The global fastener market, driven by robust demand from automotive, construction, and industrial manufacturing sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2028, according to Mordor Intelligence. With diameter-specific components like M10 bolts playing a critical role in structural integrity and mechanical assembly, the need for high-precision, standardized fasteners has intensified. As of 2023, bolts and threaded fasteners accounted for over 35% of total fastener consumption worldwide (Grand View Research), underscoring their foundational role in industrial applications. Within this landscape, M10 diameter bolts—offering an optimal balance of load capacity and versatility—are among the most widely used metric fasteners across machinery, infrastructure, and automotive platforms. This growing demand has elevated the prominence of manufacturers that combine scale, material innovation, and ISO-certified production. Below, we spotlight the top 8 M10 diameter bolt manufacturers driving quality and efficiency in today’s fastener supply chain.

Top 8 M10 Diameter Bolt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hex Hd Bolt M10 X 135 Mod 31A Sndr

Domain Est. 1995

Website: jettools.com

Key Highlights: Out of stockSpecifications Print. Hex Hd Bolt M10 X 135 Mod 31A Sndr | 31A-92. Stock Number: JT9-31A-92. $6.99. Be the first to review this product. Add to Compare.Missing: diamet…

#2 Portland Bolt

Domain Est. 1998 | Founded: 1912

Website: portlandbolt.com

Key Highlights: Portland Bolt has manufactured and distributed the highest-quality anchor bolts and nonstandard construction fasteners since 1912….

#3 Midwest Fastener

Domain Est. 2000

Website: fastenerconnection.com

Key Highlights: Midwest Fastener is a fastener supplier and fastener manufacturer offering construction fasteners, drywall screws, and much, much more.Missing: m10 diameter…

#4 Bolt M10

Domain Est. 2013

Website: store.classicdmc.com

Key Highlights: In stock $12.43 deliveryBolt M10 | Official Classic DeLorean Motor Company® | New, Original, and Reproduction Parts.Missing: diameter manufacturer…

#5 Metric Fasteners Manufacturer Based in the USA

Domain Est. 2021

Website: gobigbolt.com

Key Highlights: We take pride in providing thousands of quality fasteners in hundreds of sizes, including metric grades. Metric fasteners come in many grades and classes….

#6 The Official ARP Web Site

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: M10 x 1.50 x 20 hex black oxide bolts. UHL: 20mm. Thread Length: 20mm. Socket Size: 12mm hex 5-Pack: 662-1001. M10 x 1.50 x 25 hex black oxide bolts. UHL: 25mm…

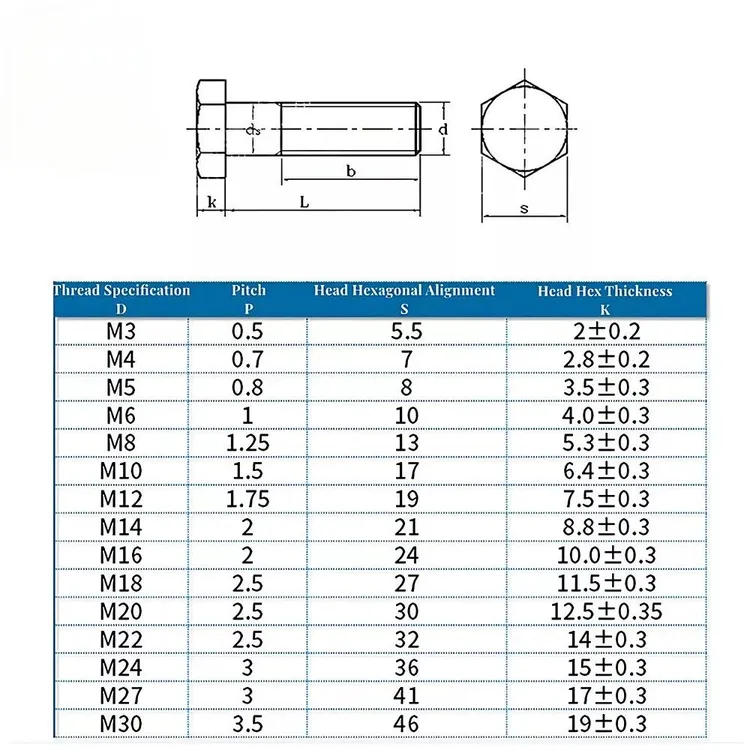

#7 Metric Hex Bolt Dimensions

Domain Est. 2006

Website: atlrod.com

Key Highlights: Metric Hex Bolt Dimensions | Atlanta Rod and Manufacturing | Manufacturing of Bolts, Concrete Embeds, Construction Fasteners, and Stainless Steel Bolts ……

