The global market for TV mounting solutions has seen steady expansion, driven by rising demand for flat-panel televisions and an increasing preference for wall-mounted installations in both residential and commercial spaces. According to a report by Mordor Intelligence, the global TV wall mount market was valued at approximately USD 1.3 billion in 2023 and is projected to grow at a CAGR of over 7.2% from 2024 to 2029, fueled by advancements in display technology and the proliferation of smart home ecosystems. As a critical component in secure mounting systems, M6 screws play a pivotal role in ensuring compatibility and stability across various TV brackets and models. With manufacturers demanding high tensile strength, corrosion resistance, and precise thread accuracy, sourcing the right M6 screws has become essential for product reliability and safety. In this evolving landscape, identifying leading manufacturers of M6 screws specifically tailored for TV brackets is crucial for OEMs and assembly partners aiming to meet stringent quality standards and market expectations.

Top 7 M6 Screws For Tv Bracket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Standard Screw Kit Supplier and Manufacturer

Domain Est. 2005

Website: lumi.cn

Key Highlights: Description. Your perfect assistant of installing a TV mount. Contains complete fittings for TV to bracket installation. No need to buy any additional fixings….

#2 Stainless Steel TV or Monitor Mounting Screws, 4 pcs. M4

Domain Est. 2002

#3 M Safety

Domain Est. 2004

Website: products.multibrackets.com

Key Highlights: Anti-theft screws for wallmounts, flex arms, and casings · Compatible with M5 and M6 screw sizes · Designed to replace original screws with tamper-resistant ……

#4 Peerless

Domain Est. 2009

Website: peerless-av.com

Key Highlights: Peerless-AV’s Security Fasteners provide theft resistance for any flat panel mount with a VESA 2 X 2 to 8 X 4 mounting pattern….

#5 VESA Mount Installation

Domain Est. 2009

Website: hideitmounts.com

Key Highlights: M6 Screws are most common for 200mm VESA hole patterns. We provide the appropriate screws based on the hole pattern options for each HIDEit Mount. Our ……

#6 Mounting Dream TV Mount Screws Kit Fits TVs up to 82” MD5754

Domain Est. 2017

#7 M6 TV Wall Mount Phillips Head Bolts/Screws • Stainless • VESA

Website: rtbolts.myshopify.com

Key Highlights: In stockThis packet contains enough hardware to mount one VESA 200 TV or Monitor. This kit includes: 1.) (4) stainless steel, Phillips head M6 x 12 mm machine screws ( ……

Expert Sourcing Insights for M6 Screws For Tv Bracket

H2: Analysis of 2026 Market Trends for M6 Screws for TV Brackets

The global market for M6 screws used in TV brackets is poised for steady growth and transformation by 2026, driven by evolving consumer electronics, mounting technology, and regional construction trends. M6 screws—metric fasteners with a 6mm diameter—are a critical component in securing flat-screen TVs to wall mounts, ensuring compatibility, safety, and stability. This analysis explores key market dynamics shaping the demand, supply, and innovation landscape for M6 screws in the TV bracket segment through 2026.

1. Rising Demand for Wall-Mounted TVs

The proliferation of large-screen LED, OLED, and QLED televisions continues to fuel consumer preference for wall mounting, especially in urban homes, hospitality spaces, and commercial environments. As TVs become thinner and lighter, the need for reliable, standardized fasteners like M6 screws grows. By 2026, the global wall-mounted TV market is expected to expand significantly, directly increasing demand for compatible M6 screws—particularly those meeting VESA (Video Electronics Standards Association) specifications.

2. Standardization and VESA Compliance

VESA mounting patterns increasingly rely on M6 screws due to their strength and compatibility with a wide range of TV sizes (typically 32 inches and above). As more manufacturers adhere to VESA standards, M6 screws remain the dominant fastener choice. The 2026 market will likely see reinforced standardization, with minimal deviation from M6 in mid-to-high-end TV models, ensuring consistent demand across OEMs and aftermarket suppliers.

