neodymium (NdFeB), is often necessary to achieve reliable performance.

It is essential to evaluate the application environment—accounting for factors such as temperature, humidity, and exposure to corrosive elements—since these can impact both the magnet’s strength and longevity. Appropriate protective coatings on neodymium magnets (e.g., nickel, epoxy, or gold plating) can help prevent corrosion, especially in demanding conditions.

Additionally, understanding whether the stainless steel has undergone cold working—which can induce slight magnetism—can influence magnet selection. In cases where magnetic attraction is critical, using ferritic or martensitic stainless steels (which are magnetic) may be preferable.

In conclusion, successful sourcing involves matching the magnet type, strength, and environmental resistance to the specific characteristics of the stainless steel and the operational requirements. Engaging with reputable suppliers, conducting application-specific testing, and considering long-term durability will ensure optimal performance and cost-effectiveness in using magnets with stainless steel components.