The global market for machine de marquage—otherwise known as marking and engraving equipment—has experienced robust growth, driven by increasing demand for traceability, product authentication, and compliance across industries such as automotive, aerospace, electronics, and medical devices. According to Grand View Research, the global laser marking machine market size was valued at USD 1.87 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. This surge is further fueled by advancements in fiber laser technology, automation integration, and the need for high-precision, non-contact marking solutions. As industries prioritize permanent, tamper-proof identification of components, manufacturers are investing heavily in innovative marking systems that offer speed, durability, and versatility. In this evolving landscape, a select group of manufacturers have emerged as leaders, shaping the technological direction of the market. Based on performance, innovation, global reach, and market presence, here are the top 9 machine de marquage manufacturers leading the charge in this expanding sector.

Top 9 Machine De Marquage Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Datalogic

Website: datalogic.com

Key Highlights: Datalogic is a world-class producer of bar code readers, mobile computers, sensors, vision and laser marking systems….

#2 Marking Machine Manufacturer France

Website: dubuit-reeltech.fr

Key Highlights: DUBUIT REELTECH specializes in the production of industrial marking machines, screen printing equipment, and pad printing machinery….

#3 MECCO

Website: mecco.com

Key Highlights: Manufacturers rely on MECCO engraving and marking systems to help problem-solve and ensure part traceability. Learn about our products for laser and pin ……

#4 Fiber Laser Cutting Machines

Website: xtlaser.com

Key Highlights: XT LASER is a laser equipment manufacturer. XT laser is sheet metal laser cutting machines, metal pipe laser cutting machines, welding machines, ……

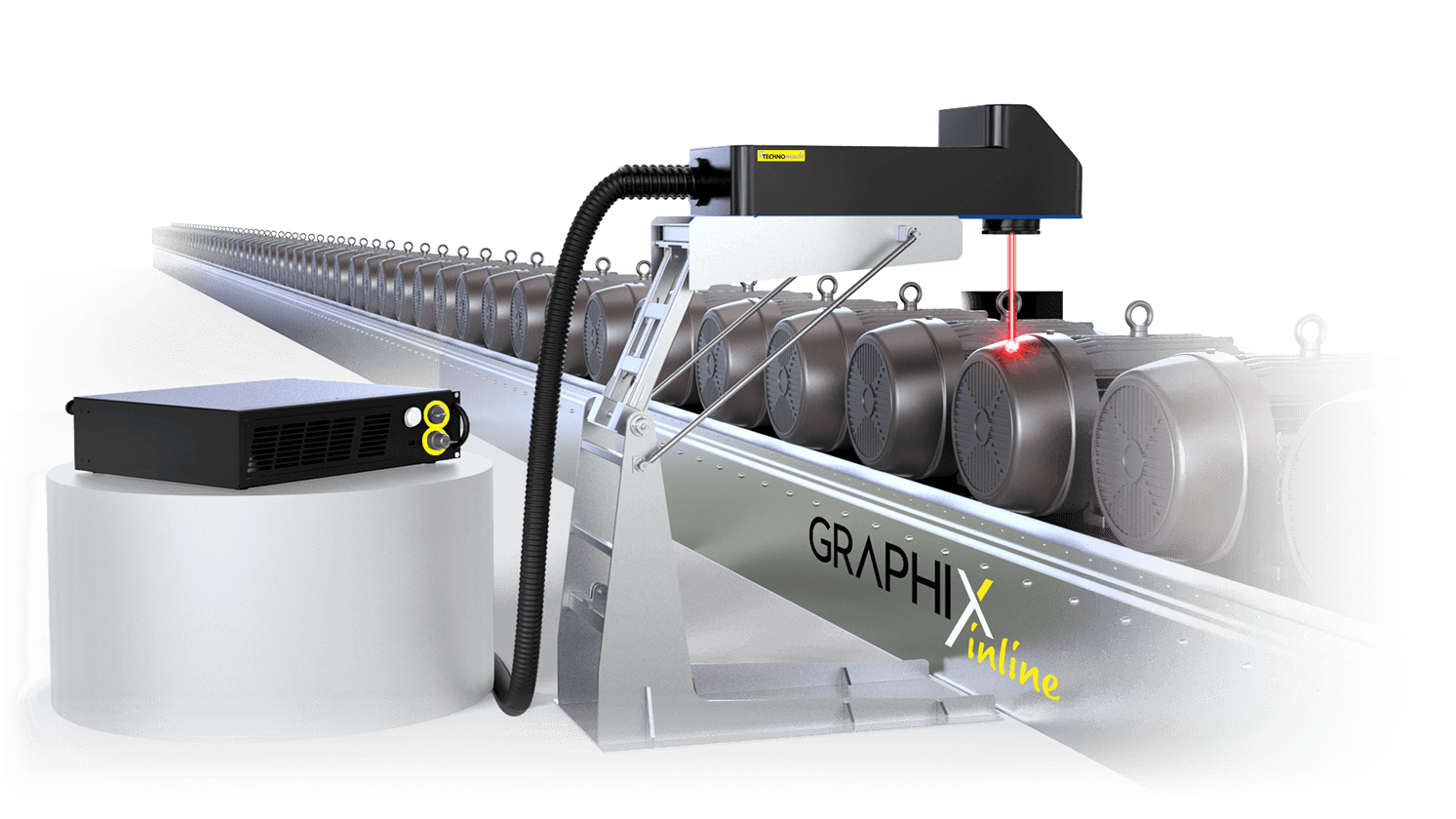

#5 Technomark: Industrial marking

Website: technomark-marking.com

Key Highlights: An industrial start-up created in 2000, Technomark is now a benchmark in the permanent marking market with its 23,000 pieces of equipment in service nationwide….