#8 The Blind Bolt

Domain Est. 2011

Website: blindbolt.com

Key Highlights: We rise to the challenge, manufacturing additional sizes designed to save time and money. … M10 x 130, 20, 11, 55, 100, 23, 30, 20. BB10130ZF, 7⁄16″, 2 11⁄64″ ……

Expert Sourcing Insights for M10 Diameter Bolt

H2: 2026 Market Trends for M10 Diameter Bolt

The global market for M10 diameter bolts is anticipated to experience steady growth by 2026, driven by sustained demand across key industrial and construction sectors. As a standardized metric fastener, the M10 bolt (with a 10mm nominal diameter) plays a critical role in automotive manufacturing, infrastructure development, machinery assembly, and renewable energy installations. Several macro- and micro-level trends are expected to shape the M10 bolt market through 2026.

-

Construction and Infrastructure Expansion

Continued urbanization, particularly in emerging economies across Asia-Pacific, Africa, and Latin America, is fueling infrastructure projects such as bridges, commercial buildings, and transportation networks. These developments require large volumes of standardized fasteners, including M10 bolts, especially in structural steel connections and pre-fabricated construction systems. Government investments in public works under post-pandemic recovery initiatives will further boost demand. -

Growth in Automotive and Transportation Sectors

The automotive industry remains a major consumer of M10 bolts, using them in chassis, engine assembly, suspension systems, and body framing. Despite the shift toward lightweight materials and electric vehicles (EVs), the need for high-strength, corrosion-resistant bolts persists. By 2026, the rise in EV production is expected to increase demand for specialized M10 bolts made from alloy steel or stainless steel, designed for durability in high-vibration environments. -

Renewable Energy Projects

Wind and solar energy infrastructure projects are emerging as significant demand drivers. M10 bolts are extensively used in turbine assembly, solar panel mounting systems, and support structures. With global commitments to net-zero emissions, countries are expanding renewable capacity, directly influencing fastener consumption. Offshore wind farms, in particular, require high-grade, galvanized or marine-grade stainless steel M10 bolts to withstand corrosive environments. -

Material and Manufacturing Innovations

By 2026, manufacturers are expected to increasingly adopt advanced materials and surface treatments to improve bolt performance. Trends include the use of high-tensile strength grades (e.g., Grade 8.8, 10.9), eco-friendly coatings (such as zinc-nickel and geopolymer coatings), and precision manufacturing via automation and cold forging. These improvements enhance durability, reduce maintenance, and support compliance with international standards (ISO, DIN, ASTM). -

Supply Chain Resilience and Localization

Geopolitical tensions and supply chain disruptions have prompted a shift toward regional sourcing and nearshoring. Many manufacturers are re-evaluating their supply chains, favoring local or regional bolt producers to reduce lead times and logistics costs. This trend supports the growth of domestic fastener industries in regions like Southeast Asia, Eastern Europe, and North America, increasing competition but also stabilizing M10 bolt availability. -

Sustainability and Regulatory Pressures

Environmental regulations are pushing manufacturers to adopt sustainable practices. The production of M10 bolts is increasingly scrutinized for energy consumption, recyclability, and emissions. By 2026, producers investing in green manufacturing—such as using recycled steel and energy-efficient processes—are likely to gain a competitive edge. Additionally, stricter safety and quality standards in construction and automotive sectors will drive demand for certified, traceable fasteners. -

Digitalization and Smart Inventory Management

Industry 4.0 technologies, including IoT-enabled inventory systems and digital procurement platforms, are transforming fastener distribution. Companies are adopting just-in-time (JIT) delivery models and digital catalogs, improving supply chain efficiency. For M10 bolts—being a high-volume SKU—such systems enhance demand forecasting, reduce stockouts, and support lean manufacturing across end-user industries.

