The global wood pellet market is experiencing robust growth, driven by rising demand for renewable energy and increasing government support for sustainable fuel alternatives. According to Grand View Research, the global wood pellets market size was valued at USD 9.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This upward trajectory is fueled by expanding applications in residential heating, industrial power generation, and co-firing in coal-based power plants, particularly across Europe and North America. As sustainability becomes a core focus in energy policy, machine pellet wood manufacturers are scaling production, improving efficiency, and investing in advanced technology to meet tightening quality and environmental standards. In this evolving landscape, identifying the leading manufacturers—those combining innovation, capacity, and global reach—is essential for stakeholders across the supply chain. The following list highlights the top 10 machine pellet wood manufacturers shaping the industry’s future.

Top 10 Machine Pellet Wood Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

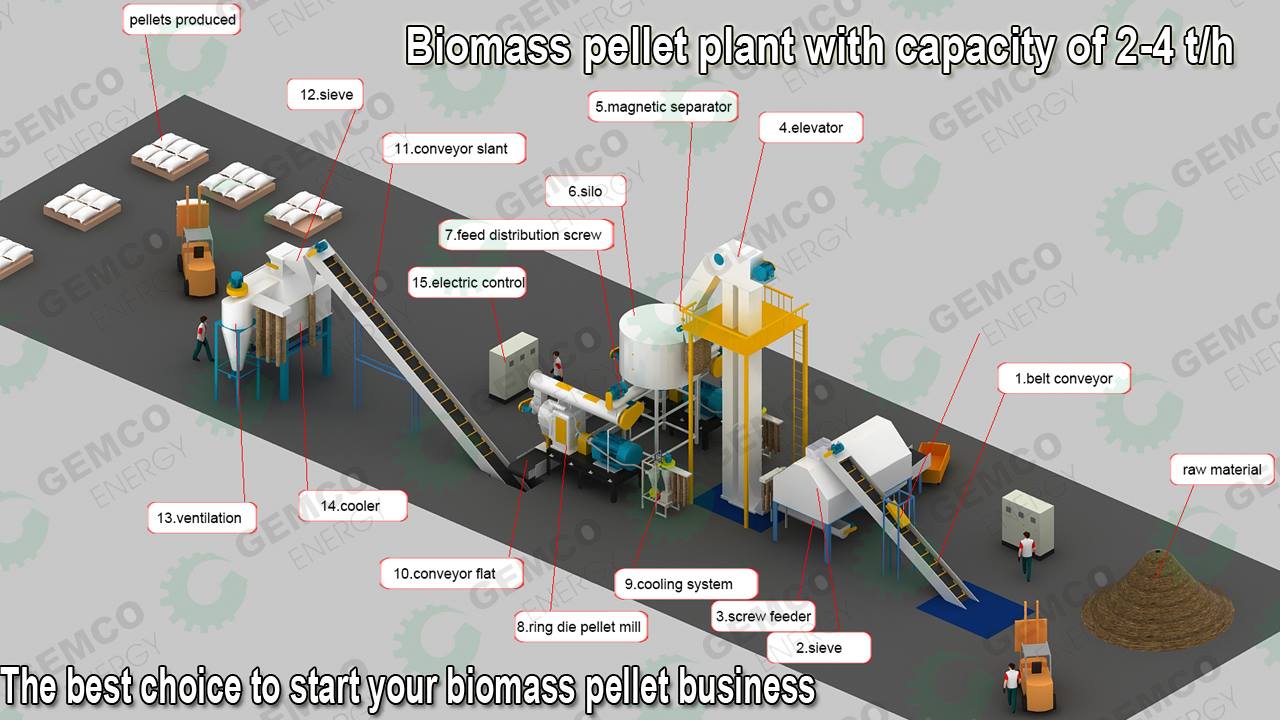

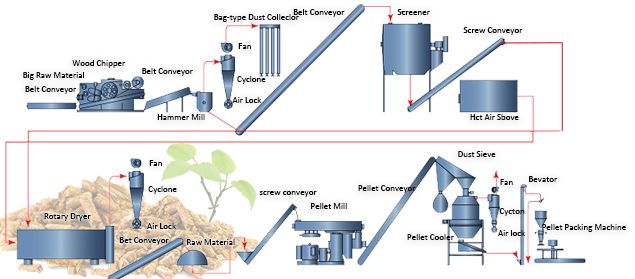

Domain Est. 2013

Website: gemco-energy.com

Key Highlights: Anyang GEMCO Energy Machinery Co., Ltd (a divison of ABC Machinery) is a leading manufacturer of renewable energy machinery which include pellet mill, pellet ……

