The global fastener market, valued at approximately $115.6 billion in 2023, is projected to grow at a compound annual growth rate (CAGR) of 5.8% through 2030, driven by robust demand from automotive, construction, and industrial manufacturing sectors (Grand View Research, 2023). Within this expansive market, precision components like M5 nuts—standard metric threaded fasteners with a 5mm diameter—play a critical role in ensuring structural integrity and assembly efficiency. As industries prioritize reliability and compliance with international standards, sourcing high-quality M5 nuts from reputable manufacturers has become increasingly vital. With Asia-Pacific emerging as both the largest producer and consumer of fasteners, the competitive landscape is dominated by manufacturers who combine scale, innovation, and stringent quality control. Based on production capacity, global reach, and adherence to ISO and DIN standards, the following eight companies have established themselves as leading M5 nut manufacturers, shaping the backbone of modern industrial assembly.

Top 8 M5 Nut Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

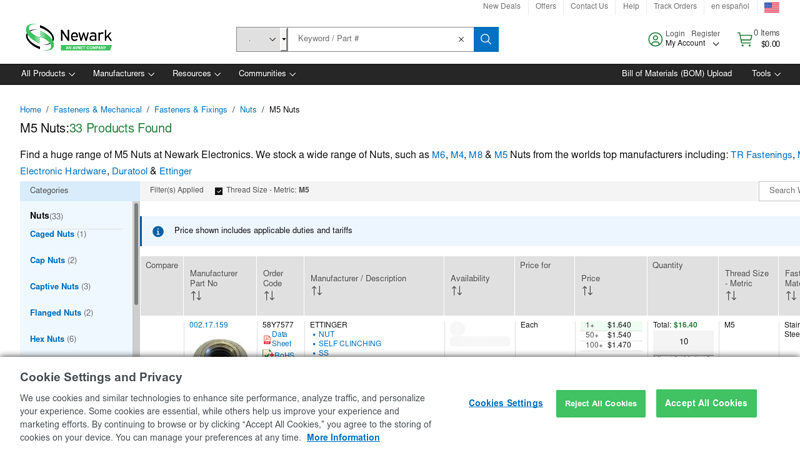

#1 M5 Nuts

Domain Est. 1994

Website: newark.com

Key Highlights: Free delivery over $150 · 60-day returnsFind a huge range of M5 Nuts at Newark Electronics. We stock a wide range of Nuts, such as M6, M4, M8 & M5 Nuts from the worlds top manufac…

#2 M5 x .8 Zinc Plated Class 8 DIN 934 Left Hand Hex Nut

Domain Est. 1995

Website: fastenal.com

Key Highlights: Manufacturer. FASTENAL APPROVED VENDOR ; System of Measurement. Metric ; Material. Steel ; Dia/Thread Size. M5-0.8 ; Type. Hex Nut – Finished….

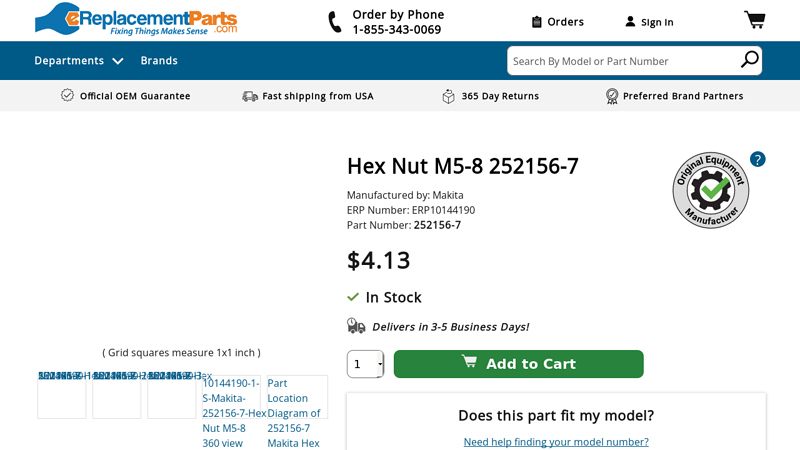

#3 Hex Nut M5

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: 1–2 day delivery 365-day returnsBuy the official Makita Hex Nut M5-8 252156-7 replacement – Use our model diagrams, repair help, and video tutorials to help get the job done….