In conclusion, the M10 diameter bolt market in 2026 will be shaped by structural demand from construction and automotive sectors, accelerated by renewable energy growth and technological advancements. Manufacturers who adapt to sustainability requirements, invest in quality and innovation, and leverage digital supply chains will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing M10 Diameter Bolts (Quality, IP)

Sourcing M10 diameter bolts may seem straightforward, but several quality and identification pitfalls (IP) can lead to performance failures, safety risks, or supply chain inefficiencies. Below are common issues to watch for:

1. Misinterpretation of Bolt Grade or Strength Class

A frequent pitfall is assuming all M10 bolts meet the same strength requirements. Bolts are marked with strength classes (e.g., 8.8, 10.9, 12.9), and sourcing without verifying the correct grade can result in structural weakness. For instance, using a 4.6-grade bolt instead of a 10.9 in high-stress applications can lead to catastrophic failure.

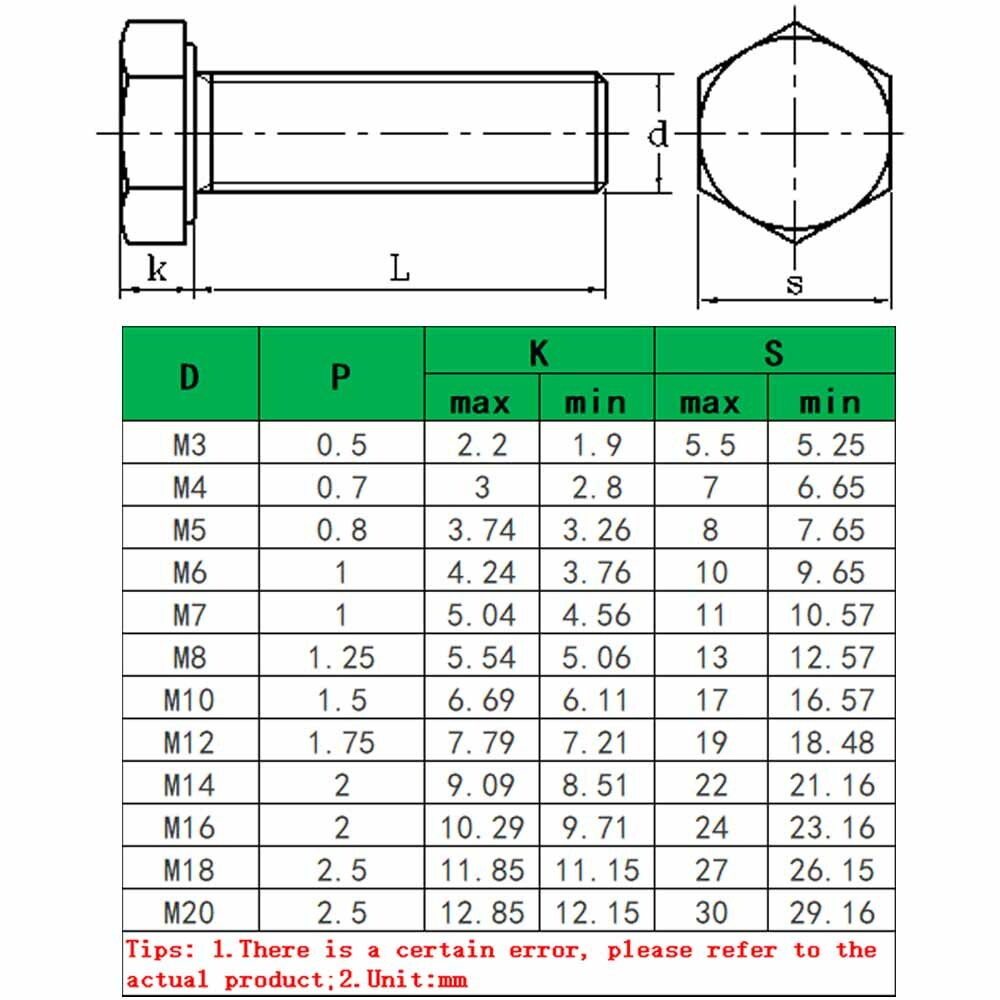

2. Inconsistent Thread Quality and Tolerance

Poor thread rolling or incorrect pitch (e.g., coarse vs. fine thread – M10 vs. M10x1.25) can cause assembly issues, galling, or reduced clamping force. Suppliers may offer non-standard threads that don’t comply with ISO 965 tolerances, leading to fitment problems.