#2 Pellet Mill & Pelleting Plant Manufacturer

Domain Est. 2012

Website: akahl.com

Key Highlights: PELLET MILL MANUFACTURER: Your expert in the field of flat die pellet mills for feed mills, wood pelleting plants, recycling plants and much more | AMANDUS ……

#3 World

Domain Est. 2014

Website: yuf-china.com

Key Highlights: Owning 200 more worldwide clients’ biomass pellet machine operating site, Yufchina is a China manufacturer which is worth your trust. Ask today !…

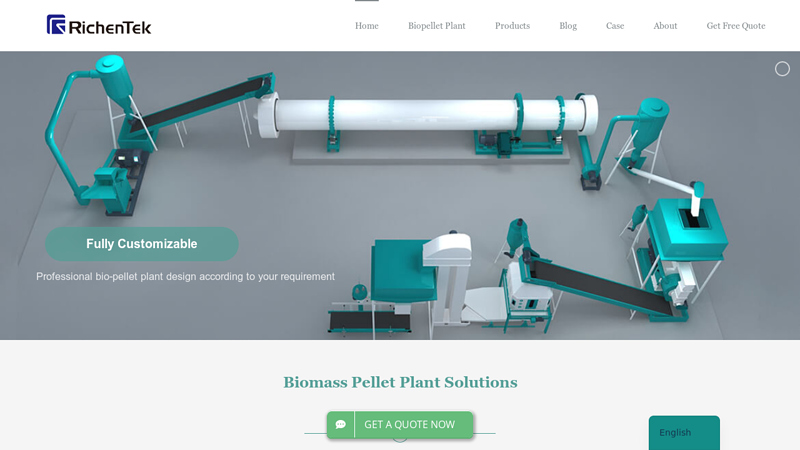

#4 Yulong-Gattuwala

Website: yulonggattuwala.com

Key Highlights: Yulong Gattuwala Energy is a leading biomass pellet machine manufacturer and supplier in India, providing high-quality solutions for biomass fuel production….

#5 Pellet Mills

Domain Est. 2013

Website: onecpm.com

Key Highlights: Our pellet mills are built to the highest possible standards and designed to make your job easier, safer and more efficient (and deliver you the best possible ……

#6 Biomass Pellet Machine & Wood Pellet Plants Manufactures. One …

Domain Est. 2013

Website: biopelletmachine.com

Key Highlights: We specialize in providing reliable, efficient, and eco-friendly biomass pellet machines and complete biomass pellet plant solutions to customers worldwide….

#7 Wood Pellet Mill Supplier

Domain Est. 2013

Website: wood-pellet-mill.com

Key Highlights: We offer high-quality wood pellet mills and complete wood pellet solutions for efficient biomass pellet processing….

#8 Wood Pellet Mill

Domain Est. 2015

Website: pellet-richi.com

Key Highlights: Wood pellet mill is a machine used to pelletize different wood raw materials. They are often utilized in fuel pellet production, forest waste recycling and ……

#9 USA Pellet Mill Pellet Mills & Extruders (Miami, FL)

Domain Est. 2018

Website: usapelletmill.com

Key Highlights: U.S.-based supplier of pellet mills & extruders for feed, biomass & pet food. Shipping globally from Miami. Request your quote today and boost production!…

#10 Pellet Mills For Sale

Domain Est. 2020

Website: elfpelletmills.com

Key Highlights: Pellet Mills for sale in Canada, USA & North America. Turn wood, biomass, feed, plastic, hops & hemp into pellets with ELF Pellet Making Machines….

Expert Sourcing Insights for Machine Pellet Wood

H2: Projected Market Trends for Machine Pellet Wood in 2026

The global Machine Pellet Wood market is poised for significant transformation by 2026, driven by increasing demand for renewable energy, technological advancements in pellet production machinery, and evolving environmental policies. Below is an analysis of key trends expected to shape the market in 2026:

-

Rising Demand for Renewable Energy

As countries intensify efforts to meet climate targets under agreements such as the Paris Accord, wood pellets are gaining traction as a carbon-neutral heating and power generation alternative. The European Union, North America, and parts of Asia are expected to increase imports and domestic production of wood pellets, directly boosting demand for pelletizing machines. -

Technological Advancements in Pellet Machines

By 2026, pellet machine manufacturers are anticipated to focus on energy efficiency, automation, and smart manufacturing technologies. Innovations such as AI-driven process control, IoT-enabled monitoring systems, and modular designs will enhance production efficiency, reduce downtime, and lower operational costs—making pellet production more accessible to small and medium enterprises (SMEs). -

