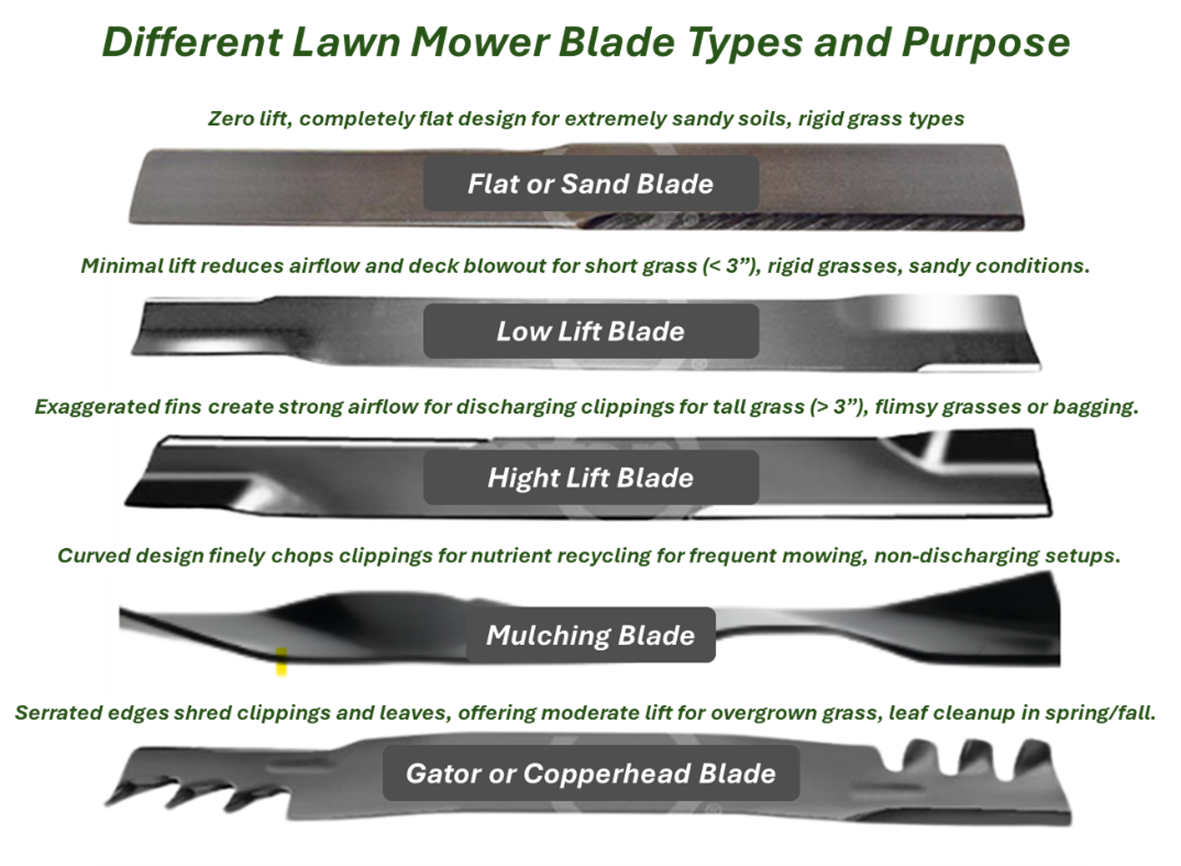

The global lawn mower blades market is experiencing steady growth, driven by rising demand from residential landscaping, commercial groundskeeping, and municipal maintenance sectors. According to Grand View Research, the global lawn and garden equipment market was valued at USD 37.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by increasing urbanization, growing emphasis on aesthetic landscaping, and the proliferation of DIY gardening trends, particularly in North America and Europe. Low lift mower blades—known for their fuel efficiency, reduced noise, and suitability for dry, even terrain—represent a strategic segment within this market, especially for walk-behind and residential riding mowers. As demand for high-performance, durable cutting solutions rises, manufacturers specializing in low lift blade technology are scaling innovation in materials, blade geometry, and wear resistance. Based on market presence, product quality, and technological advancement, the following eight manufacturers have emerged as leading suppliers in the low lift mower blades segment.