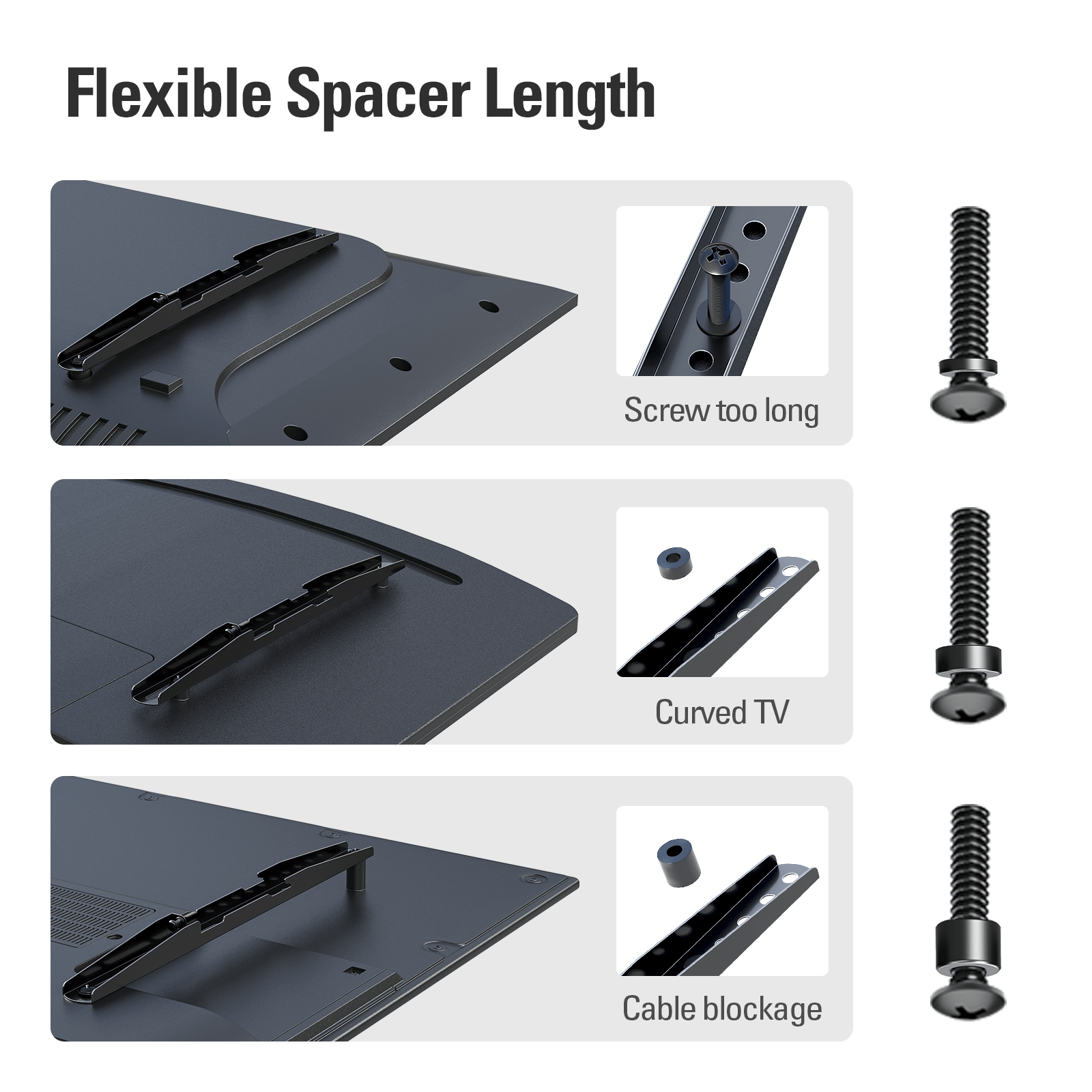

3. Growth in Aftermarket and DIY Installation

The DIY home improvement trend is accelerating, with consumers purchasing TV brackets and installation kits separately. This shift benefits the aftermarket segment for M6 screws, where bundled hardware kits—including corrosion-resistant M6 variants—are in high demand. Retailers and e-commerce platforms are expected to expand product offerings, emphasizing user-friendly, universal M6 screw kits with washers and spacers.

4. Material and Finish Innovations

By 2026, sustainability and durability will drive material innovation. Zinc-plated, black oxide, and stainless steel M6 screws will gain market share due to their anti-corrosion properties and aesthetic appeal. Demand for eco-friendly coatings and recyclable packaging will increase, especially in Europe and North America, aligning with broader ESG (Environmental, Social, and Governance) goals in manufacturing.

