The global laser marking machine market is experiencing robust expansion, driven by increasing demand for precision, traceability, and automation across industries such as automotive, electronics, medical devices, and pharmaceuticals. According to Grand View Research, the market was valued at USD 1.9 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 8.7% from 2023 to 2030. This growth is fueled by advancements in fiber and UV laser technologies, rising adoption of Industry 4.0 practices, and stringent regulatory requirements for product serialization. As businesses prioritize durable, high-speed marking solutions, leading manufacturers are innovating to deliver efficient, scalable, and integrated systems. Based on market presence, technological capabilities, and global reach, the following nine companies have emerged as key players shaping the future of laser marking technology.

Top 9 Machine Marquage Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Marking Machine & Industrial Laser Marking Systems

Website: videojet.com

Key Highlights: Laser marking systems provide manufacturers with a safe, ink-free method of marking permanent codes, text, and graphics for product identification and branding….

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#3 Laser Marking Machines for Integration

Website: gravotech.com

Key Highlights: Gravotech offers a wide range of laser marking equipment for industrial traceability applications. Our lasers are ready to be integrated for production ……

#4 Industrial laser marking machines, laser engraving solution

Website: sic-marking.com

Key Highlights: Our laser engraving machines can mark all alphanumeric characters, logos, 1D and 2D standard codes (datamatrix, QR code…) with precision and contrast. The ……

#5 Applied Laser Engineering

Website: appliedlaser.co.uk

Key Highlights: ALE design & manufacture a range of multipurpose laser engraving & scanning systems. Our engraving systems utilise state of the art laser technology….

#6 Laser Machines

Website: lclasers.com

Key Highlights: Distribution and manufacture of laser machinery. Sales of laser marking, laser cleaning, laser engraving and welding machines….

#7 Laser Marking Precision in the Smallest Space

Website: asys-group.com

Key Highlights: INSIGNUM systems offer precise laser marking. They process printed circuit boards made of solder resist, metal, plastic and ceramic….

#8 Laser Marking and Engraving Machines

Website: coherent.com

Key Highlights: Choose from a wide range of laser marking and engraving machines, from self-contained table-top systems to fully automated machines with robotic parts ……

#9 Fiber Laser Marking Machine, Laser Engraving System Price

Website: alldolaser.com

Key Highlights: Alldo fiber laser marking machine is mainly used for marking and engraving various metals, and some non-metals with amazing speedy marking. RFQ Now….

Expert Sourcing Insights for Machine Marquage Laser

H2: 2026 Market Trends for Machine Marquage Laser (Laser Marking Machines)

The global laser marking machine market is poised for robust growth by 2026, driven by increasing industrial automation, stringent traceability requirements, and advancements in laser technology. Here’s an analysis of key trends shaping the market:

1. Sustained Demand from High-Growth Industries:

* Electronics & Semiconductors: The relentless miniaturization of components and the need for permanent, high-precision marking of serial numbers, barcodes, and logos on delicate materials (PCBs, chips, sensors) will remain a primary growth driver. Demand for ultra-fine marking with fiber and UV lasers will surge.

* Medical Devices & Pharmaceuticals: Stringent regulations (UDI – Unique Device Identification, serialization for anti-counterfeiting) mandate permanent, tamper-proof markings on surgical instruments, implants, and packaging. This sector will continue demanding high-reliability, clean (non-contaminating) marking solutions, favoring fiber and UV lasers.

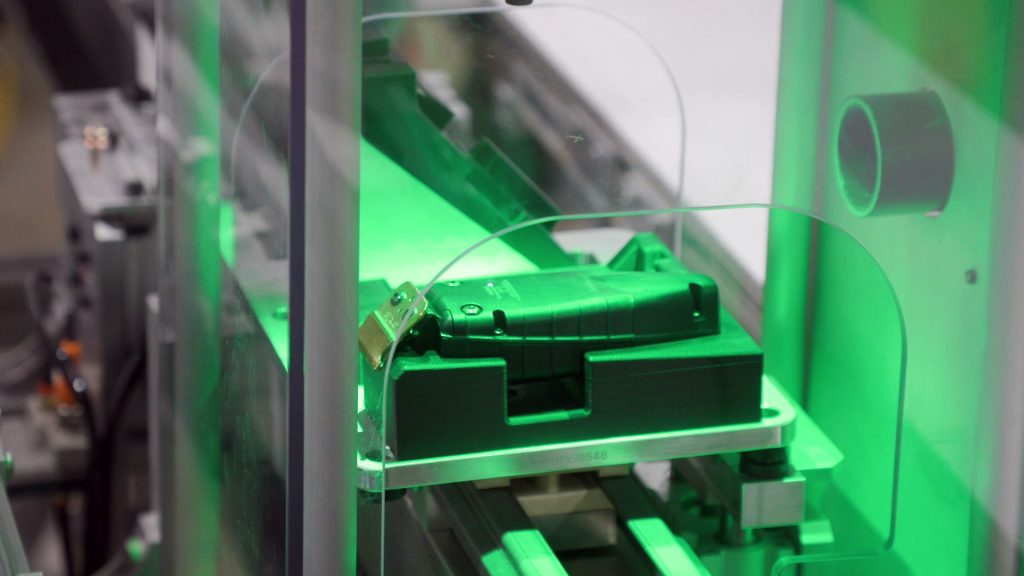

* Automotive: Traceability throughout the supply chain (engine parts, chassis, ECUs, batteries) is critical. The rise of EVs increases demand for marking battery components (cells, modules, packs) with high durability. Integration with automated production lines is essential.