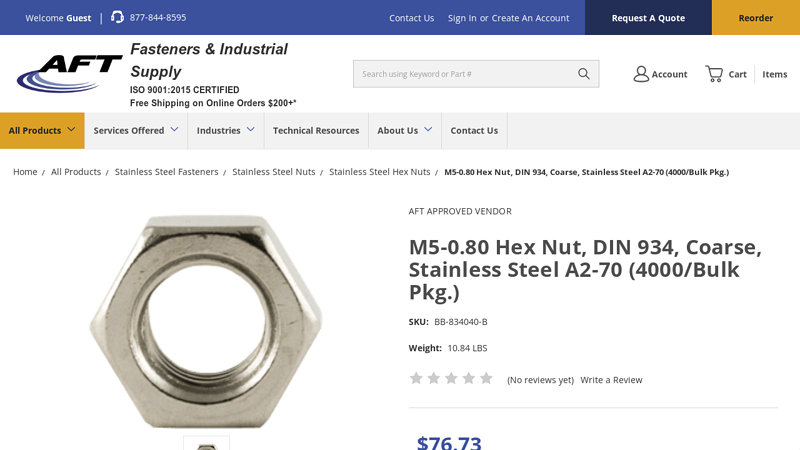

#4 M5-0.80 DIN 934 Hex Nuts A2 Stainless Bulk

Domain Est. 2008

Website: aftfasteners.com

Key Highlights: In stock Free delivery over $200M5-0.80 Hex Nut, DIN 934, Coarse, Stainless Steel A2-70 (4000/Bulk Pkg.) ; Package Quantity: 4000 ; Package Size: Bulk ; Manufacturer Part #:: 83404…

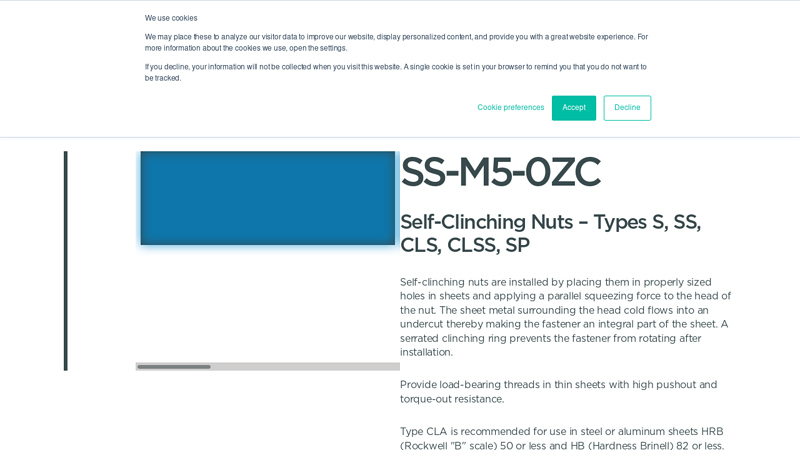

#5 SS

Domain Est. 1996

Website: pemnet.com

Key Highlights: Self-clinching nuts are installed by placing them in properly sized holes in sheets and applying a parallel squeezing force to the head of the nut….