Top 8 Low Lift Mower Blades Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lawn Mower Blades Cut Better and Last Longer

Domain Est. 1998

Website: fisherbarton.com

Key Highlights: We engineer and manufacture a wide range of lawn mower blades and wear components to fit the needs of leading lawn mower OEMs worldwide….

#2 Products

Domain Est. 2013

Website: usamowerblades.com

Key Highlights: USA Mower Blades produces high-quality, OEM replacement blades for the most popular commercial and residential lawn mowers, edgers, and power rakes….

#3 42 in Deck Low

Domain Est. 1995

Website: ariens.com

Key Highlights: In stock Free delivery over $40Made in the USA, these alloy-steel replacement blades are engineered with advanced heat treatment for superior wear resistance and durability….

#4 Blades

Domain Est. 1996

Website: rotarycorp.com

Key Highlights: All Rotary blades are manufactured in the USA, including commercial-strength and heavy-duty blades, commercial mulching blades, flat blades, high and low-lift ……

#5 Lawn Mower Blades FAQ

Domain Est. 2000

Website: sunbeltparts.com

Key Highlights: Great blades for use when horsepower is a concern. Produce medium lift but requires less horsepower than high lift blades. Low-Lift Blade Under 3/4″ of lift….

#6 Mower Blade, 18″

Domain Est. 2001

Website: oregonproducts.com

Key Highlights: Free delivery over $75 30-day returnsThe Oregon 91-235 blade for lawn mowers are created to provide consistency and longevity, while delivering a cleaner cut and quality results….

#7 Low Lift Blade for 60-inch Cutting Decks – 742P04415-L

Domain Est. 2002

Website: mtdparts.com

Key Highlights: In stock Free delivery over $44.99Low-Lift Sand blades offer high performance in Southern and Coastal Regions with very dry and sandy conditions or for seasonal scalping….

#8 LAWNRAZOR® Mower Blades by 8TEN

Domain Est. 2014

Website: 8tenparts.com

Key Highlights: Low-lift lawn mower blades by 8TEN Parts perform best in low-cutting circumstances, sandy soil, and dry lawn conditions. Our lineup of low-lift blades enhances ……

Expert Sourcing Insights for Low Lift Mower Blades

H2: Projected 2026 Market Trends for Low Lift Mower Blades

The low lift mower blade market in 2026 is poised for steady growth and strategic evolution, driven by shifting consumer preferences, sustainability mandates, and technological advancements. Here’s a breakdown of the key trends shaping the landscape:

1. Heightened Demand for Eco-Efficiency & Mulching Performance:

Environmental awareness will be a primary market driver. Consumers and commercial operators alike will increasingly favor low lift blades specifically designed for superior mulching. These blades excel at finely chopping clippings and returning nutrients to the soil, reducing waste and the need for fertilizers. In 2026, expect a surge in demand for “high-efficiency” or “eco-mulching” low lift blades engineered with optimized lift surfaces and cutting angles to maximize mulching performance while maintaining a clean cut across diverse grass types and conditions.

2. Integration with Battery-Electric & Smart Mowers:

The rapid adoption of battery-electric (cordless) lawn mowers, particularly in the residential and light commercial sectors, will significantly impact blade design. Low lift blades are inherently well-suited for these mowers due to their lower power requirements and reduced strain on motors. In 2026, manufacturers will increasingly offer low lift blades specifically engineered and marketed as optimal companions for popular battery platform mowers, emphasizing extended run times, quieter operation, and seamless compatibility. Integration with smart mower features (like automated blade engagement based on grass height) may also emerge.

3. Focus on Durability, Materials, and Low Maintenance:

The lifespan and wear resistance of low lift blades will be a key competitive differentiator. Expect advancements in blade steel alloys (e.g., high-carbon, boron-infused steels) and heat treatment processes to enhance durability, especially for commercial and high-traffic applications. Coatings (like ceramic or specialized polymers) to reduce corrosion and grass adhesion (improving mulching and reducing cleaning) will become more common. The trend towards “set-and-forget” maintenance will favor blades requiring less frequent sharpening and offering longer overall service life.