#6 Fiber Laser Marking Machine, Laser Engraving System Price

Website: alldolaser.com

Key Highlights: Alldo fiber laser marking machine is mainly used for marking and engraving various metals, and some non-metals with amazing speedy marking. RFQ Now….

#7 Our custom marking machines

Website: sic-marking.com

Key Highlights: Our custom marking solutions are modular: we can adapt 3D marking functions, integrated viewing systems, specific marking window sizes, PLCs, etc….

#8 Design and manufacture of special machines

Website: dmagroupe.com

Key Highlights: We design and manufacture your special machine. We offer solutions ranging from independent machines to fully integrated and custom-designed lines….

#9 PRESSES SEFA, fabricant de presses pour le marquage sur tout …

Website: sefa.fr

Key Highlights: SEFA fabrique en France depuis 1973 des presses pour le marquage sur tout support de communication, par transfert à chaud ou impression directe….

Expert Sourcing Insights for Machine De Marquage

H2: 2026 Market Trends for Machine de Marquage

The global market for machine de marquage (marking machines) is projected to undergo significant transformation by 2026, driven by technological innovation, increasing industrial automation, and stringent regulatory demands for product traceability. As industries across manufacturing, automotive, aerospace, pharmaceuticals, and consumer electronics prioritize precision, efficiency, and compliance, marking technologies are evolving to meet these needs. Below are the key market trends shaping the machine de marquage landscape in 2026:

1. Rise of Advanced Laser Marking Technologies

Laser marking machines continue to dominate the market, with fiber, UV, and green lasers gaining traction due to their precision, speed, and ability to mark on a wide variety of materials—from metals to plastics and ceramics. By 2026, the adoption of ultrafast (picosecond and femtosecond) lasers is expected to grow, particularly in high-precision sectors such as medical devices and microelectronics, where non-contact, clean marking is essential.

2. Integration with Industry 4.0 and Smart Manufacturing

Marking machines are increasingly being integrated into smart factory ecosystems. In 2026, machine de marquage systems will feature IoT connectivity, real-time monitoring, and data logging capabilities. This enables seamless traceability through Digital Product Passports (DPP), supports serialization, and enhances quality control through cloud-based analytics and predictive maintenance.

3. Growing Demand for Permanent and Tamper-Proof Marking

Regulatory frameworks such as the EU Medical Device Regulation (MDR), FDA UDI requirements, and automotive safety standards are pushing manufacturers to adopt permanent marking solutions. This drives demand for durable marking methods like laser engraving and dot peening, which ensure barcodes, QR codes, and Data Matrix codes remain readable throughout a product’s lifecycle.

4. Expansion in Emerging Markets

Asia-Pacific, particularly China, India, and Southeast Asia, is witnessing rapid industrialization and growth in electronics and automotive manufacturing. This regional expansion is fueling demand for cost-effective and reliable marking solutions. Local manufacturers are also investing in R&D to produce competitive domestic marking machines, reducing reliance on imports.

5. Sustainability and Energy Efficiency

Environmental concerns are influencing equipment design. By 2026, machine de marquage manufacturers are prioritizing energy-efficient components, reduced material waste, and longer service intervals. Laser systems, which consume less power and produce no chemical byproducts compared to inkjet marking, are becoming the preferred sustainable alternative.

6. Shift Toward Hybrid and Multi-Technology Platforms

To offer greater flexibility, vendors are developing hybrid marking systems that combine laser, inkjet, and pneumatic technologies in a single unit. These multi-functional platforms allow manufacturers to switch between marking methods depending on material type, production speed, or regulatory requirements—enhancing operational versatility.

7. Increased Customization and User-Friendly Interfaces

Modern marking machines are incorporating intuitive software with touchscreen HMI, AI-powered design assistants, and CAD/CAM integration. This enables faster setup, remote programming, and customization of logos, serial numbers, and variable data—critical for mass personalization trends in consumer goods.

8. Strong Growth in the Automotive and EV Sectors

The rise of electric vehicles (EVs) is creating new marking requirements for battery cells, power electronics, and structural components. In 2026, marking machines capable of high-speed, high-contrast coding on challenging surfaces (e.g., anodized aluminum, composites) will be in high demand to support traceability and safety compliance in EV production lines.

In conclusion, the machine de marquage market in 2026 is characterized by digital integration, regulatory-driven adoption, and technological sophistication. Companies that invest in smart, flexible, and sustainable marking solutions will be well-positioned to lead in this evolving industrial landscape.

