The global portable laser cutting machine market is experiencing robust growth, driven by increasing demand for precision, energy efficiency, and mobility across industries such as automotive, metal fabrication, and aerospace. According to a report by Mordor Intelligence, the global laser cutting equipment market is projected to grow at a CAGR of over 7.5% from 2023 to 2028, with portable systems gaining traction due to their flexibility in field operations and reduced setup time. Similarly, Grand View Research highlights that the rising adoption of advanced manufacturing technologies and the shift toward automation are accelerating the expansion of the laser processing sector. As manufacturers seek cost-effective and versatile cutting solutions, portable machine laser systems have emerged as a preferred choice. This growing demand has spurred innovation and competition among key players worldwide, paving the way for advancements in power efficiency, portability, and integration with digital controls. In this dynamic landscape, we spotlight the top 10 portable machine laser manufacturers leading the charge in technology, reliability, and market reach.

Top 10 Machine Laser Portable Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 LaserPecker

Website: laserpecker.com

Key Highlights: LaserPecker is offering laser engraving and cutting machines for you, with the aim to produce portable, smart and powerful DIY technology and tools!…

#2 LaserPecker Global Official

Website: global.laserpecker.net

Key Highlights: LaserPecker is offering LaserPecker laser engraving and cutting machine for you, with the aim to produce powerful and portable DIY technology and tools!…