Growth in Decentralized and Small-Scale Production

There is a growing trend toward localized biomass energy solutions. Rural communities, agricultural cooperatives, and forestry operations are investing in compact, mobile pellet machines to convert waste wood into value-added fuel. This shift supports circular economy models and reduces transportation emissions, aligning with sustainability goals. -

Stringent Environmental and Quality Standards

Regulatory bodies are expected to enforce stricter pellet quality standards (e.g., ENplus, DINplus) and emissions regulations for pellet production. Machinery manufacturers will need to ensure their equipment meets these standards, driving demand for high-precision, low-emission pelletizing systems with advanced dust and emission control features. -

Expansion in Emerging Markets

Regions such as Southeast Asia, India, and parts of Africa are anticipated to see increased investment in biomass energy infrastructure. Growing awareness of clean cooking solutions and government incentives for renewable energy will stimulate demand for affordable and efficient wood pellet machines in these markets. -

Integration with Digital Platforms and Industry 4.0

Pellet machine suppliers are likely to adopt digital platforms for remote diagnostics, predictive maintenance, and customer support. Cloud-based analytics will allow operators to optimize machine performance and monitor supply chain logistics, improving overall productivity. -

Sustainability and Feedstock Sourcing Challenges

While demand grows, concerns about sustainable wood sourcing and deforestation may influence machine design and operational practices. Pellet machine manufacturers may integrate features that allow for efficient processing of alternative feedstocks (e.g., agricultural residues, energy crops), reducing reliance on virgin timber.

In conclusion, the Machine Pellet Wood market in 2026 will be shaped by a confluence of environmental imperatives, technological innovation, and shifting energy policies. Companies that adapt to these trends—by offering efficient, scalable, and sustainable pelletizing solutions—are likely to capture significant market share in the evolving bioenergy landscape.

Common Pitfalls in Sourcing Machine Pellet Wood (Quality and Intellectual Property)

Sourcing machine pellet wood involves more than just selecting a supplier—it requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to production inefficiencies, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Quality Control and Inconsistent Feedstock

One of the most frequent issues in sourcing machine pellet wood is inconsistent raw material quality. Variability in moisture content, wood species, bark content, and particle size can severely impact pelletizing efficiency and final product quality. Suppliers may offer low-cost wood without proper drying or screening, leading to equipment clogging, increased energy consumption, and substandard pellets that fail industry standards (e.g., ENplus or ISO 17225).

Lack of Certification and Traceability

Failing to verify certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) exposes buyers to sustainability risks and non-compliance with environmental regulations. Without traceability, it’s difficult to ensure that the wood is legally harvested and sourced from responsibly managed forests—an issue increasingly scrutinized by customers and regulators.

Unverified Supplier Claims and Misrepresentation

Some suppliers may misrepresent the quality or origin of their wood materials. Claims of “clean,” “resin-free,” or “hardwood-only” feedstock may not be backed by testing or documentation. Relying on verbal assurances without third-party verification or sample testing increases the risk of receiving contaminated or unsuitable material.

Overlooking Intellectual Property in Pelletizing Technology

When sourcing not just raw materials but also integrated pellet production systems, buyers often neglect IP protections. Using machinery or processes that infringe on patented technologies—such as specific die designs, automated control systems, or proprietary drying methods—can result in legal disputes, cease-and-desist orders, or costly licensing fees. It’s essential to confirm that equipment suppliers hold proper rights to the technology they provide.

Failure to Secure Licensing for Proprietary Pellet Formulations

Some advanced pellet producers use proprietary blends or additives to enhance combustion efficiency, reduce emissions, or improve durability. Sourcing wood intended for such formulations without proper licensing or partnership agreements may constitute IP infringement, especially if the wood is processed using protected methods or recipes.

Inadequate Contracts Addressing Quality and IP

Generic supply agreements often lack specific clauses on quality tolerances, testing protocols, IP ownership, and liability for infringement. Without clear terms, resolving disputes over subpar materials or unauthorized use of technology becomes difficult and costly. Contracts should define quality metrics, audit rights, and explicit IP warranties from the supplier.

Avoiding these pitfalls requires due diligence: conduct site audits, request material certifications, perform lab testing, and consult legal experts to review both quality specifications and IP provisions in supplier agreements.

Logistics & Compliance Guide for Machine Pellet Wood

Overview of Machine Pellet Wood

Machine Pellet Wood, commonly referred to as wood pellets, are compressed biomass fuel products primarily used for heating and energy generation. Made from sawdust and wood residues, these pellets must meet specific quality, packaging, and regulatory standards. This guide outlines key logistics and compliance considerations for the international and domestic transport of Machine Pellet Wood.