5. Regional Market Dynamics

– Asia-Pacific: Rapid urbanization, rising disposable incomes, and smart home adoption in countries like China, India, and South Korea will make this region the largest consumer of M6 screws for TV brackets by 2026. Local manufacturing will reduce costs and lead times.

– North America and Europe: Mature markets with steady demand, driven by TV replacements and home renovations. Emphasis on high-quality, precision-engineered screws will persist.

– Middle East & Africa and Latin America: Emerging markets showing growing interest in home entertainment systems, presenting untapped potential for M6 screw suppliers.

6. Supply Chain and Manufacturing Trends

Automation and lean manufacturing will optimize the production of M6 screws, reducing defects and improving consistency. Nearshoring and regional supply chains may emerge post-2023 disruptions, enhancing delivery reliability. Additionally, integration with smart packaging and QR-coded installation guides could differentiate brands in a competitive landscape.

7. Competitive Landscape

The market will remain fragmented, with key players including fastener manufacturers (e.g., Bossard, Würth, Stanley Black & Decker) and specialized bracket producers. Private-label and OEM partnerships will grow, with customization (e.g., pre-lubricated threads, anti-loosening features) becoming a differentiator.

Conclusion

By 2026, the M6 screw market for TV brackets will be shaped by standardization, regional growth, material advancements, and the booming DIY sector. While the product itself is commoditized, value will increasingly come from quality assurance, sustainability, and integration into smart home ecosystems. Suppliers who innovate in packaging, durability, and customer education will lead the market, capitalizing on the enduring need for secure, reliable TV mounting solutions.

Common Pitfalls When Sourcing M6 Screws for TV Brackets (Quality & IP Rating)

Sourcing the right M6 screws for TV brackets is critical to ensure safety, durability, and compliance with installation standards. However, several common pitfalls related to quality and IP (Ingress Protection) rating can compromise performance. Being aware of these issues helps in making informed purchasing decisions.

Poor Material Quality

One of the most frequent issues is selecting M6 screws made from low-grade materials. Substandard steel or non-stainless alloys may corrode over time, especially in humid environments, leading to weakened joints and potential TV mounting failure. Always opt for screws made from high-quality stainless steel (e.g., A2 or A4 stainless) to ensure strength and longevity.

Inadequate Corrosion Resistance

Even if screws are labeled as “stainless,” not all grades offer sufficient corrosion resistance. For coastal or high-moisture areas, A4 (marine-grade) stainless steel is recommended. Purchasing screws without verifying the exact grade can lead to rusting and structural compromise—especially critical when the TV is mounted near windows or in bathrooms.

Misunderstanding IP Ratings

IP ratings apply primarily to electronic enclosures and do not directly define screw performance. However, some suppliers misleadingly advertise screws with IP ratings, implying environmental protection. In reality, IP ratings for fasteners are irrelevant; instead, focus on material composition and surface treatments (e.g., passivation or coatings) for environmental resilience.

Incorrect Thread Length or Pitch

Using M6 screws with the wrong thread length or pitch can lead to improper fit, stripping of threads, or insufficient grip. Always verify that the screw dimensions (length, pitch, and thread type—e.g., coarse vs. fine) match the TV manufacturer’s specifications and the bracket design.

Lack of Certification or Traceability

Low-cost screws may lack proper certification (e.g., ISO, DIN, or ASME standards), making it difficult to verify their tensile strength and reliability. Always source from reputable suppliers who provide material test reports or compliance documentation to ensure the screws meet required mechanical properties.

Overlooking Load Requirements

TV brackets must support substantial weight, especially for larger screens. Using undersized or low-tensile-strength M6 screws can result in failure under load. Ensure the screws are rated for the weight of the TV and include a safety margin—ideally, screws should exceed the minimum load requirements by a comfortable margin.

By avoiding these common pitfalls, you ensure a secure, long-lasting installation that meets both safety standards and environmental demands.