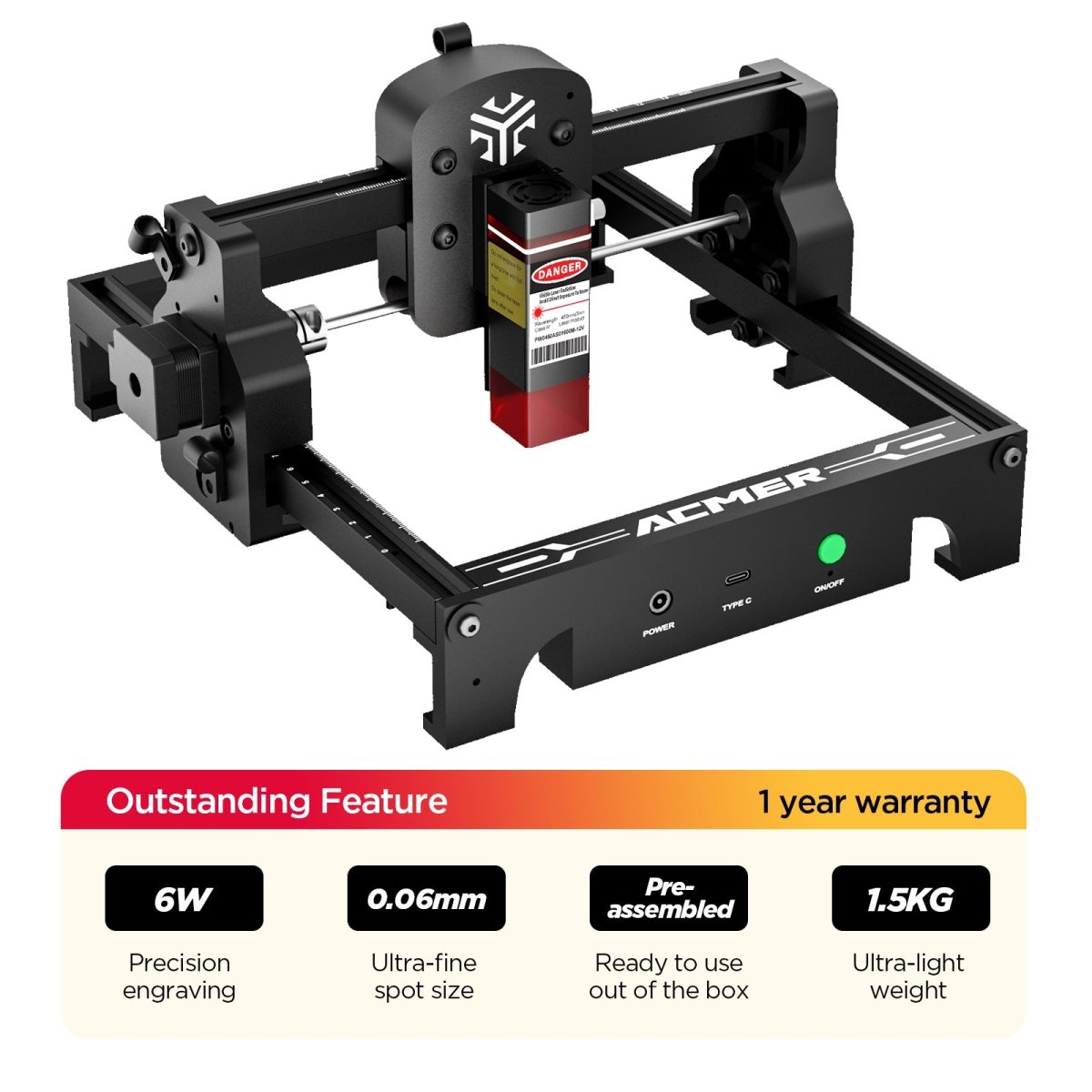

#3 ACMER

Website: acmerlaser.com

Key Highlights: Free delivery 30-day returnsACMER is committed to top laser technology, it is equipped with the world’s first corexy laser engraving machine and the world’s first Gantry dual laser…

#4 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies is a US manufacturer of laser products and has engineered, designed, and built laser systems and solutions for use in high-precision ……

#5 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#6 Full Spectrum Laser

#7 DAJA Laser Engraver

Website: dajastores.com

Key Highlights: Discover DAJA laser engraving machines – powerful, portable, and perfect for DIY, craft, and professional projects. Engrave metal, wood, acrylic, ……

#8 Laser engravers & laser cutters

Website: gravotech.us

Key Highlights: Check out Gravotech’s laser engraving and cutting machines. The most efficient and durable engraving solutions on the market. Free trials and quotes!…

#9 OMTech Laser

Website: omtech.com

Key Highlights: Turn your creative dreams into reality with our laser engraving and cutting machines, from desktop CO2 lasers to fiber lasers, which are perfect for ……

#10 Best Laser Cutting and Engraving Machine, Metal …

Expert Sourcing Insights for Machine Laser Portable

H2: 2026 Market Trends for Portable Machine Laser Technology

The portable machine laser market is poised for significant transformation by 2026, driven by technological advancements, expanding industrial applications, and increasing demand for flexible manufacturing solutions. As industries prioritize efficiency, precision, and mobility, portable laser systems are emerging as critical tools across sectors such as automotive, aerospace, construction, and metal fabrication.

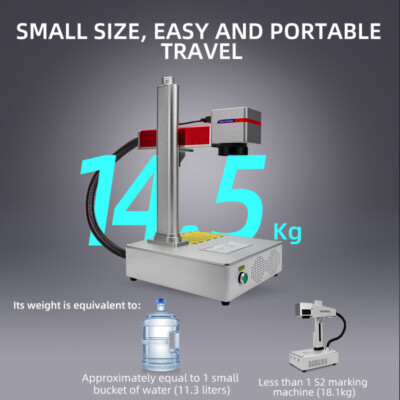

One of the primary trends shaping the 2026 landscape is the miniaturization and enhanced energy efficiency of laser systems. Innovations in fiber laser technology and battery-powered designs are enabling compact, lightweight units that maintain high cutting and welding performance. This shift supports field-based operations, such as on-site pipeline repairs or structural modifications, where traditional stationary lasers are impractical.

Integration with smart technologies—including IoT connectivity, real-time monitoring, and AI-driven process optimization—is another key trend. By 2026, leading portable laser machines are expected to feature built-in diagnostic systems and cloud-based data sharing, allowing for predictive maintenance and remote operation. This digital integration improves uptime and operational accuracy, especially in complex or hazardous environments.