#6 Nut M5

Domain Est. 1996

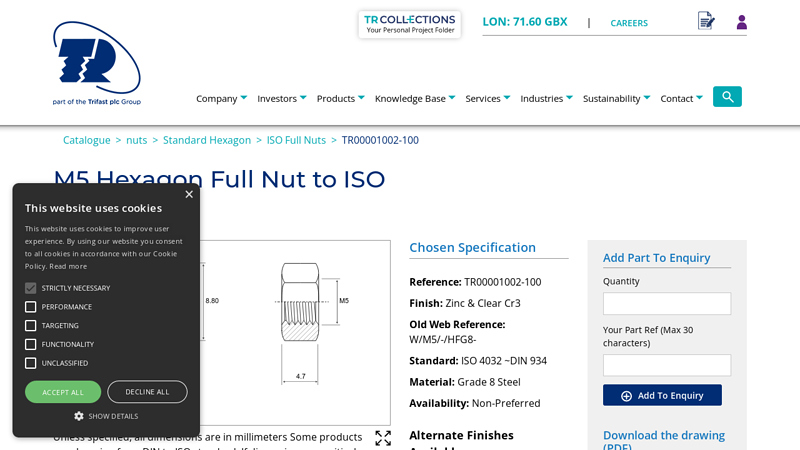

#7 M5 Hexagon Full Nut to ISO

Domain Est. 2000

Website: trfastenings.com

Key Highlights: M5 Hexagon Full Nut to ISO in Grade 8 Steel Zinc & Clear Cr3 with dimensional measurements and 3D model, in a range of finishes….

#8 M5

Domain Est. 2004

Expert Sourcing Insights for M5 Nut

H2: Market Trends for M5 Nuts in 2026

The global market for M5 nuts—a standard metric fastener with a 5mm internal thread diameter—is expected to experience steady growth and transformation in 2026, driven by industrial expansion, technological advancements, and evolving manufacturing demands. The following analysis outlines key trends shaping the M5 nut market during this period.

1. Rising Demand from Automotive and Electric Vehicle (EV) Manufacturing

The automotive sector remains a primary consumer of M5 nuts, used extensively in engine assemblies, chassis components, and interior systems. In 2026, the accelerated global shift toward electric vehicles (EVs) is expected to boost demand for precision-engineered fasteners. M5 nuts, valued for their reliability and compatibility with lightweight materials such as aluminum and high-strength steel, are increasingly integrated into EV battery enclosures, powertrain systems, and body structures. This shift is driving innovation in corrosion-resistant and heat-treated M5 variants to meet stringent EV safety and durability standards.

2. Growth in Industrial Automation and Robotics

The proliferation of automation across manufacturing, logistics, and healthcare industries is fueling demand for standardized, high-tolerance fasteners. M5 nuts are widely used in robotic arms, conveyor systems, and automated assembly lines due to their consistent size and mechanical performance. By 2026, the expansion of smart factories under Industry 4.0 initiatives will further increase the need for reliable M5 fasteners that support modular and reconfigurable machinery.

3. Emphasis on Sustainable and Recyclable Materials

Environmental regulations and corporate sustainability goals are pushing manufacturers to adopt eco-friendly materials. In 2026, there is a growing trend toward producing M5 nuts from recycled steel and non-plated or zinc-flake-coated alternatives to reduce environmental impact. Additionally, manufacturers are investing in energy-efficient production processes and cleaner surface treatments to comply with international standards such as REACH and RoHS.

4. Regional Market Shifts and Supply Chain Diversification

Asia-Pacific, particularly China and India, continues to dominate M5 nut production and consumption in 2026 due to robust infrastructure and manufacturing activity. However, geopolitical tensions and supply chain vulnerabilities have prompted companies in North America and Europe to reshore or nearshore fastener production. This trend is fostering regional manufacturing hubs and increasing investment in local M5 nut production to ensure supply stability.

5. Technological Advancements in Fastener Design

Innovations such as flange hex nuts, nylon-insert lock nuts, and weld nuts in M5 size are gaining traction in 2026. These variants offer enhanced vibration resistance, ease of assembly, and improved load distribution—critical for aerospace, renewable energy, and consumer electronics applications. Digital tools like AI-driven quality control and IoT-enabled inventory management are also being adopted by leading M5 nut suppliers to enhance precision and reduce waste.