3. Material and Corrosion Resistance Misrepresentation

Many suppliers claim stainless steel (e.g., A2-70 or A4-80), but counterfeit or substandard materials may lack proper alloy content. This leads to premature rusting or failure in corrosive environments. Always verify material certification and perform spot testing if necessary.

4. Inadequate or Missing Identification Markings (IP Issues)

Proper identification markings—such as manufacturer symbol, strength class, and standard (e.g., ISO 898-1)—are essential. Bolts without clear markings make traceability difficult and increase the risk of using uncertified fasteners in regulated industries.

5. Non-Compliance with International Standards

Some suppliers provide bolts labeled as “ISO-compliant” without valid certifications. Always verify compliance with ISO 4014 (hex head bolts), ISO 4017 (socket head), or other relevant standards. Lack of conformity affects interchangeability and safety.

6. Poor Surface Finish and Coating Defects

Zinc plating, Dacromet, or hot-dip galvanizing may be poorly applied, leading to uneven coating, hydrogen embrittlement (especially in high-tensile bolts), or flaking. These defects compromise corrosion resistance and mechanical integrity.

7. Counterfeit or Grey Market Products

Sourcing from unverified suppliers increases the risk of counterfeit fasteners. These may appear identical but fail under load due to inferior heat treatment or raw materials. Always source from reputable, audited suppliers.

