The global power tools market, valued at USD 32.7 billion in 2022, is projected to expand at a CAGR of 5.8% through 2030, driven by rising demand in construction, manufacturing, and DIY sectors (Grand View Research, 2023). Within this ecosystem, the segment for M18 bolt-compatible equipment—primarily led by Milwaukee Tool’s renowned M18 platform—has emerged as a cornerstone of professional-grade cordless tool performance. As demand for compatible accessories and fasteners intensifies, a growing number of manufacturers have entered the space, producing high-strength, precision-engineered M18 bolts designed to meet rigorous industry standards. These bolts, critical in structural applications, machinery assembly, and infrastructure projects, require tight tolerances and durable materials to ensure reliability under load. Based on market penetration, product quality, compliance certifications, and industry feedback, we’ve identified the top 7 M18 bolt manufacturers shaping this expanding niche.

Top 7 M18 Bolt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 M18 Bolts

Domain Est. 1998

Website: globalspec.com

Key Highlights: List of M18 Bolts Product Specs, Datasheets, Manufacturers & Suppliers….

#2 Milwaukee® Tool

Domain Est. 2000

Website: milwaukeetool.com

Key Highlights: Milwaukee Tool is the most respected manufacturer of heavy-duty power tools, hand tools, instruments, and accessories….

#3 Fasteners

Domain Est. 1995

Website: hilti.com

Key Highlights: See how your daily applications and your most critical engineering challenges can be served by our fasteners – such as chemical anchors, mechanical anchors, ……

#4 ARP

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: Fastener Tech • ARP Ultra-Torque • Find Your Kit Instructions • Fastener Installation Overview • Torque Value Lookup • Fastener Installation FAQs…

#5 Hex Bolts Dimensions Table

Domain Est. 2017

Website: itafasteners.com

Key Highlights: Shop high quality Hex Bolts from ITA Fasteners at the reasonable price. Available in a range of sizes from M2 to M42 and din 933. Get a quote for Hex Anchor ……

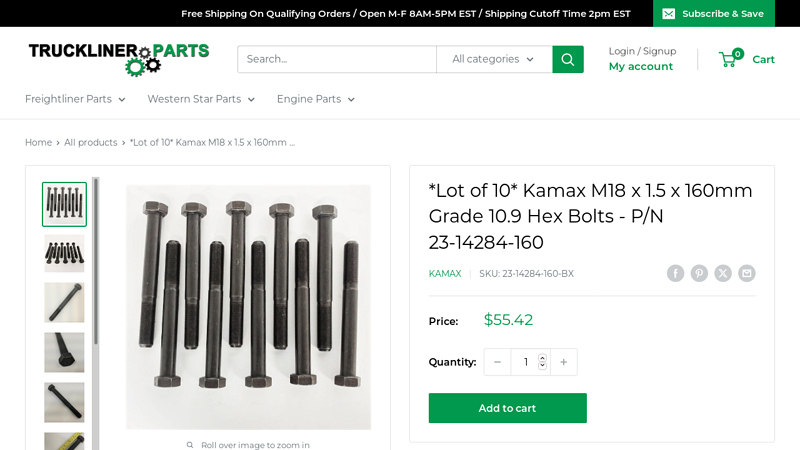

#6 Kamax M18 x 1.5 x 160mm Grade 10.9 Hex Bolts

Domain Est. 2019

Website: trucklinerparts.com

Key Highlights: In stock 3–6 day delivery*Lot of 10* Kamax M18 x 1.5 x 160mm Grade 10.9 Hex Bolts. Selling in Lot of 10 Bolts. Bolt – Hexagonal, Grade 10.9, Phosphate, M18 x 1.5 x 160….

#7 M18™ Shear Bolt Tool

Website: milwaukeetool.eu

Key Highlights: 30-day returnsM18™ shear bolt tool. Huge capacity up to a cable size of 1000 mm² or connector diameter of 78 mm. Outstanding power with a max torque of 100 Nm….

Expert Sourcing Insights for M18 Bolt

H2: Market Trends for M18 Bolt in 2026

As we approach 2026, the market for the M18 Bolt—a high-performance, cordless power tool platform developed by Milwaukee Tool—continues to evolve in response to technological advancements, shifting consumer demands, and broader industrial trends. The M18 ecosystem, known for its versatility, power, and compatibility across over 200 tools, remains a dominant force in the professional trades and DIY sectors. Below is an analysis of key market trends shaping the M18 Bolt (a core component in Milwaukee’s M18 FUEL™ lineup) and the broader M18 platform in 2026.