6. Price Volatility and Raw Material Challenges

Fluctuations in steel and alloy prices—driven by global energy costs and trade policies—are expected to impact M5 nut pricing in 2026. Suppliers are responding by securing long-term raw material contracts and exploring alternative materials like stainless steel and titanium for high-performance applications.

Conclusion

The M5 nut market in 2026 is characterized by strong demand from high-growth sectors like EVs and automation, coupled with a push for sustainability and supply chain resilience. Manufacturers who invest in innovation, environmental compliance, and regional production capabilities are well-positioned to capitalize on these evolving trends. As standardization and reliability remain critical in industrial applications, the M5 nut will continue to be a foundational component in global manufacturing.

Common Pitfalls Sourcing M5 Nuts (Quality, IP)

Sourcing M5 nuts may seem straightforward, but several pitfalls can compromise quality, performance, and intellectual property (IP) protection—especially in high-volume or safety-critical applications. Being aware of these risks ensures reliable sourcing and avoids costly failures.

Poor Material and Grade Specification

One of the most frequent issues is failing to specify the correct material and strength grade. M5 nuts come in various grades (e.g., Grade 5, Grade 8, A2-70, A4-80 for stainless steel). Using a low-grade or incorrect material can lead to thread stripping, galling, or structural failure under load. Always verify material certifications (e.g., mill test reports) and ensure compliance with standards like ISO 888, ISO 4032, or ASTM.

Inconsistent Thread Quality and Tolerances

Low-cost suppliers may produce nuts with poor thread accuracy, leading to cross-threading or inconsistent torque values. Threads that are out of tolerance (per ISO 965) can compromise joint integrity. Insist on dimensional inspection reports and conduct sample testing for thread fit using calibrated gauges.

Lack of Traceability and Certification

Reputable applications, especially in automotive, aerospace, or medical fields, require full traceability. Sourcing from suppliers who cannot provide lot traceability, material certifications, or ISO/TS compliance increases risk. This lack of documentation can also hinder root cause analysis during failures.

Counterfeit or Non-Compliant Fasteners

The fastener market is plagued by counterfeit products falsely labeled as high-grade or corrosion-resistant. These may use substandard alloys or inadequate heat treatment. Always source from certified distributors or manufacturers and verify markings (e.g., strength grade symbols, manufacturer ID) on the nut.

Intellectual Property (IP) Risks in Custom Designs

When sourcing custom-designed M5 nuts (e.g., with unique locking features or coatings), IP protection is critical. Working with overseas suppliers without robust IP agreements can lead to design cloning or unauthorized production. Ensure clear contractual terms on design ownership, non-disclosure agreements (NDAs), and restrictions on secondary tooling.

Inadequate Corrosion Resistance

Stainless steel M5 nuts are often assumed to be corrosion-proof, but counterfeit or low-quality versions may use inferior alloys (e.g., 200-series instead of 304/316). This leads to premature rusting. Specify exact alloy types and request salt spray test reports when corrosion resistance is critical.

Inconsistent Coatings and Surface Treatments

Coatings like zinc plating, dacromet, or Geomet can vary widely in thickness and performance. Poor coating application results in hydrogen embrittlement or reduced corrosion protection. Define coating specifications (e.g., ASTM B633) and require process control documentation.

Supply Chain Reliability and Lead Times

Relying on a single low-cost supplier, especially in volatile markets, risks delays and quality inconsistencies. Diversify sourcing strategies and audit supplier production capacity and quality management systems (e.g., ISO 9001) to ensure long-term reliability.

Avoiding these pitfalls requires diligence in supplier qualification, clear technical specifications, and ongoing quality verification—protecting both product performance and intellectual assets.

Logistics & Compliance Guide for M5 Nut

Product Overview

The M5 nut is a standard metric fastener with a nominal diameter of 5 millimeters. Typically made from steel, stainless steel, or other alloys, it is designed to mate with an M5 bolt or threaded rod. Common types include hex nuts, lock nuts, and flange nuts. This guide outlines the logistics handling and regulatory compliance considerations for the international shipment and use of M5 nuts.