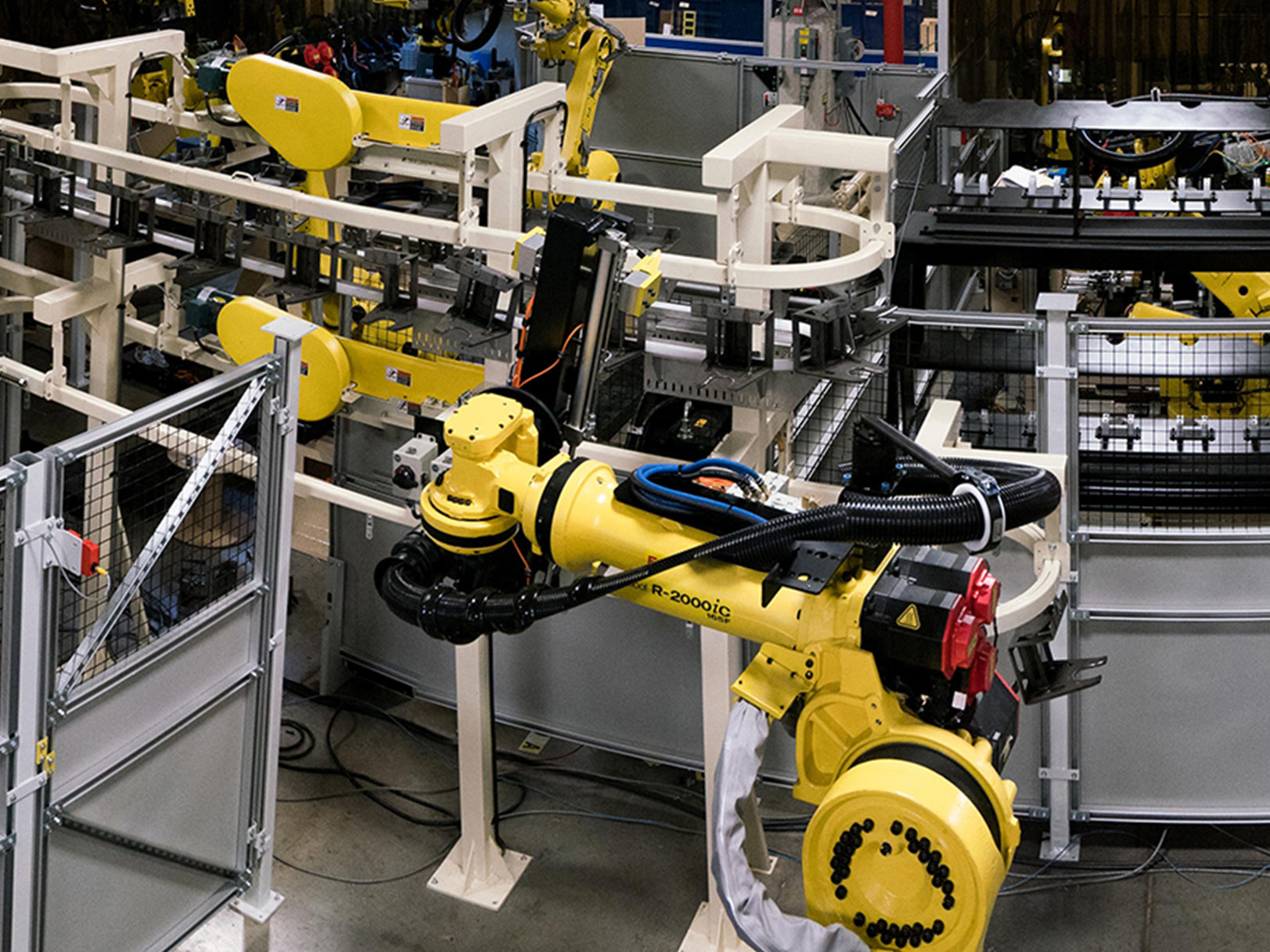

Additionally, the demand for automation and robotic compatibility is rising. Portable laser units are increasingly designed to work with robotic arms or collaborative robots (cobots), enabling precise, repeatable tasks in dynamic workspaces. This trend aligns with the broader Industry 4.0 movement, emphasizing flexible and scalable production systems.