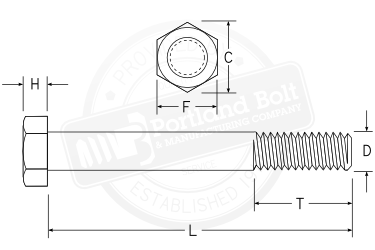

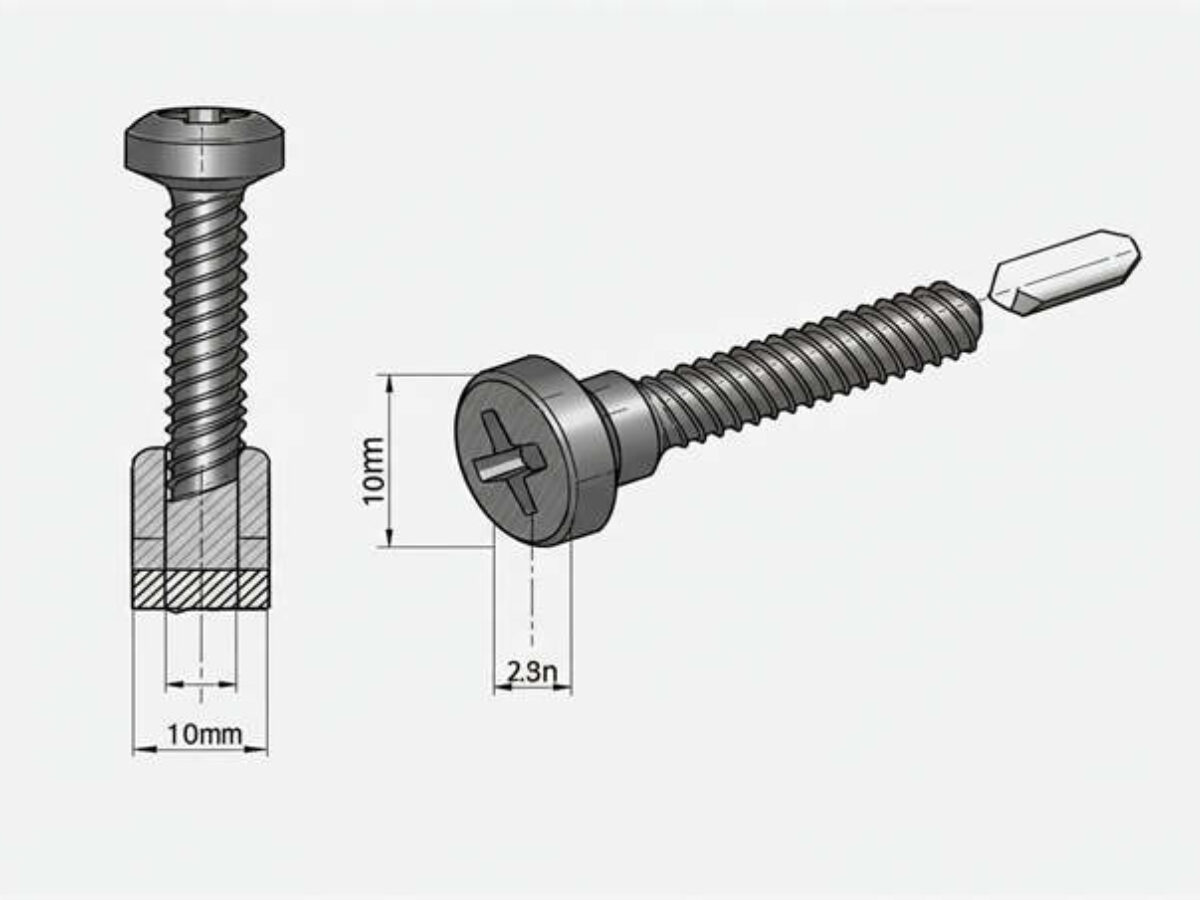

8. Incorrect Length or Head Dimensions

Variations in total length, shank diameter, or head size outside ISO tolerances can affect fit and torque performance. Even minor deviations can prevent proper assembly or reduce shear strength.

9. Inadequate Quality Control Documentation

Lack of mill test certificates (e.g., EN 10204 3.1) or traceability records is a red flag. In regulated sectors (aerospace, construction, automotive), missing documentation can result in compliance violations.

10. Confusion Between Metric and Imperial Equivalents

While M10 is metric, some suppliers may offer near-equivalent imperial sizes (e.g., 3/8” bolt ≈ 9.525mm), leading to mismatched assemblies. Ensure true metric compliance to avoid fit issues.

Conclusion

To avoid these pitfalls, always verify bolt specifications, demand proper documentation, conduct supplier audits, and perform incoming quality inspections. Clear communication of requirements—especially regarding grade, material, finish, and standards—is essential for reliable sourcing.

H2: Logistics & Compliance Guide for M10 Diameter Bolt

This guide outlines key logistics and compliance considerations for the procurement, handling, transportation, and use of M10 diameter bolts. Adherence ensures safety, regulatory compliance, and supply chain efficiency.

1. Technical Specifications & Classification

- Product: Metric Bolt, Nominal Diameter 10mm (M10).

- Key Attributes: Thread Pitch (e.g., 1.5mm coarse, 1.25mm fine), Length, Head Style (Hex, Socket Cap, etc.), Material (e.g., Steel Grade 8.8, A2/A4 Stainless), Surface Finish (e.g., Zinc Plated, Galvanized, Plain).

- HS Code (Example): 7318.15.00 (Threaded articles of iron or steel, bolts, wood screws, nuts, etc.). Verify exact code based on material, finish, and alloy composition for destination country.

- UN Number: Typically not classified as hazardous (UN 3077 “Environmentally hazardous substance, solid, n.o.s.” might apply if heavily oiled/greased, but often exempt for small quantities). Confirm based on specific finish/coating.

2. Packaging & Handling

- Standard Packaging: Bulk in boxes/bags, on reels, or in pre-counted kits. Use anti-corrosion packaging (VCI paper, desiccant) for susceptible finishes (e.g., plain steel).

- Labeling: Must include:

- Product Description (e.g., “BOLT M10x50 8.8 Zn”).

- Quantity.

- Lot/Batch Number (Critical for traceability).

- Manufacturer/Supplier Name & Address.

- Material Grade/Standard (e.g., “ISO 4014”, “DIN 933”, “ASTM A325”).

- Country of Origin.

- Handling Symbols (e.g., “Fragile”, “This Way Up” if stacked carefully).