Classification and Harmonized System (HS) Code

Wood pellets are typically classified under the Harmonized System (HS) Code:

– HS 4401.31 – Wood pellets, whether or not agglomerated.

This classification is critical for customs declaration, tariff assessment, and import/export documentation. Accurate coding ensures compliance with trade regulations and avoids delays.

International Standards and Quality Requirements

To ensure market acceptance and compliance, Machine Pellet Wood should meet recognized international standards:

– ENplus Certification (EN 14961-2): The most widely accepted standard in Europe, classifying pellets into quality grades (A1, A2, B). Requires compliance with moisture, ash content, calorific value, and durability specifications.

– ISO 17225-2: International standard specifying fuel quality classes and sustainability criteria.

– PFI (Pellet Fuels Institute) Standards: Commonly used in North America, ensuring consistency in pellet density, size, and emissions.

Producers and distributors should provide certified test reports and quality documentation with each shipment.

Packaging and Marking Requirements

Proper packaging and labeling are essential for safe handling and regulatory compliance:

– Packaging Options: Supersacks (1 ton), bulk containers, or 15–20 kg consumer bags.

– Labeling: Each package must include:

– Product name and type (e.g., “Wood Pellets – Grade A1”)

– Net weight

– Manufacturer name and address

– Batch number and production date

– Compliance with relevant standards (e.g., “ENplus A1 Certified”)

– Safety and handling instructions

Bulk shipments should include accompanying documentation with full product specifications.

Transport and Storage Logistics

Efficient logistics planning is crucial due to the hygroscopic nature of wood pellets:

– Moisture Protection: Pellets must be stored and transported in dry, covered conditions to prevent moisture absorption (>10% moisture degrades quality).

– Containerization: Use of dry, clean containers or covered trucks. Silo trucks or pneumatic systems recommended for bulk delivery.

– Stacking and Handling: Avoid crushing bags; follow manufacturer stacking limits. Use non-sparking equipment in storage areas.

– Shelf Life: Recommended storage duration is up to 6 months in optimal conditions.

Import/Export Documentation

Key documents required for cross-border trade include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Phytosanitary Certificate (if required by destination country)

– Quality and Compliance Certificates (e.g., ENplus, ISO)

– Material Safety Data Sheet (MSDS) – recommended for safety and handling

Regulatory and Environmental Compliance

- REACH and CLP Regulations (EU): Ensure no hazardous substances are present in additives. Declaration may be required.

- Customs Duties and Trade Agreements: Verify preferential tariffs under trade agreements (e.g., EU-South Korea FTA) using correct HS code and Certificate of Origin.

- Sustainability Requirements: Many markets (e.g., EU Renewable Energy Directive – RED II) require proof of sustainable sourcing, chain of custody, and carbon footprint calculations.

- Import Restrictions: Some countries restrict wood product imports to prevent pest spread. Check phytosanitary rules with national agricultural authorities.

Safety and Handling Precautions

Wood pellets pose specific safety risks:

– Dust Explosion Risk: Pellet dust is combustible. Use explosion-proof equipment in processing and storage areas. Follow ATEX directives in the EU.

– Asphyxiation Hazard: In confined spaces, off-gassing (carbon monoxide and CO2) can occur. Ensure proper ventilation during transport and storage.

– Personal Protective Equipment (PPE): Recommend dust masks, gloves, and eye protection during handling.

Conclusion

Successful logistics and compliance for Machine Pellet Wood depend on adherence to quality standards, accurate documentation, proper handling, and awareness of regulatory frameworks. Businesses should stay updated on evolving environmental regulations and sustainability certification schemes to maintain market access and ensure safe, efficient operations.

Conclusion: Sourcing Wood Pellet Machines

Sourcing a wood pellet machine is a critical step for businesses and individuals aiming to enter or expand within the biomass energy sector. The decision involves evaluating various factors such as production capacity, raw material compatibility, machine quality, energy efficiency, and cost-effectiveness. Conducting thorough research, comparing suppliers, and verifying certifications ensures the acquisition of reliable and durable equipment.

Moreover, considering after-sales support, spare parts availability, and technical assistance significantly impacts long-term operational success. Whether sourcing locally or internationally, due diligence in selecting a reputable manufacturer will lead to improved productivity, reduced downtime, and a strong return on investment.

In conclusion, a strategic and informed approach to sourcing wood pellet machines lays the foundation for sustainable biomass production, contributing to both environmental goals and economic profitability in the growing renewable energy market.