Geographically, North America and Asia-Pacific are anticipated to lead market growth, fueled by investments in advanced manufacturing and infrastructure development. Regulatory support for clean and efficient technologies, along with growing emphasis on reducing carbon footprints, further boosts adoption of laser-based solutions over traditional mechanical methods.

In summary, by 2026, the portable machine laser market will be defined by smarter, smaller, and more adaptable systems that meet the evolving needs of modern industry—ushering in a new era of on-demand precision manufacturing.

Common Pitfalls When Sourcing Portable Laser Machines (Quality and IP)

Sourcing portable laser machines can offer flexibility and cost savings, but it comes with notable risks related to quality and intellectual property (IP). Being aware of these common pitfalls helps ensure a reliable and legally sound procurement process.

Inconsistent or Substandard Build Quality

Many portable laser machines, especially those from less-established suppliers, suffer from inconsistent manufacturing standards. Components such as laser diodes, cooling systems, and optical assemblies may be of inferior quality, leading to reduced precision, frequent breakdowns, or shortened machine lifespan. Buyers often overlook certifications (e.g., CE, FDA, ISO) or fail to verify actual performance through third-party testing, resulting in unreliable equipment.

Lack of IP Compliance and Risk of Infringement

A significant risk in sourcing portable lasers—particularly from regions with weak IP enforcement—is the potential use of counterfeit or cloned technology. Suppliers may incorporate patented optics, control software, or mechanical designs without proper licensing. Purchasing such equipment exposes the buyer to legal liability, including customs seizures, lawsuits, or forced equipment decommissioning, especially when operating in IP-sensitive markets.

Inadequate After-Sales Support and Spare Parts Availability

Portable laser machines require maintenance and occasional part replacements. Sourcing from distant or unknown suppliers often means limited access to technical support, firmware updates, or genuine spare parts. This can lead to extended downtime and increased total cost of ownership, undermining the perceived affordability of the initial purchase.

Misleading Specifications and Performance Claims

Some suppliers exaggerate laser power, cutting depth, or accuracy in product specifications. Without independent verification or real-world testing, buyers may end up with equipment that underperforms for their intended applications—such as engraving or cutting specific materials—leading to project delays and wasted resources.

Absence of Safety and Regulatory Certifications

Portable lasers must meet safety standards (e.g., IEC 60825 for laser safety). However, many low-cost models lack proper certification or include inadequate safety features like interlocks and protective housings. Using non-compliant equipment poses safety risks to operators and may violate workplace regulations, resulting in fines or operational shutdowns.

Weak Contractual Protections and Warranty Terms

Purchase agreements for portable laser machines often contain vague or unenforceable warranty clauses. Buyers may discover too late that warranty coverage excludes critical components or requires return shipping to the supplier’s country—a costly and time-consuming process. Clear, legally binding contracts with defined quality assurance and IP indemnity clauses are frequently overlooked.

Avoiding these pitfalls requires due diligence: verifying supplier credentials, requesting product testing, auditing compliance certifications, and ensuring contractual protection against IP risks and quality failures.

Logistics & Compliance Guide for Portable Laser Machines

Overview

This guide outlines the essential logistics and compliance considerations for the transportation, import/export, and safe operation of portable laser machines. Adherence to international and regional regulations is critical to ensure legal compliance, safety, and smooth supply chain operations.

Classification & Documentation

Portable laser machines are classified under specific product categories based on function, power output, and application. Accurate classification is required for customs clearance and regulatory compliance.

– HS Code: Typically 8515.21 or 8515.30 (Laser-based equipment), but verify based on exact specifications.

– Required Documentation:

– Commercial Invoice

– Packing List

– Bill of Lading/Air Waybill

– Certificate of Origin

– Technical Specifications (including laser class, wavelength, power output)

– FDA or equivalent regulatory compliance certificate (e.g., FDA 510(k) for U.S.)

– CE Declaration of Conformity (for EU)

Laser Safety Classification

Portable laser machines must comply with laser safety standards, such as IEC 60825-1.