4. Consolidation of Multi-Function Blades and OEM Partnerships:

The line between dedicated low lift, mulching, and bagging blades will continue to blur. In 2026, the market will see more “3-in-1” or “all-purpose” blades that incorporate low-lift aerodynamics optimized for excellent mulching performance while still being effective with side-discharge and bagging attachments. Stronger partnerships between blade manufacturers and Original Equipment Manufacturers (OEMs) of mowers will be crucial. OEMs will increasingly specify or co-brand low lift blades as the standard or recommended option for their new mower models, particularly battery-powered ones, driving consumer adoption.

5. Growth in Commercial & Municipal Adoption for Sustainability Goals:

Beyond residential use, commercial landscaping services and municipal parks departments will increasingly adopt low lift mulching blades as part of broader sustainability and cost-reduction initiatives. The ability to eliminate grass waste hauling, reduce fertilizer use, and lower fuel/electricity consumption aligns perfectly with ESG (Environmental, Social, Governance) goals and operational budgets. This segment will drive demand for heavy-duty, high-volume low lift blades.

Conclusion:

By 2026, the low lift mower blade market will be characterized by a strong emphasis on eco-efficiency, seamless integration with battery technology, enhanced durability, and multi-functionality. Success will belong to manufacturers who innovate in materials and design to deliver superior mulching performance with minimal power draw, while effectively partnering with OEMs and targeting both environmentally conscious consumers and commercial operators focused on sustainable and cost-effective lawn care.

Common Pitfalls Sourcing Low Lift Mower Blades (Quality, IP)

Sourcing low lift mower blades can be cost-effective, but it comes with significant risks related to quality consistency and intellectual property (IP) infringement. Being aware of these pitfalls is essential for maintaining equipment performance, safety, and legal compliance.

Poor Material Quality and Inconsistent Hardness

One of the most frequent issues is receiving blades made from substandard steel alloys or with inconsistent heat treatment. Low-cost suppliers may use inferior materials that lack the necessary hardness and toughness, leading to rapid dulling, chipping, or even catastrophic failure during operation. Blades that are too soft wear quickly, while those that are too brittle are prone to cracking under impact. Without proper quality control documentation or metallurgical testing, verifying material specs becomes difficult.

Inaccurate Blade Geometry and Balance

Low lift blades require precise curvature, angle, and weight distribution to ensure proper airflow and cutting performance. Offshore or unqualified manufacturers may produce blades with deviations in lift design, cutting edge bevel, or asymmetrical mass. These inconsistencies result in poor grass discharge, uneven cutting patterns, and increased vibration that can damage mower decks and spindles over time. Lack of dynamic balancing further exacerbates wear and safety risks.

Non-Compliance with Safety and Industry Standards

Many generic or counterfeit blades fail to meet recognized safety standards such as ANSI or ISO specifications. This includes inadequate edge retention, insufficient structural integrity, or failure to withstand operational stress. Using non-compliant blades voids equipment warranties and exposes operators and businesses to liability in the event of injury or equipment damage.

Intellectual Property (IP) Infringement Risks

Sourcing inexpensive blades often leads to unintentional IP violations. Many low-cost options are direct copies of patented OEM (Original Equipment Manufacturer) blade designs, logos, and performance characteristics. Distributing or using these blades can expose buyers to legal action for trademark or design patent infringement. Even if the supplier claims the blades are “compatible,” replicating protected features without licensing constitutes IP theft.

Lack of Traceability and Warranty Support

Off-brand or gray-market blades typically come without batch traceability, quality certifications, or reliable warranty support. When a blade fails prematurely or causes damage, recovering costs or identifying the source of the defect is nearly impossible. This absence of accountability increases long-term operational risks and downtime.

Shortened Equipment Lifespan and Increased Maintenance

Due to imbalanced design, poor balance, or subpar materials, low-quality blades place additional stress on mower spindles, bearings, and decks. This leads to accelerated wear, higher maintenance costs, and reduced equipment longevity. The initial savings on blade cost are often outweighed by increased repair bills and lost productivity.