-

Increased Demand for Cordless Power Tools in Professional Trades

The construction, HVAC, plumbing, and electrical industries are increasingly adopting cordless tools for their portability and efficiency. By 2026, the global cordless power tools market is projected to grow at a CAGR of over 7%, with North America leading adoption. The M18 Bolt, as a compact and high-torque impact driver, benefits from this shift. Contractors prefer M18 tools due to their long battery life (M18 REDLITHIUM™), durability, and seamless integration within the M18 ecosystem. -

Advancements in Battery and Motor Technology

In 2026, Milwaukee continues to enhance the M18 platform with innovations such as higher-capacity batteries (e.g., M18 HD12.0), faster charging, and brushless motors with improved thermal management. The M18 Bolt leverages these upgrades, offering professionals greater runtime and performance in tight spaces. Integration of Milwaukee’s ONE-KEY™ technology allows users to track tool usage, set output levels, and enhance job site accountability—features increasingly valued in enterprise-level contracting. -

Sustainability and Electrification Trends

Regulatory pressures and environmental awareness are accelerating the electrification of worksites. Governments in the U.S. and EU are incentivizing low-emission tools, pushing contractors away from gas-powered equipment. The M18 Bolt, as an electric, zero-emission tool, aligns with these sustainability goals. Milwaukee’s investment in recyclable battery programs and energy-efficient manufacturing further strengthens its ESG positioning, appealing to eco-conscious businesses. -

Expansion of the M18 Ecosystem and Accessories

Milwaukee’s strategy of expanding the M18 platform—adding new tools, attachments, and storage solutions—continues to drive customer lock-in. In 2026, the M18 Bolt benefits from this ecosystem effect, as users who own multiple M18 tools are more likely to adopt new compatible products. Milwaukee also enhances user experience with modular accessories, smart holsters, and integrated lighting—features increasingly expected in premium tools. -

Competition and Market Consolidation

The power tool market remains highly competitive, with rivals such as DeWalt (20V MAX), Makita (18V LXT), and Ryobi expanding their brushless and smart tool offerings. However, the M18 Bolt maintains a strong niche due to its superior ergonomics, power-to-size ratio, and brand loyalty among professionals. In 2026, market consolidation may lead to partnerships or acquisitions, but Milwaukee’s first-mover advantage in the 18V segment supports continued leadership. -

Digital Integration and IoT Adoption

By 2026, IoT-enabled tools are becoming standard on smart job sites. The M18 Bolt, when paired with ONE-KEY™, offers remote diagnostics, inventory management, and performance analytics. This data-driven approach improves productivity and reduces downtime, making the M18 platform attractive to large contracting firms investing in digital transformation.

Conclusion

In 2026, the M18 Bolt remains a critical product within Milwaukee’s broader strategy to dominate the professional cordless tool market. Driven by technological innovation, sustainability mandates, and deep ecosystem integration, demand for the M18 Bolt is expected to remain strong. As industries continue to prioritize efficiency, durability, and smart capabilities, Milwaukee’s focus on performance and user-centric design positions the M18 Bolt as a key player in shaping the future of power tools.

Common Pitfalls Sourcing M18 Bolts (Quality, IP)

Sourcing M18 bolts requires careful attention to avoid critical failures. Overlooking quality and Ingress Protection (IP) specifications can lead to compromised safety, performance, and longevity. Here are key pitfalls to avoid:

1. Prioritizing Cost Over Certified Quality Standards

Choosing the cheapest M18 bolts often means sacrificing material integrity and manufacturing precision. Bolts may lack proper tensile strength (e.g., Grade 8.8 or 10.9 certification), leading to thread stripping, shearing, or fatigue failure under load. Always verify compliance with ISO 898-1 or ASTM A325 standards and request mill test certificates.

2. Ignoring Environmental Suitability and IP Ratings

In outdoor or harsh environments (e.g., marine, chemical, or high-moisture settings), standard carbon steel bolts corrode rapidly. Assuming all M18 bolts are weather-resistant is a critical error. Select stainless steel (A2/A4) or coated variants, and ensure enclosures or assemblies meet required IP ratings (e.g., IP66 for dust and water resistance) to protect bolted joints from degradation.

3. Overlooking Thread Engagement and Tolerance Mismatches

Using bolts with incorrect thread class (e.g., 6g vs. 6H tolerance) can result in poor fit, galling, or insufficient clamping force. M18 bolts must match the mating nut or tapped hole specifications precisely—especially in high-vibration applications where loose fits accelerate fatigue.

4. Failing to Verify Load and Torque Specifications

Applying improper torque due to incorrect bolt grade assumptions risks under-tightening (vibration loosening) or over-tightening (thread damage, bolt fracture). Always confirm the bolt’s proof load and yield strength, and use calibrated torque tools during installation.

5. Sourcing from Unverified Suppliers Without Traceability

Procuring M18 bolts from uncertified vendors increases the risk of counterfeit or substandard products. Lack of traceability makes failure analysis impossible. Partner with reputable suppliers who provide full documentation, batch tracking, and compliance certifications.

Avoiding these pitfalls ensures reliable, safe, and durable assemblies—especially in structural, automotive, or industrial applications where M18 bolts are critical load-bearing components.

Logistics & Compliance Guide for M18 Bolt

Overview of the M18 Bolt Platform

The M18 Bolt is part of Milwaukee Tool’s M18™ series of cordless power tools and accessories, designed for professional-grade performance. As a compact, high-efficiency fastening solution, the M18 Bolt requires careful attention to logistics and compliance protocols throughout its supply chain—from manufacturing and importation to distribution and end-user deployment.