Common Pitfalls When Sourcing Machine de Marquage: Quality and Intellectual Property Risks

Logistics & Compliance Guide for Machine De Marquage (Marking Machines)

Product Classification & Regulatory Overview

Marking machines (Machine De Marquage) are industrial systems used to permanently mark or engrave materials such as metal, plastic, or glass using technologies like laser, dot peen, inkjet, or electrochemical methods. These machines are subject to various international and regional regulations due to their use of electrical components, potential laser emissions, and mechanical operation. Proper classification under trade and safety frameworks is essential.

HS Code & Import/Export Classification

The Harmonized System (HS) code for marking machines typically falls under 8479.89, which covers “Machines of a kind used solely or principally for a specific industrial process, not elsewhere specified or included.” However, final classification may depend on the marking technology:

– Laser marking machines: May fall under 8515.21 (Laser machines for engraving or cutting).

– Dot peen or mechanical markers: Often classified under 8477.80 (Other machines for working rubber or plastics).

Always verify with local customs authorities and provide detailed technical specifications to ensure accurate classification and avoid delays.

Safety & Certification Requirements

Marking machines must comply with safety standards in both the country of origin and destination. Key certifications include:

– CE Marking (EU): Mandatory under the Machinery Directive (2006/42/EC) and, for laser models, the Low Voltage Directive (2014/35/EU) and EMC Directive (2014/30/EU).

– FDA/CDRH Compliance (USA): Required for laser marking systems under 21 CFR 1040.10 and 1040.11. Registration with the Center for Devices and Radiological Health (CDRH) is mandatory.

– CSA (Canada): Compliance with Canadian Electrical Code and machinery safety standards.

– UKCA Marking (UK): Required post-Brexit for placement on the UK market, aligning with CE standards during transition periods.

Laser-Specific Regulatory Considerations

Laser marking machines are subject to additional controls:

– Laser Class: Most industrial marking lasers are Class 4 and require safety interlocks, warning labels, and protective enclosures.

– IEC 60825-1: International standard for laser product safety; compliance is often required globally.

– Export Controls: High-powered lasers may be subject to dual-use export regulations under Wassenaar Arrangement guidelines. A license may be required for shipment to certain countries.

Packaging & Shipping Requirements

Proper packaging is critical to prevent damage during transit:

– Use reinforced wooden crates for heavy machinery, with internal foam or custom inserts to secure components.

– Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up,” “Do Not Stack”).

– Include desiccants to prevent moisture damage, especially for ocean freight.

– Ensure all electrical components are protected from dust and vibration.

Documentation for International Shipments

Accurate documentation ensures smooth customs clearance:

– Commercial Invoice (with detailed description, value, and HS code)

– Packing List (itemizing contents, weights, and dimensions)

– Certificate of Conformity (CE, CSA, or other applicable certifications)

– Bill of Lading or Air Waybill

– CDRH Report (for laser machines exported to the U.S.)

– Export License (if applicable under dual-use or laser-specific regulations)

Import Duties & Taxation

Duties vary by country and HS classification. Examples include:

– European Union: Generally low duty rates for industrial machinery (0–2%), but VAT (19–27%) applies.

– United States: Often duty-free under HTSUS 9801.00.10 if originating from a GSP-eligible country; otherwise, rates vary.

– China: Import tariffs range from 5–10% depending on machine type; VAT at 13% also applies.

Consult a customs broker to determine exact liabilities and eligibility for trade agreements.

Environmental & Disposal Compliance

Marking machines may contain components subject to environmental regulations:

– RoHS (EU): Restricts hazardous substances in electrical equipment.

– WEEE (EU): Requires producers to manage end-of-life equipment recycling.

– REACH: May apply if the machine includes certain chemical substances in coatings or components.

Ensure compliance when placing machines on the market and provide necessary documentation for end-of-life handling.

After-Sales Service & Technical Support Logistics

Plan for global after-sales support:

– Include multilingual user manuals and safety instructions.

– Provide spare parts kits and maintain an inventory in key regions.

– Train local technicians or partner with regional service providers.

– Comply with local warranty and product liability laws.

Conclusion

Successfully shipping and operating marking machines internationally requires careful attention to classification, safety standards, documentation, and regional regulations. Early engagement with compliance experts and freight forwarders is recommended to avoid delays, penalties, or shipment rejection. Regularly review updates to regulations, especially for laser-based systems and export controls.

Conclusion for Sourcing a Marking Machine:

In conclusion, sourcing a marking machine requires a careful evaluation of several key factors including the type of marking technology (e.g., laser, dot peen, inkjet), material compatibility, production volume, precision requirements, and budget constraints. It is essential to identify suppliers that offer reliable machines with adequate technical support, warranty, and service availability. Conducting a thorough market analysis, comparing quotes from multiple vendors, and assessing after-sales service will ensure a cost-effective and efficient investment. Ultimately, selecting the right marking machine will enhance product traceability, improve branding, and support compliance with industry standards, contributing to long-term operational success.