- Handling: Use appropriate PPE (gloves to prevent oils/sweat causing corrosion, eye protection). Avoid dropping (can damage threads). Segregate different grades/finishes.

3. Storage

- Environment: Dry, well-ventilated, temperature-stable warehouse. Avoid condensation.

- Conditions: Protect from moisture, corrosive atmospheres (salts, acids), and direct sunlight. Elevate off concrete floors (use pallets).

- Segregation: Store different materials (e.g., carbon steel vs. stainless), grades, and finishes separately to prevent cross-contamination (e.g., carbon steel dust on stainless causes pitting).

- FIFO/FEFO: Implement First-In-First-Out or First-Expired-First-Out stock rotation.

4. Transportation

- Mode: Road, rail, sea, or air. Select based on urgency, cost, and volume.

- Securing: Pallets must be securely strapped/shrink-wrapped. Unit loads must be stable and prevent shifting. Use dunnage if necessary.

- Documentation: Commercial Invoice, Packing List, Bill of Lading/Air Waybill. Ensure HS Code and accurate description are included.

- Hazardous Materials: Confirm if plating (e.g., cadmium – restricted) or heavy lubricants require special handling (ADR, IMDG, IATA regulations). Most common M10 bolts do not require hazmat classification.

- International Shipments: Comply with Incoterms® (e.g., FOB, CIF, DDP). Ensure export/import licenses are obtained if required (rare for standard bolts, but check destination restrictions).

5. Regulatory Compliance

- Material Regulations:

- REACH (EU): Verify Substances of Very High Concern (SVHC) are below thresholds. Declare if >0.1% w/w. Common platings (Zn, CrIII) are generally compliant; avoid CrVI.

- RoHS (EU/China): Restricts hazardous substances (Pb, Cd, Hg, Cr6+, PBB, PBDE, DEHP, BBP, DBP, DIBP). Standard steel/stainless with Zn/Geomet/Passivated finishes typically compliant. Verify plating processes.

- Prop 65 (California): Requires warning if contains listed chemicals (e.g., lead in some brass platings – rare for M10 steel bolts). Generally not a concern for standard products.

- Product Standards: Ensure bolts meet relevant standards (e.g., ISO 898-1, ASTM F568M, DIN, JIS). Documentation (Certificates of Conformity, Test Reports) must be available.

- Traceability: Maintain records (batch numbers, supplier certs, test reports) for minimum 5-10 years (or as per industry standard like automotive/ aerospace) to enable recall if needed.

- Country of Origin (CoO): Accurate CoO is critical for tariffs, trade agreements (e.g., USMCA, RCEP), and import restrictions. Verify supplier declarations.

6. Key Risks & Mitigation

- Counterfeiting: Source from reputable, certified suppliers. Verify material certs and physical testing if high-risk application.

- Corrosion: Ensure correct finish for environment (e.g., A4 stainless for marine). Proper packaging and storage.

- Incorrect Specification: Use clear, unambiguous purchase orders and drawings. Verify received goods against specs.

- Supply Chain Disruption: Qualify multiple suppliers if critical. Maintain strategic safety stock.

- Non-Compliance Penalties: Fines, shipment rejection, or product recall due to missing docs, incorrect HS code, or violating substance regulations.

Critical Action: Always confirm specific requirements with suppliers, customers, and legal/regulatory experts, as regulations and standards are constantly evolving and application-specific.

Conclusion for Sourcing M10 Diameter Bolt:

Sourcing M10 diameter bolts requires careful consideration of material, grade, thread type, finish, and compliance with relevant standards (such as ISO, DIN, or ASTM) to ensure suitability for the intended application. Availability is generally high due to the standardization of M10 bolts, with numerous suppliers and manufacturers offering cost-effective and reliable options. However, critical factors such as load requirements, environmental conditions (e.g., corrosion resistance), and industry specifications must guide the selection process. By evaluating supplier credibility, lead times, and total cost—including shipping and quality assurance—organizations can secure high-quality M10 bolts that meet performance and safety standards while optimizing procurement efficiency. Effective sourcing ultimately ensures reliability, longevity, and cost-effectiveness in assembly and construction applications.