Regulatory Compliance Requirements

All M18 Bolt units must comply with regional and international standards to ensure safety, performance, and environmental responsibility. Key compliance areas include:

– Electrical Safety: Conformance with IEC 62840 (safety of battery-operated hand-held tools) and regional standards such as UL 62840 in the United States and EN 62840 in the European Union.

– Battery Regulations: Lithium-ion batteries must meet UN/DOT 38.3 for transport safety, including testing for vibration, pressure differentials, and thermal stability.

– RoHS & REACH (EU): Compliance with Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) is mandatory for products sold in the European market.

– FCC & EMC (USA/Global): Electromagnetic compatibility (EMC) and radiofrequency (RF) emissions must align with FCC Part 15 in the U.S. and equivalent standards elsewhere.

– CE & UKCA Marking: Required for European Economic Area (EEA) and UK markets, indicating conformity with health, safety, and environmental protection standards.

Packaging and Labeling Standards

Proper packaging ensures product integrity and regulatory compliance during transit and storage:

– Each M18 Bolt unit must be sealed in manufacturer-certified packaging with tamper-evident features.

– Labels must include: product name, model number, voltage (18V), battery chemistry (Li-ion), CE/UKCA/FCC marks, WEEE symbol (for EU), and country of origin.

– Multi-language labeling is required for international shipments, particularly for EU, Canada, and Australia.

– Battery-specific labels must indicate “LITHIUM ION” and include the UN3480 hazard class label for air transport.

Shipping and Transportation Guidelines

Logistics for the M18 Bolt must adhere to global transport regulations, especially due to its lithium-ion battery:

– Air Transport (IATA DGR): Batteries must be shipped at ≤30% state of charge and protected from short circuits. Packaging must pass vibration, drop, and crush tests per UN 38.3.

– Ground & Sea (IMDG/ADR): Follow applicable modal regulations; lithium-ion batteries are classified under UN3480, Class 9 hazardous material. Use certified dangerous goods packaging and documentation.

– Documentation: Include commercial invoice, packing list, Safety Data Sheet (SDS), and Dangerous Goods Declaration (when applicable).

– Temperature Control: Avoid exposure to extreme temperatures (>60°C or <-20°C) during transit to prevent battery damage.

Import and Customs Clearance

Successful customs entry requires accurate classification and documentation:

– HS Code: Typically classified under 8467.21 (hand tools powered by electric motors) or 8507.80 (lithium-ion batteries), depending on configuration. Confirm with local customs authority.

– Duty & Tariff Treatment: Leverage trade agreements (e.g., USMCA, EU-FTA) where applicable. Maintain records for audit and preferential tariff claims.

– Importer of Record (IOR): Must be registered and compliant with local tax and regulatory systems (e.g., EORI in EU, FDA/USCC in U.S.).

– Product Certification: Provide proof of certification (e.g., UL, CE, CCC for China) upon request.

Warehouse and Inventory Management

Optimize storage and handling to maintain compliance and product quality:

– Store in a dry, temperature-controlled environment (10–25°C recommended).

– Segregate lithium-ion tools and batteries from flammable materials.

– Implement FIFO (First-In, First-Out) inventory rotation to reduce shelf-life risks.

– Maintain traceability through batch/lot numbers and serial tracking for recalls or warranty claims.

End-of-Life and Environmental Responsibility

Support circular economy principles and regulatory obligations:

– Comply with WEEE (Waste Electrical and Electronic Equipment) Directive in the EU—provide take-back options and recycling information.

– Encourage participation in Milwaukee’s battery recycling program.

– Train logistics partners on proper disposal procedures for damaged or expired units.

Audit and Documentation Retention

Maintain a robust compliance record system:

– Retain test reports, certificates of conformity, shipping documents, and SDS for a minimum of 5 years (or per local regulation).

– Conduct annual audits of logistics partners to verify adherence to safety and compliance standards.

– Implement corrective action plans (CAPA) for any non-conformances identified.

Adhering to this guide ensures safe, legal, and efficient handling of the M18 Bolt across global supply chains while minimizing risk and supporting sustainability goals.

Conclusion for Sourcing M18 Bolts

In conclusion, sourcing M18 bolts requires careful consideration of several critical factors including material grade (such as Grade 8.8, 10.9, or stainless steel), thread type (coarse or fine), compliance with international standards (e.g., ISO, DIN, ASTM), and the specific application requirements (e.g., structural, automotive, or machinery use). Reliable suppliers with certifications, consistent quality control, and the ability to provide traceability and technical documentation are essential to ensure performance and safety.

Cost-effectiveness should not compromise quality, especially in high-stress or safety-critical applications. Exploring both local and global suppliers, conducting sample testing, and establishing long-term relationships with trusted vendors can optimize supply chain efficiency. Additionally, considering lead times, minimum order quantities, and customization options will further support an effective procurement strategy.

Ultimately, a well-informed sourcing strategy for M18 bolts ensures reliability, compliance, and operational efficiency, minimizing risks of failure and contributing to the overall integrity of the assembly or structure.