* Consumer Goods & Packaging: Growing need for brand protection, anti-counterfeiting (e.g., holographic effects, micro-text), and consumer engagement (QR codes linking to digital content) drives adoption, especially on plastics and flexible packaging.

2. Technological Advancements Driving Performance & Flexibility:

* Fiber Laser Dominance: Fiber lasers will solidify their position as the workhorse, offering superior reliability, lower maintenance, higher efficiency, and excellent marking quality on metals and many plastics. Power levels and speeds will continue to increase.

* Growth of UV & Green Lasers: UV lasers will see significant growth for high-contrast, cold marking on sensitive materials (plastics, glass, medical devices) without thermal damage. Green lasers will gain traction for marking highly reflective materials (copper, gold) and certain transparent plastics where standard fiber lasers struggle.

* Increased Power & Speed: Higher power lasers (beyond 100W) will enable faster marking on challenging materials and deeper engraving, improving throughput in high-volume production.

* Improved Beam Quality & Focus: Advancements in beam delivery and focusing optics (e.g., dynamic focus, galvo scanners with higher speeds/resolution) will enable finer details, smaller features, and higher marking quality.

* “Smart” and Connected Machines: Integration of IoT capabilities for remote monitoring, predictive maintenance, data logging, and seamless integration with MES/ERP systems will become standard, enhancing operational efficiency and traceability.

3. Software & Automation Integration:

* Advanced Marking Software: User-friendly software with enhanced features (CAD/CAM import, database connectivity for serialization, barcode/2D code generation, vision system integration for alignment) will be crucial. AI/ML might start being explored for process optimization and defect detection.

* Robot & Line Integration: Seamless integration with robotic arms and automated production lines will be non-negotiable for high-volume manufacturers, demanding standardized communication protocols (e.g., OPC UA) and modular designs.

4. Market Dynamics & Competitive Landscape:

* Intensifying Competition: The market will see fierce competition, particularly in the mid-range fiber laser segment, driving price pressure and innovation. Chinese manufacturers will remain strong competitors on price and volume.

* Consolidation & Partnerships: Expect continued M&A activity and strategic partnerships as companies seek to expand technology portfolios (e.g., combining laser sources, software, and vision systems) and global reach.

* Focus on Total Cost of Ownership (TCO): Buyers will increasingly evaluate machines based on TCO (initial cost, maintenance, consumables, energy efficiency, uptime, yield) rather than just upfront price, favoring reliable, efficient brands.

* Regional Growth Variations: Asia-Pacific (especially China, India, Southeast Asia) will remain the fastest-growing region due to manufacturing expansion. North America and Europe will see steady growth driven by automation, regulatory compliance, and technology upgrades.

5. Sustainability & Environmental Focus:

* Energy Efficiency: Demand for lower power consumption will grow, favoring inherently efficient fiber lasers over older technologies like CO2 or lamp-pumped lasers.

* Reduced Waste: Non-contact, precise marking minimizes material waste compared to mechanical methods, aligning with sustainability goals.

* Chemical-Free Process: Laser marking is a clean, chemical-free alternative to inkjet or chemical etching, reducing environmental impact and safety concerns.

Conclusion for H2 2026:

By the second half of 2026, the laser marking machine market will be characterized by maturation in core technologies (fiber) coexisting with rapid innovation in specialized applications (UV, green) and digital integration. Success will depend on manufacturers’ ability to offer highly reliable, fast, and easily integrable solutions tailored to specific industry needs (electronics, medical, automotive), backed by sophisticated software and connectivity. While price competition persists, value will increasingly be derived from performance, durability, low TCO, and seamless integration into Industry 4.0 environments. Companies focusing on application expertise, service, and solving complex traceability challenges will be best positioned to capture market share.

Common Pitfalls When Sourcing Machine Marquage Laser: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Machine Marquage Laser (Laser Marking Machine)

Overview

This guide outlines the essential logistics and compliance considerations for the international shipment, handling, and operation of a Machine Marquage Laser (Laser Marking Machine). Proper adherence ensures regulatory compliance, operator safety, and efficient supply chain operations.

Regulatory Compliance

Laser Safety Standards

- IEC 60825-1: Ensure the machine complies with the International Electrotechnical Commission standard for laser product safety, covering classification, labeling, and technical requirements.