Logistics & Compliance Guide for M6 Screws for TV Bracket

Product Overview

M6 screws are metric fasteners with a 6mm diameter, commonly used in TV mounting brackets to secure the bracket to the television’s VESA mounting points. These screws must meet specific strength, dimensional, and material standards to ensure safe and reliable installation.

Packaging & Labeling

- Inner Packaging: Screws should be individually bagged or packed in sealed poly bags with quantity clearly labeled (e.g., “4 pcs M6 x 12mm”).

- Outer Packaging: Use durable master cartons with sufficient cushioning to prevent damage during transit. Label cartons with product name, SKU, quantity, weight, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

- Labeling Requirements: Include manufacturer details, country of origin, batch/lot number, and compliance markings. Labels must be in the local language of the destination market.

Shipping & Transportation

- Mode of Transport: Suitable for air, sea, or ground freight depending on order volume and urgency.

- Weight & Dimensions: Confirm total shipment weight and pallet/crate dimensions for freight classification. M6 screws are generally lightweight, allowing for cost-effective small parcel shipping.

- Hazard Classification: Non-hazardous; no special handling or documentation required under IATA, IMDG, or ADR regulations.

Import & Export Compliance

- HS Code: Typically classified under 7318.15.00 (Screws, bolts, and nuts, of iron or steel, threaded). Confirm with local customs authority as sub-codes may vary by coating or material.

- Country-Specific Requirements:

- USA: Compliant with FTC labeling rules; screws must meet ASTM or ANSI standards if referenced.

- EU: Must comply with CE marking requirements if part of a safety-critical assembly. Although standalone screws may not require CE, they should conform to EN ISO 898-1 (mechanical properties of fasteners).

- UK: Follow UKCA marking guidelines post-Brexit; similar standards to EU apply.

- Australia/NZ: Comply with AS/NZS 1110 series for mechanical properties.

- Documentation: Commercial invoice, packing list, bill of lading/airway bill, and certificate of origin as required.

Quality & Safety Standards

- Material: Typically made from carbon steel, stainless steel (A2/A4), or zinc-plated steel.

- Strength Grade: Minimum grade 4.8 recommended; grade 8.8 preferred for heavy TVs.

- Dimensions: Must comply with ISO 4014 or ISO 4017 standards for hex head screws.

- Coating: Zinc plating (clear or blue) for corrosion resistance; RoHS compliant if sold in EU.

- Testing: Batch testing for tensile strength, thread accuracy, and torque resistance recommended.

Environmental & Regulatory Compliance

- REACH & RoHS (EU): Ensure no restricted substances (e.g., lead, cadmium) exceed allowable limits.

- Proposition 65 (California, USA): Include warning labels if applicable (e.g., for metal dust exposure during installation).

- WEEE Directive: Not applicable to standalone screws, but consider if sold as part of complete TV mount kits.

Storage & Handling

- Storage Conditions: Store in a dry, indoor environment to prevent rust or corrosion.

- Shelf Life: Indefinite if stored properly; inspect for oxidation before shipment.

- Handling: Use anti-static or non-contaminating tools in manufacturing/packaging to maintain coating integrity.

Returns & Warranty

- Defect Handling: Replace non-conforming screws (e.g., incorrect length, stripped threads) promptly.

- Warranty: Typically limited to manufacturing defects; exclude misuse or incorrect installation.

- Recall Procedures: Maintain traceability via batch numbers; report major compliance issues to relevant authorities.

Summary

M6 screws for TV brackets are low-risk components but must meet precise technical and regulatory standards. Ensuring compliance with international shipping, labeling, and material regulations reduces delays and liability. Always verify destination country requirements and provide clear documentation throughout the supply chain.

In conclusion, sourcing M6 screws for a TV bracket requires careful consideration of several key factors to ensure safety, compatibility, and durability. It is essential to confirm the screw specifications—such as thread diameter (M6), pitch, length, and head type—based on the TV manufacturer’s guidelines and the bracket design. Opting for high-grade screws, preferably stainless steel or zinc-coated for corrosion resistance, enhances longevity and load-bearing reliability. Sourcing from reputable suppliers or hardware stores, whether online or local, ensures product quality and authenticity. Additionally, checking customer reviews and certifications can further validate the suitability of the screws. Ultimately, using the correct M6 screws not only secures your TV safely to the wall but also protects your investment and ensures peace of mind.