Conclusion

While sourcing low lift mower blades at a lower price point is tempting, overlooking quality and IP concerns can result in safety hazards, legal exposure, and higher total cost of ownership. To mitigate these risks, prioritize suppliers with verifiable material certifications, adherence to industry standards, and transparent manufacturing practices—ensuring both performance reliability and legal compliance.

Logistics & Compliance Guide for Low Lift Mower Blades

Product Classification and Tariff Codes

Low lift mower blades are typically classified under specific Harmonized System (HS) codes for accurate international shipping and customs clearance. Common classifications include:

– HS Code 8201.10: Lawn mower blades, often grouped with other hand tools of base metal.

– HS Code 8433.90: Parts and accessories for lawn mowers, including cutting blades.

Note: Classification may vary by country. Always verify with local customs authorities or a licensed customs broker.

Packaging and Labeling Requirements

Ensure proper packaging and labeling to prevent damage and ensure compliance:

– Packaging: Use durable, moisture-resistant packaging (e.g., corrugated cardboard or poly-wrapped bundles) to protect blades during transit.

– Labeling: Include:

– Product name and model number

– Quantity per package

– Country of origin

– Weight and dimensions

– Safety warnings (e.g., “Sharp Blades – Handle with Care”)

– Compliance marks (e.g., CE, if applicable)

Shipping and Transportation

Follow best practices for safe and efficient logistics:

– Domestic Shipping: Use standard freight carriers with secure palletization; blades should be banded or shrink-wrapped to prevent shifting.

– International Shipping:

– Ensure compliance with IATA/IMDG regulations if shipping by air or sea (though blades are generally non-hazardous).

– Use ISPM 15-compliant wooden pallets if applicable.

– Provide accurate commercial invoices, packing lists, and bill of lading or air waybill.

– Weight and Dimensions: Optimize packaging to minimize dimensional weight charges.

Import and Export Compliance

- Export Controls: Low lift mower blades are generally not subject to export restrictions, but verify with the relevant government agency (e.g., BIS in the U.S.) for dual-use concerns.

- Import Duties and Taxes: Duties vary by destination country. Use the correct HS code to determine applicable rates.

- Documentation:

- Commercial Invoice

- Packing List

- Certificate of Origin (if claiming preferential tariff treatment under trade agreements)

- Import License (if required by the destination country)

Regulatory and Safety Standards

- OSHA/ANSI (U.S.): Ensure blades are packaged and labeled to meet workplace safety standards if sold to commercial users.

- CE Marking (EU): Required if the blade is part of a machine placed on the EU market. Compliance with Machinery Directive 2006/42/EC may apply.

- REACH & RoHS (EU): Confirm materials used in manufacturing (e.g., steel alloys) comply with chemical and hazardous substance regulations.

- Country-Specific Requirements: Some markets may require additional certifications (e.g., UKCA for the UK post-Brexit).

Environmental and Disposal Considerations

- Recyclability: Blades are typically made from recyclable steel; include recycling information in product documentation where required.

- Waste Disposal: Comply with local regulations for metal waste; some regions classify used blades as industrial scrap.

Recordkeeping and Traceability

- Maintain records of:

- Supplier certifications

- Material test reports (if applicable)

- Shipping and customs documentation

- Compliance certifications

- Retain records for a minimum of 5–7 years depending on jurisdiction.

Adhering to this guide ensures smooth logistics operations and regulatory compliance when distributing low lift mower blades globally. Always consult legal and logistics experts for region-specific requirements.

In conclusion, sourcing low lift mower blades requires careful consideration of several factors including blade compatibility, quality, performance requirements, and cost-effectiveness. Low lift blades are ideal for dry, normal grass conditions and provide efficient mulching with reduced drag on the mower engine, leading to improved fuel efficiency and longer engine life. When sourcing these blades, it is essential to choose reputable suppliers or manufacturers that offer durable materials—such as high-carbon steel—and proper balancing to ensure optimal cutting performance and safety. Additionally, comparing prices, warranties, and customer reviews can help identify reliable options without compromising on quality. Regular maintenance and timely replacement of worn blades will further ensure a clean, healthy cut and prolong the life of your mower. By selecting the right low lift blades from trusted sources, you can achieve a well-maintained lawn while maximizing equipment efficiency and operational savings.