– Laser Classes: Most portable lasers fall under Class 1, 2, 3R, 3B, or 4.

– Labeling Requirements:

– Clearly visible warning labels indicating laser class

– Aperture labels with wavelength and maximum output power

– Compliance: Ensure product bears CE, FDA, or other regional safety marks as applicable.

International Shipping & Transport Regulations

Transporting laser devices is subject to air, sea, and ground regulations due to potential hazards.

– IATA Dangerous Goods Regulations (DGR):

– Most portable lasers are not classified as dangerous goods if the laser emission is secured and below Class 4 thresholds.

– Class 4 lasers or those with high-power batteries may require special handling.

– Always disable the laser during transport and secure the emission window.

– Battery Compliance:

– Lithium-ion batteries (common in portable units) must comply with UN 38.3 testing.

– Packaging must meet IATA PI 965–970 standards.

– Include proper battery labels and documentation.

Import/Export Controls

Laser machines may be subject to export controls due to dual-use potential (civilian and military applications).

– Export Regulations:

– U.S. (EAR): Check Commerce Control List (CCL) – ECCN 6A003 may apply based on power and wavelength.

– EU (Dual-Use Regulation): Verify if the device falls under Annex I.

– Licensing Requirements:

– High-power lasers (especially Class 4) may require export licenses.

– Sanctioned countries (e.g., Russia, Iran) may be restricted.

Regional Compliance Requirements

Different markets have specific regulatory frameworks.

– United States:

– FDA/CDRH compliance for all laser products (21 CFR 1040.10).

– Registration and listing required.

– European Union:

– CE marking under Machinery Directive (2006/42/EC), EMC Directive, and RoHS.

– Notified Body involvement may be required for Class 3B and 4 lasers.

– Canada:

– Complies with Health Canada’s Radiation Emitting Devices Act (REDA).

– Requires product certification and labeling.

– Other Regions:

– Check local standards (e.g., PSE in Japan, KC in South Korea, CCC in China).

Packaging & Handling

Proper packaging ensures device safety and regulatory compliance during transit.

– Use anti-static, shock-resistant materials.

– Include moisture protection if shipping to humid climates.

– Secure batteries separately if removable.

– Mark packages with “Fragile,” “This Side Up,” and laser warning symbols as needed.

End-User Compliance & Training

Ensure end users are informed and trained.

– Provide multilingual user manuals with safety instructions.

– Include compliance statements and declaration of conformity.

– Recommend safety training for operators, especially for Class 3B and 4 lasers.

Record Keeping & Audits

Maintain comprehensive records for traceability and regulatory audits.

– Retain compliance certificates, test reports, and shipment documentation for minimum 5–10 years.

– Implement a quality management system (e.g., ISO 13485 or ISO 9001) if applicable.

Conclusion

Compliance with logistics and regulatory standards is essential for the global distribution of portable laser machines. Proactive classification, documentation, and adherence to safety and export controls will minimize delays, avoid penalties, and ensure user safety. Always consult local regulatory authorities or compliance experts when entering new markets.

Conclusion: Sourcing a Portable Laser Machine

Sourcing a portable laser machine requires careful evaluation of technical specifications, application needs, budget constraints, and long-term service support. Portable laser machines offer unmatched flexibility for on-site operations in industries such as metal fabrication, construction, oil and gas, and maintenance, enabling precise cutting, welding, and marking directly in the field.

Key considerations when sourcing include laser power, portability, battery life or power requirements, ease of use, safety features, and compatibility with materials. It is crucial to choose a reputable supplier or manufacturer that provides reliable technical support, training, and warranty coverage. Additionally, balancing initial investment with total cost of ownership—factoring in maintenance, consumables, and durability—ensures optimal return on investment.

In conclusion, investing in a high-quality portable laser machine enhances operational efficiency, reduces downtime, and improves precision in remote or confined work environments. With the right due diligence and supplier partnership, businesses can successfully integrate portable laser technology into their workflows, driving innovation and productivity across projects.