- FDA/CDRH (U.S.): For the U.S. market, the laser must meet U.S. Food and Drug Administration’s Center for Devices and Radiological Health regulations (21 CFR Part 1040.10 and 1040.11). This includes product certification, reporting, and proper labeling.

- CE Marking (EU): Comply with the European Union’s Machinery Directive (2006/42/EC) and the Electromagnetic Compatibility (EMC) Directive (2014/30/EU). Include a Declaration of Conformity and affix the CE mark.

- LVD and RoHS: Ensure compliance with the Low Voltage Directive and Restriction of Hazardous Substances Directive for electrical safety and environmental standards in the EU.

Environmental and Chemical Regulations

- REACH (EU): Confirm that all materials used in the machine comply with REACH regulations regarding the registration, evaluation, and restriction of chemicals.

- WEEE Compliance: Provide information for proper disposal and recycling under the Waste Electrical and Electronic Equipment Directive.

Export and Import Documentation

Required Documentation

- Commercial Invoice: Clearly stating product description, value, quantity, harmonized system (HS) code, country of origin, and Incoterms.

- Packing List: Including weight, dimensions, number of packages, and internal components.

- Certificate of Origin: Required by some countries for tariff assessment.

- Bill of Lading/Air Waybill: Essential for freight forwarding and customs clearance.

- Export License (if applicable): Some countries require export authorization for high-powered laser equipment.

Harmonized System (HS) Code

- Use the appropriate HS code for laser marking machines (e.g., 8456.11 or 8456.90 under machining tools), depending on technical specifications and regional classification.

Packaging and Handling

Secure Packaging

- Use shock-absorbent materials and rigid wooden crates to protect sensitive optical and electronic components.

- Include moisture barrier protection if shipping to humid climates.

- Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture.”

Internal Components

- Secure all movable parts (e.g., galvanometer mirrors, lenses) to prevent damage during transit.

- Remove or protect laser lenses and optical elements with protective caps.

Transport Logistics

Mode of Shipment

- Air Freight: Recommended for urgent or high-value shipments; subject to IATA Dangerous Goods Regulations if batteries are included.

- Sea Freight: Cost-effective for heavy equipment; ensure containers are sealed and climate-controlled if necessary.

Battery Considerations

- If the machine includes lithium batteries, comply with UN 38.3 testing and IATA DGR for air shipments.

- Clearly mark battery type and provide Material Safety Data Sheet (MSDS/SDS) if required.

Customs Clearance

Duties and Tariffs

- Research import duties, VAT, and potential anti-dumping taxes in the destination country.

- Leverage free trade agreements if applicable (e.g., USMCA, EU-South Korea FTA).

Customs Classification

- Provide detailed technical specifications (laser power, wavelength, application) to ensure correct tariff classification and avoid delays.

On-Site Installation and Safety

Operator Training

- Provide comprehensive training in laser safety, machine operation, and emergency shutdown procedures.

- Ensure operators are aware of laser classification (e.g., Class 1, 4) and required protective equipment (e.g., laser safety goggles).

Workplace Compliance

- Install appropriate laser safety enclosures, interlocks, and warning signs per local OSHA, EU directives, or other national safety regulations.

- Conduct a laser safety audit if installing a Class 3B or Class 4 laser system.

After-Sales and Maintenance Compliance

Spare Parts and Service

- Maintain a list of regulated components (e.g., laser source, power supply) for replacement compliance.

- Ensure service technicians are trained and certified, especially for high-risk repairs.

Software and Updates

- Comply with export controls for software updates (e.g., EAR regulations in the U.S.).

- Ensure firmware updates do not compromise safety interlocks or regulatory certifications.

Record Keeping and Audits

Documentation Retention

- Keep records of compliance certificates, shipping documents, and customer training for a minimum of 5–10 years, depending on jurisdiction.

- Maintain logs of safety inspections and maintenance.

Audit Preparedness

- Be ready for regulatory audits by customs, safety authorities, or environmental agencies with up-to-date compliance files.

Conclusion

Adhering to this logistics and compliance guide ensures the safe, legal, and efficient global deployment of Machine Marquage Laser systems. Always consult with local regulatory experts and freight forwarders to address region-specific requirements.

Conclusion for Sourcing a Laser Marking Machine

In conclusion, sourcing a laser marking machine is a strategic investment that can significantly enhance product traceability, brand authenticity, and production efficiency. After evaluating various suppliers, technologies, and machine specifications, it is essential to select a solution that aligns with your application requirements—whether for marking metals, plastics, or other materials—and meets industry standards for precision, durability, and compliance.

Key considerations such as laser type (fiber, CO₂, or UV), marking speed, integration capabilities with existing production lines, after-sales support, and total cost of ownership must be carefully weighed. Partnering with a reputable supplier offering proven technology, technical expertise, and responsive service ensures long-term reliability and operational success.

Ultimately, the right laser marking machine not only improves manufacturing quality but also supports regulatory compliance and customer satisfaction, delivering a strong return on investment. A well-informed sourcing decision today will position your operations for greater automation, traceability, and competitiveness in the evolving industrial landscape.