Packaging & Labeling

Proper packaging ensures product integrity and regulatory compliance during transit. M5 nuts should be packaged in moisture-resistant, durable materials such as sealed polybags, shrink-wrapped bundles, or corrugated cartons with internal dividers to prevent movement. Bulk quantities may require export-grade crates or pallets secured with strapping. Labels must include:

– Product identification (e.g., “M5 Hex Nut, Grade 8.8”)

– Quantity per package

– Lot or batch number

– Manufacturer or supplier name and address

– Country of origin

– Applicable hazard symbols (if coated or treated with hazardous substances)

Transportation & Handling

M5 nuts are generally classified as non-hazardous goods, allowing standard transport via air, sea, or land freight. However, compliance with carrier-specific regulations is required:

– Use ISPM 15-compliant wooden pallets for international shipments to prevent pest infestation.

– Secure loads to prevent shifting during transport.

– Store in dry, temperature-controlled environments to avoid corrosion, especially for carbon steel variants.

– Follow weight and dimensional limits set by carriers to avoid additional fees or delays.

Regulatory Compliance

M5 nuts must meet relevant international and regional standards depending on the destination market:

– ISO Standards: Comply with ISO 4032 (hex nuts), ISO 8673 (flange nuts), or ISO 10511 (prevailing torque nuts).

– REACH (EU): Declare substances of very high concern (SVHCs), especially if plating contains chromium VI or other restricted substances.

– RoHS (EU): Ensure compliance if used in electrical/electronic equipment; restrict lead, cadmium, and other hazardous materials.

– Conflict Minerals (U.S. SEC Rule 13p-1): Report use of tin, tungsten, tantalum, or gold if sourced from conflict-affected regions.

– Customs Classification: Use correct HS Code (e.g., 7318.15 for threaded fasteners of iron or steel) to ensure accurate tariffs and import controls.

Documentation Requirements

Accurate documentation is essential for customs clearance and compliance audits:

– Commercial Invoice (with value, quantity, and product description)

– Packing List

– Certificate of Origin (preferably Form A for GSP benefits)

– Material Test Reports (MTRs) or Certificates of Conformance (CoC) for quality assurance

– SDS (Safety Data Sheet) if coated with oil, lubricants, or anti-corrosion agents

Environmental & Safety Considerations

- Recycle packaging materials where possible; comply with local waste disposal regulations.

- Handle with appropriate PPE (gloves, eye protection) during large-scale distribution to prevent injury from sharp edges.

- Avoid open storage in humid environments to prevent oxidation, particularly for non-stainless variants.

Conclusion

The successful logistics and compliance management of M5 nuts involves adherence to packaging standards, international transport regulations, and regional chemical and safety directives. Maintaining accurate documentation and traceability ensures smooth customs processing and regulatory compliance across global markets.

Conclusion for Sourcing M5 Nuts

In conclusion, sourcing M5 nuts requires a strategic approach that balances quality, cost, supplier reliability, and compliance with technical specifications. After evaluating various suppliers, materials (such as steel, stainless steel, or nylon), plating options (e.g., zinc or chrome), and standards (e.g., DIN 934 or ISO 4035), it is evident that selecting the right M5 nut depends on the application environment—particularly factors like load requirements, exposure to corrosion, and temperature conditions.

Sourcing from reputable suppliers—whether local distributors or global manufacturers—ensures consistency in quality and traceability. Additionally, considering total landed costs, lead times, and minimum order quantities is crucial for maintaining supply chain efficiency and reducing downtime.

For long-term success, building strong relationships with certified suppliers, conducting periodic quality audits, and staying updated on material and industry standards will support reliable and cost-effective procurement of M5 nuts. Ultimately, a well-structured sourcing strategy not only meets technical needs but also contributes to overall operational excellence and product reliability.